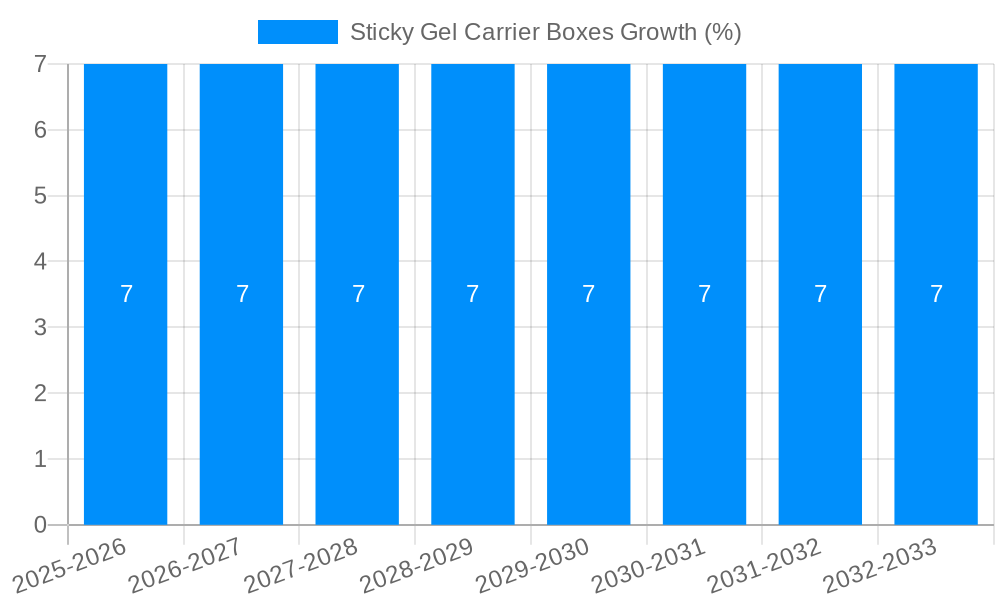

1. What is the projected Compound Annual Growth Rate (CAGR) of the Sticky Gel Carrier Boxes?

The projected CAGR is approximately 7%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Sticky Gel Carrier Boxes

Sticky Gel Carrier BoxesSticky Gel Carrier Boxes by Type (55mm x 56mm, 75mm x 56mm, Other), by Application (Semiconductor, Jewelry, Medical, Other), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2026-2034

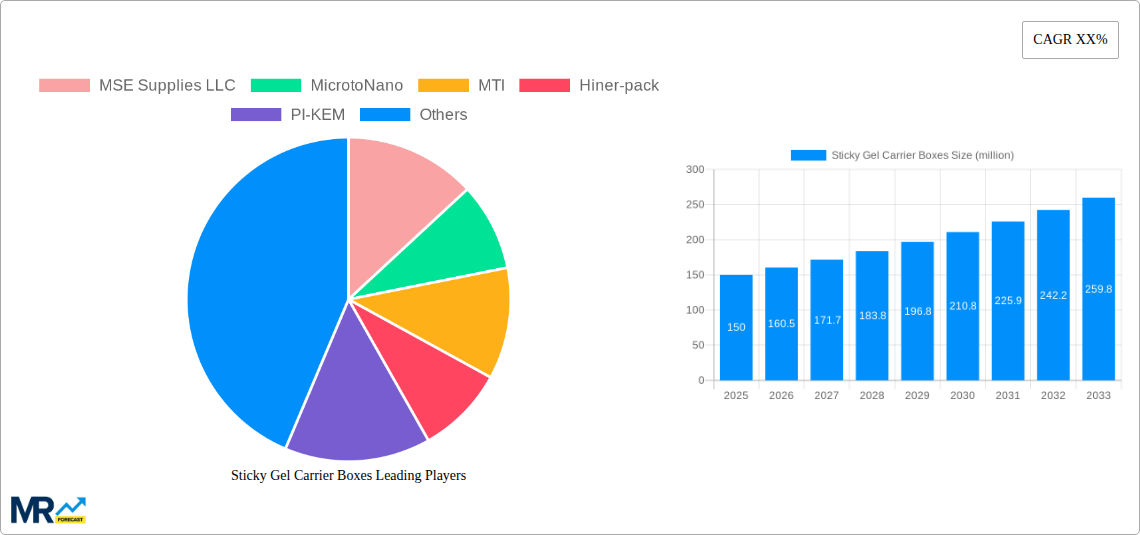

The global market for Sticky Gel Carrier Boxes is poised for substantial growth, projected to reach a significant valuation of $150 million by 2025, with a robust Compound Annual Growth Rate (CAGR) of 7% anticipated over the forecast period spanning from 2025 to 2033. This expansion is primarily fueled by the increasing demand for precise and secure sample handling solutions across a multitude of high-tech industries. The semiconductor sector, in particular, is a major driver, requiring these specialized boxes for the meticulous transportation and storage of sensitive microelectronic components. Furthermore, the burgeoning jewelry industry, with its emphasis on protecting valuable and delicate items, and the rapidly advancing medical and life sciences fields, which rely on sterile and contaminant-free containment for biological samples and pharmaceuticals, are contributing significantly to market ascent. The 55mm x 56mm and 75mm x 56mm segments are expected to dominate due to their widespread applicability, offering optimized dimensions for common sample sizes.

