1. What is the projected Compound Annual Growth Rate (CAGR) of the CMP Materials for Wafers?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

CMP Materials for Wafers

CMP Materials for WafersCMP Materials for Wafers by Type (/> CMP Slurry, CMP Pads, CMP Pad Conditioners, CMP POU Slurry Filters, CMP PVA Brushes, CMP Retaining Rings), by Application (/> 300mm Wafers, 200mm Wafers, Other), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

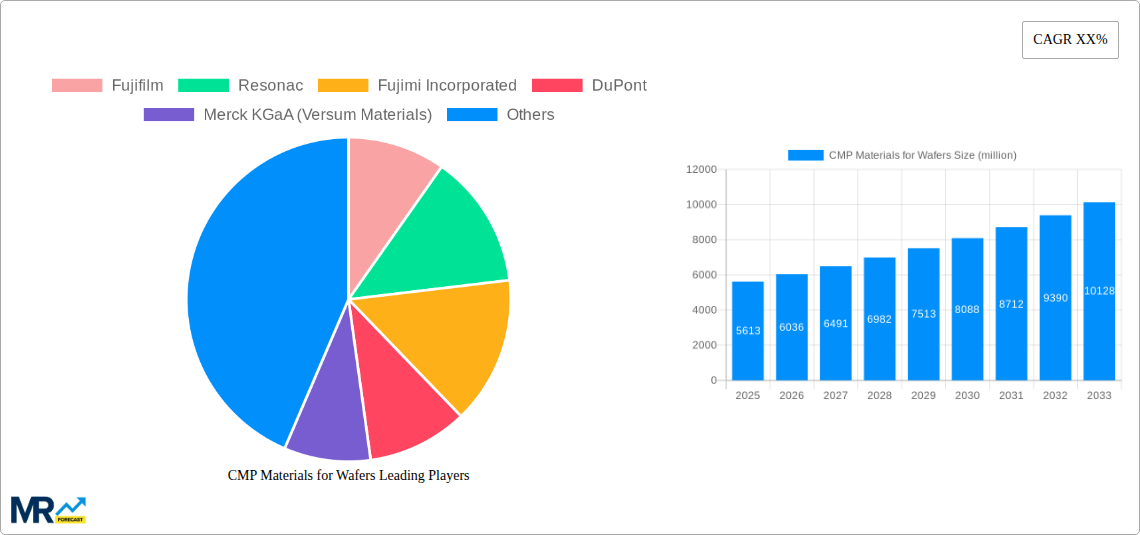

The global market for Chemical Mechanical Planarization (CMP) materials for wafers is experiencing robust growth, estimated at a market size of approximately $5,613 million in 2025. This expansion is fueled by the relentless demand for advanced semiconductor devices across numerous industries, including consumer electronics, automotive, telecommunications, and artificial intelligence. The ongoing miniaturization and performance enhancement of integrated circuits necessitate sophisticated CMP processes to achieve the ultra-flat and defect-free wafer surfaces crucial for high-yield chip manufacturing. Key growth drivers include the increasing production of 300mm wafers, which are standard for leading-edge logic and memory chips, and the sustained demand for 200mm wafers in specialized applications. The market is characterized by continuous innovation in slurry formulations and pad technologies to meet stringent requirements for tighter tolerances and improved surface finish.

