1. What is the projected Compound Annual Growth Rate (CAGR) of the Variable Inlet Guide Vane?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Variable Inlet Guide Vane

Variable Inlet Guide VaneVariable Inlet Guide Vane by Type (Metallic VIGVs, Composite VIGVs), by Application (Aerospace, Electric Power, Industrial, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

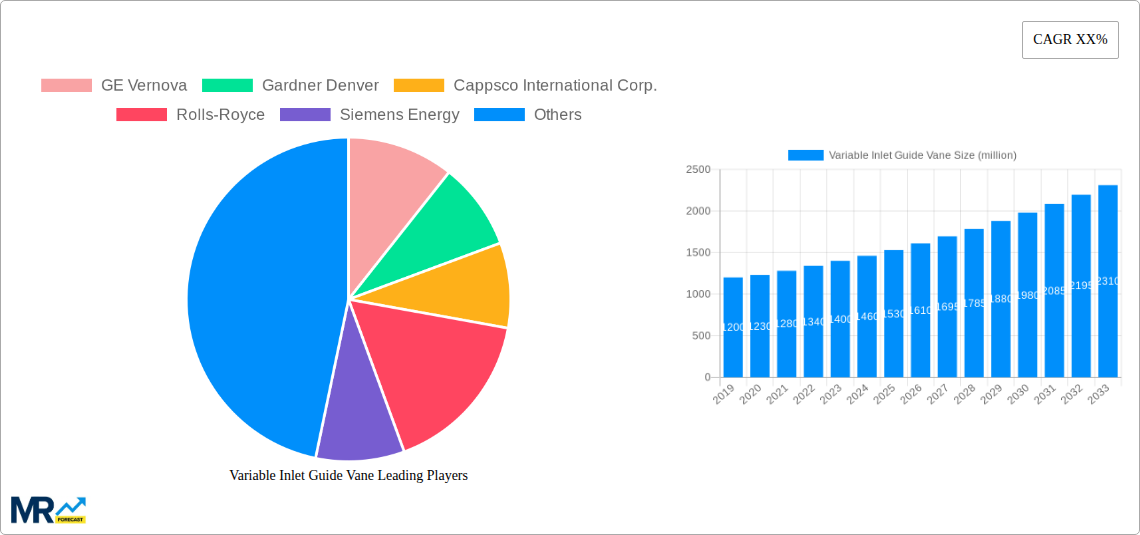

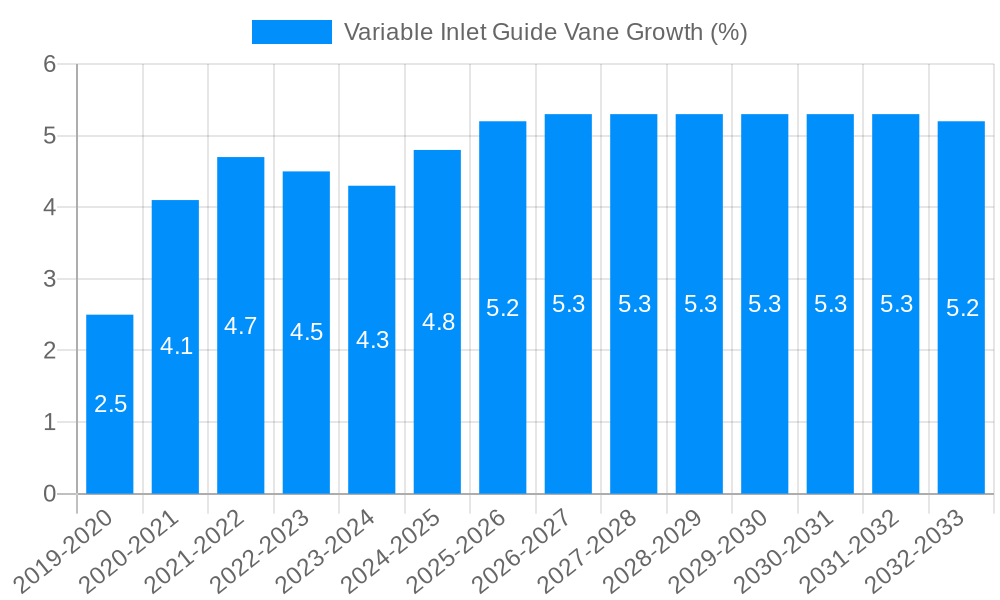

The global Variable Inlet Guide Vane (VIGV) market is poised for significant expansion, driven by the escalating demand for efficient and robust engine performance across the aerospace and industrial sectors. With an estimated market size of approximately $1.5 billion in 2025, growing at a Compound Annual Growth Rate (CAGR) of around 5.5% through 2033, the market is projected to reach over $2.3 billion by the end of the forecast period. This robust growth is primarily fueled by advancements in aerospace technology, including the development of more fuel-efficient aircraft and the increasing adoption of sophisticated engine control systems. Furthermore, the burgeoning electric power generation industry, with its focus on optimizing turbine efficiency and reducing emissions, is a key contributor to this upward trajectory. The market's value unit is in millions of USD.

The VIGV market is segmented by type into Metallic VIGVs and Composite VIGVs, with the former currently dominating due to established manufacturing processes and cost-effectiveness. However, Composite VIGVs are expected to gain traction owing to their lightweight properties and enhanced durability, particularly in demanding aerospace applications. Key applications include Aerospace, Electric Power, and Industrial, each presenting unique growth opportunities. While the aerospace sector remains a primary revenue generator, the rapid expansion of renewable energy infrastructure and the need for efficient power generation are creating substantial demand in the Electric Power segment. Restraints such as the high initial investment for VIGV systems and stringent regulatory compliance requirements in certain applications could temper growth, but the overarching need for improved performance and operational efficiency is expected to drive the market forward. Leading companies such as GE Vernova, Siemens Energy, and Rolls-Royce are at the forefront of innovation and market penetration.

Here is a comprehensive report description on Variable Inlet Guide Vanes, incorporating your specific requirements:

