1. What is the projected Compound Annual Growth Rate (CAGR) of the Polystyrene Carrier Tape?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Polystyrene Carrier Tape

Polystyrene Carrier TapePolystyrene Carrier Tape by Type (Black Carrier Tape, Clear Carrier Tape, World Polystyrene Carrier Tape Production ), by Application (Power Discrete Devices, Integrated Circuit, Optoelectronics, Others, World Polystyrene Carrier Tape Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

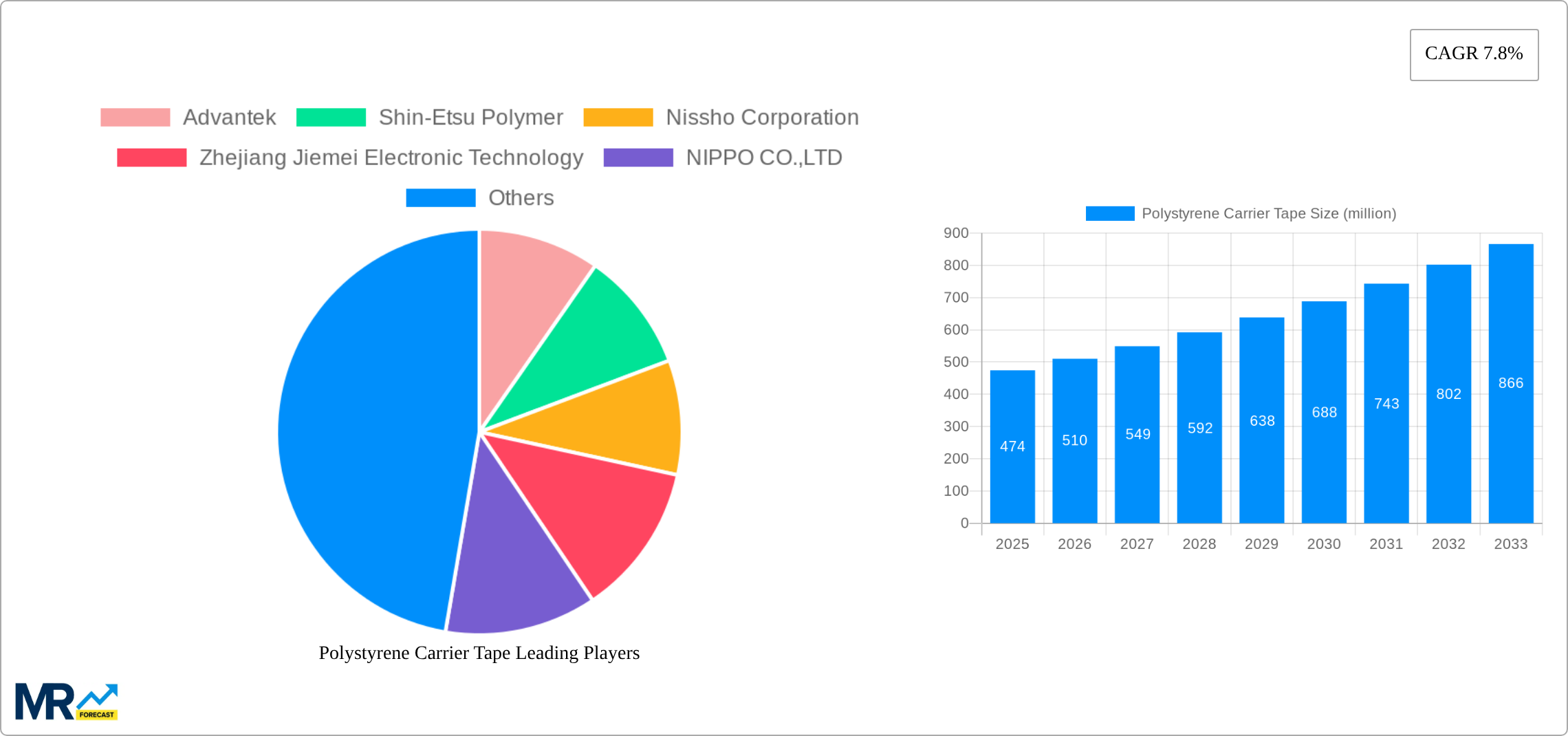

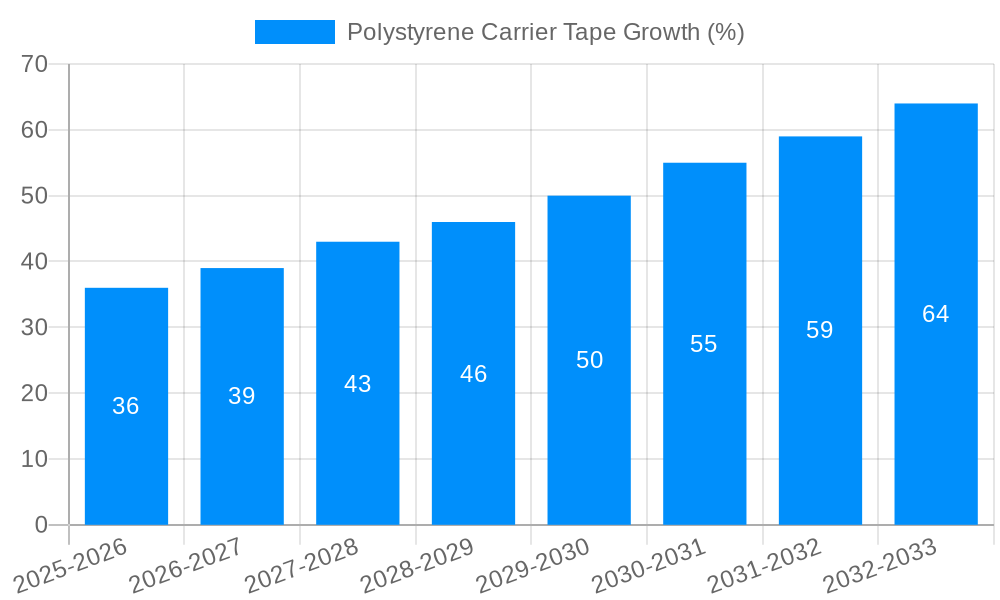

The global Polystyrene Carrier Tape market is poised for significant expansion, projected to reach a market size of approximately USD 474 million by 2025. This growth is underpinned by a robust Compound Annual Growth Rate (CAGR) estimated at around 6.5% during the forecast period of 2025-2033. The increasing demand for advanced electronic components across various sectors, including power discrete devices, integrated circuits, and optoelectronics, serves as a primary driver for this market. The inherent properties of polystyrene carrier tapes, such as their cost-effectiveness, excellent dimensional stability, and suitability for high-speed automated packaging processes, further