1. What is the projected Compound Annual Growth Rate (CAGR) of the PE Blow Molded Products?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

PE Blow Molded Products

PE Blow Molded ProductsPE Blow Molded Products by Type (HDPE, LDPE, World PE Blow Molded Products Production ), by Application (Food Packaging, Industrial Packaging, Medical Packaging, Cosmetic Packaging, Others, World PE Blow Molded Products Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

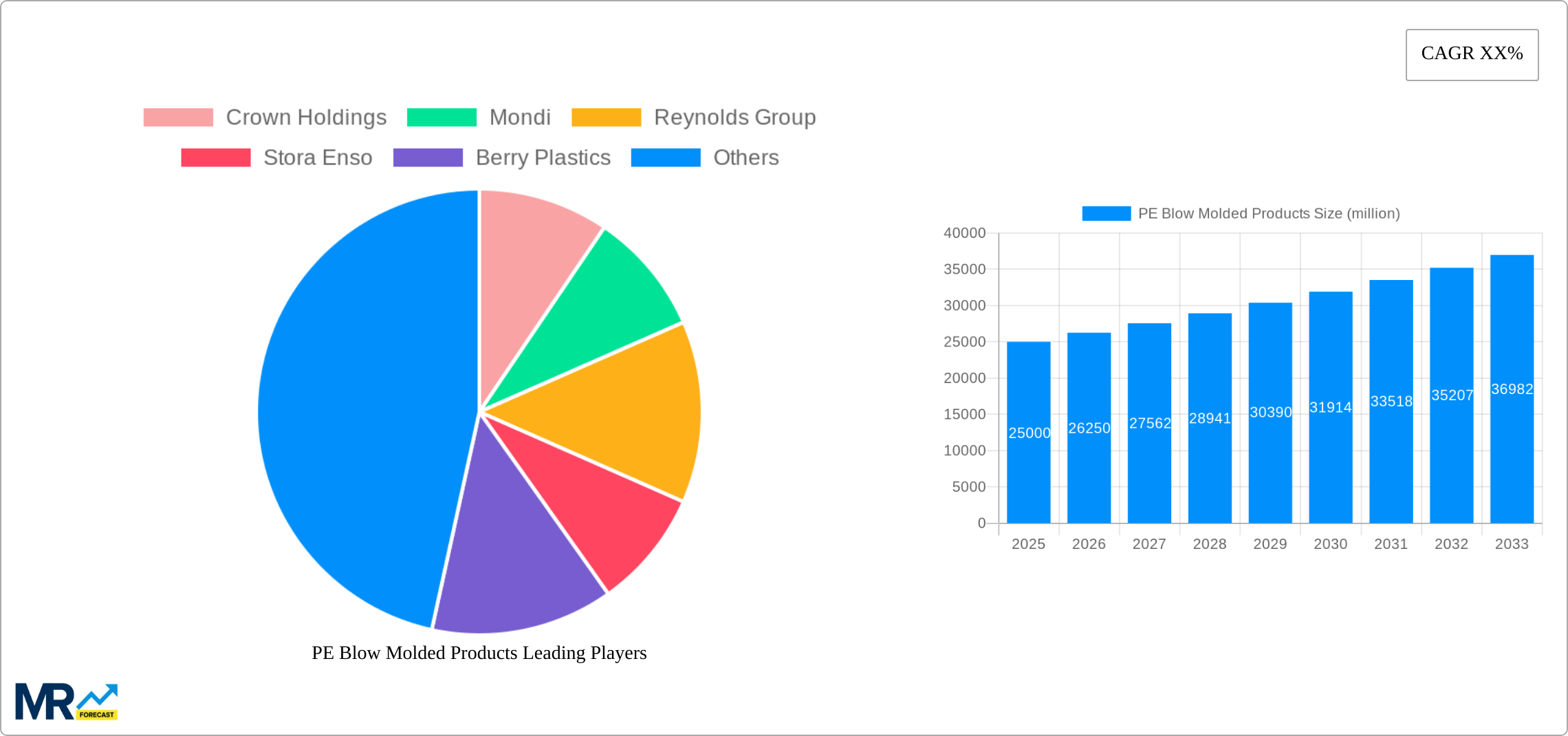

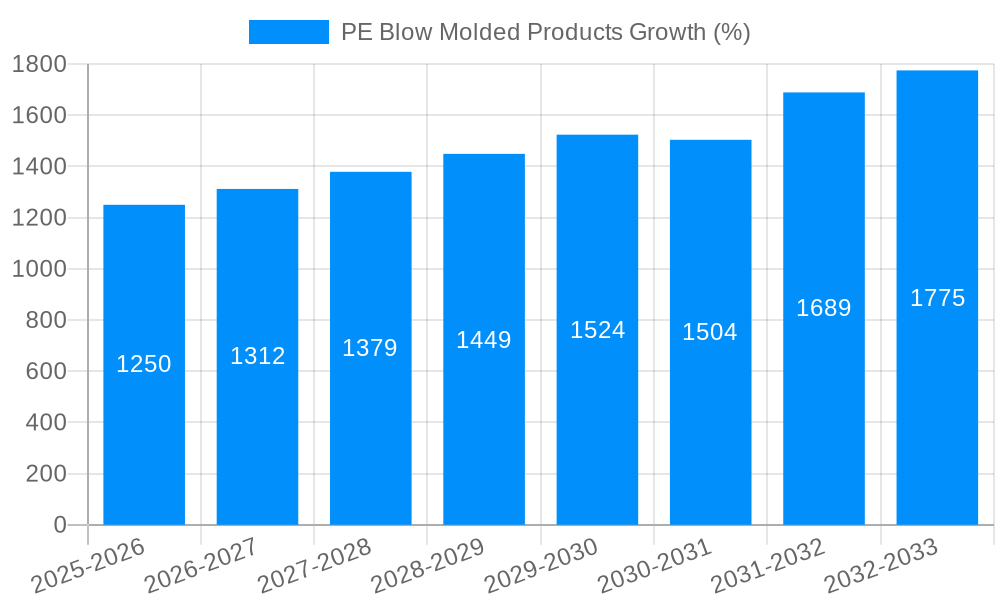

The global PE blow molded products market is experiencing robust expansion, projected to reach an estimated market size of $45,000 million by 2025, with a significant Compound Annual Growth Rate (CAGR) of approximately 5.5%. This growth is primarily fueled by the increasing demand across diverse applications, particularly in food and beverage packaging, where the lightweight, durable, and cost-effective nature of PE blow molded products makes them an ideal choice. Industrial packaging, a critical sector for product protection and logistics, also contributes substantially to market value. Furthermore, the expanding healthcare sector and the growing consumer preference for aesthetically pleasing and functional packaging in cosmetics are driving adoption. The versatility of polyethylene (PE), encompassing High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE), allows manufacturers to tailor products for specific needs, further bolstering market penetration.

Despite the positive outlook, the market faces certain restraints, including fluctuating raw material prices, which can impact profit margins for manufacturers. Stringent environmental regulations concerning plastic waste and a growing consumer demand for sustainable alternatives are also posing challenges. However, ongoing innovation in recyclability, the development of bio-based PE alternatives, and advancements in blow molding technology are mitigating these concerns. The Asia Pacific region is anticipated to lead market growth due to rapid industrialization, a burgeoning middle class, and increasing consumer spending, while North America and Europe remain significant and mature markets. Key industry players are focused on expanding production capacities, strategic collaborations, and developing innovative solutions to capture a larger market share.

This comprehensive report delves into the dynamic global market for Polyethylene (PE) blow molded products, offering in-depth analysis and robust forecasts. Spanning a significant study period from 2019 to 2033, with a focused estimation on the Base Year 2025, this report provides a detailed examination of production volumes, application trends, and key industry developments. Through meticulous data analysis of the historical period (2019-2024) and a forward-looking projection for the forecast period (2025-2033), we equip stakeholders with the insights needed to navigate this evolving landscape. The report quantifies market movements in millions of units, ensuring a precise understanding of scale and growth.

