1. What is the projected Compound Annual Growth Rate (CAGR) of the Teflon Coated Rubber Stopper?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Teflon Coated Rubber Stopper

Teflon Coated Rubber StopperTeflon Coated Rubber Stopper by Type (FEP Coated, ETFE Coated, World Teflon Coated Rubber Stopper Production ), by Application (Liquid Injectables, Powder Injectables, Lyo-injectables, World Teflon Coated Rubber Stopper Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

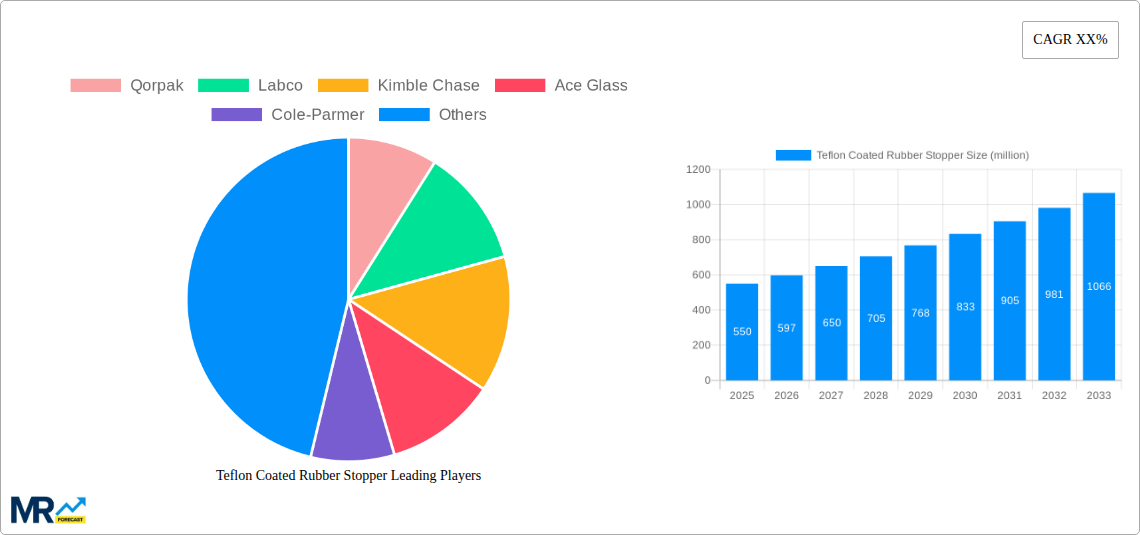

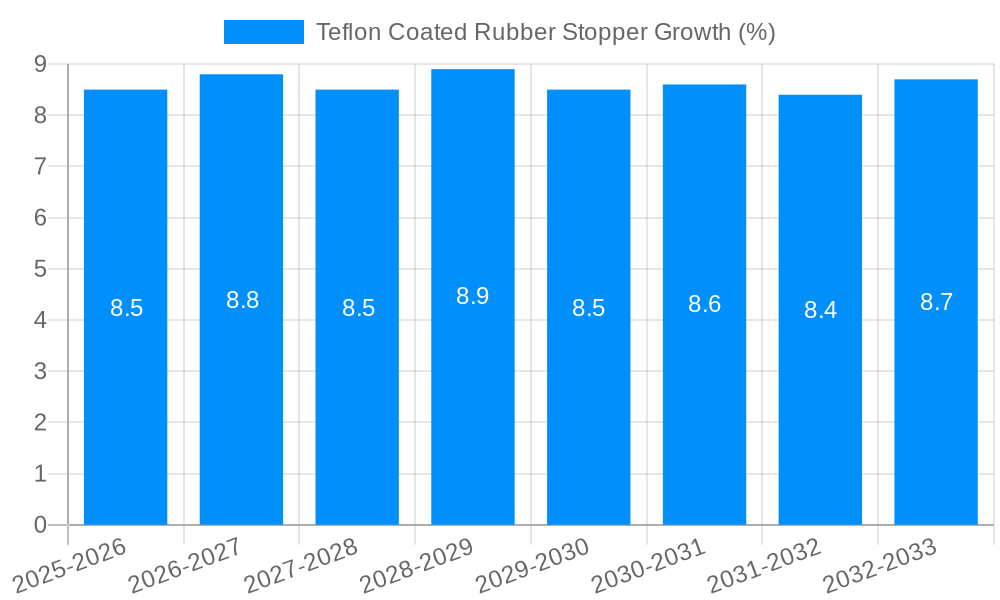

The global Teflon Coated Rubber Stopper market is poised for significant expansion, projected to reach an estimated $550 million by 2025, with a robust Compound Annual Growth Rate (CAGR) of 8.5% anticipated throughout the forecast period of 2025-2033. This growth is primarily fueled by the escalating demand for sterile and reliable pharmaceutical packaging solutions, driven by the burgeoning global pharmaceutical industry and the increasing prevalence of chronic diseases. The stringent quality control measures and the need for superior barrier properties in drug packaging further bolster the adoption of Teflon coated stoppers. These stoppers offer exceptional chemical inertness, low friction, and excellent sealing capabilities, making them indispensable for a wide array of pharmaceutical applications, including liquid injectables, powder injectables, and lyophilized products. The technological advancements in coating processes and the growing emphasis on drug safety and efficacy are also significant contributors to this upward market trajectory.

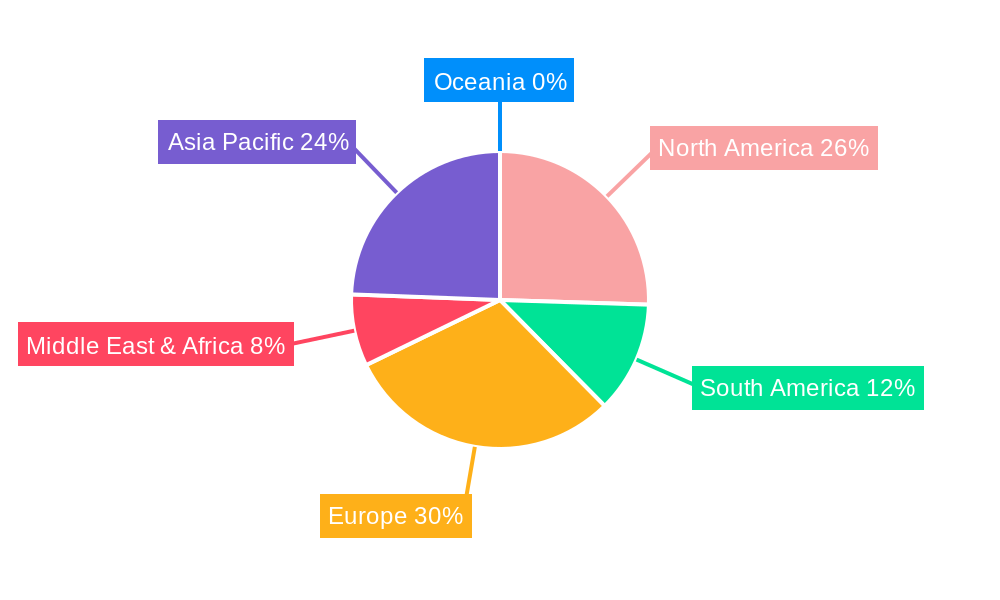

