1. What is the projected Compound Annual Growth Rate (CAGR) of the QFN Chip Packaging Tape?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

QFN Chip Packaging Tape

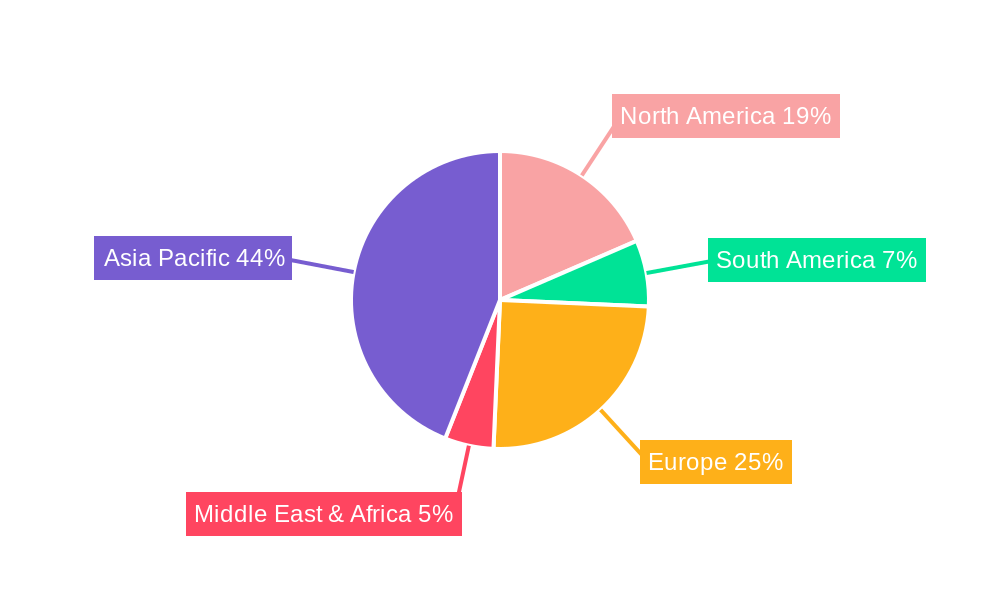

QFN Chip Packaging TapeQFN Chip Packaging Tape by Type (Silicone QFN Tape, Acrylic QFN Tape, Hot Pressed QFN Tape, World QFN Chip Packaging Tape Production ), by Application (Punching QFN, Sawing QFN, World QFN Chip Packaging Tape Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

