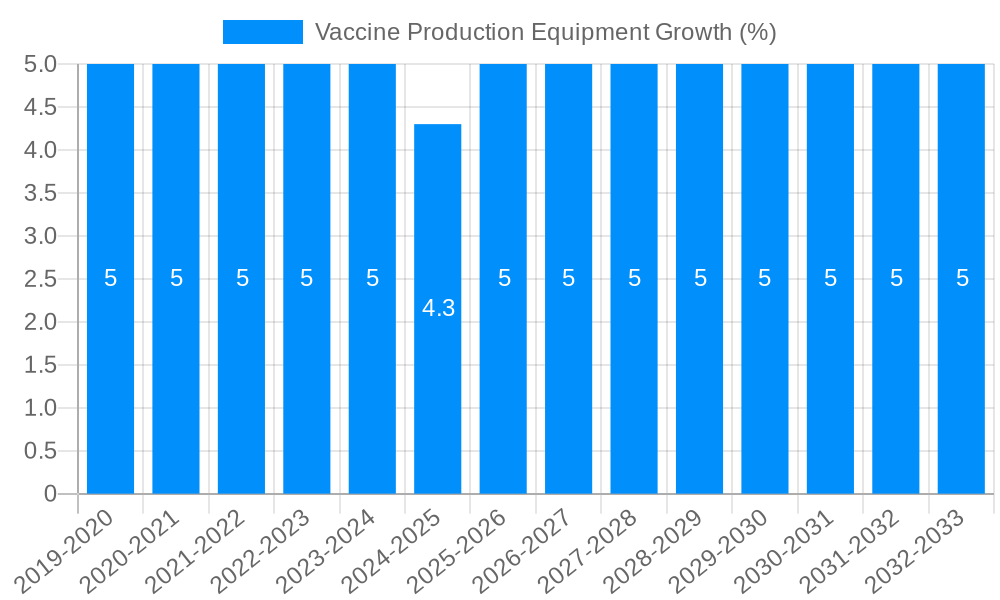

1. What is the projected Compound Annual Growth Rate (CAGR) of the Vaccine Production Equipment?

The projected CAGR is approximately 5%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Vaccine Production Equipment

Vaccine Production EquipmentVaccine Production Equipment by Type (Small Test Bench, Medium-sized Test Bench, Large Production Bench), by Application (Pharmaceutical Manufacturing, Medical Research, Others, World Vaccine Production Equipment Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