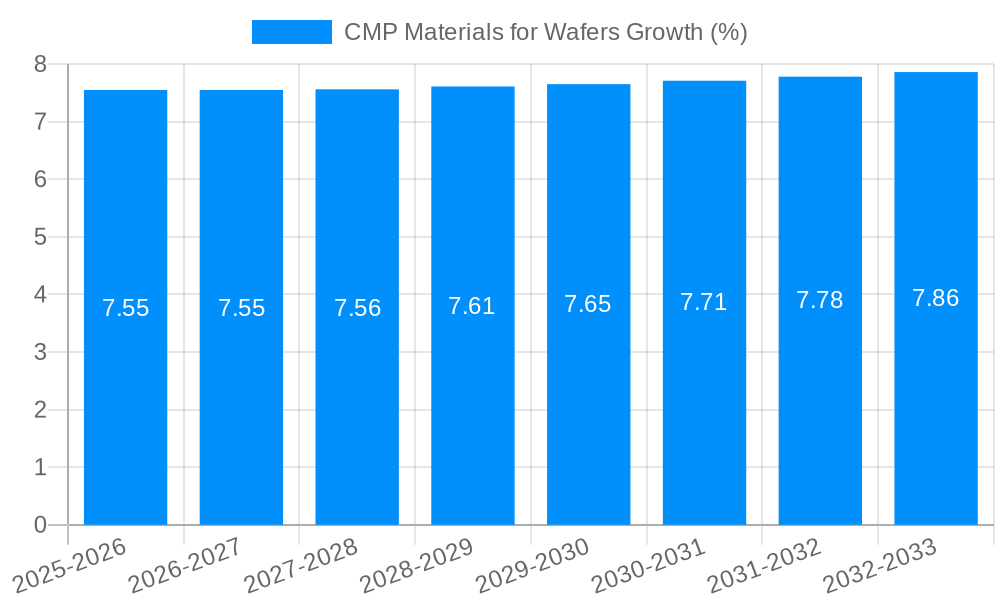

The Compound Annual Growth Rate (CAGR) for the CMP materials market is projected to be around 7.5% from 2025 to 2033. This healthy growth is underpinned by several critical trends. The development of novel CMP slurries with advanced abrasive and chemical components is paramount for polishing new materials like advanced metals and dielectrics used in next-generation semiconductors. Furthermore, the evolution of CMP pads, including innovative materials and surface textures, plays a vital role in optimizing material removal rates and minimizing defects. The increasing complexity of semiconductor architectures, such as 3D NAND and FinFET transistors, further propels the need for highly specialized CMP solutions. While the market is dynamic, potential restraints could include the high cost of advanced CMP materials and the stringent qualification processes required by leading semiconductor manufacturers, which can extend product adoption timelines. However, the overarching demand for higher computing power and more integrated semiconductor devices ensures a promising outlook for the CMP materials market.

Here's a unique report description for CMP Materials for Wafers, incorporating your specified elements:

The global CMP Materials for Wafers market is poised for robust expansion, projected to reach a staggering $28,500 million by 2033. This upward trajectory, driven by the insatiable demand for increasingly sophisticated semiconductor devices, underscores the critical role of Chemical Mechanical Planarization (CMP) in modern microelectronics fabrication. During the Historical Period of 2019-2024, the market witnessed steady growth, fueled by advancements in wafer processing technologies and the relentless miniaturization of integrated circuits. The Base Year of 2025 stands as a pivotal point, with preliminary estimates indicating a market valuation of approximately $17,200 million. The subsequent Forecast Period, spanning 2025-2033, anticipates a compound annual growth rate (CAGR) of around 6.5%, reflecting sustained innovation and escalating production volumes. Key market insights reveal a significant shift towards 300mm Wafers as the dominant application, driven by economies of scale and the need for higher performance in advanced nodes. Simultaneously, the development of novel CMP slurries with enhanced selectivity and reduced defectivity is a paramount trend, aiming to address the complex material stacks and stringent planarization requirements of cutting-edge chip designs. The market is also experiencing a growing emphasis on sustainability, with manufacturers exploring eco-friendlier formulations and recycling initiatives for CMP consumables. The interplay between material science innovation, advanced manufacturing processes, and the ever-increasing complexity of semiconductor architectures will continue to shape the dynamics of this crucial market segment. Furthermore, the pursuit of sub-10nm process nodes necessitates the development of ultra-fine abrasive particles and specialized chemical additives within slurries, a trend that will intensify throughout the study period. The increasing adoption of advanced packaging techniques, such as 2.5D and 3D integration, also presents new opportunities and challenges for CMP materials, demanding greater precision and compatibility across diverse substrate materials.