XXX The global PE blow molded products market is experiencing a sustained and robust upward trajectory, driven by an insatiable demand across a myriad of sectors. A significant trend observed is the increasing adoption of blow molded PE for Food Packaging, a segment projected to continue its dominance. The inherent properties of PE, such as its inertness, excellent barrier properties against moisture, and tamper-evident sealing capabilities, make it an ideal choice for preserving food freshness and safety. This is further amplified by evolving consumer preferences towards convenience and ready-to-eat meals, necessitating innovative and reliable packaging solutions. The Industrial Packaging segment is another powerhouse, fueled by the burgeoning global trade and the need for durable, lightweight, and cost-effective containers for chemicals, lubricants, and agricultural products. The shift from heavier traditional materials like metal and glass to lighter PE alternatives is a discernible trend, contributing to reduced transportation costs and a lower carbon footprint.

Furthermore, the report highlights the growing penetration of PE blow molded products in Medical Packaging. Stringent regulatory requirements and the increasing demand for sterile and safe delivery of pharmaceuticals and medical devices are pushing manufacturers towards advanced PE solutions. Innovations in material science are enabling the production of specialized PE grades that offer superior chemical resistance and enhanced shelf-life for sensitive medical contents. The Cosmetic Packaging sector, while perhaps a smaller contributor in sheer volume compared to food or industrial, is witnessing a surge in demand for aesthetically pleasing and functional PE containers. The ability to mold PE into complex shapes and designs, coupled with its affordability and recyclability, makes it an attractive option for cosmetic brands looking to differentiate their products. The "Others" segment, encompassing a diverse range of applications from personal care products to household goods, also plays a crucial role in the overall market expansion. Across all segments, the overarching trend is a continuous pursuit of lightweighting, enhanced functionality, and sustainable solutions, prompting significant investment in research and development by key market players. This intricate interplay of material properties, end-user demand, and technological advancements is shaping the future of PE blow molded products.

The global PE blow molded products market is experiencing formidable growth, propelled by a confluence of interconnected driving forces. Foremost among these is the ever-increasing demand for efficient and cost-effective packaging solutions across diverse industries. The inherent cost-effectiveness of polyethylene in conjunction with the efficient mass production capabilities of blow molding technology makes it an attractive choice for businesses seeking to optimize their supply chains and reduce overheads. This economic advantage is particularly pronounced in high-volume sectors like food and beverages, where packaging costs can significantly impact profitability.

Secondly, the growing global population and rising disposable incomes are fueling consumer spending on packaged goods. As economies develop and urbanization accelerates, the demand for convenience, safety, and hygiene in product consumption escalates, directly translating into a greater need for robust and reliable packaging. PE blow molded products, with their versatility and ability to protect contents effectively, are perfectly positioned to cater to this expanding consumer base. The versatility and adaptability of PE blow molding technology itself is another critical driver. This manufacturing process allows for the creation of a wide array of shapes, sizes, and designs, enabling manufacturers to tailor packaging to specific product requirements and brand aesthetics. This flexibility is invaluable in meeting the diverse needs of industries ranging from food and pharmaceuticals to chemicals and consumer goods. Finally, the growing emphasis on sustainability and recyclability, while presenting some challenges, is also a significant driver for innovation within PE blow molding. As brands and consumers increasingly prioritize environmentally conscious options, the recyclability of PE and the development of new, more sustainable PE formulations are becoming key selling points, further solidifying its market position.

Despite its robust growth, the PE blow molded products market is not without its share of challenges and restraints that can impede its full potential. A primary concern revolves around environmental regulations and concerns surrounding plastic waste. The persistent global focus on reducing single-use plastics and improving waste management infrastructure can lead to stricter regulations, potential bans, or increased taxes on plastic products, impacting market demand and increasing operational costs for manufacturers. The perceived negative environmental impact of traditional PE can also lead to consumer backlash and a preference for alternative, albeit often more expensive, packaging materials.