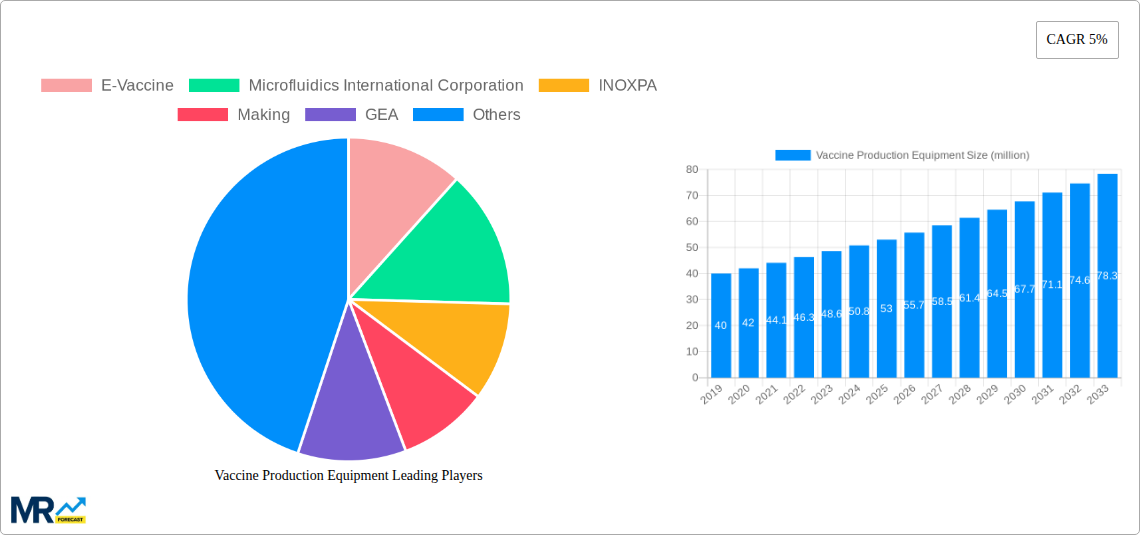

The global Vaccine Production Equipment market is poised for substantial growth, projected to reach an estimated $56 million by the end of 2025, with a robust Compound Annual Growth Rate (CAGR) of 5% anticipated through 2033. This expansion is primarily fueled by the escalating demand for vaccines globally, driven by increasing awareness of preventative healthcare, the persistent threat of infectious diseases, and the critical role of vaccine manufacturing in public health initiatives. The COVID-19 pandemic served as a significant catalyst, highlighting the necessity for advanced and scalable vaccine production capabilities, thereby accelerating investments in sophisticated equipment. Furthermore, the growing prevalence of chronic diseases necessitates the development and production of a wider array of vaccines, further bolstering market demand.

The market is segmented into distinct types of test benches, including small, medium, and large production benches, catering to diverse needs from early-stage research to mass manufacturing. Key application areas dominate the market landscape, with Pharmaceutical Manufacturing and Medical Research emerging as the primary consumers of vaccine production equipment. The "World Vaccine Production Equipment Production" segment also represents a significant area of focus, indicating the broader industry's commitment to enhancing global vaccine supply chains. Leading companies such as E-Vaccine, Microfluidics International Corporation, INOXPA, Making, GEA, and Cytiva are at the forefront, driving innovation and providing essential solutions. However, the market faces restraints such as the high initial investment costs for advanced equipment and stringent regulatory compliances, which can sometimes slow down adoption. Despite these challenges, the overarching trend towards personalized medicine and the development of novel vaccine technologies are expected to create new avenues for growth and innovation in the coming years.

Here's a comprehensive report description on Vaccine Production Equipment, incorporating your specified elements:

This report offers an in-depth analysis of the global Vaccine Production Equipment market, providing a detailed examination of trends, drivers, challenges, and the competitive landscape. Spanning a study period from 2019 to 2033, with a base year of 2025, this report leverages historical data from 2019-2024 and forecasts growth for the period of 2025-2033. The report delves into the intricate world of specialized machinery and infrastructure vital for the development and mass production of vaccines, a sector that has witnessed unprecedented attention and investment in recent years. With a focus on understanding the nuances of equipment types, their applications, and the evolving manufacturing processes, this report aims to equip stakeholders with actionable insights.

The market is segmented by equipment type, including Small Test Bench, Medium-sized Test Bench, and Large Production Bench, catering to diverse needs from early-stage research and development to high-volume commercial manufacturing. Furthermore, applications are categorized into Pharmaceutical Manufacturing, Medical Research, and Others, highlighting the broad utility of these sophisticated systems. This report meticulously quantoys the global vaccine production equipment production, providing valuable data points, with production volumes expressed in the million unit range, particularly for bulk manufacturing equipment.

The report identifies key industry players such as E-Vaccine, Microfluidics International Corporation, INOXPA, Making, GEA, Comecer, VAXXITEK, Corning, AST, Mecart Cleanrooms, Alfa Laval, Cytiva, Eppendorf, and MGA, offering a competitive overview of their market presence and technological contributions. It also tracks significant developments and technological advancements within the sector from 2019 to the present, with a keen eye on future innovations.