The CMP Materials for Wafers market is experiencing a powerful surge propelled by several interconnected driving forces, chief among them being the exponential growth of the global semiconductor industry. The relentless pursuit of higher computational power, enhanced efficiency, and miniaturization across diverse end-use applications, including artificial intelligence (AI), 5G connectivity, the Internet of Things (IoT), and high-performance computing (HPC), necessitates a continuous increase in wafer production and a corresponding demand for advanced CMP consumables. As chip manufacturers push the boundaries of Moore's Law, striving for smaller process nodes, the precision and effectiveness of CMP processes become paramount. This drives innovation in CMP slurries, pads, and conditioners, with companies like Fujifilm, Resonac, and Fujimi Incorporated investing heavily in R&D to develop materials that can achieve sub-nanometer level planarization while minimizing defects. Furthermore, the increasing complexity of semiconductor device architectures, featuring intricate multi-layer interconnects and novel materials, demands highly specialized CMP solutions. The transition to larger wafer diameters, particularly 300mm Wafers, also fuels market growth by enabling higher throughput and cost efficiencies in manufacturing. The growing demand for advanced packaging technologies, which often involve wafer-level processing, further amplifies the need for sophisticated CMP materials.

Despite the optimistic growth trajectory, the CMP Materials for Wafers market faces several significant challenges and restraints that could temper its expansion. The most prominent among these is the escalating cost of advanced CMP consumables, particularly specialized slurries and high-performance pads, which can represent a substantial portion of wafer fabrication costs. This cost pressure is exacerbated by the intense competition among wafer manufacturers to reduce overall production expenses. Another critical challenge lies in the stringent quality and performance requirements demanded by leading-edge semiconductor manufacturing. Achieving ultra-low defectivity and precise planarization at sub-10nm nodes requires extensive R&D and rigorous testing, leading to longer development cycles and higher investment for material suppliers. Supply chain disruptions, as witnessed in recent global events, can also pose a significant risk, impacting the availability of key raw materials and potentially hindering production. Furthermore, environmental regulations and the increasing focus on sustainability are pushing manufacturers to develop more eco-friendly CMP formulations and processes, which can be technically challenging and costly to implement. The rapid pace of technological change in the semiconductor industry also means that CMP materials can become obsolete quickly, requiring continuous adaptation and innovation from suppliers. The high capital expenditure required for advanced CMP equipment also acts as a barrier to entry for new players.

