1. What is the projected Compound Annual Growth Rate (CAGR) of the Tablet Film Coating Machines?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Tablet Film Coating Machines

Tablet Film Coating MachinesTablet Film Coating Machines by Type (Standard Coating Pan, Perforated Coating Pan, Fluidized Bed Coater), by Application (Sugar Coating, Film Coating, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

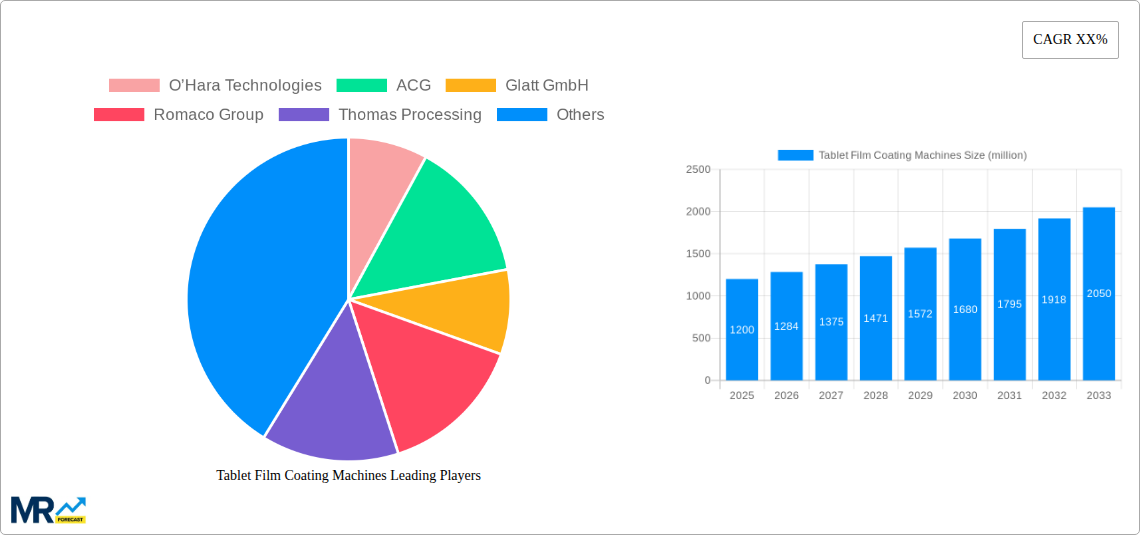

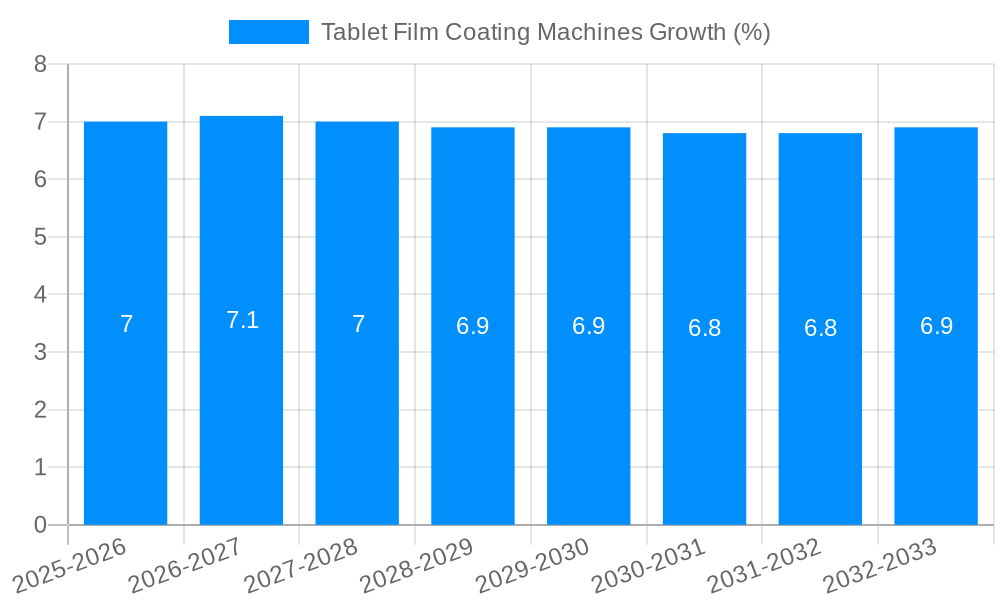

The global tablet film coating machines market is poised for robust growth, driven by an increasing demand for aesthetically pleasing and functionally enhanced pharmaceutical tablets. With a substantial market size estimated at approximately $1.2 billion in 2025, the industry is projected to expand at a Compound Annual Growth Rate (CAGR) of roughly 7.5% during the forecast period of 2025-2033. This sustained expansion is primarily fueled by the pharmaceutical industry's continuous innovation in drug delivery systems, requiring advanced coating technologies for controlled release, taste masking, and improved patient compliance. The rising prevalence of chronic diseases globally and the subsequent surge in pharmaceutical production further bolster the demand for efficient and high-throughput tablet coating solutions. Moreover, advancements in machine design, including automated systems, precision spraying, and integrated process analytical technology (PAT), are enhancing operational efficiency and product quality, making these machines indispensable in modern pharmaceutical manufacturing.

