1. What is the projected Compound Annual Growth Rate (CAGR) of the Solvent Recovery Bags?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Solvent Recovery Bags

Solvent Recovery BagsSolvent Recovery Bags by Type (Customized Size, Standard Size, World Solvent Recovery Bags Production ), by Application (Oil Industry, Gas Industry, Pharmaceutical Industry, Others, World Solvent Recovery Bags Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

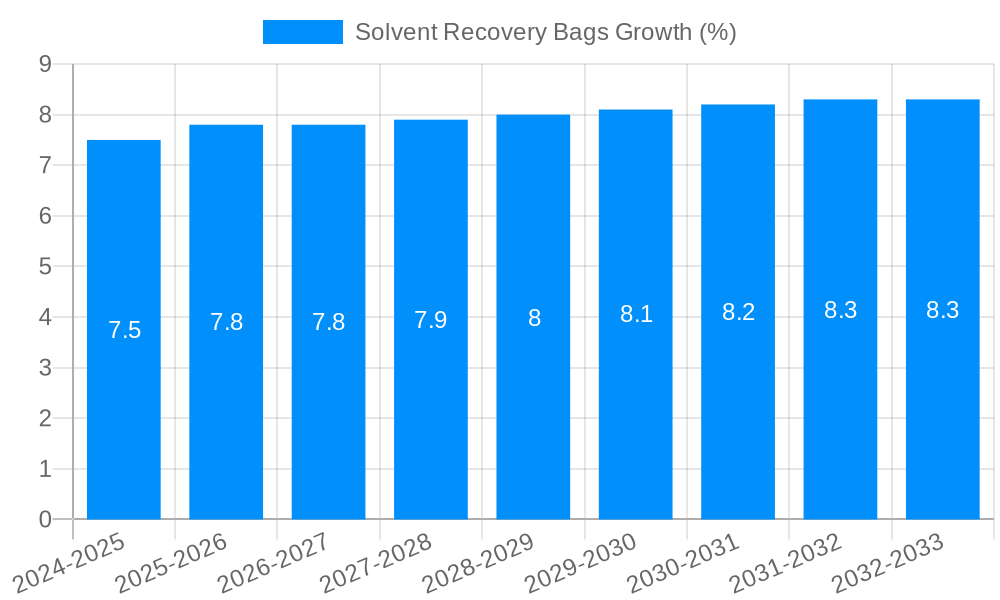

The global Solvent Recovery Bags market is poised for significant growth, projected to reach a substantial valuation driven by increasing industrialization and a heightened emphasis on environmental sustainability. The market size was estimated at $609.7 million in 2024, and is anticipated to expand at a Compound Annual Growth Rate (CAGR) of approximately 7.5% from 2025 to 2033. This robust expansion is primarily fueled by the growing need for efficient solvent recovery systems across key sectors such as the oil and gas, pharmaceutical, and chemical industries. As regulatory frameworks around waste management and emissions become more stringent, industries are actively seeking cost-effective and environmentally responsible solutions for solvent disposal and reuse. The demand for customized size solvent recovery bags is also on the rise, as industries require bespoke solutions to optimize their specific operational processes and maximize solvent capture efficiency. This trend underscores a maturing market that is adapting to the nuanced requirements of diverse industrial applications.

Furthermore, technological advancements in material science are contributing to the development of more durable, efficient, and chemically resistant solvent recovery bags, further bolstering market expansion. Key drivers include the inherent cost savings associated with solvent reuse, reducing the need for virgin solvent purchases and minimizing hazardous waste disposal expenses. The increasing adoption of solvent recovery technologies in emerging economies, coupled with a global push towards circular economy principles, presents significant growth opportunities. However, the market also faces certain restraints, such as the initial capital investment required for implementing advanced recovery systems and the availability of alternative solvent management methods. Nevertheless, the long-term benefits of solvent recovery, including reduced environmental impact and improved operational efficiency, are expected to outweigh these challenges, ensuring a dynamic and expanding market landscape for solvent recovery bags.

