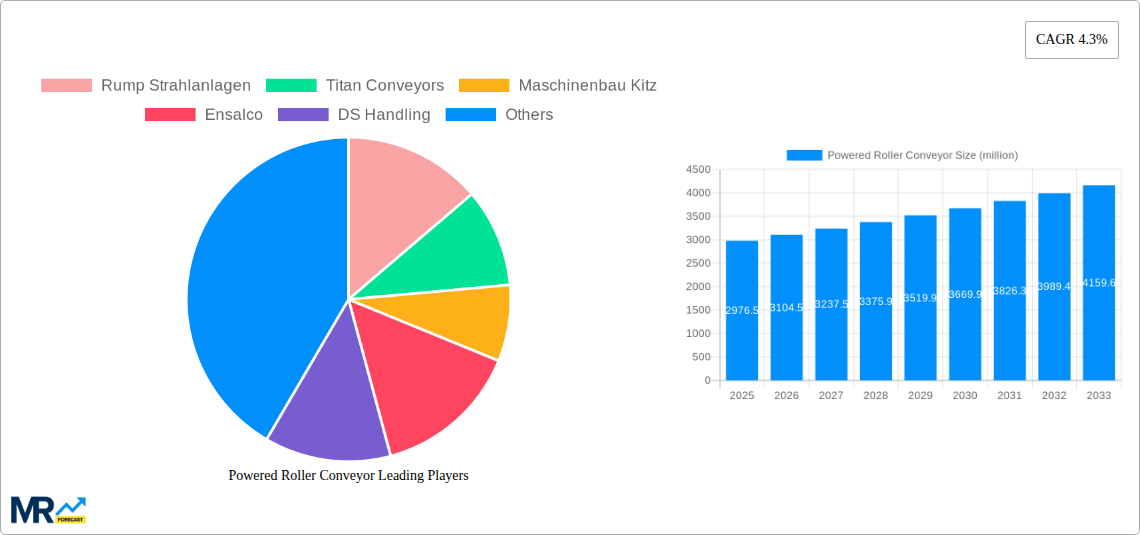

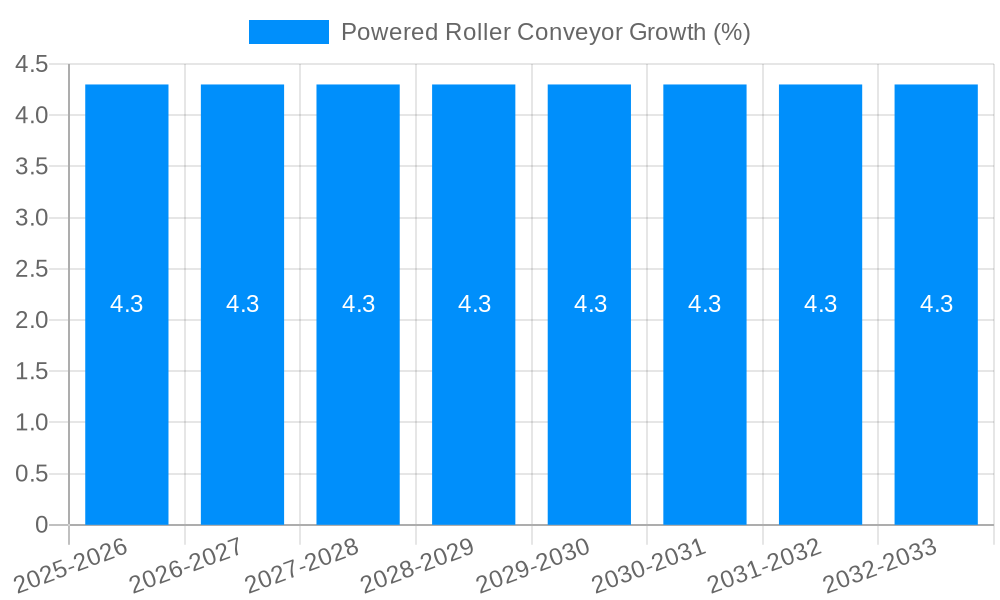

1. What is the projected Compound Annual Growth Rate (CAGR) of the Powered Roller Conveyor?

The projected CAGR is approximately 4.3%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Powered Roller Conveyor

Powered Roller ConveyorPowered Roller Conveyor by Type (Low Carbon Steel Material, Galvanized Steel Material, Stainless Steel Material), by Application (Conveyor Systems, Structural Conveyor Systems, Paint Preparation), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

The global Powered Roller Conveyor market is projected for robust growth, with an estimated market size of $2,976.5 million in 2025. This growth is fueled by a steady Compound Annual Growth Rate (CAGR) of 4.3% anticipated over the forecast period of 2025-2033. The increasing demand for automation across various industrial sectors, particularly in logistics and manufacturing, serves as a primary driver. Businesses are investing in efficient material handling solutions to enhance productivity, reduce labor costs, and streamline supply chain operations. The adoption of advanced technologies, including smart sensors, IoT integration, and data analytics for predictive maintenance, is also contributing to market expansion by offering greater operational visibility and control. Furthermore, the growth of e-commerce, with its complex warehousing and distribution needs, directly translates into a higher demand for reliable and scalable conveyor systems.