Another significant restraint is the volatility in raw material prices, particularly for polyethylene. The price of PE is closely tied to crude oil and natural gas prices, which are subject to geopolitical factors, supply disruptions, and global economic fluctuations. Sudden and sharp increases in the cost of raw materials can erode profit margins for blow molders and lead to higher prices for end-users, potentially impacting sales volumes. Furthermore, the increasing competition from alternative packaging materials poses a considerable threat. While PE offers numerous advantages, materials like paperboard, glass, and newer bioplastics are gaining traction in certain applications, especially where a "green" image is paramount or for products with specific barrier or aesthetic requirements that PE may not optimally meet. The capital-intensive nature of blow molding machinery and tooling can also act as a barrier to entry for smaller players and necessitate significant investment for existing manufacturers looking to upgrade or expand their production capabilities. Finally, supply chain disruptions and logistical challenges, exacerbated by global events and trade tensions, can affect the timely availability of raw materials and the efficient distribution of finished products, leading to production delays and increased costs.

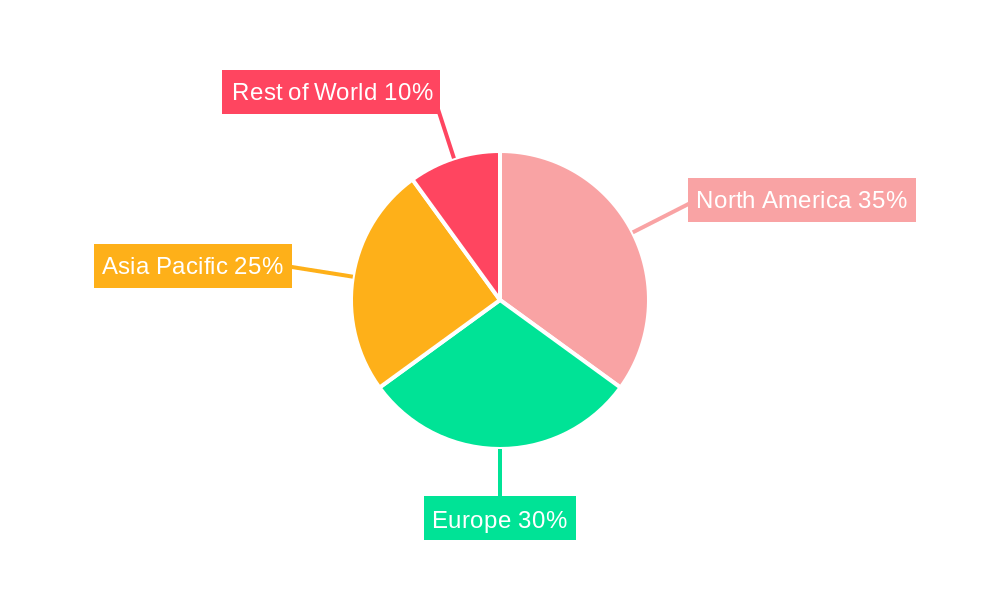

The global PE blow molded products market exhibits distinct regional dominance and segment leadership, shaped by economic development, industrial activity, and regulatory landscapes.

Asia Pacific: This region is poised to be the undisputed leader in PE blow molded products production and consumption. The sheer scale of its population, coupled with rapid economic growth, burgeoning middle class, and significant industrialization, drives unparalleled demand across all application segments. Countries like China, India, and Southeast Asian nations are major manufacturing hubs and burgeoning consumer markets, leading to massive consumption of PE blow molded packaging for food, beverages, consumer goods, and industrial products. The presence of a vast manufacturing base, relatively lower labor costs, and increasing investments in packaging infrastructure further solidify the dominance of the Asia Pacific region. The production volumes here are expected to reach unprecedented heights, significantly contributing to the global total.