Here's a unique report description on Solvent Recovery Bags, incorporating your specified details and structure:

This comprehensive report delves into the dynamic global market for Solvent Recovery Bags, offering a detailed analysis of trends, driving forces, challenges, and future growth opportunities. Spanning a crucial study period from 2019 to 2033, with a deep dive into the base year of 2025 and an extensive forecast period of 2025-2033, this research provides invaluable insights for stakeholders. The historical period of 2019-2024 lays the foundation for understanding market evolution. This report is designed to equip industry leaders, investors, and strategic planners with actionable intelligence to navigate the complexities and capitalize on the burgeoning opportunities within this critical environmental sector. We project a market valuation in the hundreds of millions for the global Solvent Recovery Bags market, reflecting its significant economic impact and growing importance.

The global Solvent Recovery Bags market is experiencing a robust and sustained upward trajectory, driven by a confluence of escalating environmental regulations, a heightened corporate focus on sustainability, and the inherent economic advantages of solvent reclamation. During the historical period (2019-2024), we observed a steady increase in adoption, fueled by initial awareness of hazardous waste reduction and the cost savings associated with reusing valuable solvents. As we move into the base year (2025) and the subsequent forecast period (2025-2033), this trend is poised to accelerate significantly. The report highlights a particular surge in demand for customized size solvent recovery bags, catering to the diverse and often highly specific needs of industries like pharmaceuticals and specialized manufacturing. Standard size bags will continue to hold a substantial market share, particularly in high-volume applications within the oil and gas sectors. A key insight from our research indicates that the "World Solvent Recovery Bags Production" itself is becoming a focal point, with a growing emphasis on localized manufacturing to reduce supply chain risks and carbon footprints. Innovations in material science are also playing a pivotal role, leading to the development of more durable, chemically resistant, and efficient solvent recovery bags, thereby enhancing their longevity and overall cost-effectiveness. The increasing stringency of international and national environmental protection laws worldwide is a primary catalyst, compelling businesses across various sectors to invest in sustainable waste management solutions. Furthermore, the growing awareness of the circular economy principles among manufacturers and consumers alike is fostering a demand for products and processes that minimize waste and maximize resource utilization. This paradigm shift is directly benefiting the solvent recovery bags market as companies actively seek methods to recover and reuse solvents, thereby reducing their environmental impact and operational costs. The market is also witnessing a trend towards integrated solutions, where solvent recovery bags are part of larger systems designed for efficient solvent management, further solidifying their position as an essential component in modern industrial practices. The economic imperative of reducing solvent purchase costs and waste disposal fees is a powerful incentive, particularly for small and medium-sized enterprises. The increasing sophistication of filtration and separation technologies is also enhancing the effectiveness of solvent recovery, making the use of specialized bags a more viable and attractive proposition. This evolution underscores the market's maturity and its integral role in promoting responsible industrial operations. The market is evolving towards more intelligent and automated solutions, where solvent recovery bags are integrated with advanced monitoring systems to optimize recovery rates and ensure compliance with environmental standards. The demand for high-performance bags capable of handling a wider range of aggressive solvents and operating under diverse industrial conditions is also on the rise, signaling a move towards specialized and value-added offerings.