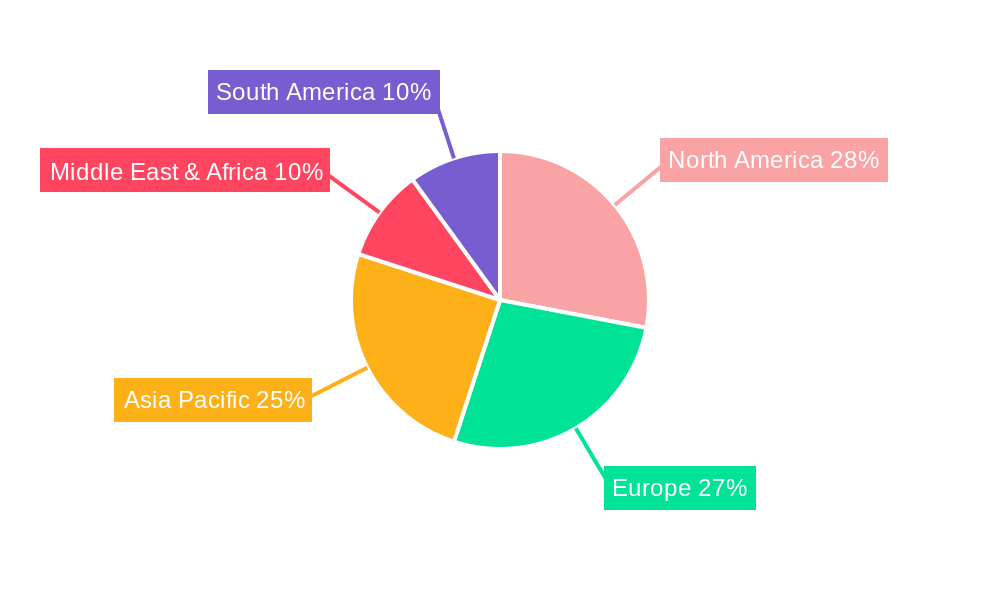

The market is segmented into Standard Coating Pans, Perforated Coating Pans, and Fluidized Bed Coaters, with Perforated Coating Pans and Fluidized Bed Coaters expected to witness significant adoption due to their superior efficiency and versatility in handling a wide range of tablet types and coating materials. Applications span Sugar Coating, Film Coating, and Others, with Film Coating being the dominant segment, reflecting the growing preference for advanced film coatings that offer protection, functional properties, and improved swallowability. Geographically, North America and Europe currently lead the market due to the presence of major pharmaceutical manufacturers and stringent quality standards. However, the Asia Pacific region is anticipated to emerge as the fastest-growing market, driven by the expanding pharmaceutical manufacturing base in countries like China and India, increasing healthcare expenditure, and a growing focus on drug quality and innovation. Key players such as GEA Group Aktiengesellschaft, Syntegon Technology, and IMA SpA are at the forefront of this market, investing in research and development to introduce technologically advanced and sustainable coating solutions.

