1. What is the projected Compound Annual Growth Rate (CAGR) of the PZT Thin-Film Piezo MEMS Foundry?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

PZT Thin-Film Piezo MEMS Foundry

PZT Thin-Film Piezo MEMS FoundryPZT Thin-Film Piezo MEMS Foundry by Type (/> MEMS Sensor Foundry, MEMS Actuator Foundry), by Application (/> Consumer Electronics, Automotive, Industrial, Medical, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

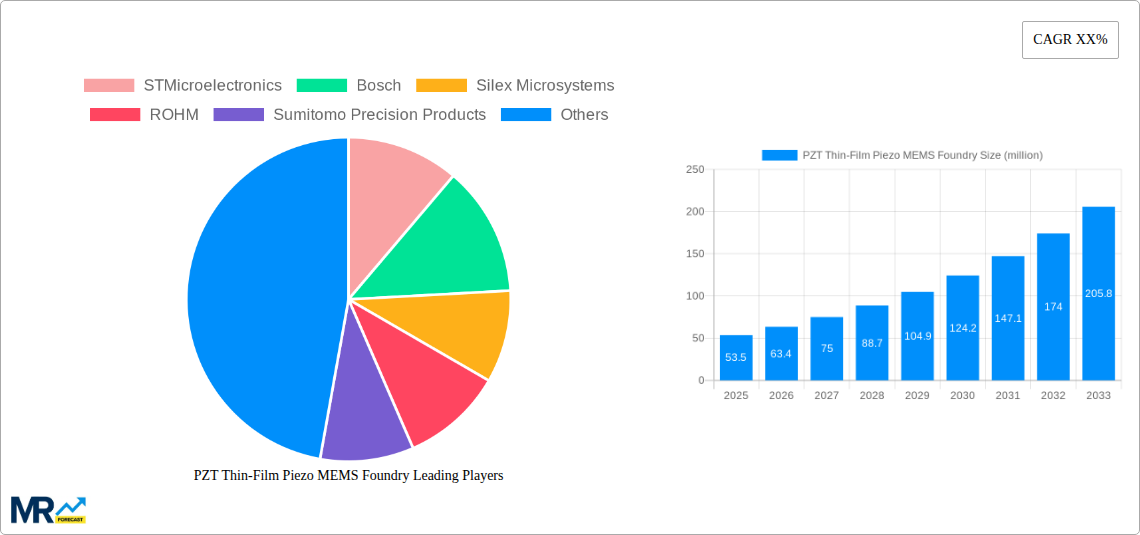

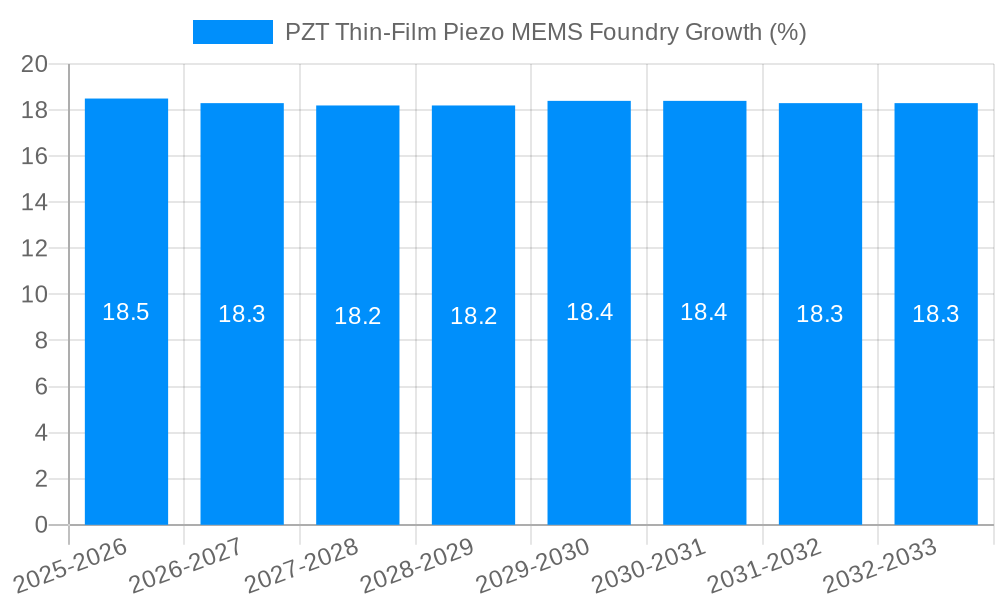

The PZT Thin-Film Piezo MEMS Foundry market is poised for significant expansion, projected to reach an estimated market size of approximately USD 53.5 million in 2025. This growth is fueled by a confluence of technological advancements and increasing demand across a variety of critical industries. The compound annual growth rate (CAGR) is estimated to be around 18.5% over the forecast period (2025-2033), indicating a robust and dynamic market trajectory. Key drivers include the burgeoning adoption of MEMS sensors and actuators in the consumer electronics sector, where miniaturization, higher performance, and lower power consumption are paramount. The automotive industry's relentless pursuit of enhanced safety features, autonomous driving capabilities, and improved in-car experiences, heavily reliant on sophisticated MEMS devices, further bolsters market expansion. Furthermore, the industrial sector's increasing need for precision measurement, automation, and predictive maintenance, alongside the medical field's drive for advanced diagnostics and minimally invasive devices, represent