The global Solvent Recovery Bags market is being propelled by a powerful combination of regulatory pressures and economic incentives. Escalating environmental regulations, particularly concerning volatile organic compound (VOC) emissions and hazardous waste disposal, are forcing industries to adopt more sustainable practices. Governments worldwide are implementing stricter guidelines that penalize excessive solvent waste and encourage the adoption of reclamation technologies. This regulatory push, evident across developed and emerging economies, directly translates into increased demand for effective solvent recovery solutions, with bags forming a crucial component of these systems. Simultaneously, the economic benefits of solvent recovery are becoming increasingly undeniable. The cost of purchasing virgin solvents can be substantial, and the fees associated with hazardous waste disposal are perpetually rising. By investing in solvent recovery bags, businesses can significantly reduce their operational expenditures by reusing valuable solvents, thereby offsetting initial capital outlays and improving their bottom line. This dual impetus of compliance and cost savings is creating a fertile ground for market growth. Furthermore, the growing corporate commitment to Environmental, Social, and Governance (ESG) principles is adding another layer of impetus. Companies are actively seeking ways to demonstrate their environmental responsibility, and solvent recovery is a tangible and impactful way to achieve this. This trend is particularly pronounced in sectors where environmental impact is under greater scrutiny.

Despite the promising growth, the Solvent Recovery Bags market is not without its hurdles. A significant challenge revolves around the initial capital investment required for sophisticated solvent recovery systems that incorporate these specialized bags. For smaller enterprises, the upfront cost can be a deterrent, leading to a preference for less efficient, albeit cheaper, traditional disposal methods. Another restraint stems from the technical expertise needed for the optimal operation and maintenance of solvent recovery systems. Improper handling or incorrect application of solvent recovery bags can lead to reduced efficiency, solvent contamination, or even premature failure of the bags, thereby undermining the perceived value proposition. Furthermore, the market can be fragmented by the lack of standardization in certain applications, necessitating customized solutions that can increase lead times and costs. The disposal of spent solvent recovery bags themselves, while less hazardous than spent solvents, still requires appropriate handling and disposal protocols, adding another layer of complexity. The availability and consistency of high-quality raw materials for bag manufacturing can also pose a challenge, potentially impacting product performance and pricing. Finally, intermittent demand fluctuations in certain end-user industries, such as cyclical sectors within the oil and gas industry, can create periods of restrained growth for solvent recovery bag suppliers.