bolster their adoption. As the electronics industry continues to innovate and miniaturize components, the need for precise and reliable packaging solutions like carrier tapes will only intensify, fueling market expansion.

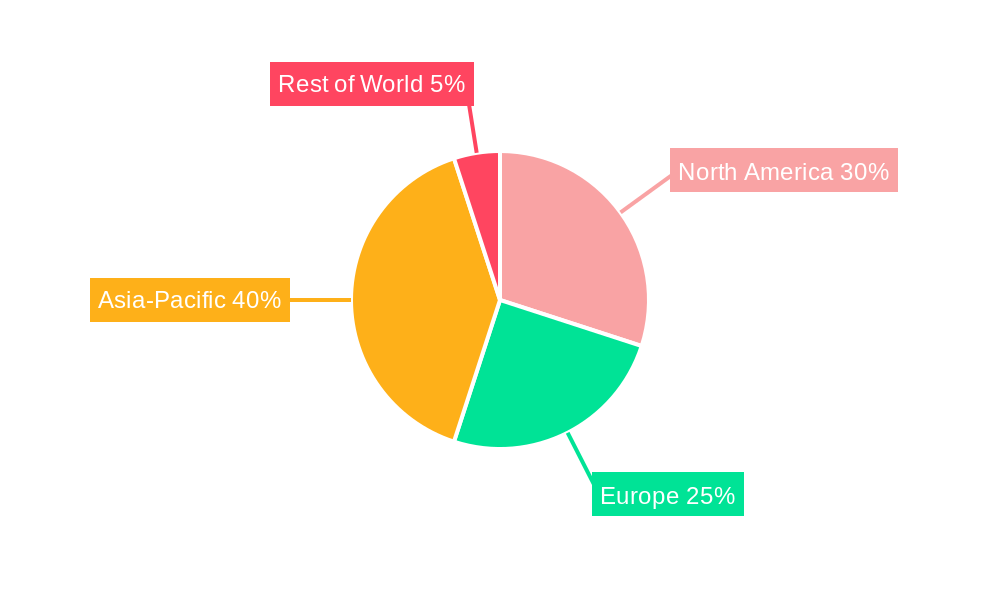

Key market trends indicate a growing preference for specialized carrier tapes that offer enhanced protection and compatibility with next-generation semiconductor devices. Innovations in material science are leading to the development of tapes with improved antistatic properties and higher thermal resistance, catering to the stringent requirements of advanced electronics. Geographically, the Asia Pacific region, particularly China and Japan, is expected to dominate the market, driven by its strong manufacturing base for electronics and a burgeoning domestic demand. While the market presents substantial opportunities, certain restraints, such as the volatility of raw material prices and the emergence of alternative packaging materials, may pose challenges. However, strategic investments in research and development, coupled with a focus on sustainable manufacturing practices, will be crucial for players to capitalize on the evolving landscape of the Polystyrene Carrier Tape market.