The market's segmentation reveals a dynamic landscape. FEP (Fluorinated Ethylene Propylene) coated stoppers are expected to lead the market due to their superior performance characteristics, followed by ETFE (Ethylene Tetrafluoroethylene) and other Teflon variants. In terms of application, liquid injectables represent the largest segment, attributed to the high volume production of injectable drugs. However, the growing trend of lyophilization for enhanced drug stability will drive significant growth in the lyo-injectable segment. Geographically, the Asia Pacific region, led by China and India, is emerging as a key growth engine, owing to its expanding pharmaceutical manufacturing base and increasing healthcare expenditure. North America and Europe remain significant markets, driven by established pharmaceutical industries and stringent regulatory standards. Key players like Qorpak, Labco, and Kimble Chase are instrumental in shaping the market through product innovation and strategic collaborations.

This report delves into the dynamic global Teflon Coated Rubber Stopper market, offering a comprehensive analysis of trends, drivers, challenges, and future opportunities. Spanning the historical period of 2019-2024, with a base and estimated year of 2025, and extending through a robust forecast period of 2025-2033, this study provides actionable intelligence for stakeholders. The report meticulously examines market segmentation by type and application, alongside an in-depth exploration of industry developments and leading players. Projections are based on meticulous data analysis, aiming to deliver a forward-looking perspective on this critical component within the pharmaceutical and healthcare industries.

