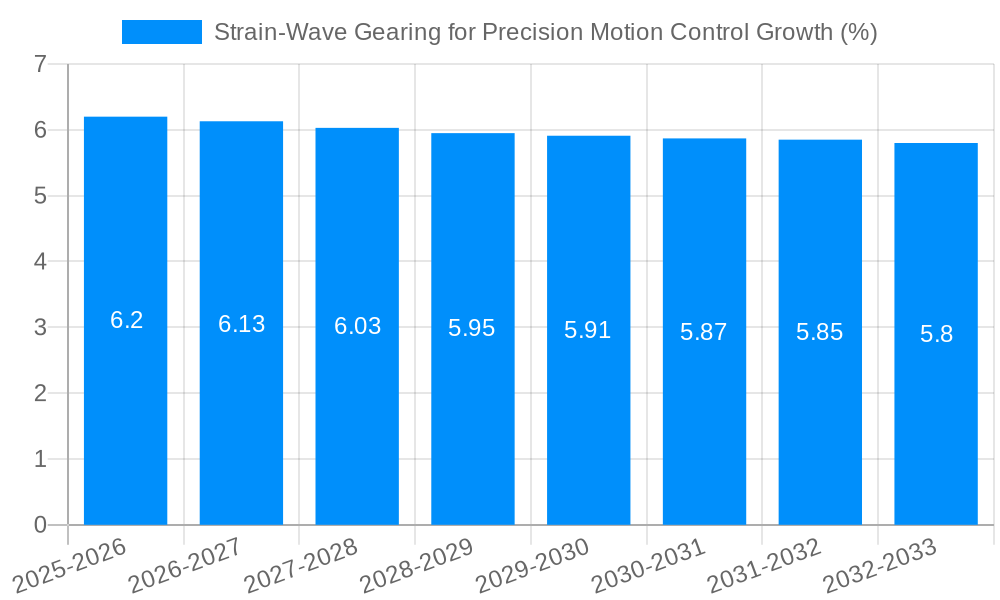

1. What is the projected Compound Annual Growth Rate (CAGR) of the Strain-Wave Gearing for Precision Motion Control?

The projected CAGR is approximately 6.2%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Strain-Wave Gearing for Precision Motion Control