The global Variable Inlet Guide Vane (VIGV) market is poised for substantial growth, driven by increasing demand across various critical sectors. During the Study Period of 2019-2033, with a Base Year and Estimated Year of 2025, the market is projected to witness a Compound Annual Growth Rate (CAGR) that will see its valuation ascend from tens of millions in the Historical Period (2019-2024) to hundreds of millions by the end of the Forecast Period (2025-2033). This expansion is underpinned by the relentless pursuit of enhanced operational efficiency and fuel savings in turbomachinery. Aerospace, a cornerstone of VIGV adoption, continues to be a dominant force, with advancements in engine technology necessitating more sophisticated airflow control. Electric power generation, particularly in gas turbines, is another significant contributor, as utilities strive to optimize performance and reduce emissions to meet stringent environmental regulations. The Industrial segment, encompassing applications such as compressors and process gas turbines, also presents a growing avenue for VIGV integration, offering benefits in terms of process control and energy management.

The technological evolution of VIGVs is characterized by a shift towards lighter and more durable materials. While Metallic VIGVs have traditionally dominated due to their robustness, the emergence of Composite VIGVs is reshaping the landscape. These advanced materials offer significant weight reductions, leading to improved fuel efficiency and reduced structural loads, particularly crucial in aerospace applications. The ability of VIGVs to dynamically adjust airflow based on real-time operating conditions is paramount to their increasing adoption. This dynamic control allows for optimized performance across a wider range of operating points, preventing stall conditions, improving thrust or power output, and consequently reducing fuel consumption. Furthermore, the increasing complexity and power output of modern gas turbines and jet engines necessitate precise airflow management, a role that VIGVs are uniquely positioned to fulfill. The market is also witnessing a trend towards smart VIGVs, incorporating advanced sensors and control systems for even finer-tuned adjustments and predictive maintenance capabilities.

The ongoing digitalization of industrial processes and the rise of Industry 4.0 principles are also influencing the VIGV market. Integration with sophisticated control platforms allows for seamless data exchange and coordinated operation within larger systems. This interconnectedness enables real-time performance monitoring, fault detection, and optimization, further enhancing the value proposition of VIGVs. The drive for sustainable energy solutions is also indirectly fueling VIGV demand. As renewable energy sources become more prevalent, the grid often relies on flexible and efficient gas turbines for backup power and grid stabilization. VIGVs play a crucial role in ensuring these turbines operate optimally under varying load conditions, thus contributing to a more resilient and efficient energy infrastructure. The forecast period anticipates continued innovation in VIGV design, manufacturing processes, and control algorithms, solidifying their position as indispensable components in high-performance turbomachinery.