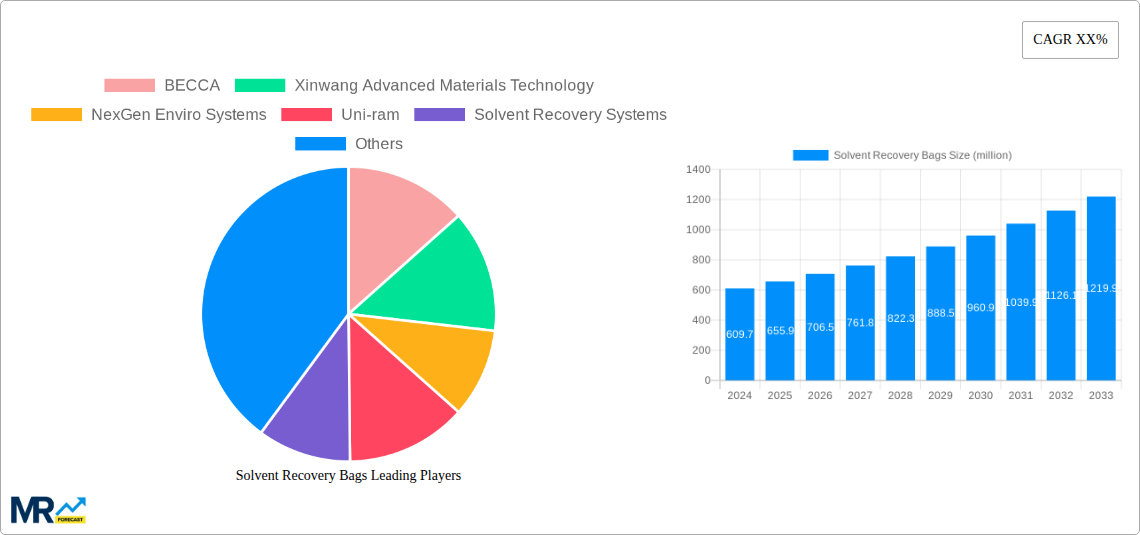

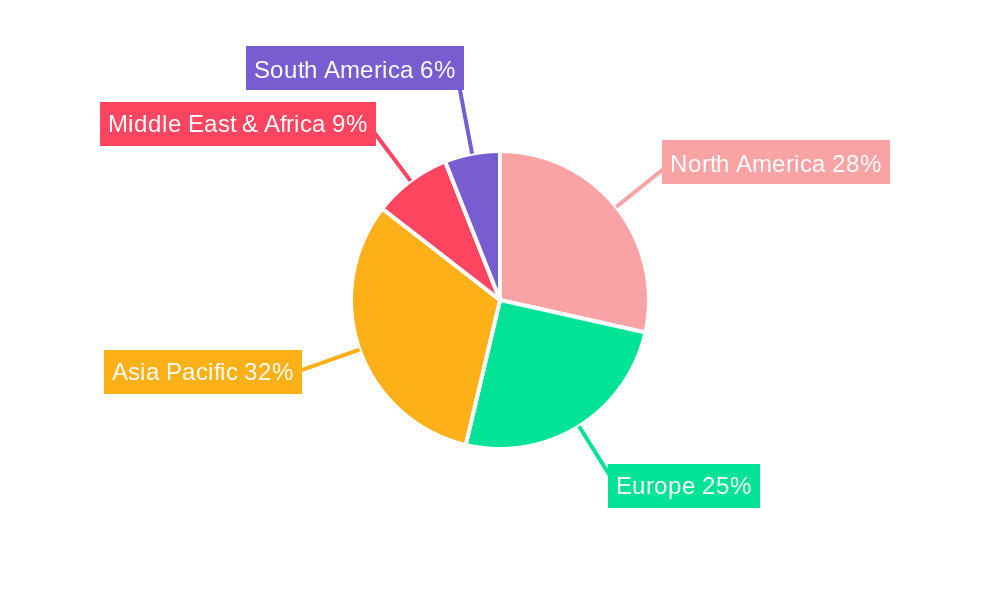

The global Solvent Recovery Bags market is poised for dominance by specific regions and market segments due to a combination of regulatory frameworks, industrial activity, and technological adoption.

Dominating Regions/Countries:

North America (United States, Canada): This region is a powerhouse in the solvent recovery bags market, driven by stringent environmental regulations, a highly industrialized economy, and a strong emphasis on sustainability. The presence of major players in the oil and gas, pharmaceutical, and manufacturing sectors necessitates efficient solvent management. The robust enforcement of EPA regulations regarding VOC emissions and hazardous waste disposal directly fuels the demand for advanced solvent recovery solutions. The Oil Industry and Pharmaceutical Industry are particularly significant end-users, with substantial investments in reclamation technologies. The adoption of Customized Size solvent recovery bags is also prevalent, catering to the specialized needs of diverse manufacturing processes. The sheer volume of industrial operations and the proactive approach to environmental compliance make North America a consistent leader.

Europe (Germany, United Kingdom, France): Europe, with its comprehensive REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) legislation and strong commitment to the circular economy, stands as another dominant force. The industrial landscape, particularly in countries like Germany and the UK, is characterized by a high density of chemical manufacturing, automotive production, and pharmaceutical research, all of which are significant consumers of solvents. The growing focus on reducing the carbon footprint of industrial processes further amplifies the demand for solvent recovery. The Pharmaceutical Industry and Others (encompassing diverse manufacturing and printing sectors) are key contributors to market growth. The demand for Standard Size bags is robust due to the large-scale operations, but Customized Size solutions are also crucial for niche applications.

Asia Pacific (China, India, Japan): This region is emerging as a rapidly growing market, propelled by increasing industrialization, expanding manufacturing capabilities, and a growing awareness of environmental concerns. China, in particular, with its vast manufacturing base and evolving environmental policies, represents a significant growth engine. As industries in this region mature and face more rigorous environmental scrutiny, the adoption of solvent recovery technologies, including solvent recovery bags, is expected to accelerate. The Oil Industry and Gas Industry are key drivers, alongside a burgeoning manufacturing sector within the Others segment. The potential for large-scale adoption of both Standard Size and Customized Size bags is immense, driven by the sheer volume of industrial activity.