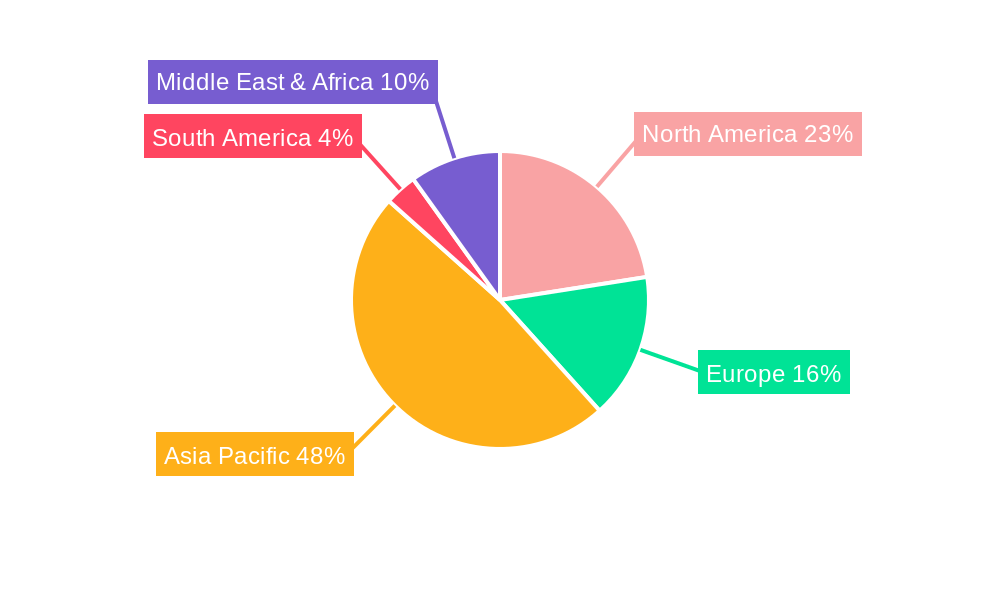

The global CMP Materials for Wafers market is characterized by distinct regional dynamics and segment dominance, with Asia-Pacific emerging as the undisputed powerhouse and the 300mm Wafer application segment leading the charge in terms of market share and projected growth. This dominance in Asia-Pacific is primarily attributed to the region's status as the global hub for semiconductor manufacturing, housing major foundries and integrated device manufacturers (IDMs). Countries like Taiwan, South Korea, China, and Japan are home to a significant concentration of advanced wafer fabrication plants, driving substantial demand for CMP materials.

Within the Asia-Pacific region, key market insights highlight:

Examining the Segments within the CMP Materials for Wafers market:

The synergistic relationship between these dominant regions and segments, fueled by technological advancements and growing end-user demand, will continue to define the market landscape for CMP Materials for Wafers.

The CMP Materials for Wafers industry is experiencing significant growth catalysts, primarily driven by the insatiable demand for advanced semiconductors across various emerging technologies. The proliferation of artificial intelligence (AI), 5G networks, and the Internet of Things (IoT) is leading to an unprecedented surge in the development and production of complex chip architectures. This escalating demand for higher performance and smaller form factors necessitates continuous innovation in wafer manufacturing processes, making CMP a critical enabler. Furthermore, the ongoing transition to advanced process nodes, such as those below 10nm, demands increasingly sophisticated CMP slurries and pads capable of achieving ultra-precise planarization and minimizing defects. Investments in expanding wafer fabrication capacity globally, particularly in Asia-Pacific, are also directly fueling the market for CMP consumables.

This comprehensive report provides an in-depth analysis of the global CMP Materials for Wafers market, offering valuable insights for stakeholders across the semiconductor value chain. The study encompasses a detailed examination of market trends, driving forces, challenges, and future growth prospects, with a robust forecast from 2025 to 2033. It includes an extensive analysis of key market segments such as CMP Slurry, CMP Pads, CMP Pad Conditioners, CMP POU Slurry Filters, CMP PVA Brushes, and CMP Retaining Rings, alongside application segments including 300mm Wafers and 200mm Wafers. The report delves into the strategic initiatives and innovations of leading players, providing a competitive landscape analysis. Furthermore, it highlights significant developments and regional market dynamics, with a particular focus on the dominant Asia-Pacific region. This report serves as an indispensable resource for market participants seeking to understand the evolving dynamics and capitalize on the significant opportunities within this critical sector of the semiconductor industry.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Fujifilm, Resonac, Fujimi Incorporated, DuPont, Merck KGaA (Versum Materials), Fujifilm, AGC, KC Tech, JSR Corporation, Anjimirco Shanghai, Soulbrain, Saint-Gobain, Ace Nanochem, Dongjin Semichem, Vibrantz (Ferro), WEC Group, SKC (SK Enpulse), Shanghai Xinanna Electronic Technology, Hubei Dinglong, Beijing Hangtian Saide, Fujibo Group, 3M, FNS TECH, IVT Technologies Co, Ltd., TWI Incorporated, KPX Chemical, Engis Corporation, TOPPAN INFOMEDIA, Samsung SDI, Entegris, Pall, Cobetter, Kinik Company, Saesol Diamond, EHWA DIAMOND, Nippon Steel & Sumikin Materials, Shinhan Diamond, BEST Engineered Surface Technologies, Willbe S&T, CALITECH, Cnus Co., Ltd., UIS Technologies, Euroshore, PTC, Inc., AKT Components Sdn Bhd, Ensinger, CHUANYAN, Zhuhai Cornerstone Technologies, Konfoong Materials International, Tianjin Helen, Shenzhen Angshite Technology, Advanced Nano Products Co.,Ltd, Zhejiang Bolai Narun Electronic Materials, Xiamen Chia Ping Diamond Industrial.

The market segments include Type, Application.

The market size is estimated to be USD 5613 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million.

Yes, the market keyword associated with the report is "CMP Materials for Wafers," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the CMP Materials for Wafers, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.