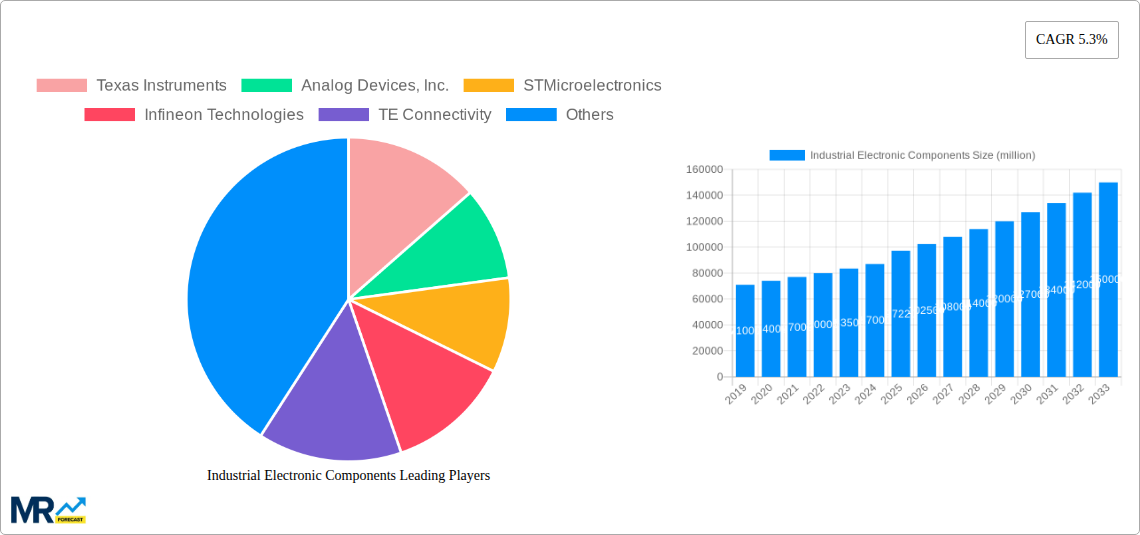

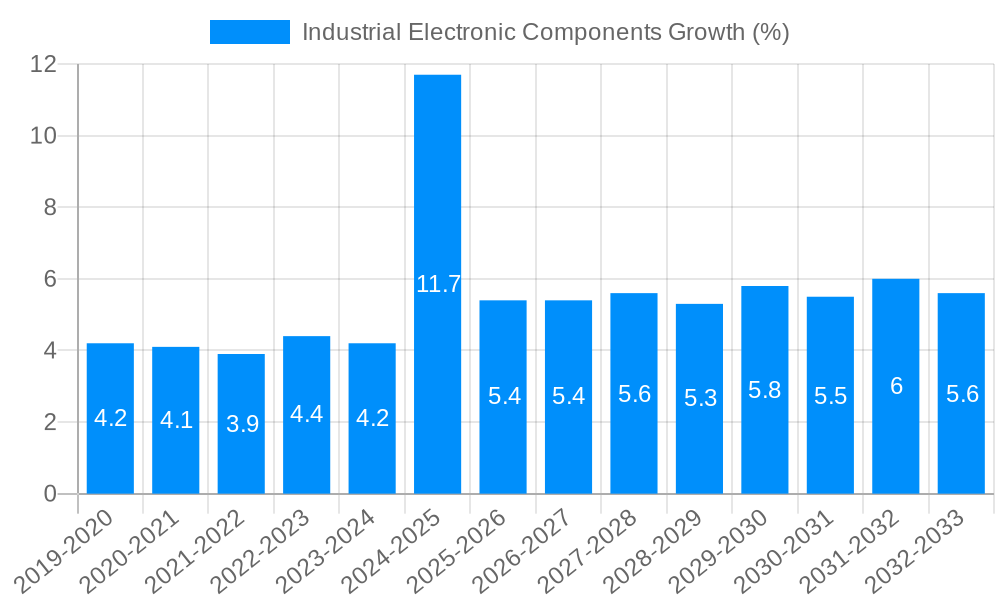

1. What is the projected Compound Annual Growth Rate (CAGR) of the Industrial Electronic Components?

The projected CAGR is approximately 5.3%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Industrial Electronic Components

