1. What is the projected Compound Annual Growth Rate (CAGR) of the Steel-aluminum Composite Conductor Rail?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Steel-aluminum Composite Conductor Rail

Steel-aluminum Composite Conductor RailSteel-aluminum Composite Conductor Rail by Application (Port, Shipbuilding Plant, Mine, Theme Park), by Type (Unipolar Conductor Rail, Multistage Conductor Rail), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

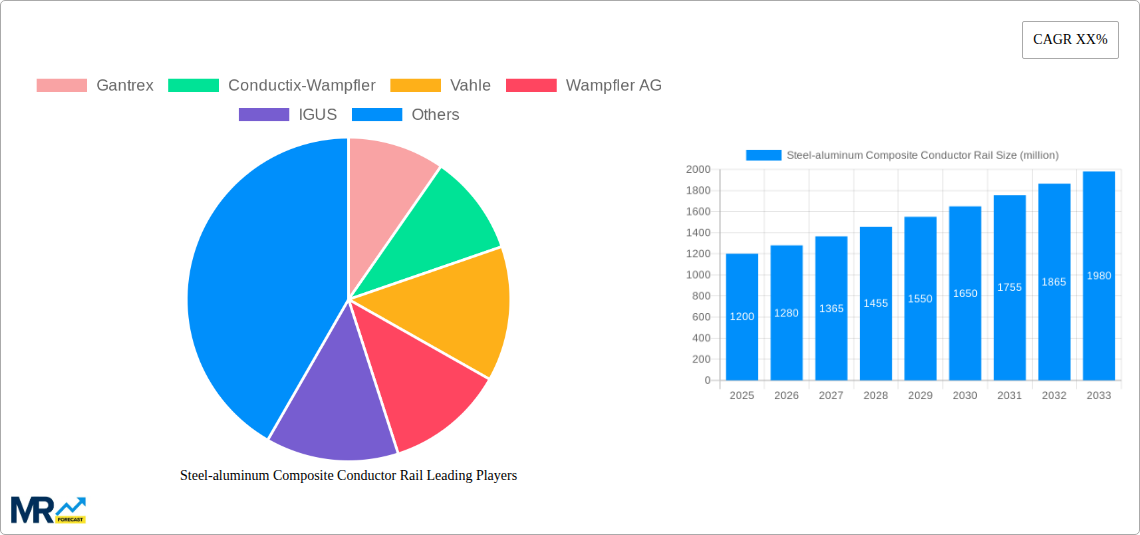

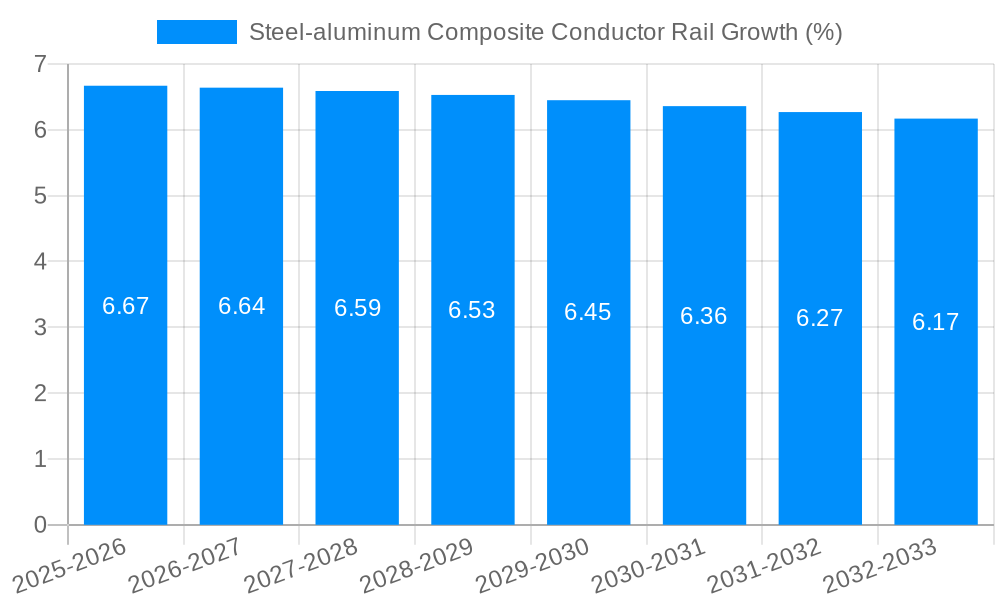

The global Steel-aluminum Composite Conductor Rail market is poised for significant expansion, projected to reach an estimated market size of $1,200 million by 2025, with a robust Compound Annual Growth Rate (CAGR) of approximately 6.5% anticipated over the forecast period of 2025-2033. This upward trajectory is primarily fueled by the escalating demand for efficient and reliable power supply solutions across a multitude of industrial applications. The inherent advantages of steel-aluminum composite conductor rails, including their superior conductivity, enhanced corrosion resistance, and extended lifespan compared to traditional materials, make them a preferred choice for demanding environments. Key drivers include the burgeoning shipbuilding industry, which requires extensive and dependable electrification for port operations and vessel construction, and the mining sector, where the need for safe and continuous power delivery in challenging conditions is paramount. Furthermore, the increasing adoption of advanced automation and electrification in theme parks and other entertainment venues is also contributing to market growth.