The global Variable Inlet Guide Vane (VIGV) market is experiencing robust expansion, primarily fueled by the escalating demand for enhanced efficiency and performance in turbomachinery. In the aerospace sector, the continuous drive for fuel economy and reduced emissions in aircraft engines is a paramount concern. VIGVs are instrumental in optimizing airflow into the compressor, allowing engines to operate more efficiently across a wider range of altitudes and speeds, thereby directly contributing to significant fuel savings, which can amount to millions of dollars annually for large fleets. Similarly, in the electric power generation industry, particularly with gas turbines, the need to maximize power output while minimizing operational costs and environmental impact is critical. VIGVs enable gas turbines to achieve higher efficiencies and respond more effectively to fluctuating grid demands, leading to cost savings in fuel consumption and potentially millions in operational expenditure reduction over their lifespan.

Furthermore, the industrial segment, which includes applications like large compressors in oil and gas operations and process gas turbines in manufacturing, also benefits significantly from VIGV technology. These systems often operate under variable load conditions, and VIGVs provide the precise airflow control necessary to maintain optimal performance, prevent surge conditions in compressors, and reduce overall energy consumption. The increasing complexity and power density of modern turbomachinery, designed to deliver more performance from smaller packages, necessitates advanced control mechanisms. VIGVs offer a sophisticated and reliable method for managing the intricate airflow dynamics within these machines, ensuring longevity and preventing costly damage. The growing emphasis on predictive maintenance and operational optimization across all these sectors also propels VIGV adoption, as these vanes contribute valuable data for performance monitoring and diagnostics.

Despite the promising growth trajectory, the Variable Inlet Guide Vane (VIGV) market faces certain challenges and restraints that could temper its full potential. One significant hurdle is the initial capital investment associated with VIGV systems. For certain applications, particularly in less demanding industrial settings or for older equipment, the upfront cost of retrofitting or incorporating advanced VIGV technology may be perceived as too high, especially when the projected long-term savings might not be immediately apparent or significant enough to justify the expenditure. This is particularly true for smaller enterprises or those with tighter operational budgets, where the allocation of millions for such upgrades could be a considerable undertaking.

Moreover, the complexity of VIGV systems, encompassing intricate mechanical designs, advanced actuators, and sophisticated control algorithms, can lead to higher maintenance requirements and the need for specialized technical expertise. Ensuring the reliability and longevity of these components under demanding operating conditions, such as extreme temperatures or corrosive environments, requires stringent quality control and ongoing support, which can add to the overall cost of ownership. Supply chain disruptions and the availability of critical raw materials for manufacturing VIGVs, especially for specialized metallic alloys or composite materials, can also pose a challenge, potentially leading to production delays and increased costs, impacting the delivery timelines and pricing of VIGV solutions.

The stringent certification and regulatory requirements, particularly in the aerospace sector, add another layer of complexity and can extend product development and approval timelines, requiring significant investment in testing and validation. Developing and certifying new VIGV designs or materials can easily cost millions. Furthermore, the established presence of fixed inlet guide vanes (IGVs) in some legacy systems means that replacement or upgrade decisions are often weighed against the performance benefits of switching to variable technology, which may not always present a compelling business case for every operator. Overcoming these financial and technical barriers is crucial for the sustained and accelerated growth of the VIGV market.