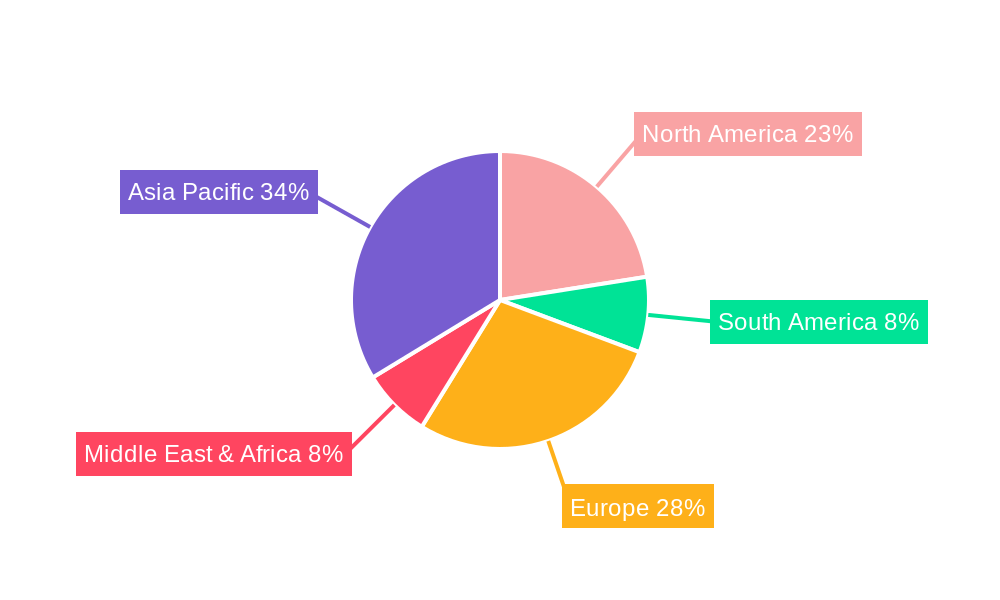

Strain-Wave Gearing for Precision Motion ControlStrain-Wave Gearing for Precision Motion Control by Application (Industry Robot, Semiconductor Equipment, Flat Panel Equipment, Machine Tools, Optical Machine, Printing, Bookbinding and Paper Machine, Metal Working Machine, Medical Equipment, Space Equipment), by Type (Cup Style, Hat Style, Pancake Style), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

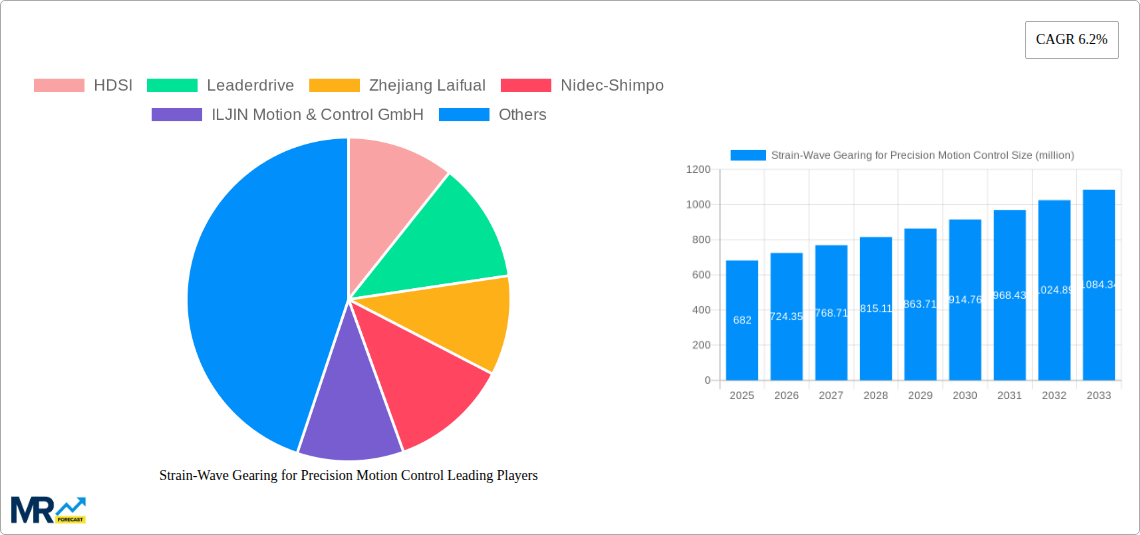

The Strain-Wave Gearing for Precision Motion Control market is poised for substantial expansion, projected to reach a valuation of $682 million by 2025, driven by a robust Compound Annual Growth Rate (CAGR) of 6.2% throughout the forecast period of 2025-2033. This significant growth is underpinned by the increasing demand for high-precision motion control solutions across a multitude of advanced industries. Key applications such as industrial robots, semiconductor equipment, and flat panel display manufacturing are primary catalysts, requiring the exceptional accuracy, compact design, and zero-backlash characteristics offered by strain-wave gearing. The burgeoning automation trend and the continuous miniaturization of electronic components necessitate gearing solutions that can deliver superior performance in confined spaces, a niche where strain-wave gears excel. Furthermore, the growing adoption of advanced manufacturing techniques and the development of next-generation medical and aerospace equipment are expected to sustain this upward trajectory, solidifying strain-wave gearing as an indispensable component for achieving sophisticated motion control.