The market's trajectory is further shaped by several key trends, including the ongoing miniaturization of electronic components, which necessitates smaller and more precise handling solutions, and the growing emphasis on quality control and contamination prevention in pharmaceutical and biotechnological applications. Innovations in gel technology, offering enhanced adhesion and anti-static properties, are also playing a crucial role. However, the market is not without its challenges. Potential restraints include the relatively high cost of specialized gel carrier boxes compared to conventional packaging, and the emergence of alternative advanced packaging technologies that might offer competitive solutions. Despite these hurdles, the increasing investments in research and development within the semiconductor and medical industries, coupled with a growing global demand for high-precision manufacturing and healthcare, are expected to propel the Sticky Gel Carrier Boxes market to new heights. Key players like MSE Supplies LLC, MicrotoNano, and MTI are at the forefront of innovation, driving the market forward with their advanced product offerings and strategic expansions.

This comprehensive market research report delves into the intricate dynamics of the Sticky Gel Carrier Boxes market, projecting a robust growth trajectory fueled by advancements in various high-tech industries. The study spans a significant period, from the historical baseline of 2019 through to an estimated future of 2033, with the base and estimated year firmly set at 2025. Our detailed analysis meticulously covers the historical period of 2019-2024, providing a foundational understanding of past market performance, and then extends into a dynamic forecast period from 2025-2033. The report quantifies market size in millions of units, offering precise insights into production volumes and consumption patterns. We have investigated key industry players, including MSE Supplies LLC, MicrotoNano, MTI, Hiner-pack, PI-KEM, CrysPack, Ted Pella, Labtech, Zhengzhou TCH Instrument, Gel-Pak, SPI Supplies, Nisshin EM, and Nanoscience Instruments, alongside an in-depth examination of critical market segments such as Type (55mm x 56mm, 75mm x 56mm, Other) and Application (Semiconductor, Jewelry, Medical, Other). This extensive coverage aims to equip stakeholders with the actionable intelligence necessary to navigate and capitalize on the evolving landscape of the sticky gel carrier boxes industry.

The Sticky Gel Carrier Boxes market is experiencing a significant surge in demand, driven by an escalating need for secure and delicate handling solutions across a multitude of sophisticated industries. During the study period of 2019-2033, with a particular focus on the base year of 2025, the market has witnessed a consistent upward trend. This growth is primarily attributed to the inherent properties of sticky gel carrier boxes, which offer exceptional vibration dampening, anti-static protection, and precise component positioning, thereby minimizing damage and contamination during transport and storage. The semiconductor industry, a cornerstone of technological innovation, continues to be a dominant consumer. The increasing miniaturization of electronic components and the intricate nature of semiconductor fabrication processes necessitate packaging solutions that can safeguard these highly sensitive materials. As the global semiconductor market aims for an estimated output in the hundreds of millions of units annually, the demand for specialized carrier boxes that can accommodate intricate wafers and microchips, such as the 55mm x 56mm and 75mm x 56mm types, is projected to soar. Furthermore, the medical industry is emerging as a significant growth avenue. The stringent requirements for sterile and contamination-free transport of sensitive medical devices, diagnostic kits, and even biological samples are perfectly met by the protective capabilities of sticky gel carrier boxes. The increasing complexity and fragility of modern medical implants and instruments further bolster this demand. Even within niche sectors like jewelry, the need for safeguarding precious and easily scratched items during shipping and display is contributing to market expansion, albeit at a more modest scale compared to the industrial giants. The report anticipates that the market size, measured in millions of units, will witness sustained double-digit percentage growth year-on-year throughout the forecast period of 2025-2033. This growth is not solely dependent on volume but also on the development of specialized, high-performance sticky gel formulations and box designs tailored to specific industry needs, such as enhanced chemical resistance or extreme temperature tolerance. The evolution of automated handling systems in manufacturing and logistics also plays a crucial role, as these systems often integrate seamlessly with standardized sticky gel carrier box dimensions, further streamlining operations and reducing the likelihood of human error. The trend towards greater supply chain efficiency and risk mitigation in sensitive industries will continue to propel the adoption of these specialized packaging solutions.

