1. What is the projected Compound Annual Growth Rate (CAGR) of the Ultrasonic Reactors?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Ultrasonic Reactors

Ultrasonic ReactorsUltrasonic Reactors by Application (Chemical Industry, Agricultural, Pharmaceutical, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

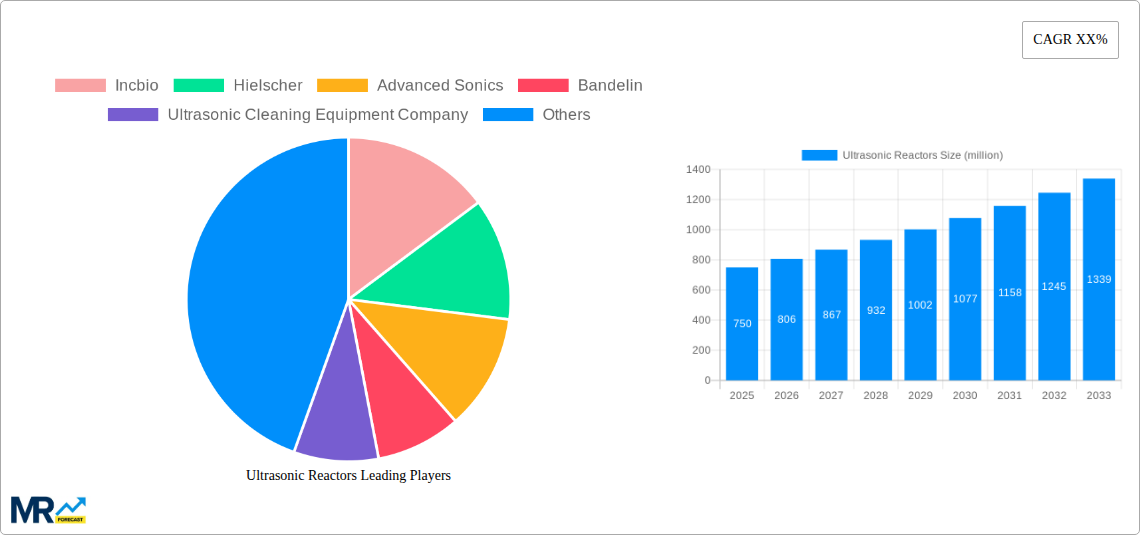

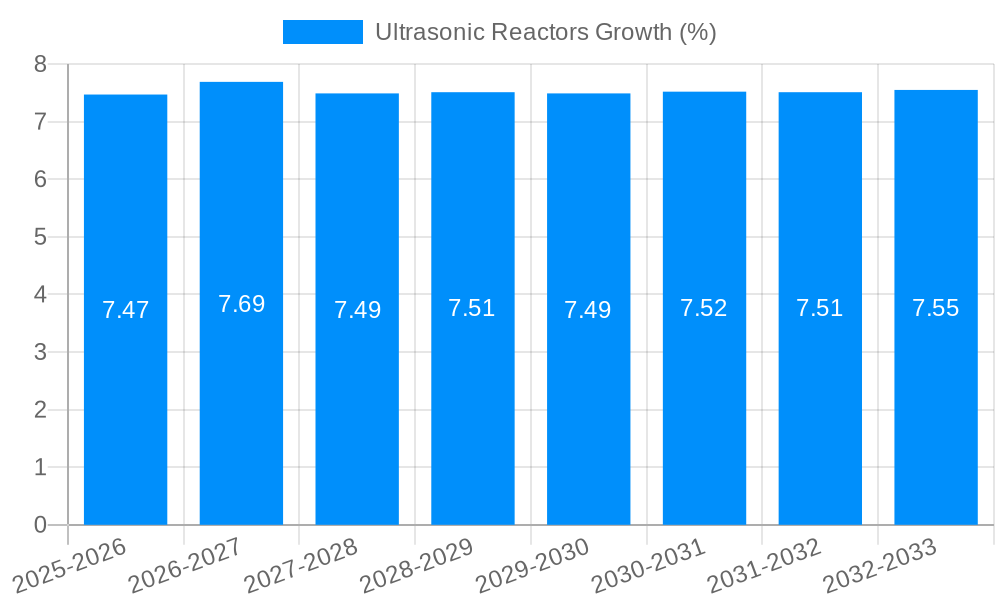

The global Ultrasonic Reactors market is experiencing robust growth, estimated at approximately $750 million in 2025. This expansion is propelled by the increasing adoption of advanced sonochemical processing techniques across diverse industries, including the chemical, agricultural, and pharmaceutical sectors. The chemical industry, in particular, is a significant driver, leveraging ultrasonic reactors for enhanced reaction rates, improved yields, and energy efficiency in synthesis and extraction processes. The agricultural sector is increasingly utilizing these reactors for the development of novel pesticides, fertilizers, and for processing plant-based materials. Furthermore, the pharmaceutical industry's demand for efficient drug synthesis, nanoparticle production, and advanced drug delivery systems is also contributing to market impetus. The market is projected to witness a Compound Annual Growth Rate (CAGR) of approximately 7.5% over the forecast period of 2025-2033, reaching an estimated market size of around $1.3 billion by 2033. This sustained growth trajectory is a testament to the inherent advantages of ultrasonic reactors, such as their ability to facilitate