The market is segmented by material, with Low Carbon Steel, Galvanized Steel, and Stainless Steel materials catering to diverse application requirements and environmental conditions. Applications such as Conveyor Systems, Structural Conveyor Systems, and Paint Preparation highlight the versatility and widespread utility of powered roller conveyors. While the market is experiencing significant expansion, potential restraints include high initial investment costs for sophisticated systems and the need for skilled personnel for installation and maintenance. However, these challenges are being mitigated by the long-term cost savings and operational efficiencies that powered roller conveyors deliver. Key players like Rump Strahlanlagen, Titan Conveyors, and Hytrol are actively innovating and expanding their product portfolios to meet evolving industry demands and maintain a competitive edge in this dynamic market.

Here's a report description on Powered Roller Conveyors, incorporating your specified elements:

This comprehensive report provides an in-depth analysis of the global Powered Roller Conveyor market, encompassing historical trends, current market dynamics, and future projections. The study period spans from 2019 to 2033, with a detailed examination of the historical period (2019-2024) and a robust forecast period (2025-2033), using 2025 as both the base and estimated year. The report will explore the market's growth trajectory, driven by evolving industrial needs and technological advancements. We will delve into the various types of powered roller conveyors, including those constructed from Low Carbon Steel Material, Galvanized Steel Material, and Stainless Steel Material, as well as their applications in Conveyor Systems, Structural Conveyor Systems, and Paint Preparation. Furthermore, the report will highlight industry developments and the strategic initiatives undertaken by key players in the market. The projected market size is anticipated to reach significant figures, with valuations expected in the millions of units across various segments.

The powered roller conveyor market is poised for substantial growth, driven by an increasing demand for efficient material handling solutions across a multitude of industries. From 2019 to 2024, the market witnessed steady expansion, fueled by the automation initiatives within manufacturing and logistics sectors. The base year, 2025, serves as a critical juncture, with projections indicating a continued upward trend throughout the forecast period extending to 2033. A key insight from our analysis is the escalating adoption of powered roller conveyors in e-commerce fulfillment centers, where speed and accuracy in sorting and transporting packages are paramount. This surge is directly linked to the exponential growth of online retail, necessitating sophisticated internal logistics. Furthermore, the manufacturing sector's ongoing embrace of Industry 4.0 principles, emphasizing smart factories and interconnected production lines, is a significant driver. This includes the integration of advanced robotics and automated guided vehicles (AGVs) that often interface seamlessly with powered roller conveyor systems. The demand for customization and modular designs is also a prevailing trend, allowing businesses to tailor conveyor solutions to their specific operational layouts and product types, from lightweight components to heavier industrial goods. The increasing focus on workplace safety and ergonomics is another important trend, as powered roller conveyors can significantly reduce manual handling, thereby minimizing the risk of injuries. This emphasis on safer and more efficient operations is a core tenet shaping the future of material handling. The environmental consciousness also plays a role, with manufacturers developing more energy-efficient roller conveyor systems and exploring sustainable material options. The market is expected to witness a substantial value in the millions of units as these trends solidify and drive wider adoption globally.

Several potent forces are actively propelling the growth of the powered roller conveyor market. The relentless pursuit of operational efficiency and cost reduction across industries remains a primary catalyst. Businesses are increasingly recognizing that effective material handling is not merely a supporting function but a critical component of their overall productivity and profitability. Powered roller conveyors automate the movement of goods, significantly reducing labor costs associated with manual transportation and minimizing errors that can lead to costly rework or product damage. The burgeoning e-commerce sector, as mentioned, is a monumental driver, creating an unprecedented demand for high-throughput, reliable, and flexible conveyor systems to manage the complexities of warehousing and distribution. This surge in online shopping translates directly into a need for more sophisticated material handling infrastructure. Moreover, the global push towards advanced manufacturing and smart factories, often referred to as Industry 4.0, is a significant influencer. Powered roller conveyors are integral to these automated environments, enabling seamless integration with robotics, AI-driven sorting systems, and other intelligent technologies. Their ability to handle a wide range of products, from small components to large pallets, with precision and speed makes them indispensable for modern production lines and logistics hubs. The increasing complexity of supply chains, driven by globalization and diverse product portfolios, further necessitates robust and adaptable material handling solutions like powered roller conveyors to maintain agility and responsiveness.

