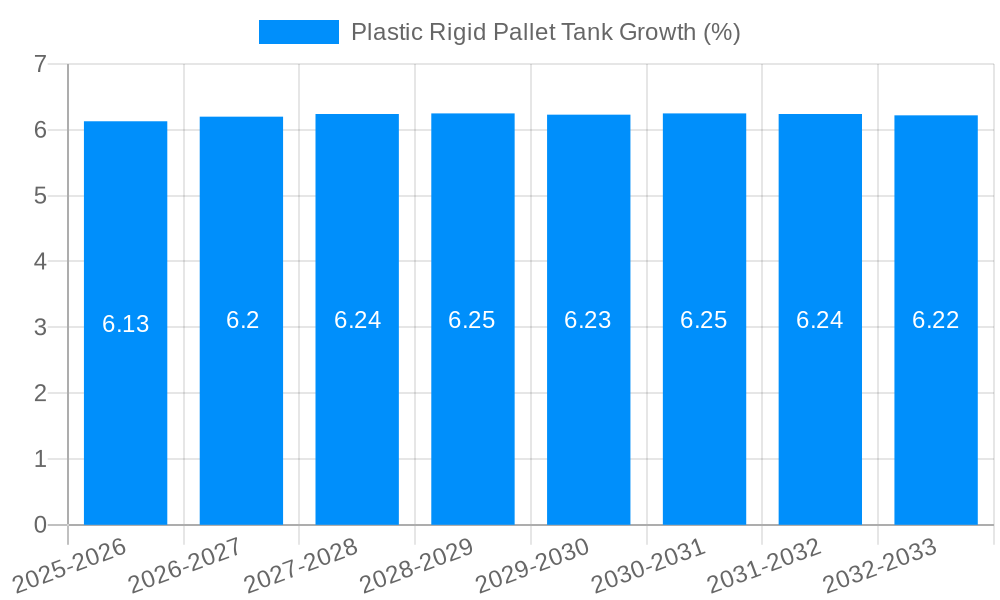

1. What is the projected Compound Annual Growth Rate (CAGR) of the Plastic Rigid Pallet Tank?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Plastic Rigid Pallet Tank

Plastic Rigid Pallet TankPlastic Rigid Pallet Tank by Application (Pharmaceutical, Food, Chemical Industries, Others), by Type (High Density Polyethylene (HDPE), Low density polyethylene (LDPE), Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