XXX The global vaccine production equipment market is undergoing a profound transformation, driven by an escalating demand for vaccines across various therapeutic areas and a renewed focus on pandemic preparedness. The Historical Period of 2019-2024 witnessed a significant surge in investment, particularly post-2020, as the world grappled with the COVID-19 pandemic. This unprecedented demand accelerated the need for advanced manufacturing capabilities, leading to substantial growth in the Large Production Bench segment, with production volumes for critical components and integrated systems reaching tens of million units. The Base Year of 2025 serves as a crucial pivot point, with estimations pointing towards sustained, albeit more stabilized, growth. A key trend is the increasing adoption of microfluidics-based technologies and single-use systems, which offer greater flexibility, reduced contamination risks, and faster turnaround times. Companies like Microfluidics International Corporation are at the forefront of this innovation, developing compact and efficient Small Test Bench solutions for rapid prototyping and early-stage research, contributing to a market segment that, while smaller in volume than large-scale production, is critical for pipeline development.

The trend towards automation and digitalization is also paramount. The integration of Industry 4.0 principles, including AI-powered process optimization, real-time data analytics, and robotic automation, is reshaping the production landscape. This is evident in the demand for sophisticated control systems and integrated software solutions, enhancing efficiency and traceability throughout the manufacturing process. GEA and Alfa Laval, for instance, are heavily investing in smart manufacturing solutions for biopharmaceutical production, including vaccine manufacturing. Furthermore, the emphasis on modular and scalable manufacturing platforms is growing, allowing for quicker adaptation to different vaccine types and production volumes. This trend is particularly beneficial for Medium-sized Test Bench and adaptable Large Production Bench configurations, enabling manufacturers to pivot production lines more efficiently. The increasing complexity of novel vaccine platforms, such as mRNA and viral vector vaccines, also necessitates specialized equipment designed for precise handling of sensitive biological materials, further driving innovation in areas like sterile fill-finish and downstream processing. The overall market trajectory indicates a move towards more agile, efficient, and technologically advanced vaccine production infrastructure, with the Pharmaceutical Manufacturing application segment remaining the dominant consumer of this equipment, accounting for an estimated 70-80% of the global demand.

The vaccine production equipment market is propelled by a confluence of potent forces, primarily centered around the ever-present threat of infectious diseases and the escalating global demand for immunization. The Historical Period leading up to 2024 saw an unprecedented catalyst in the form of the COVID-19 pandemic, which starkly exposed the vulnerabilities in existing vaccine manufacturing capacities and highlighted the critical need for rapid scale-up. This event triggered massive investments in expanding and modernizing production facilities, consequently driving the demand for Large Production Bench equipment. Beyond immediate pandemic response, the continuous emergence of novel pathogens and the rise of antibiotic-resistant bacteria necessitate ongoing research and development, fueling the market for Medical Research equipment, including advanced Small Test Bench and Medium-sized Test Bench systems for preclinical and clinical trials.

Government initiatives and public health organizations worldwide are increasingly prioritizing vaccine security and self-sufficiency, leading to substantial funding for domestic manufacturing capabilities. This translates into a sustained demand for a wide range of production equipment. Moreover, the growing prevalence of chronic diseases and the aging global population are expanding the market for therapeutic vaccines, such as cancer vaccines and those targeting Alzheimer's disease, further augmenting the need for specialized production machinery. The ongoing advancements in biotechnology, particularly in areas like genetic engineering, cell culture, and protein synthesis, enable the development of more complex and effective vaccines. This, in turn, drives the demand for highly specialized and technologically sophisticated equipment designed to handle these novel biological products with precision and sterility. The market is also benefiting from the increasing focus on preventative healthcare and the expansion of vaccination programs to cover a broader spectrum of diseases, ensuring a continuous and robust demand for vaccine production equipment across all segments and applications.