Industrial Electronic ComponentsIndustrial Electronic Components by Application (Automation Equipment Control, Industrial Power Management, Industrial Communication Equipment, Measurement and Testing Equipment, Others), by Type (Active Electronic Components, Passive Electronic Components), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

The Industrial Electronic Components market is poised for significant expansion, projected to reach a substantial valuation of $97,220 million by 2025, exhibiting a Compound Annual Growth Rate (CAGR) of 5.3% from 2019 to 2033. This robust growth is fueled by the relentless demand for automation across various industrial sectors, including manufacturing, energy, and logistics. The increasing adoption of Industry 4.0 technologies, such as the Industrial Internet of Things (IIoT), artificial intelligence (AI) in industrial processes, and advanced robotics, necessitates a constant influx of sophisticated electronic components. These components are the backbone of modern industrial systems, enabling enhanced efficiency, precision, and connectivity. Furthermore, the imperative for greater energy efficiency and stringent regulatory compliance in industrial operations drives the demand for advanced power management solutions and reliable measurement and testing equipment. The market is segmented into two primary categories: Applications such as Automation Equipment Control, Industrial Power Management, Industrial Communication Equipment, Measurement and Testing Equipment, and Others; and Component Types including Active Electronic Components and Passive Electronic Components. The dominance of Automation Equipment Control and Active Electronic Components is expected to continue, reflecting the complexity and interconnectedness of contemporary industrial infrastructure.