Dominating Segments:

Type: Customized Size: While Standard Size bags will continue to command a significant market share due to their broad applicability and cost-effectiveness, the Customized Size segment is exhibiting a particularly impressive growth rate. This dominance is driven by the unique and often complex solvent recovery needs across various industries, especially in the Pharmaceutical Industry and specialized manufacturing within the Others segment. Pharmaceutical companies, for instance, require highly precise solvent recovery solutions tailored to specific drug synthesis processes, demanding bags that are dimensionally accurate and compatible with a wide range of potent solvents. Similarly, the electronics and aerospace industries often require custom-fit solutions for their intricate cleaning and degreasing operations. This demand for bespoke solutions underscores a market shift towards higher-value, application-specific products.

Application: Pharmaceutical Industry: The Pharmaceutical Industry is a key segment that is expected to dominate the Solvent Recovery Bags market. The stringent quality control requirements, the high value of solvents used in drug manufacturing, and the imperative to minimize contamination and waste make solvent recovery a critical process. Pharmaceutical companies invest heavily in advanced recovery systems to ensure compliance with Good Manufacturing Practices (GMP) and to reduce operational costs associated with expensive solvents and waste disposal. The need for purity and consistency in recovered solvents directly translates to a demand for high-performance solvent recovery bags.

World Solvent Recovery Bags Production: The overarching trend of increasing World Solvent Recovery Bags Production itself signifies a fundamental shift in the market. As global demand grows, so too does the emphasis on optimizing production processes, enhancing manufacturing efficiency, and exploring new materials and technologies. This segment reflects the overall maturation and expansion of the industry, driven by both increased consumption and advancements in manufacturing capabilities. The report will analyze the geographic distribution of this production and the factors influencing its growth.

The Solvent Recovery Bags industry is experiencing significant growth catalysts. Foremost among these is the escalating global focus on sustainability and the circular economy, pushing industries to minimize waste and maximize resource utilization. Increasingly stringent environmental regulations worldwide, particularly concerning VOC emissions and hazardous waste disposal, are compelling businesses to invest in effective solvent reclamation solutions. Furthermore, the rising cost of virgin solvents and the associated disposal fees provide a strong economic incentive for companies to adopt solvent recovery technologies, thereby enhancing their profitability. Continuous innovation in material science, leading to the development of more durable, chemically resistant, and efficient recovery bags, is also a key growth enabler.

This report provides an in-depth and comprehensive analysis of the global Solvent Recovery Bags market, encompassing a detailed examination of its intricate dynamics. The research delves into the current market landscape, historical performance, and future projections, offering a holistic view for stakeholders. It meticulously analyzes key trends, driving forces, and challenges that shape the industry's trajectory. Furthermore, the report identifies dominant regions and crucial market segments poised for significant growth, providing strategic insights for market entry and expansion. With a forward-looking perspective, it highlights emerging innovations and the competitive landscape, empowering businesses to make informed decisions and capitalize on future opportunities within this vital environmental sector.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include BECCA, Xinwang Advanced Materials Technology, NexGen Enviro Systems, Uni-ram, Solvent Recovery Systems, PPC Technologies & Solutions, Hongyi Environmental Tech, Ingeniven, Mid-States Equipment, Maratek, Recbags, ALPHA LINER, Sidewinder, Martin Senour, Sprayfish, CleanPlanet Chemical, Maratek Environmental, CBG Technologies, IST Pure, Pollution Control Products, Safetykleen, .

The market segments include Type, Application.

The market size is estimated to be USD 609.7 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Solvent Recovery Bags," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Solvent Recovery Bags, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.