1. What is the projected Compound Annual Growth Rate (CAGR) of the Plastic Die Cut Lid?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Plastic Die Cut Lid

Plastic Die Cut LidPlastic Die Cut Lid by Type (Polyethylene Terephthalate (PET), Polyethylene (PE), Polypropylene (PP)), by Application (Cups, Trays, Bottles, Jars, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

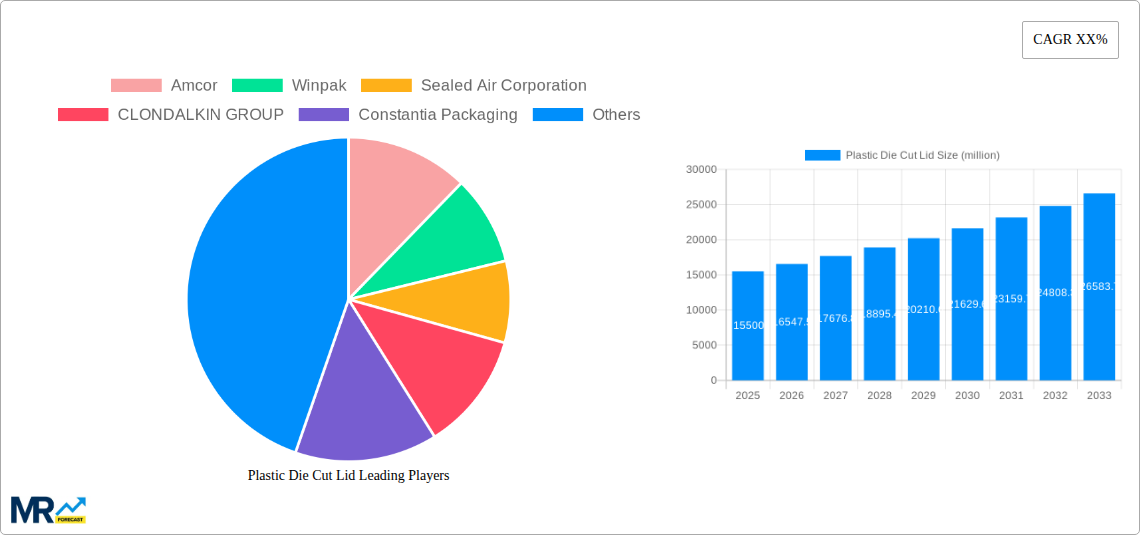

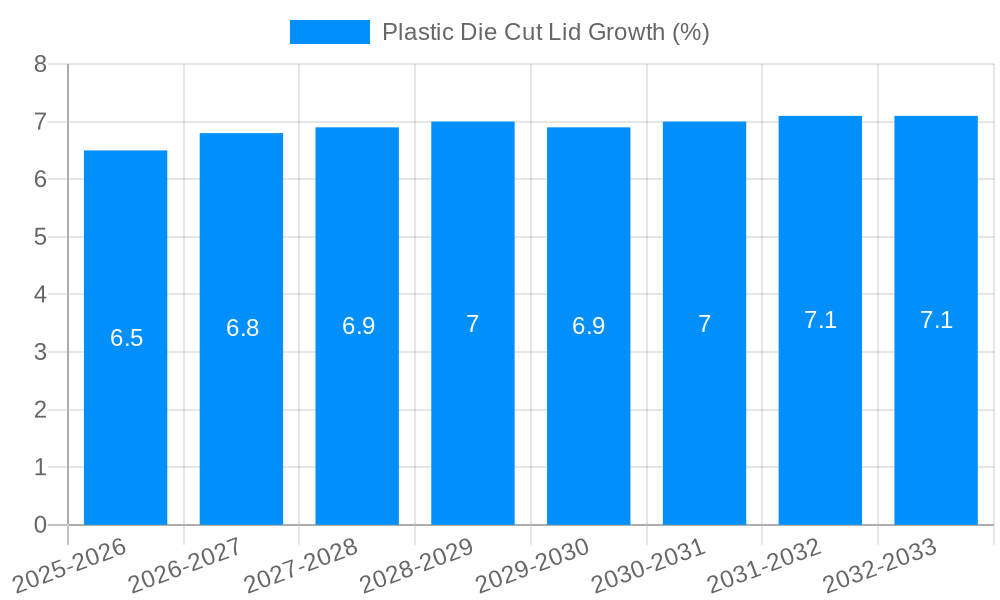

The global Plastic Die Cut Lid market is poised for significant expansion, projected to reach an estimated USD 15,500 million by 2025, growing at a robust Compound Annual Growth Rate (CAGR) of 6.5% through 2033. This upward trajectory is primarily fueled by the escalating demand for convenient and secure packaging solutions across the food & beverage, pharmaceutical, and personal care industries. The inherent versatility and cost-effectiveness of plastic die cut lids, particularly those made from Polyethylene Terephthalate (PET), Polyethylene (PE), and Polypropylene (PP), make them indispensable for a wide array of applications including cups, trays, bottles, and jars. The increasing consumer preference for single-serving portions and ready-to-eat meals further amplifies the need for efficient and tamper-evident lid solutions. Moreover, advancements in material science and printing technologies are enabling manufacturers to offer more sophisticated and customizable lid designs, enhancing product appeal and brand visibility, thereby contributing to market growth.

The market is experiencing dynamic shifts driven by evolving consumer expectations and regulatory landscapes. Key growth drivers include the expanding e-commerce sector, which necessitates robust secondary packaging, and the growing awareness of food safety and hygiene, leading to higher adoption of hermetically sealed packaging. Innovative barrier properties and the development of sustainable plastic alternatives are also emerging as significant trends, addressing environmental concerns and paving the way for a circular economy within the packaging industry. However, the market faces certain restraints, including fluctuating raw material prices, particularly for petrochemical derivatives, and increasing competition from alternative packaging materials like paper-based and compostable solutions. Stringent environmental regulations in certain regions may also pose challenges, pushing manufacturers towards more sustainable production processes and materials. Despite these hurdles, the market's fundamental growth is underpinned by its ability to provide a reliable, affordable, and adaptable sealing solution for a vast range of consumer goods.

Here's a report description for Plastic Die Cut Lids, incorporating your specific requirements:

This report offers an in-depth examination of the global Plastic Die Cut Lid market, meticulously analyzing trends, drivers, challenges, and the competitive landscape from 2019 to 2033. With a base year of 2025 and a forecast period extending through 2033, the study provides actionable insights for stakeholders navigating this dynamic sector. The report delves into market segmentation by material type (Polyethylene Terephthalate (PET), Polyethylene (PE), Polypropylene (PP)) and application (Cups, Trays, Bottles, Jars, Others), as well as charting crucial industry developments. The market is projected to witness significant growth, with current estimates for 2025 pointing towards a multi-million unit valuation, and further expansion anticipated in the coming decade.

The plastic die cut lid market is experiencing a significant evolution driven by a confluence of consumer preferences, technological advancements, and regulatory shifts. In the historical period of 2019-2024, the market saw steady growth, largely fueled by the expanding food and beverage industry and the increasing demand for convenient packaging solutions. As we move into the base year of 2025, a key trend dominating the landscape is the heightened focus on sustainability and recyclability. Manufacturers are increasingly investing in the development of mono-material lids and exploring advanced recycling technologies to address environmental concerns. This shift is not merely a response to consumer pressure but also a proactive strategy to comply with evolving waste management regulations in various regions. The forecast period of 2025-2033 is expected to witness a surge in demand for bio-based and compostable plastic lid alternatives, although their market penetration will be contingent on cost-effectiveness and performance parity with conventional plastics. Furthermore, there's a discernible trend towards enhanced functionality, with innovations like easy-open features, tamper-evident seals, and resealable options becoming standard rather than premium offerings. The application of advanced printing technologies, allowing for intricate branding and product information directly on the lid, is also a significant trend. This not only aids in brand differentiation but also provides a convenient platform for conveying crucial product details, such as nutritional information and expiry dates. The growing adoption of e-commerce and food delivery services further amplifies the demand for robust and secure packaging, making die cut lids an essential component in maintaining product integrity during transit. The market is also seeing a move towards thinner yet stronger lid materials, optimizing material usage and reducing overall packaging weight, contributing to both cost savings and environmental benefits. The ongoing research and development efforts are focused on creating lids that offer superior barrier properties against moisture, oxygen, and other environmental factors, thereby extending product shelf life and reducing food waste. The integration of smart packaging features, such as QR codes for traceability and interactive consumer engagement, is another emerging trend that is poised to gain traction in the coming years. The meticulous design and precision engineering of die cut lids are paramount in ensuring optimal sealing performance, preventing leaks, and maintaining product freshness, all of which are critical factors driving demand across diverse product categories.