This report offers a deep dive into the global Polystyrene Carrier Tape market, analyzing trends, driving forces, challenges, and future prospects from 2019 to 2033. With a base year of 2025, the study provides an estimated outlook for the market up to 2033, leveraging historical data from 2019-2024 to paint a comprehensive picture. The analysis delves into various segments, including Type (Black Carrier Tape, Clear Carrier Tape) and Application (Power Discrete Devices, Integrated Circuit, Optoelectronics, Others), offering granular insights into market dynamics. Furthermore, it examines World Polystyrene Carrier Tape Production volumes and industry developments to provide stakeholders with actionable intelligence. The report is meticulously researched, incorporating data points often measured in the millions of units, offering a robust understanding of market size and growth trajectories.

The global Polystyrene Carrier Tape market is poised for significant evolution, driven by the relentless advancement of the electronics industry and the increasing demand for sophisticated packaging solutions. Over the study period of 2019-2033, a notable trend has been the growing preference for specialized carrier tapes tailored to specific component requirements. This includes a discernible shift towards enhanced material properties such as improved antistatic performance, higher temperature resistance, and superior dimensional stability to accommodate increasingly miniaturized and sensitive electronic components. The demand for both Black Carrier Tape and Clear Carrier Tape remains robust, with each segment catering to distinct application needs. Black carrier tape, for instance, often finds application in components sensitive to light, while clear carrier tape allows for visual inspection and automated optical inspection (AOI) during manufacturing processes. The market is also witnessing an increased focus on sustainability, with manufacturers exploring bio-based or recyclable polystyrene formulations, albeit the widespread adoption is still in its nascent stages. The overarching trend is towards higher precision, greater protection, and more efficient integration into automated assembly lines. The sheer volume of electronic devices being produced globally, estimated to be in the hundreds of millions of units annually, directly translates into substantial demand for carrier tapes. For example, the global production of carrier tapes, as a whole, is projected to reach several thousand million units by the forecast period's end. This growth is not uniform across all applications; while integrated circuits continue to be a dominant force, the burgeoning optoelectronics sector and the ever-present need for power discrete devices are also significant contributors to market expansion. The market's trajectory indicates a steady, incremental growth, punctuated by surges driven by technological breakthroughs and the introduction of next-generation electronic components. The interplay between innovation in semiconductor manufacturing and the packaging solutions offered by carrier tape providers will continue to shape market trends, with a constant drive to reduce costs while enhancing performance and reliability. The fundamental need to transport and protect minute electronic components during manufacturing processes ensures a sustained demand, making the Polystyrene Carrier Tape market a critical, albeit often unseen, enabler of the modern technological landscape. The sheer scale of the electronics manufacturing ecosystem, producing billions of components annually, underscores the indispensable role of carrier tapes in this intricate supply chain. The market is also seeing increased consolidation and strategic partnerships, as companies strive to achieve economies of scale and expand their global reach to serve major electronics manufacturing hubs.

The Polystyrene Carrier Tape market is experiencing robust growth, fueled by a confluence of powerful driving forces within the global electronics ecosystem. At the forefront is the exponential expansion of the semiconductor industry, a sector that underpins virtually all modern technology. The relentless miniaturization of integrated circuits (ICs) and the increasing complexity of these components necessitate highly precise and protective packaging solutions, a role perfectly fulfilled by carrier tapes. As companies strive to pack more functionality into smaller form factors, the demand for carrier tapes with tighter tolerances, superior antistatic properties, and enhanced durability escalates. Furthermore, the burgeoning Internet of Things (IoT) revolution is a significant propellant. The proliferation of connected devices across various sectors—from consumer electronics and automotive to industrial automation and healthcare—translates into an unprecedented demand for a wide array of electronic components, each requiring secure transportation and handling. This surge in IoT device production directly translates into higher volumes of ICs, sensors, and power discrete devices being manufactured, thereby boosting the demand for polystyrene carrier tapes. The rapid advancements in optoelectronics, particularly in areas like LED lighting, displays, and advanced sensor technology, also contribute significantly to market growth. These components, often delicate and sensitive, benefit immensely from the protective and standardized packaging offered by carrier tapes. The continued innovation in manufacturing processes, including the widespread adoption of surface-mount technology (SMT) and advanced automation, further reinforces the importance of standardized carrier tapes for efficient, high-speed assembly lines. The need for a reliable and cost-effective method of delivering components to these automated processes makes carrier tapes indispensable. This synergy between technological innovation and the fundamental requirements of mass electronics production forms the bedrock of the polystyrene carrier tape market's sustained growth, ensuring that volumes consistently reach several thousand million units as the industry expands.