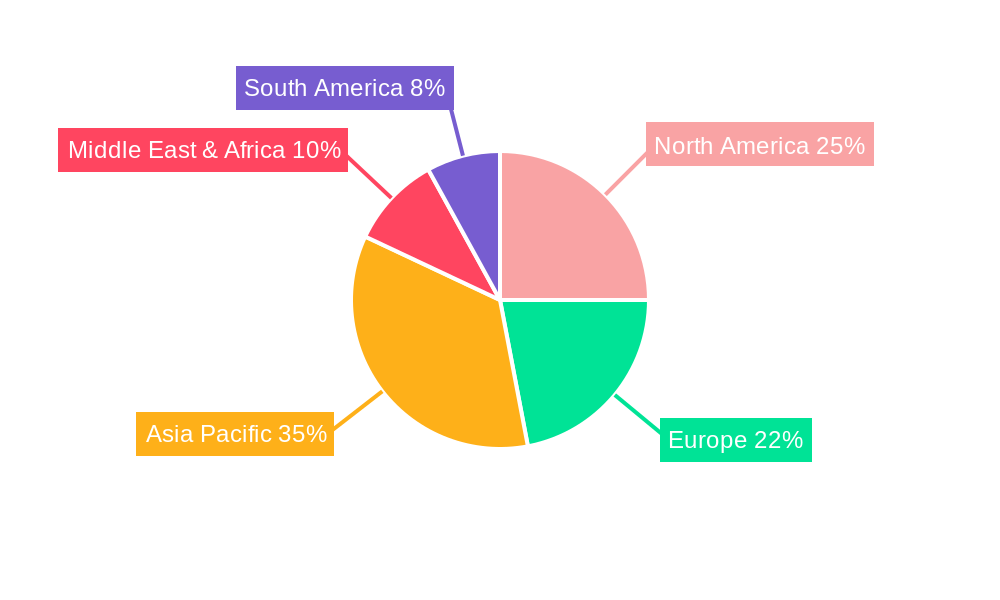

Navigating this dynamic landscape requires a keen understanding of prevailing trends and potential challenges. Key trends include the miniaturization of components for increased density and improved performance, the integration of advanced materials for enhanced durability and thermal management, and a growing emphasis on sustainability and eco-friendly manufacturing practices within the electronics sector. The proliferation of connected devices and the resultant surge in data generation are also spurring innovation in industrial communication equipment. However, the market is not without its restraints. Supply chain disruptions, geopolitical uncertainties impacting raw material availability and pricing, and the high cost of research and development for cutting-edge technologies can pose significant hurdles. Intense competition among established players like Texas Instruments, Analog Devices, Inc., and STMicroelectronics, alongside emerging manufacturers, is a constant factor. Regional market dynamics are also crucial, with Asia Pacific, particularly China and India, leading in terms of market size and growth due to rapid industrialization, followed by North America and Europe, which are characterized by advanced technological adoption and stringent quality standards.

Here's a unique report description for Industrial Electronic Components, incorporating your specified elements:

This comprehensive report delves into the dynamic landscape of the Industrial Electronic Components market, offering a granular analysis of trends, drivers, challenges, and future projections from 2019 to 2033. With a base year of 2025, the report meticulously examines historical data from 2019-2024 and provides robust estimations for the estimated year of 2025 and the forecast period of 2025-2033. The market is segmented by application, including Automation Equipment Control, Industrial Power Management, Industrial Communication Equipment, Measurement and Testing Equipment, and Others. Furthermore, it categorizes components into Active Electronic Components and Passive Electronic Components, providing a holistic view of the market's structure. The report will analyze the significant contributions of key players such as Texas Instruments, Analog Devices, Inc., STMicroelectronics, Infineon Technologies, TE Connectivity, Panasonic, Onsemi, NXP Semiconductors, Vishay, Yageo, Murata, Microchip, Amphenol, TDK Corporation, Samsung Electro-Mechanics, Omron, Taiyo Yuden, Kyocera, Skyworks, Littelfuse, and Nippon Chemi-Con. The insights presented are crucial for stakeholders seeking to navigate the evolving industrial electronics ecosystem, with particular attention paid to market movements in the millions of units.

The global Industrial Electronic Components market is undergoing a profound transformation, driven by the relentless pursuit of efficiency, intelligence, and sustainability across diverse industrial sectors. A key trend observed is the escalating demand for sophisticated Active Electronic Components, particularly microcontrollers and advanced sensors, powering the ongoing industrial automation revolution. The increasing adoption of Industry 4.0 technologies, including the Internet of Things (IoT) and artificial intelligence (AI) in manufacturing, is a significant catalyst. These technologies necessitate robust and high-performance components capable of processing vast amounts of data, enabling real-time decision-making, and facilitating predictive maintenance. For instance, the market for high-density microprocessors used in advanced robotics and automated guided vehicles is projected to see a compound annual growth rate (CAGR) exceeding 8% in the coming years, representing a significant volume increase in the millions of units. Simultaneously, the passive components sector, encompassing capacitors, resistors, and inductors, is witnessing a surge in demand for miniaturized, high-reliability, and high-power-density solutions. This is particularly evident in the industrial power management segment, where the transition towards renewable energy sources and the electrification of industrial processes require efficient power conversion and distribution systems. The development of advanced materials and manufacturing techniques is leading to components that can withstand extreme temperatures and harsh environmental conditions, further expanding their applicability in critical industrial infrastructure. Moreover, the increasing integration of edge computing capabilities within industrial settings is fueling the demand for specialized components that can handle on-site data processing, reducing latency and enhancing operational responsiveness. The sheer volume of these components in deployed systems, often in the tens of millions per facility, underscores their critical importance. This trend towards miniaturization and enhanced performance is not merely an evolutionary step but a foundational shift, enabling the next generation of smart factories and intelligent industrial operations, with specific segments like industrial communication equipment seeing an uplift of over 7 million units of specialized transceivers in the historical period alone.