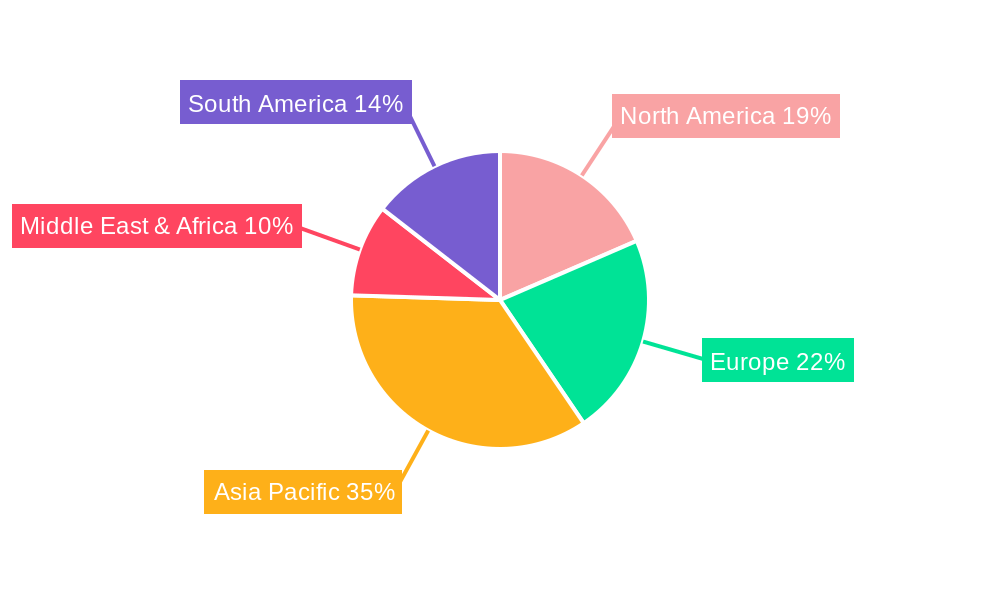

The market is segmented by application into Ports, Shipbuilding Plants, Mines, and Theme Parks, with Ports and Shipbuilding Plants expected to represent the largest share due to ongoing infrastructure development and fleet expansion globally. By type, the market is divided into Unipolar Conductor Rails and Multistage Conductor Rails, with both segments witnessing steady growth, catering to diverse power transmission needs. Geographically, Asia Pacific, particularly China and India, is emerging as a dominant region, driven by rapid industrialization, massive infrastructure projects, and substantial investments in manufacturing capabilities. North America and Europe also represent significant markets, driven by stringent safety regulations, technological advancements, and the need to upgrade existing infrastructure. However, challenges such as fluctuating raw material prices and the initial capital investment required for advanced conductor rail systems may pose some restraints, though the long-term benefits and operational efficiencies are expected to outweigh these concerns. Key players like Gantrex, Conductix-Wampfler, and Vahle are at the forefront, innovating and expanding their offerings to meet the evolving demands of this dynamic market.