The global Teflon Coated Rubber Stopper market is experiencing a steady ascent, driven by the increasing demand for high-purity and inert packaging solutions in the pharmaceutical and biopharmaceutical sectors. The intrinsic chemical resistance and low friction properties of Teflon coatings, such as FEP and ETFE, are paramount in preventing leachables and extractables from compromising the integrity of sensitive drug formulations. This trend is amplified by the growing emphasis on drug stability and shelf-life extension, where the barrier properties of these stoppers play a crucial role. The market is witnessing a continuous evolution in coating technologies, with manufacturers striving for thinner, more uniform, and more durable coatings to enhance product performance and reduce manufacturing costs. Innovations in surface treatments and application methods are also contributing to this upward trajectory, ensuring better compatibility with a wider range of drug products, including biologics and vaccines, which demand the highest levels of containment and sterility.

Furthermore, the expanding global healthcare infrastructure, particularly in emerging economies, is a significant contributor to the market's growth. As access to advanced pharmaceutical treatments increases, so does the need for reliable and safe primary packaging components. The rise in parenteral drug delivery systems, including sophisticated injectables and lyophilized products, directly fuels the demand for Teflon coated rubber stoppers. The stringent regulatory landscape, with agencies like the FDA and EMA advocating for enhanced drug product safety and containment, further bolsters the adoption of these premium stopper solutions. The market is also seeing a subtle but significant shift towards customized solutions, where manufacturers are collaborating with pharmaceutical companies to develop stoppers tailored to specific drug characteristics and packaging requirements. This includes variations in stopper size, shape, and specific coating formulations to optimize compatibility and performance. The overall sentiment within the market is one of sustained and positive growth, underpinned by technological advancements and an ever-increasing global need for safe and effective drug delivery. The base year of 2025 marks a pivotal point, with projections indicating continued expansion driven by these foundational trends.

The Teflon Coated Rubber Stopper market is experiencing robust growth, propelled by a confluence of compelling factors. Foremost among these is the escalating global demand for high-quality pharmaceutical products, particularly those administered via injection or lyophilization. The inherent inertness and exceptional chemical resistance of Teflon coatings (FEP and ETFE) are critical in safeguarding the purity and efficacy of sensitive drug formulations, thereby mitigating the risk of leachables and extractables that can compromise patient safety and drug stability. This is particularly crucial for biologics, vaccines, and other complex therapeutic agents where even minute contamination can have significant consequences. The stringent regulatory environment across the globe, with health authorities emphasizing the importance of drug product integrity and patient safety, serves as a significant catalyst. This regulatory push necessitates the use of advanced packaging solutions like Teflon coated rubber stoppers to meet increasingly rigorous compliance standards.

Moreover, the expanding global healthcare infrastructure, coupled with rising disposable incomes in emerging economies, is translating into a greater demand for sophisticated drug delivery systems. As more individuals gain access to advanced medical treatments, the need for reliable and safe primary packaging components, such as these specialized stoppers, escalates. The burgeoning biopharmaceutical industry, with its focus on novel and complex drug molecules, further fuels this demand. These molecules often require packaging that offers superior barrier properties and minimal interaction to maintain their therapeutic value. The continuous innovation in drug formulation and delivery technologies, including the growth of pre-filled syringes and advanced lyophilization techniques, also directly contributes to the increased adoption of Teflon coated rubber stoppers, as they are essential for ensuring the integrity and sterility of these sophisticated products throughout their shelf life.

Despite its promising growth trajectory, the Teflon Coated Rubber Stopper market faces certain inherent challenges and restraints that could temper its expansion. One of the primary concerns revolves around the cost of production. The advanced manufacturing processes and high-quality raw materials required for producing Teflon coated rubber stoppers, such as FEP and ETFE, often translate into higher unit costs compared to conventional rubber stoppers. This price differential can be a significant barrier for smaller pharmaceutical companies or those operating in cost-sensitive markets, potentially limiting their adoption of these premium solutions. Furthermore, the complexity of the coating process itself can lead to quality control issues. Achieving uniform and defect-free Teflon coatings across a large batch of stoppers requires precise temperature control, application techniques, and rigorous inspection. Any inconsistencies can lead to reduced barrier properties or premature degradation, impacting product integrity.

Another considerable challenge pertains to the availability and consistency of raw materials. The production of specialized fluoropolymers like FEP and ETFE is concentrated among a limited number of global suppliers. Any disruptions in the supply chain, geopolitical instability, or fluctuations in the price of these raw materials can directly impact the manufacturing costs and availability of Teflon coated rubber stoppers. Additionally, the regulatory compliance landscape, while a driver, also presents a challenge. While regulations promote the use of high-quality packaging, the continuous evolution of these standards and the need for extensive validation of new packaging components can be a time-consuming and expensive process for manufacturers and pharmaceutical companies alike. Finally, competition from alternative packaging materials and technologies also poses a restraint. While Teflon coated stoppers offer significant advantages, ongoing research into other advanced barrier materials and innovative closure systems could present alternative solutions that might compete on price or performance in specific applications, thus potentially limiting market share.