Despite the robust growth trajectory, the vaccine production equipment market faces several significant challenges and restraints. One of the primary hurdles is the high capital investment required for sophisticated production machinery. Acquiring Large Production Bench systems, specialized bioreactors, sterile fill-finish lines, and advanced quality control instruments can run into tens or even hundreds of million units, posing a substantial barrier, especially for smaller biotechnology firms or companies in emerging economies. This limits the pace of adoption and expansion. Furthermore, the long lead times associated with the design, manufacturing, and installation of highly customized vaccine production equipment can be a constraint, particularly in responding to urgent public health crises. The regulatory landscape for vaccine manufacturing is also complex and stringent, requiring equipment to meet rigorous international standards for safety, efficacy, and quality. Ensuring compliance with these evolving regulations adds to the cost and time involved in equipment procurement and validation.

The short shelf-life of some vaccine components and the need for cold chain infrastructure throughout the production and distribution process present logistical challenges that can impact equipment design and operational planning. Moreover, skilled labor shortages in specialized areas such as bioprocess engineering, automation, and sterile manufacturing can hinder the efficient operation and maintenance of advanced production equipment. The rapid pace of technological evolution in vaccine development can also pose a challenge, as equipment purchased today might become obsolete relatively quickly, necessitating continuous reinvestment. Finally, the geopolitical landscape and trade restrictions can sometimes disrupt the supply chain for critical raw materials and specialized components, impacting the production and availability of the equipment itself. These factors, collectively, can temper the otherwise optimistic growth outlook for the vaccine production equipment market.

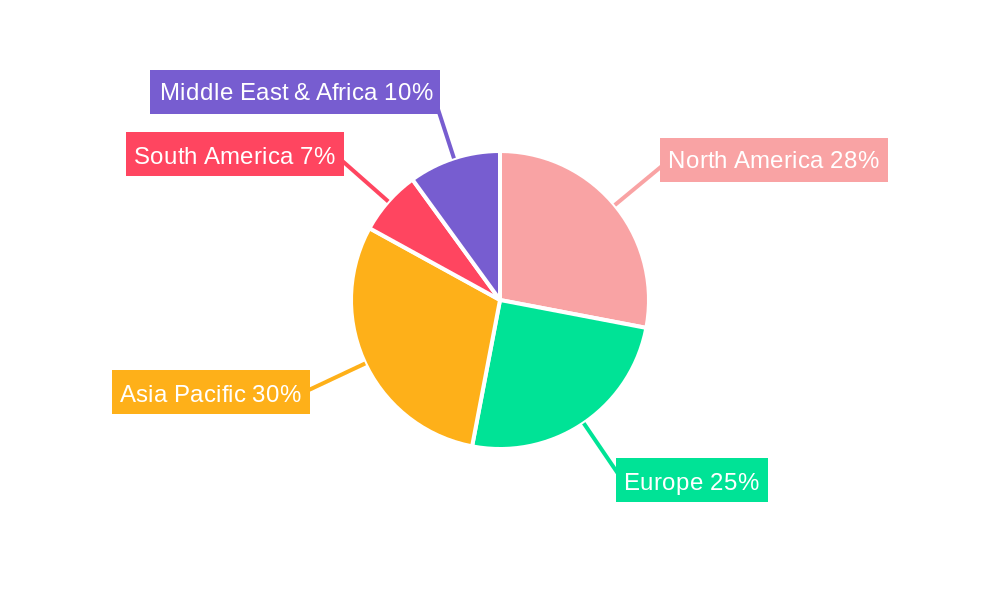

The global Vaccine Production Equipment market is characterized by a dynamic interplay between regional strengths and segment dominance. North America, particularly the United States, is poised to maintain its leadership position throughout the Forecast Period of 2025-2033. This dominance is underpinned by a robust pharmaceutical industry, significant government investment in research and development, and the presence of major vaccine manufacturers and biotechnology hubs. The region's commitment to pandemic preparedness and its proactive approach to vaccine innovation have consistently driven demand for advanced production equipment. The Pharmaceutical Manufacturing application segment is unequivocally the largest and most influential segment within the market, accounting for an estimated 70-80% of global equipment demand. This is driven by the continuous need for vaccines to combat existing diseases, the development of new therapeutic vaccines, and the imperative to maintain robust manufacturing capacities.