The global Steel-Aluminum Composite Conductor Rail market is poised for significant expansion, driven by an increasing demand for efficient and reliable power transmission solutions across various heavy-duty industrial applications. During the Study Period (2019-2033), the market is anticipated to witness a robust Compound Annual Growth Rate (CAGR), with the Base Year (2025) serving as a critical benchmark for evaluating its trajectory. The Estimated Year (2025) confirms the immediate growth potential, while the Forecast Period (2025-2033) outlines the sustained expansion anticipated. Historical data from the Historical Period (2019-2024) indicates a foundational adoption phase characterized by increasing awareness of the composite conductor rail's advantages over traditional copper or solely aluminum systems.

A key market insight is the growing preference for these composite rails due to their optimized balance of conductivity, mechanical strength, and cost-effectiveness. Aluminum, known for its lightweight nature and good conductivity, is complemented by the superior mechanical strength and durability of steel. This synergistic combination addresses the limitations of using either material exclusively, especially in demanding environments. The market size, estimated to be in the tens of millions in the Base Year (2025), is projected to surge into the hundreds of millions by the end of the Forecast Period (2025-2033). This growth is intrinsically linked to the expansion of infrastructure projects in developing economies and the ongoing modernization of industrial facilities globally. Furthermore, advancements in manufacturing techniques are contributing to improved product quality and a wider range of available specifications, catering to diverse application needs. The report will delve into the specific market dynamics, including segmentation by type and application, to provide a granular understanding of this evolving sector.

The surge in demand for steel-aluminum composite conductor rails is being propelled by a confluence of critical factors, primarily centered on the need for enhanced operational efficiency and reduced long-term costs in industrial settings. The inherent properties of these composite rails – superior conductivity compared to pure steel and enhanced mechanical strength and lower cost compared to pure copper – make them an attractive proposition for a wide spectrum of heavy-duty applications. For instance, in ports and shipbuilding plants, where overhead cranes and material handling equipment operate continuously, the need for reliable and uninterrupted power supply is paramount. Composite conductor rails offer a robust solution that can withstand the rigors of these environments while minimizing power loss, directly translating into improved productivity and energy savings.

Moreover, the increasing global focus on infrastructure development, particularly in burgeoning economies, is a significant driver. As more ports are developed, mines are expanded, and large-scale industrial complexes are established, the demand for reliable and cost-effective electrical infrastructure, including conductor rails, escalates. The inherent durability and resistance to corrosion of the steel-aluminum composite structure also contribute to a longer service life, thereby reducing maintenance costs and replacement frequency. This translates into a lower total cost of ownership for end-users, making it a compelling choice for long-term investments. The escalating price volatility of copper further amplifies the appeal of steel-aluminum composite conductor rails as a more stable and economically viable alternative for electrical power distribution.

Despite the promising growth trajectory, the steel-aluminum composite conductor rail market is not without its challenges and restraints. A significant hurdle pertains to the complex manufacturing process involved in creating a reliable metallurgical bond between steel and aluminum. Ensuring consistent and durable adhesion is crucial to prevent delamination and maintain the electrical and mechanical integrity of the conductor rail over its lifespan. Any compromise in this bonding process can lead to premature failure and diminished performance, thereby impacting the reputation of the technology and specific manufacturers. This complexity can also translate into higher initial production costs compared to simpler conductor systems, potentially limiting adoption in price-sensitive markets.