faster and more efficient chemical reactions, reduce processing times, and lower energy consumption compared to conventional methods. The technology's versatility in enabling a wide array of chemical transformations, from oxidation and reduction to polymerization and emulsification, further solidifies its market position.

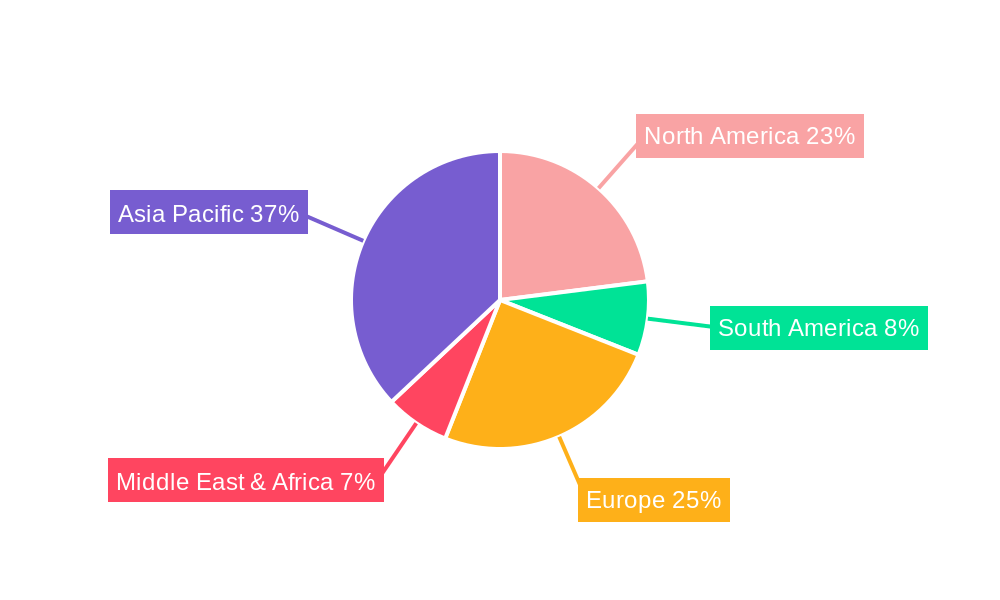

Key trends shaping the Ultrasonic Reactors market include the ongoing advancements in reactor design, leading to more sophisticated and scalable solutions, and the growing emphasis on green chemistry principles, where ultrasonic technology offers a sustainable and environmentally friendly alternative to traditional methods. The development of high-intensity ultrasonic systems and continuous flow reactors is also a significant trend, catering to the evolving needs of industrial-scale applications. Restraints to market growth include the initial capital investment associated with setting up ultrasonic reactor systems and the need for specialized expertise in operating and maintaining this technology. However, these challenges are increasingly being mitigated by the long-term cost savings and efficiency gains offered by ultrasonic reactors. Geographically, Asia Pacific, particularly China and India, is emerging as a dominant region due to its rapidly expanding chemical and pharmaceutical manufacturing base and increasing R&D investments. North America and Europe also represent substantial markets, driven by stringent regulatory standards and a focus on innovative and sustainable manufacturing practices.