The global tablet film coating machines market is poised for significant expansion, projected to witness a compound annual growth rate (CAGR) exceeding 7.5% during the forecast period of 2025-2033. The market, valued at an estimated USD 500 million in the base year of 2025, is expected to reach approximately USD 900 million by 2033. This upward trajectory is largely attributed to the burgeoning pharmaceutical industry, driven by increasing global healthcare expenditure, a rising prevalence of chronic diseases, and the continuous development of novel drug formulations. The demand for highly efficient and precise tablet coating solutions, capable of delivering uniform and protective coatings, is escalating. Specifically, the shift towards advanced film coating technologies that offer enhanced drug delivery profiles, improved stability, and aesthetic appeal is a dominant trend. The market is witnessing a growing preference for perforated coating pans and fluidized bed coaters over traditional standard coating pans due to their superior process control and efficiency. This is particularly evident in the application segment, where film coating applications are outpacing traditional sugar coating, driven by the need for better taste masking, controlled release, and barrier properties. Furthermore, the increasing adoption of automation and smart manufacturing technologies, including Industry 4.0 principles, is shaping the market. Manufacturers are investing in machines equipped with advanced sensors, data analytics, and integrated control systems to optimize coating processes, reduce batch variability, and enhance overall productivity. The focus on developing sustainable and energy-efficient coating solutions also represents a notable trend, aligning with global environmental regulations and corporate social responsibility initiatives. The historical period from 2019-2024 laid the groundwork for this growth, characterized by steady innovation and increasing adoption of automated systems. The estimated year of 2025 marks a pivotal point, with accelerated market dynamics anticipated in the subsequent forecast period.

The tablet film coating machines market is experiencing robust growth, fueled by several powerful drivers. Foremost among these is the relentless expansion of the global pharmaceutical industry. An aging global population and the increasing incidence of chronic conditions are leading to a higher demand for medications, consequently driving the need for efficient and high-quality tablet manufacturing processes, including film coating. Furthermore, advancements in pharmaceutical research and development are leading to the creation of more complex drug formulations. Film coating plays a crucial role in enhancing the stability of these sensitive compounds, masking unpleasant tastes, and enabling controlled or targeted drug release, all of which are critical for therapeutic efficacy. The increasing focus on patient compliance also significantly contributes to market growth. Film coating can improve the visual appeal of tablets, making them more palatable and easier for patients to swallow, especially in pediatric and geriatric populations. Regulatory mandates from health authorities worldwide, emphasizing product quality, safety, and uniformity, are pushing manufacturers to adopt advanced coating technologies that ensure consistent and reliable results. This is leading to a greater demand for automated and validated systems.

Despite the optimistic growth outlook, the tablet film coating machines market is not without its hurdles. A significant challenge lies in the high initial investment cost associated with sophisticated, automated film coating equipment. For small and medium-sized enterprises (SMEs) in emerging economies, this capital expenditure can be a considerable barrier to entry, limiting their adoption of cutting-edge technologies. The complexity of certain film coating applications, particularly those involving sensitive active pharmaceutical ingredients (APIs) or requiring highly specialized coatings for targeted delivery, necessitates specialized expertise and a deep understanding of coating chemistry and equipment operation. This can lead to a skills gap, requiring extensive training for operators and technicians, which can be time-consuming and costly. Furthermore, the stringent regulatory environment in the pharmaceutical sector, while a driver for quality, also presents challenges. Compliance with Good Manufacturing Practices (GMP) and validation requirements for coating processes can be intricate and resource-intensive, adding to the overall operational burden for manufacturers. The global supply chain disruptions experienced in recent years have also impacted the availability and cost of raw materials for coating formulations, as well as critical components for manufacturing the machines themselves, leading to potential production delays and increased costs.