Several interconnected forces are collectively propelling the growth of the Industrial Electronic Components market. Foremost among these is the unwavering digitalization of industries and the widespread adoption of Industry 4.0 principles. This overarching trend encompasses the integration of automation, data exchange, and cloud computing in manufacturing and industrial processes. The insatiable need for enhanced productivity, improved operational efficiency, and reduced downtime is compelling businesses to invest heavily in smart technologies. Consequently, this fuels the demand for sophisticated electronic components that underpin these advancements. For example, the deployment of advanced robotic systems in assembly lines, driven by the need for precision and speed, has significantly boosted the consumption of high-performance microcontrollers and specialized sensors, with an estimated consumption of over 15 million units of advanced sensor modules within the historical period of 2019-2024. Furthermore, the growing emphasis on energy efficiency and sustainability within industrial operations is another potent driver. Governments and corporations worldwide are actively seeking to reduce their carbon footprints and optimize energy consumption. This translates into a greater demand for high-efficiency power management components, such as advanced power modules, inverters, and controllers, essential for optimizing energy usage in everything from large-scale industrial machinery to smaller control systems. The increasing prevalence of electric vehicles (EVs) and their associated charging infrastructure also contributes significantly to this trend, necessitating a vast array of power electronics components. The need for enhanced industrial safety and security is also a key propeller. As industries become more complex and interconnected, the demand for reliable communication equipment, advanced monitoring systems, and robust control components capable of ensuring safe operations and protecting sensitive data has escalated. This has led to increased investment in components for industrial communication networks and safety-critical systems, with the demand for specialized industrial communication modules alone estimated to be in the millions of units annually.

Despite the robust growth trajectory, the Industrial Electronic Components market faces several significant challenges and restraints that can temper its expansion. A primary concern is the persistent issue of supply chain disruptions and material shortages. The intricate nature of global supply chains, coupled with geopolitical uncertainties, natural disasters, and the lingering effects of the COVID-19 pandemic, has led to intermittent shortages of critical raw materials, semiconductors, and specialized components. This unpredictability can lead to significant production delays, increased lead times, and ultimately, higher costs for manufacturers. For instance, the shortage of specific passive components, such as high-capacitance ceramic capacitors, has historically impacted production lines, with lead times extending to over 20 million weeks in some instances. Another considerable restraint is the increasing complexity and cost of research and development (R&D). The rapid pace of technological innovation demands continuous investment in R&D to develop cutting-edge components with enhanced performance, smaller form factors, and lower power consumption. This R&D investment can be substantial, posing a barrier for smaller players and necessitating strategic partnerships or acquisitions. The stringent regulatory landscape and standardization requirements across different regions and industries can also act as a restraint. Compliance with various safety, environmental, and performance standards requires meticulous design, testing, and certification processes, which can be time-consuming and add to the overall cost of bringing new products to market. Furthermore, the ever-evolving technological landscape and rapid obsolescence of certain component types necessitate constant adaptation and investment in next-generation technologies, which can be challenging for established industrial systems that often have long life cycles and require backward compatibility. The skilled labor shortage in specialized areas like semiconductor design and manufacturing also poses a significant impediment to scaling production and innovation, impacting the ability to meet the demand for millions of units required by the burgeoning industrial sector.

The Asia-Pacific region, particularly China, is poised to dominate the Industrial Electronic Components market in terms of both production and consumption. This dominance is underpinned by a confluence of factors including a robust manufacturing base, significant government investments in industrial modernization and technological advancement, and the presence of major electronics manufacturing hubs. China's "Made in China 2025" initiative and similar policies in other Asian countries are actively promoting the development and adoption of advanced manufacturing technologies, driving substantial demand for a wide array of industrial electronic components. The region’s sheer scale of manufacturing output across various sectors, from automotive and consumer electronics to heavy machinery and renewable energy, translates into an immense and ever-growing requirement for these components, often measured in hundreds of millions of units annually.