Despite the strong growth trajectory, the powered roller conveyor market is not without its challenges and restraints. One significant hurdle is the substantial initial capital investment required for implementing advanced powered roller conveyor systems. For small and medium-sized enterprises (SMEs), this upfront cost can be a deterrent, even with the long-term benefits of increased efficiency and reduced labor costs. The need for specialized maintenance and skilled personnel to operate and service these sophisticated systems also presents a challenge. Malfunctions or downtime can lead to significant operational disruptions and productivity losses, necessitating a well-trained technical workforce. Furthermore, the integration of powered roller conveyors with existing legacy systems can be complex and costly, requiring considerable planning and potential retrofitting. The dynamic nature of some industrial environments, where frequent layout changes or product mix variations occur, can also pose a challenge. While modular designs are evolving, adapting rigid conveyor systems to highly fluid operations might require significant reconfiguration or replacement. Moreover, the energy consumption of continuously operating powered roller conveyors, especially in large-scale installations, is a growing concern for businesses focused on sustainability and reducing operational expenses. Developing more energy-efficient solutions and optimizing system usage are key areas that need continuous attention. Finally, the availability of alternative material handling solutions, such as automated guided vehicles (AGVs) and robotic arms, while often complementary, can also be perceived as competitive in certain niche applications, potentially limiting the market share of pure roller conveyor systems.

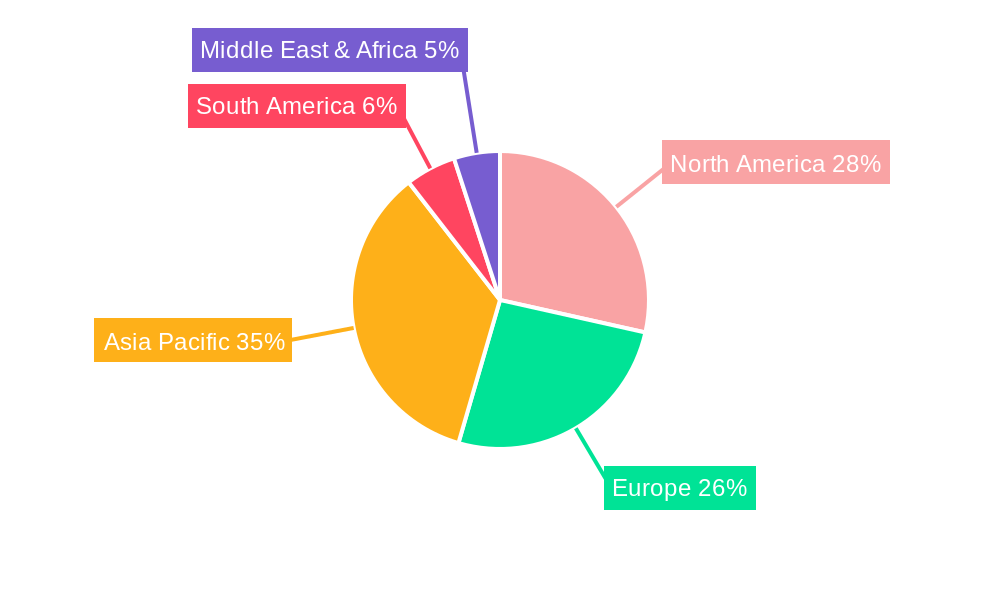

The global Powered Roller Conveyor market is characterized by regional dominance and segment leadership, with significant potential for growth across various geographical and application areas.

Dominant Segments:

Low Carbon Steel Material: This segment is projected to hold a substantial market share due to its cost-effectiveness, durability, and widespread availability. Low carbon steel is the workhorse of many industrial applications, offering a robust solution for a broad range of material handling needs. Its inherent strength makes it suitable for carrying heavy loads in demanding environments such as general manufacturing, warehousing, and distribution centers. The ease of fabrication and modification also contributes to its popularity, allowing for customized conveyor designs to meet specific operational requirements. The accessibility of this material globally ensures a steady supply chain and competitive pricing, making it an attractive option for businesses seeking reliable yet economical material handling solutions. The projected market value in this segment is expected to be in the millions of units.