The market's dynamic landscape is shaped by a confluence of technological advancements and evolving industrial needs. While the intrinsic performance benefits of strain-wave gearing serve as major drivers, the market also faces certain restraints. These might include the initial cost of advanced units compared to traditional gearing, the need for specialized manufacturing expertise, and the ongoing development of alternative high-precision motion control technologies. However, the versatility in form factors, including cup style, hat style, and pancake style, alongside the expanding array of applications like machine tools, optical machinery, and even specialized printing and bookbinding equipment, ensures broad market penetration. The competitive ecosystem is populated by both established global players and emerging regional manufacturers, fostering innovation and driving market efficiencies. Strategic collaborations, product development focused on enhanced durability and efficiency, and expanding into rapidly growing geographical regions like Asia Pacific will be crucial for sustained success in this precision-driven market.

Here's a unique report description on Strain-Wave Gearing for Precision Motion Control, incorporating your specified parameters:

The global Strain-Wave Gearing for Precision Motion Control market is poised for significant expansion, projected to reach $1.5 billion by 2033, demonstrating a robust Compound Annual Growth Rate (CAGR) of approximately 7.8% during the forecast period (2025-2033). The base year of 2025 stands as a critical juncture, reflecting a dynamic market shaped by accelerating automation across diverse industrial landscapes. Historical data from 2019-2024 highlights a steady upward trajectory, driven by increasing demand for highly accurate and compact motion solutions. The market's evolution is marked by a growing emphasis on miniaturization, enhanced power density, and superior backlash reduction, all of which are hallmarks of strain-wave gearing technology. As industries move towards more sophisticated and efficient manufacturing processes, the inherent advantages of strain-wave gears – their ability to achieve extremely high gear ratios in a single stage, compact form factor, and zero or near-zero backlash – are becoming indispensable. This trend is further amplified by the increasing adoption of collaborative robots and advanced automation in sectors previously reliant on traditional gearing systems. The study period 2019-2033 encompasses a transformative era where technological advancements in materials science and manufacturing techniques are continuously refining strain-wave gear performance, leading to wider application possibilities. The estimated market valuation for 2025 serves as a strong indicator of the immediate growth potential and the foundational market size upon which future projections are built. This report will delve into the intricate interplay of these factors, providing a comprehensive outlook on the market's trajectory.

Several powerful forces are propelling the growth of the Strain-Wave Gearing for Precision Motion Control market. Foremost among these is the insatiable demand for increased automation and robotics. The pervasive integration of industrial robots, particularly in sectors like automotive manufacturing, electronics assembly, and logistics, necessitates highly precise and compact motion components. Strain-wave gears, with their ability to deliver exceptional accuracy and torque density in a small footprint, are ideally suited for robotic joints and end-effectors. Furthermore, the relentless pursuit of miniaturization and weight reduction in sophisticated equipment, such as medical devices, drones, and aerospace components, is a significant driver. Strain-wave gearing’s inherently compact design allows for the development of smaller, lighter, and more maneuverable systems without compromising performance. The burgeoning growth of the semiconductor and flat panel display industries also plays a crucial role. These sectors demand ultra-high precision in their manufacturing processes, requiring actuators with extremely low backlash and high positional accuracy, which strain-wave gears excel at providing. This is further underscored by the need for advanced precision optics and machine tools, where even minute deviations can impact product quality. The consistent push for improved efficiency and reduced energy consumption in industrial machinery also favors the adoption of strain-wave gears, which generally exhibit high efficiency.

Despite its promising growth, the Strain-Wave Gearing for Precision Motion Control market faces several challenges and restraints that could temper its full potential. A primary concern revolves around manufacturing complexity and cost. The intricate design and precise manufacturing tolerances required for strain-wave gears can lead to higher production costs compared to more conventional gearing systems. This can be a barrier to adoption in cost-sensitive applications or for smaller enterprises. Another significant challenge lies in limited torque capacity and speed limitations for certain high-power or high-speed applications. While strain-wave gears offer excellent torque density, they might not be suitable for extremely heavy-duty industrial machinery requiring massive torque output or extremely high rotational speeds, where traditional gearboxes might still be preferred. Lubrication and maintenance requirements can also pose a challenge. The unique operating mechanism of strain-wave gears necessitates specific lubrication strategies and potentially more frequent maintenance intervals to ensure optimal performance and longevity, which can increase the total cost of ownership. Technical expertise and specialized knowledge are also required for the proper design, selection, and integration of strain-wave gearing systems, which might be a limiting factor for some end-users. Finally, competition from alternative precision motion technologies, such as planetary gearboxes and direct-drive motors, presents a continuous competitive pressure.