Here is a unique report description on Ultrasonic Reactors, incorporating your specified requirements:

The global ultrasonic reactors market is poised for substantial expansion, driven by an escalating demand for enhanced process efficiency and sustainability across a multitude of industries. During the Study Period of 2019-2033, with a Base Year of 2025 and an Estimated Year also of 2025, the market is projected to witness robust growth. The Forecast Period of 2025-2033, building upon the Historical Period of 2019-2024, indicates a significant upward trajectory. Innovations in ultrasonic technology, such as the development of more energy-efficient and scalable reactor designs, are at the forefront of market trends. Companies like Hielscher and Incbio are actively investing in research and development to offer advanced solutions that address complex chemical synthesis, nanoparticle dispersion, and extraction processes. The Chemical Industry segment is a major contributor, benefiting from ultrasonic reactors' ability to accelerate reaction rates, improve product yields, and reduce the need for harsh chemical solvents. Furthermore, the Pharmaceutical Industry is increasingly adopting these reactors for drug formulation, sterilization, and the efficient extraction of active pharmaceutical ingredients (APIs). The market is also observing a growing interest in continuous flow ultrasonic reactors, offering superior process control and scalability compared to traditional batch systems. The increasing emphasis on green chemistry principles and the reduction of environmental footprints are further propelling the adoption of ultrasonic reactors, as they often enable lower operating temperatures and reduced waste generation. The market value, which stood at approximately $700 million in 2023, is anticipated to reach upwards of $1.8 billion by 2033, showcasing a compound annual growth rate (CAGR) of over 10%. This expansion is further fueled by increasing investments in R&D and the development of novel applications in fields such as advanced materials and biotechnology. The integration of advanced control systems and automation into ultrasonic reactor technology is also a key trend, enhancing user experience and process reproducibility.

The surge in demand for ultrasonic reactors is primarily driven by their inherent ability to significantly enhance process efficiency and accelerate reaction kinetics. The cavitation phenomenon generated by ultrasonic waves creates localized high-energy zones, leading to improved mass transfer, enhanced mixing, and faster reaction rates. This translates into reduced reaction times, lower energy consumption, and ultimately, increased throughput for manufacturers. Moreover, the quest for more sustainable and environmentally friendly industrial processes is a powerful catalyst. Ultrasonic reactors enable chemists and engineers to perform reactions under milder conditions, often at lower temperatures and pressures, thereby reducing energy expenditure and minimizing the generation of hazardous byproducts. This aligns perfectly with the global push towards green chemistry and sustainable manufacturing practices. The development of more sophisticated and versatile ultrasonic reactor designs by companies like Advanced Sonics and Bandelin is also contributing to their wider adoption. These advancements offer improved control over cavitation intensity, frequency, and amplitude, allowing for precise optimization of processes for a wide range of applications. The pharmaceutical industry's increasing reliance on efficient extraction of valuable compounds and the production of nano-sized drug delivery systems further bolsters market growth. Similarly, the agricultural sector is exploring ultrasonic applications for pesticide formulation and soil remediation, opening up new avenues for market expansion. The continuous innovation in material science, leading to the development of robust reactor materials capable of withstanding extreme ultrasonic conditions, also plays a crucial role in expanding the operational envelope of these technologies.