The global Teflon Coated Rubber Stopper market is poised for significant growth, with the North America region, particularly the United States, expected to lead in terms of market share and consumption. This dominance is attributed to several interconnected factors. Firstly, the United States boasts the largest and most advanced pharmaceutical and biopharmaceutical industry globally. This means a consistently high demand for premium packaging solutions that ensure the integrity and safety of a vast array of complex drug products. The presence of major pharmaceutical giants and a thriving ecosystem of biotechnology companies actively engaged in research and development of novel therapeutics, including biologics, vaccines, and gene therapies, creates a sustained need for high-performance stoppers.

Secondly, North America, with the US at its forefront, has some of the most stringent regulatory frameworks governing pharmaceutical packaging. Agencies like the U.S. Food and Drug Administration (FDA) impose rigorous requirements on drug product safety, purity, and containment. Teflon coated rubber stoppers, with their superior inertness and resistance to leachables and extractables, are ideally suited to meet these demanding standards. This regulatory imperative drives the adoption of these advanced stoppers over less effective alternatives.

Within the segmentation analysis, the FEP Coated Rubber Stopper segment is anticipated to be a key dominant force within the overall market. FEP (Fluorinated Ethylene Propylene) offers an excellent balance of chemical resistance, temperature stability, and clarity, making it a versatile choice for a wide range of pharmaceutical applications. Its biocompatibility and low friction properties are crucial for ensuring smooth vial stoppering and easy penetration by needles during drug administration. The broad applicability of FEP coatings across various drug types, including liquid injectables and powder injectables, further solidifies its position.

Furthermore, when considering applications, Liquid Injectables will likely represent the largest and most dominant application segment for Teflon coated rubber stoppers. The precise nature of liquid injectables, which are often highly sensitive and susceptible to contamination or degradation from packaging interactions, necessitates the use of inert and reliable closure systems. Teflon coated stoppers provide the essential barrier protection required to maintain the sterility and efficacy of these formulations throughout their shelf life. The ongoing growth in the development and production of intravenous (IV) drugs, antibiotics, anesthetics, and various other parenteral liquid formulations directly fuels the demand for FEP coated rubber stoppers within this application.

Companies like Qorpak, Labco, and Kimble Chase are major players within North America, offering a comprehensive range of Teflon coated stoppers that cater to these stringent requirements. Their established distribution networks and strong relationships with pharmaceutical manufacturers in the region further solidify their market leadership. The continuous investment in research and development by these companies, focusing on improving coating technologies and expanding product portfolios, will ensure their continued dominance in the foreseeable future.

The Teflon Coated Rubber Stopper industry is experiencing significant growth catalysts, primarily driven by the escalating demand for high-purity and inert packaging in the pharmaceutical and biopharmaceutical sectors. The increasing global focus on drug safety and efficacy, particularly for sensitive biologics and vaccines, necessitates packaging solutions that minimize extractables and leachables. Advancements in drug delivery systems, such as pre-filled syringes and lyophilized injectables, further amplify the need for reliable and chemically inert stoppers. The continuous expansion of healthcare infrastructure worldwide, especially in emerging economies, coupled with a rising incidence of chronic diseases, contributes to a sustained demand for parenteral drug formulations, thus bolstering the market for these specialized stoppers.

This comprehensive report provides an in-depth analysis of the global Teflon Coated Rubber Stopper market, spanning the historical period of 2019-2024 and projecting trends through 2033, with a base and estimated year of 2025. It meticulously examines market dynamics, including key drivers such as the growing demand for high-purity pharmaceutical packaging and the increasing stringency of regulatory requirements. The report also delves into significant challenges, such as production costs and raw material availability. Segmentation analysis covers types like FEP and ETFE coated stoppers, and applications including Liquid Injectables, Powder Injectables, and Lyo-injectables, identifying dominant segments and regions. Furthermore, it highlights significant industry developments and profiles leading players like Qorpak, Labco, and Kimble Chase, offering a holistic view of the market landscape and future opportunities.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Qorpak, Labco, Kimble Chase, Ace Glass, Cole-Parmer, Bel-Art Products, Shijiazhuang Four Medicine, Shandong Pharmaceutical Glass, Chaocheng Glass Products.

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Teflon Coated Rubber Stopper," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Teflon Coated Rubber Stopper, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.