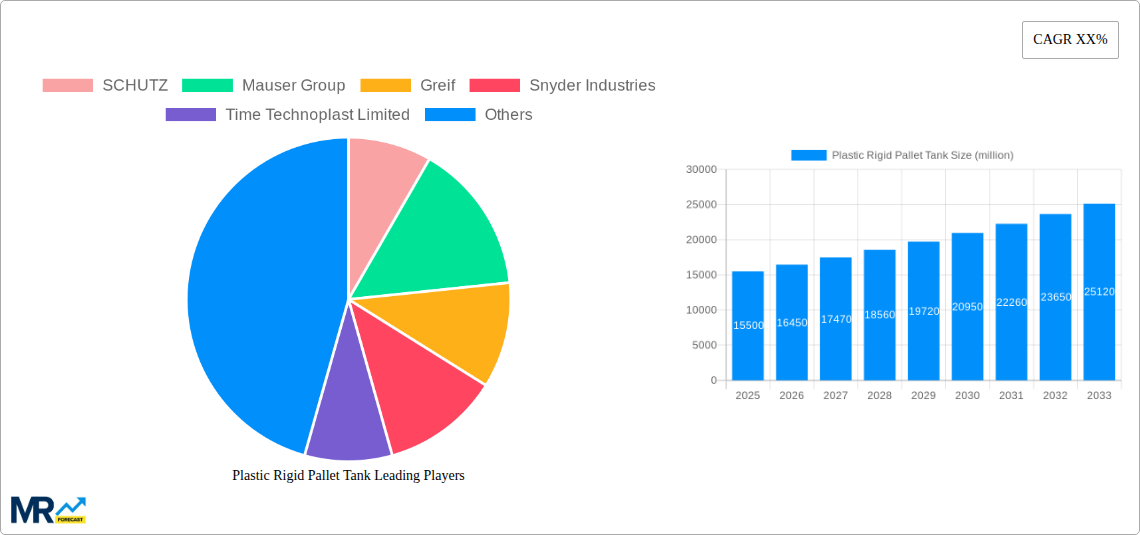

The global Plastic Rigid Pallet Tank market is poised for substantial growth, projected to reach an estimated USD 15.5 billion by 2025 and expand at a Compound Annual Growth Rate (CAGR) of 6.2% through 2033. This robust expansion is primarily fueled by the increasing demand across diverse industries, with the Pharmaceutical and Chemical sectors leading the charge. These industries rely heavily on rigid pallet tanks for the safe and efficient storage and transportation of a wide array of liquids, chemicals, and sensitive pharmaceutical compounds. The inherent advantages of these tanks, including their durability, reusability, chemical resistance, and cost-effectiveness compared to single-use containers, are significant drivers behind their widespread adoption. Furthermore, growing global trade and the need for streamlined supply chains across sectors like food & beverage and agriculture are contributing to sustained market momentum.

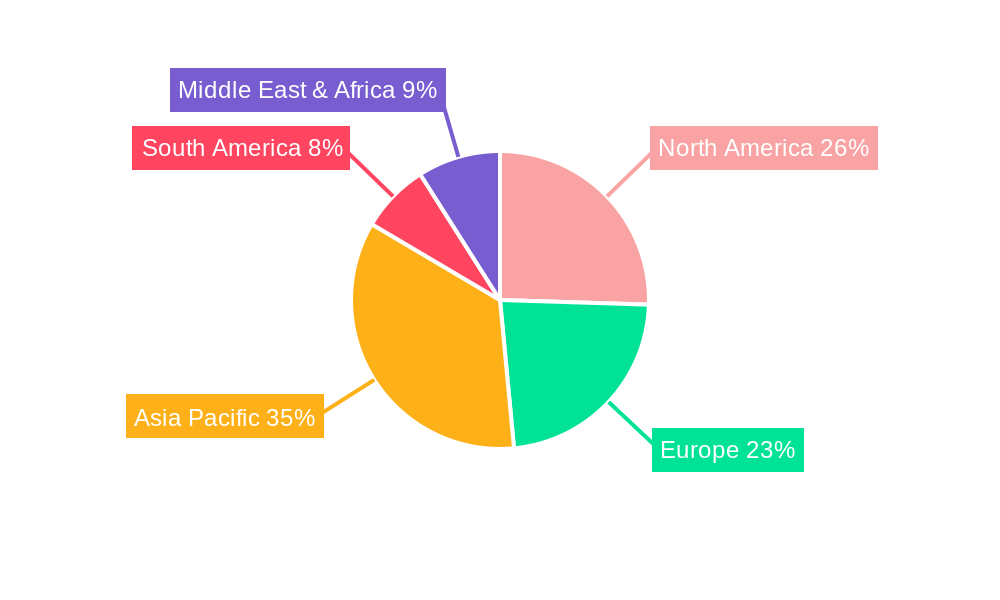

The market's trajectory is further shaped by evolving industry trends and technological advancements. The increasing focus on sustainability and circular economy principles is driving innovation in the production of eco-friendly pallet tanks, utilizing recycled materials and promoting tank refurbishment programs. Advanced manufacturing techniques are also contributing to the development of lighter, stronger, and more specialized pallet tanks tailored to specific application needs. However, the market faces certain restraints, including the fluctuating prices of raw materials, particularly polyethylene, which can impact production costs. Stringent regulatory compliances for hazardous material transportation in certain regions may also present challenges. Despite these hurdles, the overall outlook remains positive, with key players actively investing in research and development to enhance product offerings and expand their global reach. The market is segmented by type, with High Density Polyethylene (HDPE) dominating due to its superior strength and chemical resistance, followed by Low Density Polyethylene (LDPE) and other materials. Geographically, Asia Pacific, driven by China and India's burgeoning industrial sectors, is emerging as a dominant region, while North America and Europe continue to represent significant markets.

This report provides an in-depth analysis of the global Plastic Rigid Pallet Tank market, spanning from the historical period of 2019-2024, with a base year of 2025 and a forecast period extending to 2033. The study delves into market trends, driving forces, challenges, regional dominance, growth catalysts, leading players, and significant industry developments, offering a holistic view of this evolving sector. The report leverages quantitative data, with values expressed in the million unit, to paint a clear picture of market dynamics and future projections.