Within the equipment Type segmentation, Large Production Bench systems are expected to dominate in terms of production volume and overall market value. The sheer scale of global vaccine demand, especially for widely administered vaccines like influenza and routine childhood immunizations, necessitates high-capacity manufacturing lines. The production volumes for critical components and integrated Large Production Bench systems can reach tens of million units annually, particularly during periods of heightened demand or global health emergencies. However, the Medium-sized Test Bench segment is also expected to witness substantial growth, driven by the increasing number of contract manufacturing organizations (CMOs) and the need for flexible production capabilities that can be adapted to various vaccine types. These systems are crucial for mid-scale production runs and for specialized vaccines.

Asia-Pacific, particularly China and India, is emerging as a significant growth region, driven by increasing investments in domestic pharmaceutical manufacturing, a growing generics market, and government initiatives to bolster vaccine production self-sufficiency. While North America leads in terms of cutting-edge technology adoption and R&D spending, the sheer scale of population and expanding healthcare infrastructure in Asia makes it a rapidly growing market for both Large Production Bench and Medium-sized Test Bench equipment. Europe also represents a strong market, with established pharmaceutical players and a focus on innovation and quality. The region's emphasis on collaborative research and stringent regulatory standards ensures a consistent demand for high-quality, reliable production equipment. The Medical Research application segment, while smaller than Pharmaceutical Manufacturing, is a vital driver of innovation, particularly for Small Test Bench and Medium-sized Test Bench equipment, supporting the development of novel vaccine candidates and platforms. The "Others" category, which can include specialized applications or niche vaccine production, will likely see incremental growth driven by specific advancements or regional needs. Ultimately, the interplay between a dominant application segment (Pharmaceutical Manufacturing), a high-volume equipment type (Large Production Bench), and strategically important regions (North America and Asia-Pacific) will shape the market's future landscape.

Several key factors are acting as significant growth catalysts for the vaccine production equipment industry. The persistent threat of infectious diseases, coupled with the emergence of new pathogens and antimicrobial resistance, necessitates continuous innovation and expansion of vaccine manufacturing capabilities. Government mandates for increased vaccine production capacity, driven by national security and public health concerns, provide a stable and substantial funding stream. Furthermore, advancements in biotechnology, particularly in areas like mRNA technology, viral vectors, and gene therapy, are opening up new frontiers for vaccine development, creating demand for specialized and highly advanced production equipment. The increasing outsourcing of vaccine production to contract manufacturing organizations (CMOs) is also a key catalyst, as these organizations require state-of-the-art equipment to meet the diverse needs of their clients.

This report provides an exhaustive overview of the vaccine production equipment market, encompassing its historical trajectory, current state, and future projections. It delves into the intricate details of market segmentation, exploring the nuances of equipment types like Small Test Bench, Medium-sized Test Bench, and Large Production Bench, and their applications in Pharmaceutical Manufacturing, Medical Research, and Others. The report quantifies global production volumes in the million unit range, offering concrete data for key equipment categories. Furthermore, it analyzes the driving forces, challenges, and growth catalysts shaping the industry, alongside a comprehensive list of leading players and their significant developments. The Base Year of 2025 serves as a benchmark for detailed forecasts extending through 2033, ensuring stakeholders have a robust understanding of the market's evolution. This report is an indispensable resource for manufacturers, investors, researchers, and policymakers seeking to navigate and capitalize on the dynamic vaccine production equipment sector.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 5% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 5%.

Key companies in the market include E-Vaccine, Microfluidics International Corporation, INOXPA, Making, GEA, Comecer, VAXXITEK, Corning, AST, Mecart Cleanrooms, Alfa Laval, Cytiva, Eppendorf, MGA, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Vaccine Production Equipment," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Vaccine Production Equipment, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.