Despite the promising growth trajectory, the ultrasonic reactors market faces several significant challenges and restraints. One of the primary hurdles is the initial capital investment required for advanced ultrasonic reactor systems. High-power industrial-grade reactors can be considerably more expensive than conventional processing equipment, which can deter smaller enterprises or those with limited budgets. Furthermore, scaling up ultrasonic processes from laboratory to industrial production can be complex. While advancements are being made, achieving uniform cavitation and predictable process outcomes across very large volumes remains a technical challenge that requires careful engineering and optimization. Another restraint is the potential for material degradation or damage in highly corrosive or abrasive environments due to the intense cavitation. While companies are developing specialized materials, this remains a consideration for specific applications. The lack of standardized protocols and comprehensive training for operating and maintaining complex ultrasonic systems can also hinder widespread adoption, leading to concerns about process reliability and safety. Additionally, energy consumption, while often lower per unit of product compared to conventional methods, can still be substantial for high-intensity applications, requiring careful energy management strategies. The market also experiences competition from established, albeit less efficient, technologies, requiring continuous demonstration of the superior economic and environmental benefits of ultrasonic reactors.

The Pharmaceutical Industry is poised to be a dominant segment in the global ultrasonic reactors market. This dominance is fueled by the sector's relentless pursuit of enhanced drug efficacy, accelerated research and development timelines, and the growing demand for sophisticated drug delivery systems. Ultrasonic reactors offer unparalleled advantages in crucial pharmaceutical processes, including:

Enhanced API Synthesis and Extraction:

Drug Formulation and Nanotechnology:

Bioprocessing and Vaccine Development:

Geographically, North America and Europe are anticipated to lead the market, primarily driven by their established pharmaceutical industries, strong R&D infrastructure, and a robust regulatory framework that encourages the adoption of advanced and efficient manufacturing technologies. The presence of leading pharmaceutical companies and research institutions in these regions fosters innovation and the rapid adoption of cutting-edge technologies like ultrasonic reactors. Countries like the United States and Germany are at the forefront of adopting these technologies, supported by substantial government and private sector investments in pharmaceutical R&D and advanced manufacturing. Asia-Pacific, particularly China and India, is emerging as a rapidly growing market due to the expansion of their domestic pharmaceutical industries and increasing outsourcing of drug manufacturing. The presence of significant players like Incbio and Hielscher, with their extensive product portfolios and strong regional presence, further solidifies the dominance of these regions and segments.

The growth of the ultrasonic reactors industry is significantly catalyzed by the escalating emphasis on green chemistry and sustainable manufacturing practices across various sectors. Ultrasonic reactors offer a demonstrably eco-friendly alternative by reducing energy consumption, minimizing solvent usage, and lowering the generation of hazardous waste. The continuous innovation in reactor design and the development of more energy-efficient ultrasonic transducers by companies such as Hielscher and Advanced Sonics are expanding their applicability and economic viability. Furthermore, the increasing research and development activities in fields like nanotechnology and advanced materials, where precise particle size control and dispersion are crucial, are opening new avenues for ultrasonic reactor adoption. The growing demand for high-purity compounds in the pharmaceutical and fine chemical industries also acts as a significant growth driver, as ultrasonication often leads to improved reaction selectivity and product yields.

This comprehensive report delves deep into the multifaceted global ultrasonic reactors market, providing an in-depth analysis of its current landscape and future trajectory. It meticulously examines key market insights, growth drivers, and the technological innovations that are reshaping the industry. The report offers a detailed breakdown of market segmentation by application and industry, with a particular focus on the dominant Pharmaceutical Industry and its significant influence on market dynamics. It also addresses the critical challenges and restraints that market players need to navigate, alongside the growth catalysts propelling the sector forward. The report provides an exhaustive overview of the leading companies, their strategic initiatives, and significant developments that have occurred over the past few years. This comprehensive coverage ensures that stakeholders gain a complete understanding of the ultrasonic reactors market, enabling informed strategic decision-making and investment planning.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Incbio, Hielscher, Advanced Sonics, Bandelin, Ultrasonic Cleaning Equipment Company, ChemTron, Jiangshu Tenlin, Shanghai Oumeng, Shanghai Hefan, Xiaomei Ultrasonic Instrument, .

The market segments include Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Ultrasonic Reactors," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Ultrasonic Reactors, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.