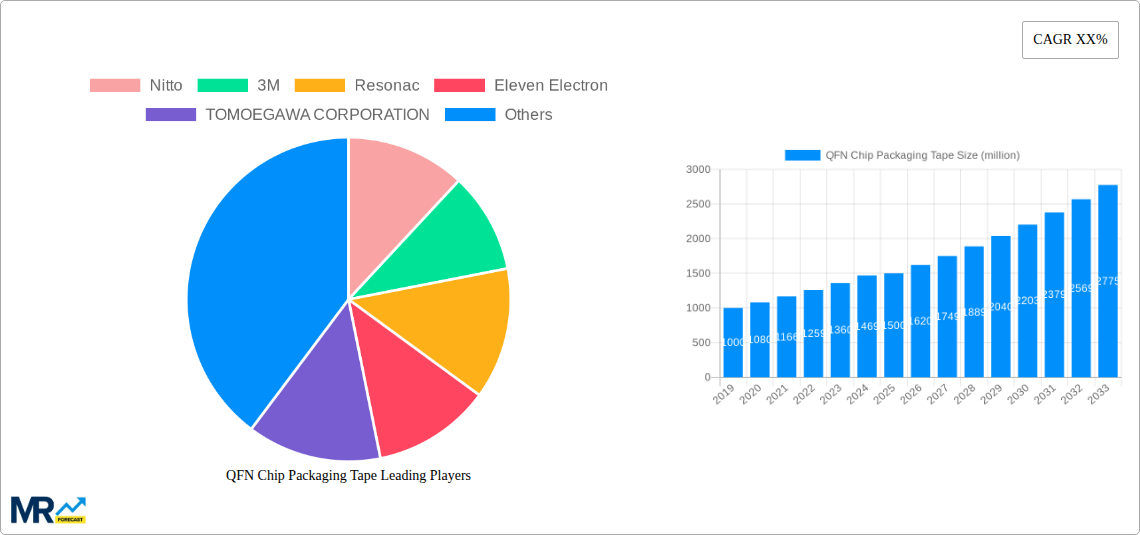

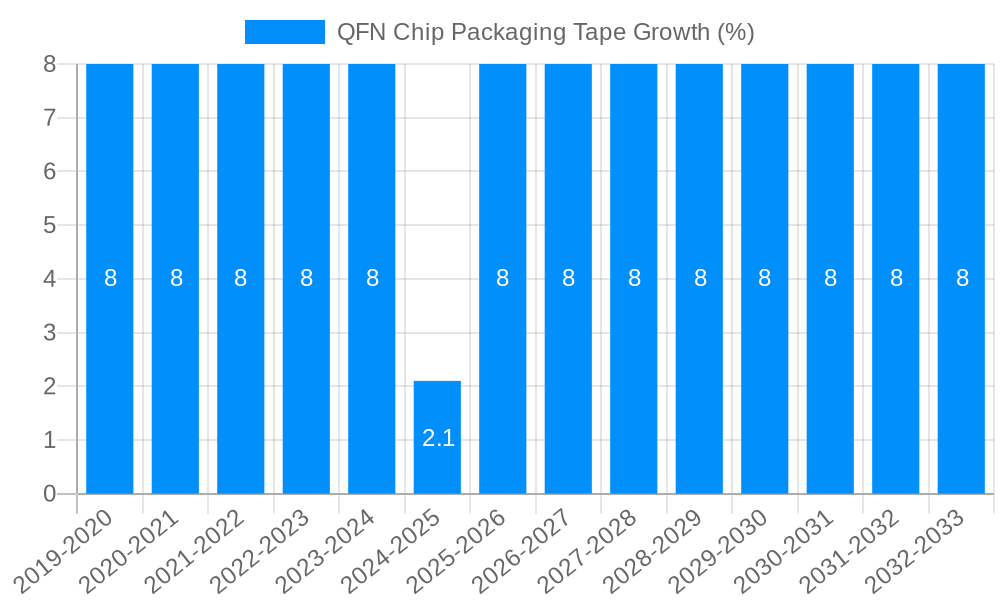

The global QFN (Quad Flat No-Lead) Chip Packaging Tape market is poised for significant expansion, projected to reach a valuation of approximately $1,500 million by 2025. This robust growth trajectory is fueled by a Compound Annual Growth Rate (CAGR) of around 8%, indicating a dynamic and expanding industry. The primary drivers of this market surge are the escalating demand for advanced semiconductor packaging solutions across a multitude of electronic devices, including smartphones, automotive electronics, and high-performance computing. The increasing miniaturization of electronic components and the need for enhanced thermal management and electrical performance in integrated circuits are further propelling the adoption of QFN packaging, and consequently, the specialized tapes used in its manufacturing. Leading companies such as Nitto, 3M, and Resonac are at the forefront, investing in innovative tape technologies to meet the evolving needs of chip manufacturers.

The market landscape for QFN chip packaging tapes is characterized by distinct segments, catering to specific manufacturing processes. Silicone QFN Tape, Acrylic QFN Tape, and Hot Pressed QFN Tape represent key product types, each offering unique advantages in terms of adhesion, temperature resistance, and mechanical properties. Application-wise, the tapes are crucial for both punching and sawing QFN chips, underscoring their essential role in the semiconductor supply chain. While the market enjoys strong growth drivers, potential restraints such as fluctuating raw material prices and intense competition among established and emerging players could influence profit margins. However, ongoing technological advancements, particularly in tape formulations that enhance reliability and reduce processing costs, are expected to mitigate these challenges, ensuring continued market expansion and innovation across key regions like Asia Pacific, North America, and Europe.

This comprehensive report delves into the intricate dynamics of the global QFN (Quad Flat No-Lead) chip packaging tape market. Spanning a study period from 2019 to 2033, with a Base Year of 2025, the analysis offers a detailed examination of historical trends, current market landscapes, and future projections. The Estimated Year for key market metrics is also 2025, providing a clear snapshot of the market at that juncture. The Forecast Period extends from 2025 to 2033, offering insights into anticipated growth trajectories and evolving market needs. Historical data from 2019 to 2024 provides the foundation for understanding past performance and identifying nascent trends. The report meticulously analyzes various QFN chip packaging tape types, including Silicone QFN Tape, Acrylic QFN Tape, and Hot Pressed QFN Tape, alongside a comprehensive overview of World QFN Chip Packaging Tape Production. Application-wise, the market is dissected based on Punching QFN and Sawing QFN processes, also considering World QFN Chip Packaging Tape Production figures. The analysis includes an in-depth look at Industry Developments that are shaping the landscape. The report will leverage market insights from millions of units to provide quantitative and qualitative assessments, empowering stakeholders with actionable intelligence.