The plastic die cut lid market is experiencing robust growth propelled by several key factors that underscore its essential role in modern commerce and consumer lifestyles. Foremost among these is the unceasing expansion of the global food and beverage sector. As populations grow and disposable incomes rise in emerging economies, the demand for packaged food and drinks continues to soar. Plastic die cut lids are indispensable for ensuring the freshness, safety, and shelf-life of a vast array of products, from dairy and desserts to ready-to-eat meals and beverages. Their ability to form a hermetic seal is critical in preventing contamination and spoilage, a paramount concern for both consumers and manufacturers. Secondly, the escalating demand for convenience and on-the-go consumption is a significant driver. Consumers increasingly seek portable and easy-to-access food and drink options, making sealed cups, trays, and bottles with reliable die cut lids a preferred choice. The rise of food delivery services and meal kit subscriptions further amplifies this trend, requiring packaging that can withstand transit and maintain product integrity until it reaches the end consumer. Technological advancements in plastic processing and material science also play a crucial role. Innovations in extrusion, thermoforming, and printing technologies enable the production of more durable, lightweight, and aesthetically pleasing die cut lids. The development of specialized barrier films and sealants enhances product protection, extending shelf life and reducing food waste, which aligns with growing consumer and regulatory concerns about sustainability. Moreover, the cost-effectiveness of plastic die cut lids compared to alternative packaging materials makes them an attractive option for manufacturers looking to optimize their packaging expenses while maintaining high quality and functionality. This economic advantage is particularly critical in highly competitive consumer markets.

Despite the strong growth trajectory, the plastic die cut lid market faces several significant challenges and restraints that could impede its full potential. The most prominent challenge is the increasing global scrutiny and regulatory pressure surrounding single-use plastics. Growing environmental awareness and concerns about plastic waste accumulation in landfills and oceans are leading to stricter regulations, including outright bans and taxes on certain types of plastic packaging. This necessitates a substantial shift towards more sustainable alternatives, which can be a costly and complex transition for many manufacturers. The cost of raw materials, which are largely derived from petroleum, is subject to volatile market fluctuations. Any significant increase in the price of these base materials can directly impact the profitability of plastic die cut lid manufacturers and potentially make them less competitive. The development and adoption of truly sustainable alternatives, such as compostable or biodegradable plastics, are still in their nascent stages. While promising, these materials often come with higher production costs, may not offer the same level of performance in terms of barrier properties or durability, and require specific disposal infrastructure, which is not universally available. This can create a barrier to widespread adoption, particularly in regions with underdeveloped waste management systems. Furthermore, consumer perception and brand reputation can be negatively impacted by the association of plastic packaging with environmental pollution. Companies are increasingly under pressure to demonstrate their commitment to sustainability, and a reliance on conventional plastic lids can, in some instances, create a perceived disconnect with these values, even if the lids are recyclable. The need for specialized recycling infrastructure for different types of plastics can also be a restraint. While many plastic die cut lids are technically recyclable, the lack of widespread and efficient collection and sorting systems for specific polymer types can lead to them ending up in landfills.