Furthermore, the perceived technical complexity of installation and maintenance can act as a restraint for some end-users, especially those accustomed to more conventional conductor systems. Specialized training and equipment might be required for optimal installation, and troubleshooting can demand a deeper understanding of the composite material's properties. The availability of skilled labor for these specialized tasks can be a limiting factor in certain regions. Additionally, while the cost-effectiveness is a major advantage, the initial capital outlay for these advanced systems can still be a barrier for smaller enterprises or projects with tight budgets. Regulatory standards and certifications specific to composite materials in electrical applications are also evolving, and any lack of standardization or perceived non-compliance can create uncertainty and slow down market penetration. The market needs to address these concerns through education, standardization efforts, and the development of more accessible installation and maintenance protocols to unlock its full potential.

The Port application segment is anticipated to emerge as a dominant force in the global Steel-Aluminum Composite Conductor Rail market during the Study Period (2019-2033). This dominance is driven by the sheer scale and operational intensity of port infrastructure worldwide. Ports are characterized by continuous movement of heavy cargo, necessitating reliable and high-capacity power supply systems for cranes, automated guided vehicles (AGVs), and other material handling equipment. The robust mechanical strength of steel-aluminum composite conductor rails, combined with their excellent conductivity, makes them ideally suited to meet these demanding operational requirements.

Geographically, Asia-Pacific is expected to be a key region contributing significantly to the market's dominance, particularly driven by China and Southeast Asian nations. This region's rapid industrialization, extensive port development projects, and substantial investments in trade infrastructure create a fertile ground for the adoption of advanced conductor rail systems. The ongoing expansion of major shipping routes and the increasing volume of global trade further bolster the demand from port operators. Countries within the Middle East also present a strong growth potential due to significant investments in port modernization and expansion to diversify their economies and bolster their roles as global trade hubs. The Multistage Conductor Rail type is also anticipated to witness substantial growth within these applications, offering the flexibility to power multiple pieces of equipment along the same track, thereby optimizing space and infrastructure within busy port environments.

The steel-aluminum composite conductor rail industry's growth is fueled by several catalysts. The relentless drive for energy efficiency across all industrial sectors is a primary driver, as these composite rails minimize power loss during transmission. Furthermore, the escalating cost of copper is making aluminum-based composite solutions increasingly economically attractive. The ongoing global infrastructure development, particularly in emerging economies, is creating a significant demand for reliable power infrastructure. Advancements in material science and manufacturing processes are also leading to improved product performance and cost-competitiveness, further propelling adoption. The increasing trend towards automation in industries like ports and mining necessitates robust and reliable power solutions, which composite conductor rails effectively provide.

This comprehensive report provides an in-depth analysis of the global Steel-Aluminum Composite Conductor Rail market, covering the Study Period (2019-2033). It meticulously examines market trends, growth drivers, and potential restraints, offering valuable insights into the sector's evolution. The report delves into the specific market dynamics of key application segments like Ports, Shipbuilding Plants, Mines, and Theme Parks, as well as the prominent types, including Unipolar and Multistage Conductor Rails. With a Base Year (2025) and Estimated Year (2025) valuation, the report offers robust market size estimations and forecasts for the Forecast Period (2025-2033), building upon historical data from 2019-2024. It highlights dominant regions and countries poised for significant growth and profiles leading industry players, providing a holistic view of the competitive landscape. Furthermore, the report details significant industry developments and offers strategic recommendations for stakeholders, making it an indispensable resource for understanding and navigating this dynamic market.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Gantrex, Conductix-Wampfler, Vahle, Wampfler AG, IGUS, Kundel Industries, Runway Rail, U-MEC Thailand, Insul-8 Corporation, Tianjin Yufei Electromechanical Equipment Co., Ltd, Simalube India, Electromotive Systems, Zhejiang GRL Electric Technology Co., Ltd., Power Electronics International Inc., REEL (Renforcement d'Equipements Electriques), BUSBAR UK, Alfa-Rail SRL, .

The market segments include Application, Type.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Steel-aluminum Composite Conductor Rail," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Steel-aluminum Composite Conductor Rail, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.