The global QFN chip packaging tape market is experiencing a dynamic evolution, characterized by several significant trends that are reshaping production, application, and demand. A paramount trend is the increasing demand for specialized tapes that cater to the intricate requirements of advanced semiconductor packaging. As miniaturization continues to be a driving force in electronics, QFN packages are becoming smaller and more complex, necessitating tapes with superior adhesion, precise die placement capabilities, and excellent handling characteristics. Silicone QFN Tapes, for instance, are gaining traction due to their high temperature resistance and flexibility, crucial for advanced manufacturing processes that involve thermal stress. The growing adoption of high-density interconnect (HDI) and 3D packaging technologies further amplifies the need for tapes that can withstand aggressive processing steps and ensure the integrity of sensitive semiconductor components. Furthermore, the market is witnessing a steady shift towards tapes that offer improved environmental profiles, with manufacturers exploring bio-based or recyclable materials. This aligns with the broader sustainability initiatives within the electronics industry. The production of QFN chip packaging tape is also becoming more geographically dispersed, with emerging economies playing an increasingly important role in both manufacturing and consumption, driven by the growth of their domestic semiconductor industries. The projected World QFN Chip Packaging Tape Production is expected to reach hundreds of millions of units, reflecting the sustained demand across various electronic device segments. From consumer electronics to automotive and industrial applications, the ubiquitous nature of QFN packages ensures a consistent need for high-performance packaging tapes. The intricate interplay between technological advancements in semiconductor manufacturing and the development of innovative packaging solutions is a cornerstone of market growth, with a projected upward trajectory in the coming years. This sustained growth is underpinned by the critical role these tapes play in ensuring the reliability and performance of the microchips that power our increasingly connected world.

Several potent forces are driving the robust growth of the QFN chip packaging tape market. The relentless pursuit of miniaturization and increased functionality in electronic devices is perhaps the most significant catalyst. As smartphones, wearables, and increasingly sophisticated IoT devices shrink in size, the demand for compact and efficient packaging solutions like QFNs escalates. This directly translates into a higher requirement for specialized packaging tapes that can facilitate the precise handling and bonding of these smaller semiconductor chips. The burgeoning automotive electronics sector is another major growth engine. With the advent of autonomous driving, advanced driver-assistance systems (ADAS), and the electrification of vehicles, the demand for reliable and high-performance semiconductor components is soaring. QFN packages are widely adopted in these applications due to their thermal management capabilities and compact footprint, consequently boosting the need for associated packaging tapes. The proliferation of 5G technology and the associated infrastructure development further fuels demand. The higher frequencies and increased data throughput require more advanced semiconductor designs and packaging techniques, where QFNs play a crucial role. The growing adoption of artificial intelligence (AI) and machine learning (ML) necessitates powerful processing units, often housed in QFN packages, thereby increasing the demand for the tapes used in their assembly. The continuous innovation in semiconductor manufacturing processes, leading to more intricate chip designs and wafer-level packaging, also necessitates the development and adoption of advanced QFN packaging tapes with improved performance characteristics.

Despite the promising growth trajectory, the QFN chip packaging tape market faces several challenges and restraints that could temper its expansion. One of the primary hurdles is the intense price sensitivity in the semiconductor supply chain. Manufacturers of QFN packaging tapes are often under pressure to reduce costs, which can impact profit margins and necessitate continuous process optimization and efficiency improvements. This competitive pricing environment can also lead to consolidation within the market as smaller players struggle to compete. Another significant challenge is the stringent quality and reliability requirements for semiconductor packaging materials. Any defect or inconsistency in the packaging tape can lead to chip failure, resulting in costly recalls and reputational damage. This necessitates rigorous quality control measures and continuous investment in research and development to ensure consistent product performance, which can be a substantial financial burden. Furthermore, the rapid pace of technological advancement in the semiconductor industry presents a dual-edged sword. While it drives demand for advanced tapes, it also means that existing tape technologies can become obsolete quickly. Companies must constantly innovate and adapt to new packaging standards and materials, requiring substantial R&D investment and a flexible manufacturing infrastructure. Supply chain disruptions, as witnessed in recent global events, can also pose a significant threat. Fluctuations in the availability of raw materials or logistical challenges can impact production schedules and lead to increased costs. Lastly, the environmental regulations surrounding manufacturing processes and material disposal are becoming increasingly stringent, requiring tape manufacturers to invest in eco-friendly alternatives and sustainable production methods, which can add to operational complexity and cost.