North America: A mature yet consistently growing market, North America, particularly the United States, remains a significant contributor. Its well-established food and beverage industry, coupled with a strong presence of industrial manufacturing and a growing healthcare sector, ensures a sustained demand for PE blow molded products. The region is also at the forefront of innovation in sustainable packaging solutions, driving the adoption of recycled PE and advanced material formulations. The focus on convenience and premiumization in consumer packaging also fuels demand for sophisticated blow molded designs.

Europe: Europe presents a strong market driven by high consumer spending and stringent quality standards. Countries like Germany, the United Kingdom, and France are major consumers, with a significant focus on sustainable packaging and circular economy initiatives. While regulatory pressures on plastics are higher in Europe, this also drives innovation in the development of more recyclable and eco-friendly PE solutions. The robust food processing and chemical industries contribute significantly to the demand for industrial and food packaging.

Type: HDPE (High-Density Polyethylene): HDPE is consistently the most dominant type of PE in blow molded products. Its excellent rigidity, chemical resistance, impact strength, and cost-effectiveness make it the material of choice for a vast array of applications.

Application: Food Packaging: This segment is the largest and most influential within the PE blow molded products market. The sheer volume of food and beverage consumption globally, coupled with the need for safe, hygienic, and shelf-stable packaging, makes this a perennial leader.

Application: Industrial Packaging: This segment represents a significant and stable demand for PE blow molded products.

The interplay of these dominant regions and segments creates a dynamic market landscape. The Asia Pacific region's massive production and consumption, driven by a growing population and industrialization, will continue to shape global trends, while the maturity and innovation focus of North America and Europe will drive advancements in material science and sustainable solutions. Within segments, HDPE's superior properties and cost-effectiveness, coupled with the ubiquitous demand from the food and industrial sectors, will ensure their continued leadership in the years to come.

Several key factors are acting as significant growth catalysts for the PE blow molded products industry. The ongoing innovation in material science, leading to the development of enhanced PE grades with improved barrier properties, greater strength, and lighter weight, is a primary driver. Furthermore, the increasing focus on sustainability and the development of closed-loop recycling systems for PE is transforming its perception and expanding its application potential. Government initiatives promoting recycling and the growing consumer preference for eco-friendly products are accelerating the adoption of recycled content in blow molded goods. Finally, the expansion of e-commerce and the subsequent demand for efficient and protective packaging for a wider range of products, including consumables and consumer goods, is providing a substantial boost to the market.

This comprehensive report offers an exhaustive analysis of the World PE Blow Molded Products market, providing unparalleled depth and breadth of coverage. Beyond market size and forecasts, it delves into the intricate interplay of Type (HDPE, LDPE) and Application (Food Packaging, Industrial Packaging, Medical Packaging, Cosmetic Packaging, Others), offering granular insights into segment-specific growth drivers, challenges, and trends. The report meticulously examines the World PE Blow Molded Products Production landscape, identifying key production hubs and capacity expansions. Crucially, it provides a forward-looking perspective on Industry Developments, including technological advancements, regulatory shifts, and sustainability initiatives that will shape the market's future. Stakeholders will benefit from detailed competitive intelligence on leading players, including Crown Holdings, Mondi, Reynolds Group, and many others, alongside an analysis of their strategic moves and innovations. The report's robust methodology, utilizing data in the millions of units and covering a Study Period of 2019-2033 with a Base Year of 2025, ensures that all strategic decisions are informed by accurate and actionable market intelligence.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Crown Holdings, Mondi, Reynolds Group, Stora Enso, Berry Plastics, Coveris, Packaging Corporation of America, RPC Group, Silgan, BWAY Corporation, Greif Inc., Technoplast Ltd., Univation Technologies, Inpack, Alpha Packaging, Microdyne Plastics Inc., Custom-Pak, Inc., Comar LLC., SCHÜTZ GmbH & Co. KGaA, APEX Plastics, Inpress Plastics ltd, Agri-Industrial Plastics Co.,.

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "PE Blow Molded Products," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the PE Blow Molded Products, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.