XXX The global Plastic Rigid Pallet Tank market is poised for robust growth, driven by a confluence of factors that underscore its increasing importance across various industrial applications. From 2019 to 2033, the market is projected to witness a significant upward trajectory, with the estimated year of 2025 serving as a pivotal point for observed and projected trends. A key insight from the study period (2019-2033) is the accelerating demand for these tanks in the Chemical Industries segment. This surge is directly linked to the growing need for safe, reliable, and efficient containment solutions for a wide array of chemicals, including hazardous materials. The inherent properties of rigid plastic, such as its resistance to corrosion, chemical inertness, and durability, make it an ideal choice for chemical storage and transportation. Furthermore, the evolving regulatory landscape surrounding chemical handling and transportation is increasingly favoring robust and compliant packaging solutions, thereby boosting the adoption of rigid pallet tanks.

Beyond the chemical sector, the Food industry also represents a significant trend driver. The escalating global demand for processed and packaged food products necessitates efficient and hygienic storage and transportation methods. Rigid pallet tanks, particularly those made from High Density Polyethylene (HDPE), offer excellent inertness, preventing contamination and preserving the quality and shelf-life of food products. Their easy-to-clean surfaces and resistance to bacterial growth further enhance their appeal in this segment. The Pharmaceutical industry, with its stringent requirements for product integrity and sterile handling, is another key area witnessing increased adoption. The need for secure containment of sensitive pharmaceutical ingredients and finished products aligns perfectly with the protective capabilities of rigid pallet tanks. Looking ahead, the "Others" application segment, which encompasses diverse industries like agriculture, water treatment, and waste management, is also expected to contribute to market expansion. The versatility and cost-effectiveness of rigid pallet tanks are making them an attractive alternative to traditional materials in these emerging applications. The study period's analysis will further highlight how the shift towards more sustainable and recyclable packaging solutions, coupled with advancements in material science and manufacturing technologies, will continue to shape the trends within the Plastic Rigid Pallet Tank market, ensuring its sustained relevance and growth. The base year of 2025 is expected to reflect a market value in the millions, with the forecast period showing continued expansion.

The global Plastic Rigid Pallet Tank market is propelled by a dynamic interplay of factors, with the escalating demand for safe and efficient material handling being a paramount driver. The inherent durability and chemical resistance of materials like High Density Polyethylene (HDPE) make them indispensable for storing and transporting a vast range of substances across diverse industries, from volatile chemicals to sensitive food products. This inherent advantage directly translates into reduced product loss, enhanced safety for handlers, and greater compliance with stringent industry regulations, particularly in the Chemical Industries. Furthermore, the increasing global emphasis on supply chain optimization and cost-efficiency plays a crucial role. Rigid pallet tanks, with their standardized dimensions and stackability, facilitate streamlined logistics, reducing storage space requirements and transportation costs compared to conventional alternatives. Their reusability and long lifespan also contribute to a lower total cost of ownership over time, making them an economically sound investment for businesses.

The expanding global population and the subsequent growth in sectors like food processing and pharmaceutical manufacturing directly fuel the need for reliable containment solutions. As these industries scale up their operations, the demand for robust and hygienic storage and transportation systems like rigid pallet tanks naturally increases. The evolving regulatory framework across various countries, aimed at enhancing safety and environmental protection, also acts as a significant impetus. Governments and industry bodies are increasingly mandating the use of compliant and secure packaging for hazardous materials, pushing industries towards adopting solutions like rigid pallet tanks that meet these demanding standards. Moreover, continuous advancements in polymer technology are leading to the development of even more robust, lightweight, and chemically resistant plastic materials, further enhancing the appeal and performance of rigid pallet tanks and opening up new application possibilities.

Despite the promising growth trajectory, the Plastic Rigid Pallet Tank market faces certain challenges and restraints that could impact its expansion. A primary concern revolves around the initial capital investment required for acquiring these tanks. While their long-term cost-effectiveness is undeniable, the upfront expense can be a deterrent for smaller businesses or those with limited capital, especially when compared to the perceived lower initial cost of some traditional packaging solutions. This can lead to a slower adoption rate in certain market segments.

Another significant challenge is the perception and management of plastic waste. Although rigid pallet tanks are often designed for reusability and recyclability, the broader societal and environmental concerns surrounding plastic pollution can cast a shadow. In regions with less developed recycling infrastructure or stricter regulations on plastic disposal, the end-of-life management of these tanks can pose a logistical and environmental hurdle. This necessitates greater investment in collection, recycling, and repurposing programs to address these concerns effectively.

Furthermore, the availability and cost fluctuations of raw materials, particularly polyethylene, can influence the market. As the price of virgin plastic resins can be subject to global economic factors, geopolitical events, and supply chain disruptions, this volatility can impact the manufacturing costs of rigid pallet tanks, potentially affecting their final price and market competitiveness. Developing robust strategies to mitigate these raw material price fluctuations, such as exploring alternative feedstocks or implementing long-term procurement contracts, will be crucial for sustained growth. Lastly, while advancements are being made, some highly specialized applications might still demand materials with properties beyond what current rigid plastic pallet tanks can offer, creating a niche restraint in specific industries requiring extreme temperature resistance or specialized chemical compatibility.