The Asia-Pacific region, particularly China, is anticipated to emerge as a dominant force in the Strain-Wave Gearing for Precision Motion Control market, driven by a confluence of factors. By 2025, China's advanced manufacturing capabilities, coupled with its massive domestic demand for automation across various sectors, will solidify its leadership. The country's substantial investment in industrial robots and its prominent position in the global semiconductor equipment and flat panel equipment manufacturing industries make it a natural hub for strain-wave gearing adoption. The burgeoning domestic production of sophisticated machinery, including machine tools and medical equipment, further fuels this demand.

Within the Asia-Pacific region, key segments are poised for significant market share:

The dominance of the Asia-Pacific region and these specific segments is further bolstered by the presence of major global and local manufacturers and a robust supply chain, creating an ecosystem conducive to market growth.

The Strain-Wave Gearing for Precision Motion Control industry is experiencing accelerated growth driven by several key catalysts. The escalating global adoption of automation and robotics across all industrial sectors is a primary driver, as strain-wave gears offer unparalleled precision and compact design for robotic joints and manipulators. The increasing demand for miniaturized and lightweight components in medical equipment, aerospace, and portable electronics further fuels adoption. Technological advancements leading to improved performance, such as higher torque density and reduced backlash, along with innovative manufacturing techniques, are making strain-wave gears more accessible and versatile. The sustained growth in the semiconductor and flat panel display industries, which rely heavily on ultra-precise motion control, also acts as a significant growth catalyst.

This comprehensive report offers an in-depth analysis of the Strain-Wave Gearing for Precision Motion Control market from 2019 to 2033, providing a granular view of its trajectory. With a base year of 2025, the report meticulously details market size, growth rates, and future projections, with an estimated market value of $1.5 billion by 2033. It dissects the market by key applications such as Industry Robot, Semiconductor Equipment, Flat Panel Equipment, Machine Tools, Optical Machine, Printing, Bookbinding and Paper Machine, Metal Working Machine, Medical Equipment, and Space Equipment, alongside exploring the prevalence of different types including Cup Style, Hat Style, and Pancake Style. The report delves into crucial industry developments, identifying significant technological advancements and strategic moves by leading companies. It provides an exhaustive list of leading players, including HDSI, Leaderdrive, Nidec-Shimpo, and many others, offering insights into their market positioning. Furthermore, the report scrutinizes the driving forces, challenges, and growth catalysts shaping the market landscape, with a particular focus on the dominant role of the Asia-Pacific region and its key segments. This report is an essential resource for stakeholders seeking to understand the current state and future potential of the precision motion control market.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 6.2% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 6.2%.

Key companies in the market include HDSI, Leaderdrive, Zhejiang Laifual, Nidec-Shimpo, ILJIN Motion & Control GmbH, Shenzhen Han's Motion Technology, OVALO GmbH, Beijing CTKM Harmonic Drive, TC Drive, Hiwin Corporation, KHGEARS, Ningbo Zhongda Leader Intelligent Transmission, Sichuan Fude Robot, Wanshsin Seikou, Main Drive, Reach Machinery, KOFON, SBB Tech, Too Eph Transmission Technology, BHDI, Guangzhou Haozhi Industrial, Schaeffler, GAM Enterprise, SPG, BENRUN Robot, Cone Drive, Jiangsu Guomao Reducer, Guohua Hengyuan Tech Dev Co., Ltd., LI-MING Machinery Co., Ltd..

The market segments include Application, Type.

The market size is estimated to be USD 682 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Strain-Wave Gearing for Precision Motion Control," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Strain-Wave Gearing for Precision Motion Control, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.