Within the Application segment, Automation Equipment Control is expected to be a key growth driver and likely a dominating segment. The relentless push towards smart factories, the adoption of robotics, AI-powered systems, and the Internet of Things (IoT) within manufacturing and industrial processes are directly fueling the demand for sophisticated control components. This includes microcontrollers, processors, specialized integrated circuits (ICs), sensors, and actuators that are critical for enabling precise, efficient, and autonomous operations. The need for real-time data processing and analysis in automated systems further amplifies the demand for high-performance active components. For instance, the production of advanced industrial robots alone requires millions of specialized processors and intricate sensor arrays annually. The development of collaborative robots (cobots) and autonomous mobile robots (AMRs) is also contributing significantly to this segment's growth, necessitating a constant supply of advanced control electronics. The increasing complexity of automated systems and the drive for greater flexibility and adaptability in manufacturing processes further solidify the position of Automation Equipment Control as a leading application area, with its demand projected to grow by over 9 million units in the forecast period.

In terms of Type, Active Electronic Components are anticipated to lead the market's growth and dominance. This category encompasses a broad spectrum of high-value components such as semiconductors, microcontrollers, microprocessors, ASICs (Application-Specific Integrated Circuits), discrete semiconductors (transistors, diodes), and optoelectronic devices. The escalating integration of intelligence and connectivity across all industrial sectors is intrinsically linked to the advancements and widespread adoption of active components. As industries embrace Industry 4.0, IoT, AI, and edge computing, the demand for powerful and versatile active components to process data, execute complex algorithms, and enable seamless communication skyrockets. The increasing complexity of industrial machinery, the need for predictive maintenance through sophisticated sensor networks, and the development of smart grids all rely heavily on advanced active electronic components. The growth in electric vehicles and their associated power management systems, for example, is driving significant demand for high-power semiconductor devices like SiC (Silicon Carbide) and GaN (Gallium Nitride) transistors, which are essential for efficient power conversion. The continuous miniaturization and performance enhancement of these components, coupled with their ability to perform complex functions, make them indispensable for the modern industrial landscape. The market for microcontrollers alone in industrial applications is projected to exceed 50 million units in the forecast period, highlighting the dominance of active components.

The Industrial Electronic Components industry is experiencing robust growth, propelled by several key catalysts. The accelerating digital transformation and adoption of Industry 4.0 technologies, including AI, IoT, and automation, are fundamentally reshaping industrial operations, driving the need for sophisticated and interconnected electronic components. Furthermore, the global push towards sustainability and energy efficiency is stimulating demand for advanced power management components and solutions that optimize energy consumption across various industrial applications. The burgeoning renewable energy sector, encompassing solar, wind, and energy storage, critically relies on a vast array of power electronic components for efficient energy conversion and grid integration. Finally, the increasing emphasis on predictive maintenance and operational efficiency is fueling the demand for advanced sensors and diagnostic components that enable real-time monitoring and early detection of potential issues.

This report provides an in-depth analysis of the Industrial Electronic Components market, offering critical insights into market dynamics, growth trends, and future projections. It examines the interplay of driving forces, challenges, and key regional influences that shape the industry. The report highlights the pivotal role of Automation Equipment Control and Active Electronic Components as dominant segments, emphasizing their contribution to the market's overall expansion. By meticulously analyzing data from the historical period (2019-2024) and providing projections for the forecast period (2025-2033), with a base year of 2025, it equips stakeholders with the necessary intelligence to make informed strategic decisions. The comprehensive coverage ensures a nuanced understanding of the market's trajectory, enabling businesses to identify opportunities and navigate potential risks within this vital sector. The report's focus on market insights in the millions of units provides concrete figures for strategic planning.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 5.3% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 5.3%.

Key companies in the market include Texas Instruments, Analog Devices, Inc., STMicroelectronics, Infineon Technologies, TE Connectivity, Panasonic, Onsemi, NXP Semiconductors, Vishay, Yageo, Murata, Microchip, Amphenol, TDK Corporation, Samsung Electro-Mechanics, Omron, Taiyo Yuden, Kyocera, Skyworks, Littelfuse, Nippon Chemi-Con.

The market segments include Application, Type.

The market size is estimated to be USD 97220 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million.

Yes, the market keyword associated with the report is "Industrial Electronic Components," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Industrial Electronic Components, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.