Conveyor Systems: This application segment encompasses the broadest use of powered roller conveyors, serving as the backbone for automated material flow in numerous industries. The increasing adoption of automated warehousing and fulfillment operations, driven by the e-commerce boom, is a primary growth engine. These systems are crucial for sorting, accumulating, and transporting goods efficiently within distribution networks. The demand for seamless integration with other logistics technologies, such as Warehouse Management Systems (WMS) and automated sorting equipment, further solidifies the dominance of this application. From inbound receiving to outbound shipping, powered roller conveyors facilitate a continuous and optimized workflow, minimizing bottlenecks and maximizing throughput. The sheer volume of goods moved daily across global supply chains ensures a perpetual demand for these fundamental Conveyor Systems.

Dominant Regions:

North America: This region, particularly the United States, is expected to be a leading market for powered roller conveyors. The established industrial base, coupled with a strong emphasis on automation and advanced manufacturing, drives significant demand. The robust e-commerce sector in North America, with its high penetration rates and continuous growth, necessitates advanced logistics and warehousing solutions, making powered roller conveyors an indispensable component. Investment in smart factory technologies and Industry 4.0 initiatives further propels the adoption of sophisticated material handling systems. The presence of major manufacturing hubs and distribution networks across various sectors, including automotive, aerospace, and consumer goods, ensures a consistent need for efficient and reliable conveyor solutions. The regulatory environment also encourages investments in automation to improve safety and productivity.

Europe: Europe presents another significant market, driven by a strong manufacturing sector, particularly in Germany, the UK, and France, and a concerted effort towards industrial modernization and sustainability. The region's advanced logistics infrastructure and the growing adoption of automation in manufacturing and warehousing operations contribute to sustained demand. The increasing focus on energy efficiency and environmentally friendly solutions is also influencing the design and adoption of powered roller conveyors, with manufacturers developing more energy-conscious models. The expansion of e-commerce and the need for efficient supply chain management across diverse industries, from automotive and pharmaceuticals to food and beverage, further bolster the market. The stringent safety regulations in many European countries also favor automated material handling solutions that reduce manual labor and associated risks.

The interplay between these dominant segments and regions, particularly the synergy between Low Carbon Steel Material in Conveyor Systems within the North American and European markets, is expected to represent a substantial portion of the global powered roller conveyor market, with valuations anticipated in the millions of units throughout the forecast period.

The powered roller conveyor industry is experiencing significant growth due to several key catalysts. The relentless drive for operational efficiency and cost optimization across diverse industrial sectors is a primary motivator. Businesses are increasingly investing in automation to streamline material handling, reduce labor dependency, and minimize errors, directly boosting the demand for powered roller conveyors. The exponential growth of the e-commerce sector and the subsequent expansion of fulfillment and distribution centers globally create an insatiable need for high-throughput, reliable, and flexible conveyor solutions. Furthermore, the widespread adoption of Industry 4.0 principles and the development of smart factories are integrating powered roller conveyors into more sophisticated automated systems, enhancing their utility and appeal.

The powered roller conveyor market is populated by a number of key players who are continuously innovating and expanding their product offerings. Some of the leading companies in this sector include:

The powered roller conveyor sector has witnessed numerous significant developments over the past few years, contributing to its evolution and market expansion. These advancements reflect a commitment to innovation and meeting the evolving needs of various industries.

This report offers a panoramic view of the powered roller conveyor market, providing granular insights that extend beyond mere statistics. It delves into the intricate interplay of technological advancements, evolving industry demands, and the strategic responses of leading market participants. The analysis encompasses a thorough examination of market segmentation by material type (Low Carbon Steel, Galvanized Steel, Stainless Steel) and application (Conveyor Systems, Structural Conveyor Systems, Paint Preparation), revealing the nuanced growth patterns and dominance within each category. Furthermore, the report forecasts market expansion with projections extending to 2033, using 2025 as a pivotal base and estimated year, and considering the historical period from 2019-2024 to establish a robust baseline. The detailed exploration of driving forces, challenges, and growth catalysts equips stakeholders with a comprehensive understanding of the market's present landscape and future trajectory, ensuring informed decision-making for businesses operating within or looking to enter this dynamic sector. The projected market value is expected to be in the millions of units, underscoring the significant economic impact of this industry.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 4.3% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 4.3%.

Key companies in the market include Rump Strahlanlagen, Titan Conveyors, Maschinenbau Kitz, Ensalco, DS Handling, Fastrax, Wheelabrator, Hytrol, Jolinpack, Wyma, AXMANN, Rack & Roll, EQM, LEWCO, Marceau, Alvey, .

The market segments include Type, Application.

The market size is estimated to be USD 2976.5 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Powered Roller Conveyor," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Powered Roller Conveyor, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.