substantial growth avenues. The PZT thin-film piezoelectric technology offers unique advantages in terms of sensitivity, energy conversion efficiency, and manufacturability for these high-demand applications, positioning it as a crucial enabler for next-generation MEMS solutions.

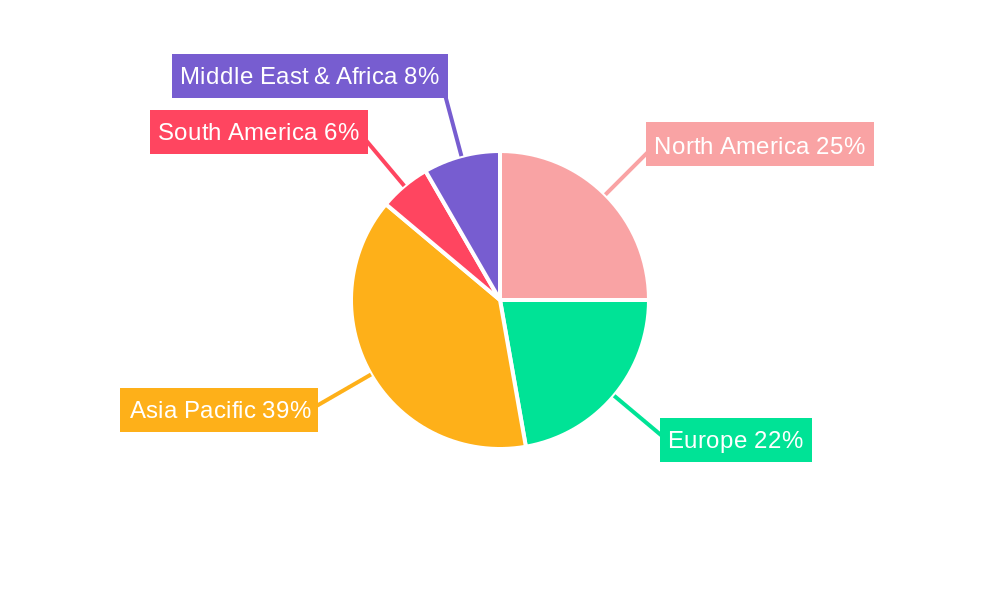

The market's growth, however, is not without its considerations. While the demand for MEMS foundry services is accelerating, potential restraints may arise from the intricate fabrication processes involved in PZT thin-film deposition, requiring specialized expertise and significant capital investment. Supply chain complexities for raw materials and the need for stringent quality control can also present challenges. Emerging trends are leaning towards higher integration of MEMS devices, the development of more complex and multi-functional MEMS, and advancements in materials science to improve piezoelectric properties and reliability. The competitive landscape features established players such as STMicroelectronics, Bosch, and Silex Microsystems, alongside emerging innovators, all vying for market share. Regional analysis indicates a strong presence and growth potential in Asia Pacific, particularly China and Japan, driven by their robust manufacturing capabilities and significant consumer electronics markets. North America and Europe also represent key markets, driven by automotive and industrial innovation.

Here's a unique report description for a PZT Thin-Film Piezo MEMS Foundry market analysis, incorporating your specified elements and aiming for the requested word counts.