The market for sticky gel carrier boxes is being propelled by a confluence of powerful driving forces, primarily rooted in the escalating sophistication and demands of high-technology manufacturing and research. The relentless pursuit of smaller, more complex, and highly sensitive components within the semiconductor industry is a paramount driver. As wafer sizes increase and intricate circuitry becomes more dense, the need for packaging that can prevent micro-fractures, contamination, and electrostatic discharge (ESD) becomes critical. Sticky gel carriers excel in providing this level of protection, effectively immobilizing components and absorbing shock during transit. Furthermore, the burgeoning growth of the medical device and life sciences sectors is significantly contributing to market expansion. The development of advanced surgical instruments, sensitive diagnostic tools, and delicate biospecimens necessitates packaging that ensures sterility, integrity, and protection from environmental factors. The unique ability of sticky gel to securely hold these items without adhesives that could leave residue or cause damage makes these carrier boxes indispensable. The historical period of 2019-2024, and the subsequent forecast period of 2025-2033, showcase a consistent upward trend fueled by these advancements. The increasing global demand for advanced electronics, from consumer gadgets to critical infrastructure, directly translates into a higher volume of semiconductor production, thereby increasing the demand for the specialized carriers required to handle these components. Moreover, regulatory requirements for the safe and secure transportation of sensitive materials in the medical and pharmaceutical industries are becoming more stringent, further incentivizing the adoption of reliable packaging solutions like sticky gel carrier boxes. The projected market size in millions of units is a testament to this sustained demand.

Despite the robust growth prospects, the Sticky Gel Carrier Boxes market is not without its challenges and restraints that could impact its full potential. One significant restraint is the inherent cost associated with high-performance sticky gel materials and the precision manufacturing required for these carrier boxes. For certain applications where cost is a primary consideration and component sensitivity is lower, alternative, less expensive packaging solutions may be preferred, limiting the market penetration of sticky gel carriers. Furthermore, the specialized nature of some sticky gel formulations means that disposal and recycling can be more complex and costly compared to traditional packaging materials. This environmental consideration could become a greater restraint as sustainability regulations tighten globally. The reliance on specific raw material suppliers for the unique polymers and tackifiers used in the sticky gel can also introduce supply chain vulnerabilities and price fluctuations, acting as a potential restraint on consistent market growth. Moreover, the development of highly customized sticky gel carrier boxes for niche applications, while a growth opportunity, can also be a challenge in terms of scalability and standardization. Achieving the right balance of tackiness, temperature resistance, and material compatibility for a diverse range of delicate components requires significant research and development investment, which can slow down the introduction of new products to the market. The historical data from 2019-2024 and the projected trends for 2025-2033 indicate that while the overall market is expanding, these factors can modulate the pace of adoption in specific segments. The estimated year of 2025, for instance, sees these challenges as areas that innovators are actively seeking to overcome.