The QFN chip packaging tape market is poised for significant growth in specific regions and segments, driven by distinct factors. Asia Pacific, particularly China, is anticipated to be the dominant region in the QFN chip packaging tape market. This dominance stems from several interconnected reasons. China is the undisputed global manufacturing hub for electronics, encompassing a vast array of QFN chip production. The sheer volume of semiconductor assembly and packaging operations within China, catering to both domestic consumption and global export markets, translates into an immense demand for QFN packaging tapes. The country's proactive industrial policies, aimed at fostering self-sufficiency in critical technologies like semiconductors, further amplify this demand. The presence of numerous contract manufacturers and original design manufacturers (ODMs) in China ensures a constant and substantial requirement for packaging materials. Moreover, the rapid growth of domestic semiconductor foundries and fabless design companies within China is contributing to a localized and escalating demand for specialized tapes.

Within the segments, Acrylic QFN Tape is projected to exhibit substantial dominance. Acrylic-based tapes offer a compelling balance of adhesion strength, temperature resistance, and cost-effectiveness, making them a versatile choice for a wide range of QFN packaging applications. Their ability to provide reliable bonding during various assembly processes, including die attach and wafer dicing, positions them favorably. Furthermore, advancements in acrylic tape formulations are continually enhancing their performance characteristics, such as improved tack, shear strength, and residue-free removal, further solidifying their appeal. The Punching QFN application segment is also expected to be a significant contributor to market dominance. Punching is a widely adopted and cost-efficient method for separating individual QFN devices from a wafer. The efficiency and high throughput associated with punching processes necessitate the use of robust and reliable packaging tapes that can withstand the mechanical stresses involved. As the volume of QFN production continues to grow, the demand for tapes optimized for punching applications will naturally surge. Consequently, the interplay of a dominant manufacturing region like Asia Pacific, a versatile and cost-effective tape type like Acrylic QFN Tape, and an efficient application method like Punching QFN will collectively shape the landscape of the global QFN chip packaging tape market. The World QFN Chip Packaging Tape Production figures are expected to be heavily influenced by these dominant factors, with millions of units being consumed annually within these key areas.

The QFN chip packaging tape industry is being propelled by several key growth catalysts. The exponential growth in consumer electronics, including smartphones, smart wearables, and gaming devices, continuously fuels the demand for QFN packages and, consequently, the specialized tapes used in their assembly. The expanding automotive sector, driven by the electrification of vehicles and the integration of advanced driver-assistance systems (ADAS), is another significant driver, as QFNs are widely used in automotive electronic control units. The ongoing rollout of 5G networks and the proliferation of Internet of Things (IoT) devices are creating a surge in demand for high-performance semiconductors, many of which are packaged using QFN technology.

This comprehensive report offers an all-encompassing analysis of the QFN chip packaging tape market, providing deep insights into its current state and future trajectory. It meticulously examines the market dynamics across various segments, including Silicone QFN Tape, Acrylic QFN Tape, and Hot Pressed QFN Tape, along with detailed assessments of World QFN Chip Packaging Tape Production. Furthermore, the report dissects the market based on key applications such as Punching QFN and Sawing QFN, offering a holistic view of their market share and growth potential. The analysis is grounded in extensive data, including millions of units of production and consumption figures, analyzed over the Study Period (2019-2033), with a specific focus on the Base Year (2025) and the Forecast Period (2025-2033). By delving into historical trends from 2019-2024, the report provides a robust foundation for understanding the market's evolution and identifying critical growth catalysts.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Nitto, 3M, Resonac, Eleven Electron, TOMOEGAWA CORPORATION, INNOX Advanced Materials, Koan Hao, Deantape, DSK Technologies, WEN LI JE ENTERPRISE, Solar Plus Company, Symbio, Shenzhen KHJ Technolog, Dongguan Anpai Electronics.

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "QFN Chip Packaging Tape," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the QFN Chip Packaging Tape, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.