The North America region is projected to be a dominant force in the tablet film coating machines market, driven by its advanced pharmaceutical research and development ecosystem, substantial healthcare expenditure, and stringent quality control standards. The region benefits from a concentration of leading pharmaceutical companies and contract manufacturing organizations (CMOs) that are early adopters of innovative technologies. The presence of major market players and a robust regulatory framework that mandates high standards for drug manufacturing further solidifies North America's leading position. The United States, in particular, with its massive pharmaceutical market and significant investment in drug innovation, will be a key contributor to this dominance.

From a segment perspective, the Film Coating application is expected to lead the market. This is primarily due to its versatility and the critical role it plays in enhancing drug efficacy, patient compliance, and product aesthetics. Film coating offers a wide range of benefits, including taste masking, odor masking, protection from environmental factors (light, moisture), modification of drug release profiles (immediate, delayed, sustained), and improved swallowability. As pharmaceutical companies continue to develop more sophisticated drug formulations, particularly those requiring controlled or targeted release mechanisms, the demand for advanced film coating technologies will only intensify.

The Perforated Coating Pan and Fluidized Bed Coater types are also anticipated to witness significant growth and contribute to market dominance. These advanced coating systems offer several advantages over traditional standard coating pans, including:

The historical period (2019-2024) has seen a steady rise in the adoption of these advanced coating types as manufacturers recognized their benefits in improving product quality and operational efficiency. The base year of 2025 marks a point where these technologies are becoming increasingly mainstream, and the forecast period (2025-2033) will witness their widespread implementation across the industry, solidifying their dominant position in the tablet film coating machines market.

The tablet film coating machines industry is propelled by several key growth catalysts. The escalating global demand for pharmaceuticals, driven by an aging population and rising chronic disease prevalence, directly translates to a higher need for efficient tablet manufacturing solutions. Innovations in drug formulation, such as targeted and controlled-release technologies, necessitate advanced film coating capabilities. Furthermore, increasing regulatory stringency worldwide emphasizes product quality and uniformity, pushing manufacturers towards sophisticated coating machinery. The growing trend of outsourcing pharmaceutical manufacturing to CMOs also stimulates demand for advanced coating equipment.

This comprehensive report on Tablet Film Coating Machines delves into the intricate dynamics of the global market. It provides an in-depth analysis of market trends, drivers, and restraints, painting a clear picture of the industry landscape. With a study period spanning from 2019-2033, and a base year of 2025, the report meticulously forecasts market growth, offering valuable insights into the estimated value of USD 500 million in 2025 and its projected reach towards USD 900 million by 2033. The report meticulously dissects key segments such as Type (Standard Coating Pan, Perforated Coating Pan, Fluidized Bed Coater) and Application (Sugar Coating, Film Coating, Others), highlighting their respective market contributions and growth potential. It also examines significant industry developments and identifies leading players, providing a holistic understanding of the market's present and future trajectory.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include O’Hara Technologies, ACG, Glatt GmbH, Romaco Group, Thomas Processing, GEA Group Aktiengesellschaft, Syntegon Technology, L.B. Bohle, DIOSNA (LINXIS Group), Gebrüder Lödige, Freund-Vector Corporation, IMA SpA, SaintyCo, Jornen Machinery Co., Ltd., United Pharmatek LLC, Nano Pharm Tech Machinery Equipment, Zhejiang Xiaolun Intelligent Manufacturing Co., Ltd., Shangdong SMA Pharmatech, Hualian Pharmaceutical Machinery, Yenchen Machinery Co., Ltd, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Tablet Film Coating Machines," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Tablet Film Coating Machines, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.