Despite the positive growth trajectory, the Polystyrene Carrier Tape market faces several challenges and restraints that could temper its expansion. A primary concern revolves around the increasing scrutiny and regulatory pressure concerning the environmental impact of plastics, including polystyrene. Growing awareness and stricter regulations regarding plastic waste and single-use materials could lead to a gradual shift towards more sustainable alternatives or demand for enhanced recyclability of polystyrene carrier tapes. This environmental consciousness may drive research and development into biodegradable or compostable alternatives, potentially impacting the long-term dominance of traditional polystyrene. Furthermore, the price volatility of raw materials, particularly crude oil derivatives which are essential for polystyrene production, can create significant cost pressures for manufacturers. Fluctuations in the global petrochemical market directly influence the cost of polystyrene resin, which can affect profit margins and pricing strategies for carrier tape producers. Competition from alternative packaging materials, such as paper-based or other polymer-based tapes, although less prevalent in certain high-precision applications, poses a potential restraint. As these alternatives mature and become more cost-effective, they could capture market share in less demanding segments. Supply chain disruptions, a recurring issue in recent years, can also impact the consistent availability of polystyrene resin and the timely delivery of carrier tapes to manufacturers. Global events, geopolitical tensions, and logistical bottlenecks can all contribute to shortages and increased lead times, hindering production schedules for electronics manufacturers. Lastly, while advancements in automation have driven demand, the capital investment required for companies to adopt and maintain advanced carrier tape handling equipment can be a barrier, particularly for smaller manufacturers or those in emerging markets. These factors collectively present a complex landscape that market players must navigate to ensure sustained growth and market leadership, even as volumes are projected in the millions of units.

The global Polystyrene Carrier Tape market exhibits distinct regional dominance and segment leadership, driven by the concentration of electronics manufacturing and the specific demands of various applications.

Dominant Region: Asia Pacific

Dominant Segment: Integrated Circuit (IC) Application

The Polystyrene Carrier Tape industry is propelled by several key growth catalysts. The unabated expansion of the global electronics manufacturing sector, driven by consumer demand for advanced gadgets and the proliferation of IoT devices, is a primary driver. The continuous miniaturization of electronic components, leading to smaller and more sensitive ICs and other parts, necessitates the use of precision-engineered carrier tapes with enhanced protective features. Furthermore, the ongoing automation of manufacturing processes across the electronics supply chain relies heavily on standardized carrier tapes for efficient component handling and high-speed assembly. The growing demand from emerging applications such as advanced automotive electronics and sophisticated medical devices also contributes to market expansion.

This comprehensive report offers an in-depth analysis of the Polystyrene Carrier Tape market, providing stakeholders with critical insights for strategic decision-making. The study meticulously examines market dynamics across its entire study period (2019-2033), with a detailed forecast from 2025 to 2033, building upon a solid base year of 2025. It dissects the market by key segments, including Type (Black Carrier Tape, Clear Carrier Tape) and Application (Power Discrete Devices, Integrated Circuit, Optoelectronics, Others), offering granular data on their respective growth trajectories and market shares. Furthermore, the report provides crucial insights into World Polystyrene Carrier Tape Production volumes, tracking trends and future projections, often measured in the millions of units. Through an exhaustive review of industry developments and key market drivers and restraints, this report equips businesses with the knowledge to navigate challenges, capitalize on opportunities, and understand the competitive landscape shaped by leading players.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Advantek, Shin-Etsu Polymer, Nissho Corporation, Zhejiang Jiemei Electronic Technology, NIPPO CO.,LTD, YAC GARTER, U-PAK, C-Pak, ROTHE, Sumitomo Bakelite, Tek Pak, Jiangyin Winpack, Asahi Kasei, Kanazu Giken, Taiwan Carrier Tape Enterprise Co., Ltd, LaserTek, Miyata System, Hwa Shu Enterpris, Xiamen Hatro Electronics.

The market segments include Type, Application.

The market size is estimated to be USD 474 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Polystyrene Carrier Tape," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Polystyrene Carrier Tape, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.