The global Plastic Rigid Pallet Tank market is characterized by distinct regional strengths and segment dominance. Asia Pacific is projected to emerge as a dominant region, driven by its rapid industrialization, burgeoning manufacturing sector, and increasing adoption of advanced logistics solutions. Countries like China and India are central to this dominance, owing to their massive production capacities, expanding domestic consumption, and significant export activities across various industries. The robust growth in the Chemical Industries in these nations, coupled with the increasing demand from the Food and Pharmaceutical sectors, provides a fertile ground for the widespread adoption of rigid pallet tanks. The sheer volume of goods being produced and transported within and out of these countries necessitates efficient and reliable containment solutions.

In terms of application segments, the Chemical Industries are expected to hold a commanding position in the market. This is largely attributable to the inherent need for safe, secure, and chemically resistant storage and transportation of a wide range of chemicals, including hazardous substances. The stringent regulatory requirements governing chemical handling and transportation globally further bolster the demand for high-quality rigid pallet tanks that offer superior containment and traceability. The inherent properties of materials like High Density Polyethylene (HDPE), such as its excellent resistance to corrosion, acids, and alkalis, make it the material of choice for such applications. The report anticipates that the market value attributed to this segment will be substantial, reflecting its critical role in the chemical supply chain.

Furthermore, the Food Industry is anticipated to be another significant segment, driven by the growing global demand for processed and packaged food. Rigid pallet tanks offer hygienic storage, prevent contamination, and maintain the quality and shelf-life of food products, making them an attractive option for food manufacturers and distributors. The increasing emphasis on food safety standards worldwide further reinforces this trend.

In terms of material type, High Density Polyethylene (HDPE) is expected to dominate the market. HDPE offers an optimal balance of strength, durability, chemical resistance, and cost-effectiveness, making it suitable for a vast array of applications. Its non-reactive nature ensures that it does not leach into stored substances, making it ideal for food and pharmaceutical applications. While other materials like Low Density Polyethylene (LDPE) and "Others" will contribute to the market, the versatility and proven performance of HDPE are likely to cement its leading position. The combination of the dynamic industrial landscape of the Asia Pacific region, the critical need for containment solutions in the Chemical and Food Industries, and the superior properties of HDPE as a material type, all point towards a powerful market dominance driven by these factors, with market values in the millions contributing to the overall global market size.

The Plastic Rigid Pallet Tank industry is experiencing growth catalyzed by several key factors. The increasing global demand for safe and compliant handling of chemicals, particularly hazardous materials, is a primary driver, pushing industries towards durable and reliable containment solutions. Advancements in polymer science are leading to the development of more robust, lightweight, and chemically inert materials, enhancing the performance and versatility of these tanks. Furthermore, the expanding global food processing and pharmaceutical sectors, with their stringent hygiene and product integrity requirements, are creating significant demand. The growing emphasis on supply chain efficiency and cost reduction, as well as the reusable and recyclable nature of many rigid pallet tanks, further contribute to their adoption as an economical and sustainable packaging choice.

This comprehensive report provides an exhaustive analysis of the Plastic Rigid Pallet Tank market, offering a detailed exploration of its current landscape and future projections. The study meticulously examines market dynamics, encompassing key trends, driving forces, and potential restraints that shape the industry's trajectory. It delves into regional market leadership, identifying dominant geographical areas and the underlying reasons for their prominence. Furthermore, the report highlights the leading application and material type segments, offering insights into their market share and growth potential. With a focus on quantitative data expressed in millions, the report aims to equip stakeholders with actionable intelligence for strategic decision-making in this vital industrial sector.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include SCHUTZ, Mauser Group, Greif, Snyder Industries, Time Technoplast Limited, Myers Industries, Hoover Ferguson Group, Maschiopack, WERIT, Sotralentz, Bulk Handling Australia Group Pty Ltd, Core Plastech, Elkhart Plastics, Rikutec America, Shanghai Fujiang Plastic Industry Group, Jielin, Shijiheng, ZhenJiang JinShan Packing Factory, Chuang Xiang, Pyramid Technoplast, Sintex, .

The market segments include Application, Type.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Plastic Rigid Pallet Tank," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Plastic Rigid Pallet Tank, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.