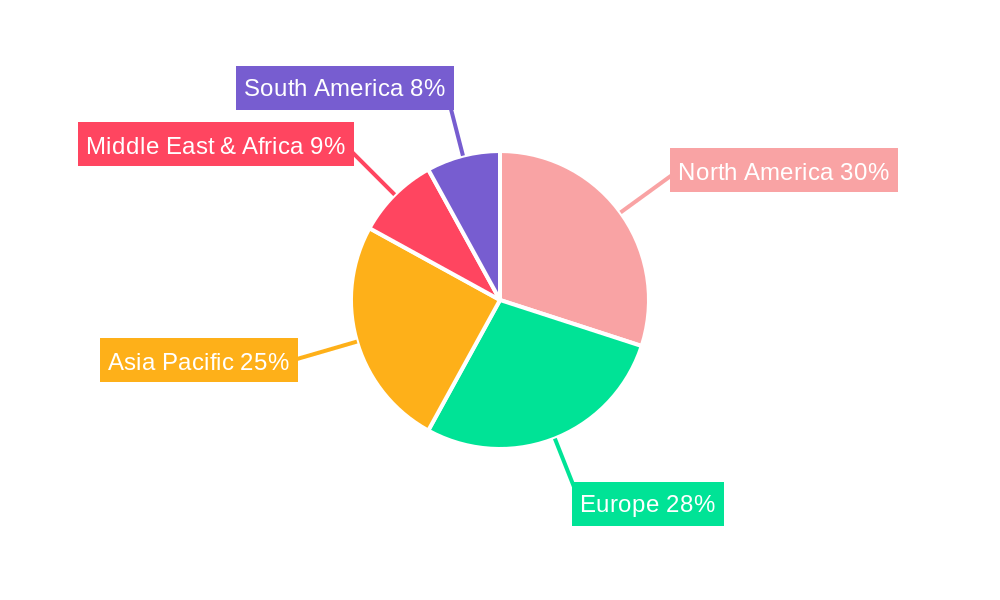

The global Variable Inlet Guide Vane (VIGV) market is characterized by significant regional and segment-specific dominance, with a clear hierarchy emerging based on technological adoption, industrial infrastructure, and regulatory drivers.

Dominant Segments:

Application: Aerospace: This segment is arguably the most significant driver of VIGV demand and technological innovation.

Type: Metallic VIGVs: Despite the rise of composite materials, metallic VIGVs continue to hold a dominant position due to their proven durability, high-temperature resistance, and cost-effectiveness in many applications.

Dominant Regions/Countries:

North America: This region exhibits strong dominance due to its advanced aerospace industry, significant investments in power generation, and a robust industrial base.

Europe: Another key region, Europe boasts a strong aerospace sector with companies like Airbus and Rolls-Royce, a significant electric power generation infrastructure, and a well-established industrial landscape.

Asia-Pacific: This region is witnessing the fastest growth and is expected to emerge as a major player in the coming years.

The synergy between dominant segments like Aerospace and Metallic VIGVs, coupled with strong regional markets like North America and the rapidly growing Asia-Pacific, forms the backbone of the global Variable Inlet Guide Vane market, ensuring its continued expansion and innovation.

The Variable Inlet Guide Vane (VIGV) industry is experiencing several key growth catalysts. The relentless pursuit of improved fuel efficiency and reduced emissions across aerospace and power generation sectors is a primary driver. As engines and turbines become more sophisticated, the need for precise airflow control offered by VIGVs becomes paramount, translating into millions of dollars saved annually through reduced fuel consumption. Furthermore, the increasing global energy demand necessitates more efficient power generation from existing infrastructure, with VIGVs playing a crucial role in optimizing gas turbine performance.

This report offers a comprehensive analysis of the Variable Inlet Guide Vane (VIGV) market, providing deep insights into its trajectory from the Historical Period (2019-2024) through to the Forecast Period (2025-2033), with 2025 serving as both the Base and Estimated Year. It meticulously examines the market's growth drivers, including the pressing need for fuel efficiency and emission reduction in aerospace and electric power generation. The report delves into the significant impact of technological advancements, such as the rise of Composite VIGVs, and explores regional market dynamics, identifying key countries poised for dominance. Furthermore, it addresses the challenges and restraints that could influence market expansion, offering a balanced perspective on the industry's future. With detailed segment analysis, this report is an invaluable resource for stakeholders seeking to understand and capitalize on the multi-million dollar opportunities within the VIGV sector.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include GE Vernova, Gardner Denver, Cappsco International Corp., Rolls-Royce, Siemens Energy, Pratt & Whitney, Mitsubishi Power, Baker Hughes, Woodward.

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Variable Inlet Guide Vane," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Variable Inlet Guide Vane, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.