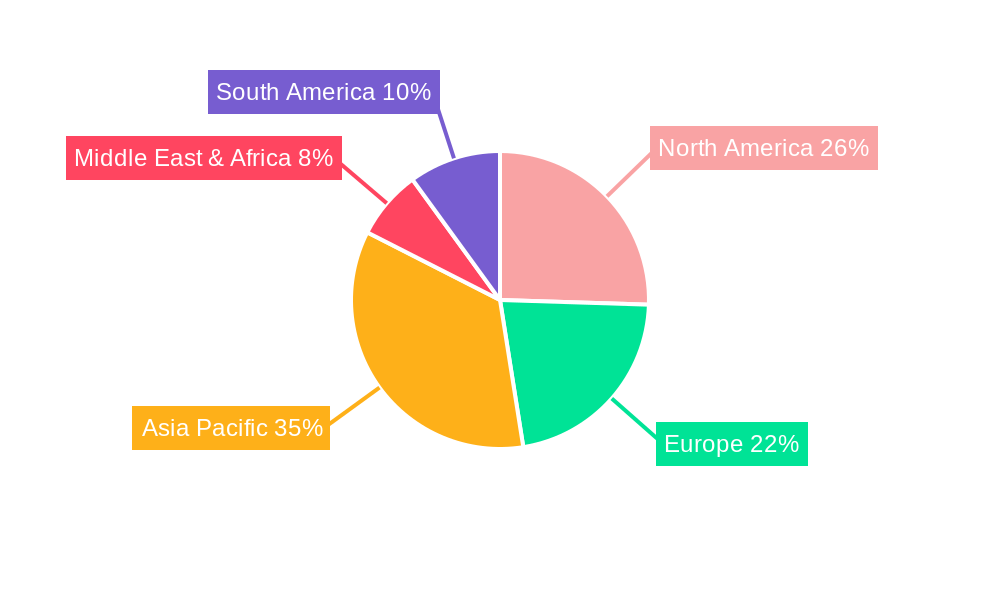

The Semiconductor industry, particularly within the Asia-Pacific region, is poised to dominate the Sticky Gel Carrier Boxes market throughout the study period of 2019-2033, with the base and estimated year at 2025. This dominance stems from a synergistic interplay of factors including a robust manufacturing infrastructure, significant government investments in semiconductor fabrication, and the sheer volume of chip production. Countries like Taiwan, South Korea, China, and Japan are at the forefront of global semiconductor manufacturing, necessitating a massive and consistent supply of high-quality sticky gel carrier boxes. The intricate nature of semiconductor wafers, which are the foundational units for microchips, requires packaging that offers unparalleled protection against particulate contamination, mechanical shock, and electrostatic discharge. Sticky gel carrier boxes, especially those designed for specific wafer sizes such as the 55mm x 56mm and 75mm x 56mm types, are critical for preserving the integrity of these highly valuable and sensitive components during every stage of production, testing, and transportation. The estimated market volume in millions of units originating from this sector alone is substantial.

Furthermore, the Medical industry is emerging as a significant and rapidly growing segment, expected to contribute substantially to market dominance, particularly within North America and Europe. The increasing complexity and miniaturization of medical devices, implants, and diagnostic kits demand packaging solutions that ensure sterility, prevent contamination, and maintain the precise positioning of fragile components. Sticky gel carrier boxes offer a contamination-free environment, as they do not rely on adhesive tapes that could leave residues. The secure immobilization of sensitive medical materials during transit is paramount, and sticky gel carriers excel in this regard. The Other application segment, encompassing areas like advanced optics, MEMS (Micro-Electro-Mechanical Systems), and precision instrumentation, also contributes significantly to the overall market. These sectors often deal with exceptionally delicate and high-value components that require specialized handling, making sticky gel carrier boxes an indispensable choice. The ability of these boxes to be customized for various shapes and sizes within the Other type category further enhances their appeal across diverse scientific and industrial applications. The forecast period of 2025-2033 is expected to see continued investment in research and development within these dominant segments, leading to the introduction of even more advanced sticky gel formulations and carrier box designs, further solidifying their market leadership in terms of volume and value. The ability of the Asia-Pacific region to scale production of the 55mm x 56mm and 75mm x 56mm variants for the burgeoning semiconductor sector, coupled with the specialized demand from the medical and other high-tech industries in North America and Europe, will collectively shape the dominant forces within this market.

Several key growth catalysts are driving the expansion of the Sticky Gel Carrier Boxes industry. The relentless miniaturization and increasing complexity of electronic components, particularly in the semiconductor sector, are major drivers. This necessitates advanced packaging solutions for damage prevention during handling and transit. Similarly, the burgeoning medical device and life sciences industries, with their stringent requirements for sterility and protection of delicate instruments and biospecimens, are creating significant demand. Furthermore, advancements in sticky gel formulations, offering improved tackiness, temperature resistance, and chemical inertness, are enhancing the performance and applicability of these carriers. The increasing adoption of automation in manufacturing and logistics also favors the standardization and efficient handling capabilities provided by sticky gel carrier boxes.

This report provides an exhaustive analysis of the Sticky Gel Carrier Boxes market, spanning from the historical period of 2019-2024 to a projected future extending to 2033, with a key focus on the base and estimated year of 2025. Quantified in millions of units, the market's growth is meticulously detailed, considering crucial segments such as Type (55mm x 56mm, 75mm x 56mm, Other) and Application (Semiconductor, Jewelry, Medical, Other). The report meticulously details market trends, driving forces, challenges, and significant regional and segmental dominance. It also highlights critical growth catalysts and provides a comprehensive overview of the leading industry players and their recent impactful developments. This in-depth coverage aims to offer stakeholders unparalleled insights into the evolving dynamics of the sticky gel carrier boxes industry, empowering strategic decision-making for future growth and investment.

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 7% from 2020-2034 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 7%.

Key companies in the market include MSE Supplies LLC, MicrotoNano, MTI, Hiner-pack, PI-KEM, CrysPack, Ted Pella, Labtech, Zhengzhou TCH Instrument, Gel-Pak, SPI Supplies, Nisshin EM, Nanoscience Instruments, .

The market segments include Type, Application.

The market size is estimated to be USD XXX N/A as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in N/A and volume, measured in K.

Yes, the market keyword associated with the report is "Sticky Gel Carrier Boxes," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Sticky Gel Carrier Boxes, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.