This in-depth market report delves into the dynamic landscape of the PZT (Lead Zirconate Titanate) thin-film piezoelectric Micro-Electro-Mechanical Systems (MEMS) foundry market. With a rigorous study period spanning from 2019 to 2033, and a base year of 2025, this analysis provides unparalleled insights into market dynamics, growth drivers, challenges, and future projections. The report leverages a wealth of data, including historical trends from 2019-2024 and precise forecasts for the period 2025-2033, offering a clear roadmap for stakeholders. We meticulously examine the burgeoning demand for PZT thin-film piezoelectric MEMS across a multitude of applications, from advanced consumer electronics and critical automotive systems to specialized industrial equipment and life-saving medical devices. The report quantures the market's evolution, pinpointing key technological advancements and their impact on manufacturing processes and product development. Our analysis includes a detailed segmentation of the market by foundry type (MEMS Sensor Foundry, MEMS Actuator Foundry) and application segments (Consumer Electronics, Automotive, Industrial, Medical, Others).

The PZT thin-film piezo MEMS foundry market is currently experiencing a robust upward trajectory, fueled by the increasing integration of advanced piezoelectric functionalities into a wide array of electronic devices. In the historical period (2019-2024), the market witnessed significant growth, primarily driven by initial adoption in high-performance consumer electronics, such as high-fidelity audio transducers and advanced haptic feedback systems. The base year (2025) is a pivotal point, reflecting established market penetration and the groundwork for accelerated expansion. Looking ahead into the forecast period (2025-2033), several key trends are poised to shape the industry. A significant trend is the escalating demand for miniaturized and energy-efficient piezoelectric MEMS devices, a direct consequence of the ever-present need for smaller, lighter, and more power-conscious products in the IoT and wearable technology sectors. Another prominent trend is the increasing sophistication of PZT deposition techniques, leading to higher piezoelectric coefficients, improved material reliability, and the ability to fabricate more complex MEMS structures. This technological advancement is crucial for enabling next-generation sensors with enhanced sensitivity and actuators with greater precision and force output. Furthermore, the market is observing a growing emphasis on customization and specialized foundry services, catering to niche applications within the industrial and medical sectors where tailored performance characteristics are paramount. The development of lead-free piezoelectric materials, while still in its nascent stages of widespread foundry adoption, represents a significant future trend driven by environmental regulations and a push towards sustainability. The market's overall value, estimated to be in the hundreds of millions of dollars, is projected to witness consistent double-digit growth throughout the forecast period, underscoring the strategic importance of this technology. The increasing adoption of advanced packaging techniques and the integration of PZT MEMS with complementary semiconductor technologies will further solidify its market position.

The PZT thin-film piezo MEMS foundry market is experiencing substantial growth, propelled by a confluence of powerful driving forces that are reshaping the technological landscape. Foremost among these is the insatiable demand for sophisticated sensing and actuation capabilities across a broad spectrum of industries. In Consumer Electronics, consumers are increasingly expecting immersive experiences, leading to a surge in the adoption of PZT-based MEMS for advanced haptic feedback in smartphones and gaming devices, high-resolution audio transducers, and precise motion sensors. The Automotive sector is another significant growth engine, where PZT MEMS are crucial for safety and performance enhancements. Applications like advanced driver-assistance systems (ADAS) utilizing ultrasonic sensors for proximity detection, active noise cancellation for enhanced cabin comfort, and precise fuel injection systems are driving substantial demand. The Industrial segment is witnessing the integration of PZT MEMS into smart manufacturing processes, predictive maintenance systems through vibration analysis, and high-precision robotics. Their ability to operate in harsh environments and provide reliable sensing makes them indispensable. Furthermore, the Medical field is increasingly leveraging PZT MEMS for minimally invasive diagnostic and therapeutic devices, such as ultrasound imaging transducers for medical diagnostics and microfluidic pumps for drug delivery systems, where precise control and biocompatibility are critical. The ongoing miniaturization trend across all sectors, driven by the relentless pursuit of smaller and more integrated devices, directly favors the adoption of thin-film PZT MEMS due to their inherent size advantage. Finally, advancements in fabrication technologies, particularly in precise thin-film deposition and lithography, are making PZT MEMS more accessible and cost-effective to manufacture, further fueling their widespread adoption.