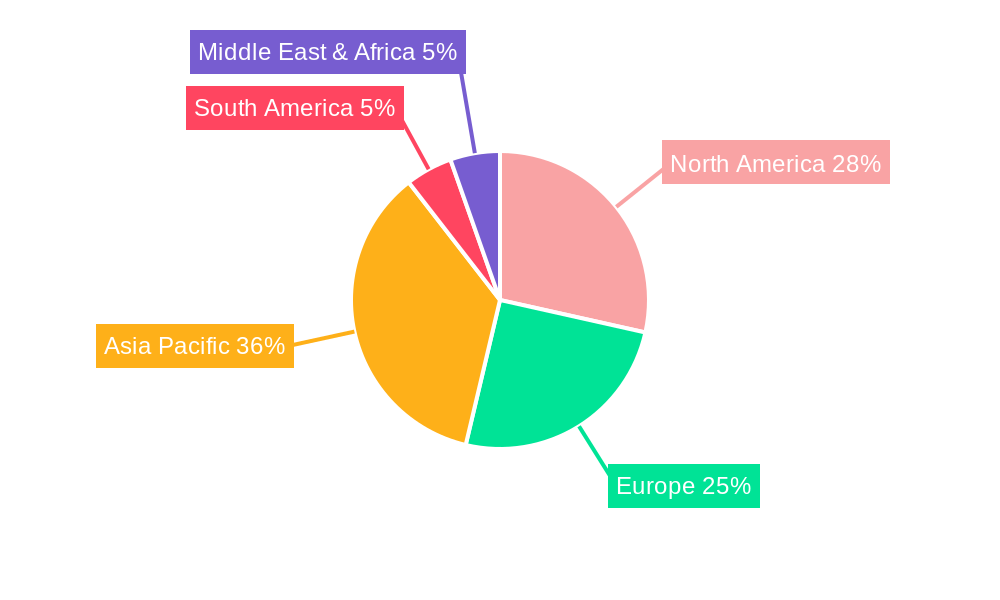

The plastic die cut lid market is poised for significant regional and segmental dominance, driven by a complex interplay of economic development, consumer behavior, and industry infrastructure. In terms of regional dominance, North America and Europe are expected to continue to be pivotal markets, largely due to their established food and beverage industries, high consumer spending, and advanced packaging technologies. These regions have a well-developed infrastructure for food processing and retail, leading to consistent demand for a wide variety of packaged goods. Furthermore, the increasing consumer awareness regarding food safety and convenience in these developed economies fuels the adoption of high-quality die cut lids. However, the Asia Pacific region presents the most significant growth potential. With a rapidly expanding population, increasing urbanization, and a burgeoning middle class, the demand for processed and packaged foods is experiencing exponential growth. Countries like China, India, and Southeast Asian nations are witnessing a surge in the adoption of Western lifestyles, which includes a greater reliance on convenience foods and beverages, thereby boosting the demand for plastic die cut lids. Government initiatives aimed at improving food safety standards and promoting the growth of the food processing industry in these regions further act as catalysts.

Focusing on segmental dominance, the Polyethylene Terephthalate (PET) material type is projected to hold a substantial market share, particularly in applications requiring clarity, rigidity, and good barrier properties. PET is widely used for beverage bottles, food trays, and containers where product visibility and shelf-life extension are critical. Its recyclability further enhances its appeal in many markets.

In terms of application, the Cups segment is expected to be a dominant force. The pervasive use of die cut lids for single-serving beverages, dairy products, desserts, and take-away food items makes this segment a consistent and high-volume market. The growing trend of on-the-go consumption, coupled with the expansion of the coffee shop culture and fast-food chains, directly contributes to the robust demand for die cut lids for cups.

Another significant segment is Trays. As the demand for convenience meals, ready-to-eat products, and fresh produce packaging continues to rise, so does the need for secure and effective tray lids. The ability of die cut lids to provide a reliable seal for various tray formats ensures product integrity and extends shelf life, making them indispensable in this application. The increasing popularity of meal kits and pre-portioned food items further solidifies the dominance of the tray segment.

The Bottles application also represents a substantial market. While many bottles have integrated caps, a significant portion of beverage bottles, particularly those containing carbonated drinks, juices, and dairy products, utilize die cut lids or foil seals for secondary sealing or tamper-evidence, especially after the primary cap has been removed.

While Jars and Others (which may include applications like single-serve condiment sachets or specialized industrial packaging) represent smaller proportions, their growth is still noteworthy. The demand for premium and niche food products packaged in jars, as well as the diverse array of other applications, contributes to the overall market expansion, albeit at a more moderate pace. The continuous innovation in material science and application-specific designs will further shape the dominance of these segments in the coming years, with sustainability and enhanced functionality being key differentiating factors.

The plastic die cut lid industry is being significantly propelled by several growth catalysts. The ever-expanding global food and beverage industry, driven by population growth and increasing consumer demand for convenience, is a primary driver. Innovations in material science leading to lighter, stronger, and more sustainable plastic formulations are enabling wider applications. Furthermore, the rise of e-commerce and food delivery services necessitates robust and reliable packaging solutions like die cut lids to ensure product integrity during transit. Consumer preferences for extended shelf life and reduced food waste also encourage the adoption of effective sealing technologies offered by these lids.

This report provides an exhaustive analysis of the global plastic die cut lid market, offering a comprehensive understanding of its current standing and future trajectory. It delves into the intricate details of market segmentation by material type (Polyethylene Terephthalate (PET), Polyethylene (PE), Polypropylene (PP)) and application (Cups, Trays, Bottles, Jars, Others), illustrating the nuances of demand and adoption across various categories. The study meticulously examines the historical performance from 2019-2024 and presents robust forecasts for the period of 2025-2033, with 2025 serving as the base year. Key industry developments, technological advancements, and the evolving regulatory landscape are thoroughly investigated, providing valuable context for market dynamics. The report also highlights the critical drivers and challenges influencing market growth, offering strategic insights for stakeholders aiming to capitalize on emerging opportunities and mitigate potential risks within this dynamic sector.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Amcor, Winpak, Sealed Air Corporation, CLONDALKIN GROUP, Constantia Packaging, Watershed packaging, Berry Plastics Group, Uflex, Tadbik, Barger Packaging.

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Plastic Die Cut Lid," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Plastic Die Cut Lid, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.