Despite the robust growth trajectory, the PZT thin-film piezo MEMS foundry market is not without its significant challenges and restraints that warrant careful consideration. A primary concern revolves around the complexity and cost of fabrication. Achieving high-quality, uniform PZT thin films with precise piezoelectric properties requires sophisticated deposition techniques, stringent process control, and specialized equipment, which can lead to higher manufacturing costs compared to other MEMS technologies. The inherent nature of lead-based PZT also presents environmental concerns. Regulatory scrutiny surrounding the use of lead and the disposal of lead-containing materials can impose restrictions and necessitate costly compliance measures, potentially limiting market expansion in certain regions or applications. Furthermore, material reliability and long-term stability remain critical areas of development. PZT thin films can be susceptible to degradation over time, particularly under harsh operating conditions involving high temperatures, humidity, or mechanical stress. Ensuring consistent performance and longevity is paramount for applications in demanding environments like automotive and industrial settings. Integration challenges with other semiconductor processes and packaging technologies can also pose a hurdle. Seamlessly integrating PZT MEMS with standard CMOS fabrication flows and developing robust packaging solutions that protect the delicate MEMS structures while enabling efficient signal transmission are ongoing areas of research and development. The lack of standardization in PZT thin-film MEMS fabrication processes and performance metrics can also create complexities for foundries and end-users alike, hindering widespread interoperability and adoption. Finally, skilled workforce availability in specialized areas like piezoelectric materials science and MEMS fabrication remains a limiting factor for rapid scaling of production. Addressing these challenges will be crucial for unlocking the full potential of the PZT thin-film piezo MEMS foundry market.

The PZT Thin-Film Piezo MEMS Foundry market is characterized by concentrated dominance in specific regions and segments, driven by technological prowess, established industrial ecosystems, and significant end-user demand.

Dominant Regions/Countries:

Dominant Segments:

MEMS Sensor Foundry: This segment is projected to hold a commanding market share. The ever-increasing demand for sophisticated sensing solutions across all application areas is a primary driver.

MEMS Actuator Foundry: While currently a smaller segment compared to sensors, the MEMS Actuator Foundry segment is poised for significant growth, driven by emerging applications requiring precise mechanical movement.

The interplay between these dominant regions and segments, characterized by technological innovation and strong end-user adoption, will define the market's trajectory during the study period (2019-2033).

Several key factors are acting as powerful catalysts for the growth of the PZT thin-film piezo MEMS foundry industry. The increasing demand for miniaturized and highly integrated electronic devices across all consumer and industrial applications is a primary driver. As devices become smaller and more feature-rich, the need for compact and efficient piezoelectric components like PZT thin-film MEMS becomes paramount. Furthermore, the rapid advancements in PZT material science and deposition techniques are leading to enhanced piezoelectric properties, improved reliability, and reduced fabrication costs, making these MEMS more commercially viable. The burgeoning Internet of Things (IoT) ecosystem, with its vast network of connected devices requiring sophisticated sensing and actuation capabilities, presents a significant growth opportunity. Finally, the ongoing exploration and development of novel applications in areas such as energy harvesting and advanced biomedical devices are further fueling innovation and market expansion.

This comprehensive report provides an exhaustive analysis of the PZT Thin-Film Piezo MEMS Foundry market, offering invaluable insights for stakeholders aiming to navigate this dynamic sector. It delves into intricate market segmentation by foundry type and application, including detailed breakdowns of the MEMS Sensor Foundry and MEMS Actuator Foundry segments, and their respective contributions from Consumer Electronics, Automotive, Industrial, Medical, and other application areas. The report meticulously traces market evolution from the historical period (2019-2024) through the base year (2025), culminating in robust forecasts for the period 2025-2033. Furthermore, it identifies and analyzes the key growth catalysts propelling the industry forward, such as the increasing demand for miniaturization, advancements in material science, and the burgeoning IoT ecosystem. The report also critically examines the challenges and restraints that may impede market growth, including fabrication complexities and regulatory concerns. With detailed regional analysis and a comprehensive overview of leading industry players, this report serves as an indispensable resource for strategic decision-making and identifying future market opportunities within the PZT thin-film piezo MEMS foundry landscape.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include STMicroelectronics, Bosch, Silex Microsystems, ROHM, Sumitomo Precision Products.

The market segments include Type, Application.

The market size is estimated to be USD 53.5 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million.

Yes, the market keyword associated with the report is "PZT Thin-Film Piezo MEMS Foundry," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the PZT Thin-Film Piezo MEMS Foundry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.