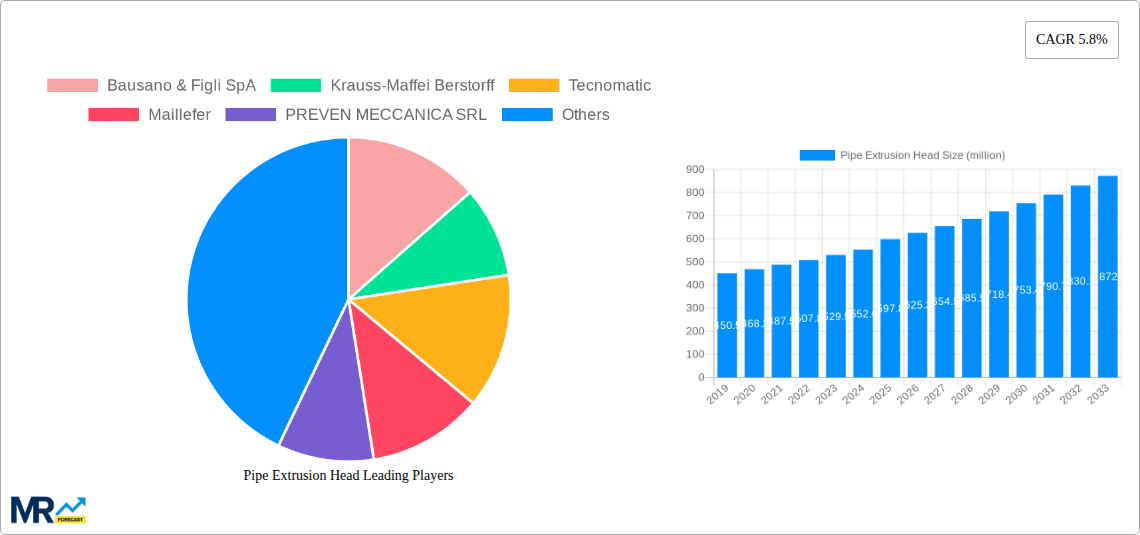

1. What is the projected Compound Annual Growth Rate (CAGR) of the Pipe Extrusion Head?

The projected CAGR is approximately 5.8%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Pipe Extrusion Head

Pipe Extrusion HeadPipe Extrusion Head by Type (Multilayer, Single-layer), by Application (Medical Industry, Construction Industry, Automobile Industry, Aerospace, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

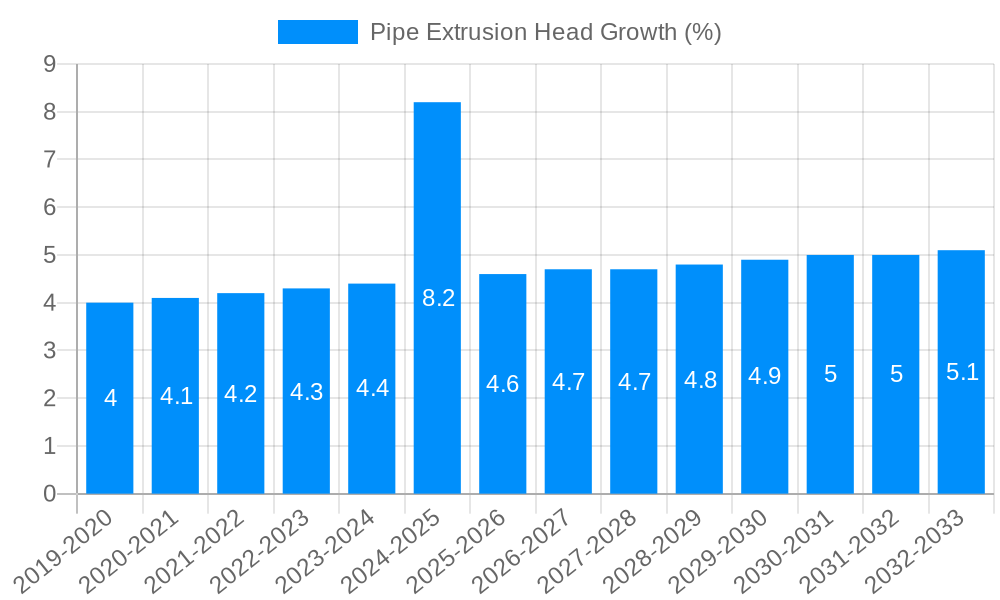

The global Pipe Extrusion Head market is poised for robust expansion, projected to reach a substantial USD 597.8 million by 2025, demonstrating a healthy Compound Annual Growth Rate (CAGR) of 5.8% through the forecast period ending in 2033. This growth is underpinned by increasing demand across critical sectors. The Medical Industry, driven by advancements in healthcare infrastructure and the growing need for specialized tubing for diagnostic and therapeutic applications, is a significant contributor. Simultaneously, the Construction Industry's continuous development and infrastructure projects worldwide, requiring efficient and durable piping solutions, further fuel market expansion. The Automobile Industry, with its increasing adoption of plastic and composite materials for lightweighting and fuel efficiency, and the Aerospace sector, demanding high-performance materials for critical applications, are also pivotal growth enablers. The market's dynamism is characterized by a strong emphasis on innovation, with manufacturers developing advanced extrusion heads capable of producing pipes with enhanced properties such as improved strength, chemical resistance, and thermal stability.

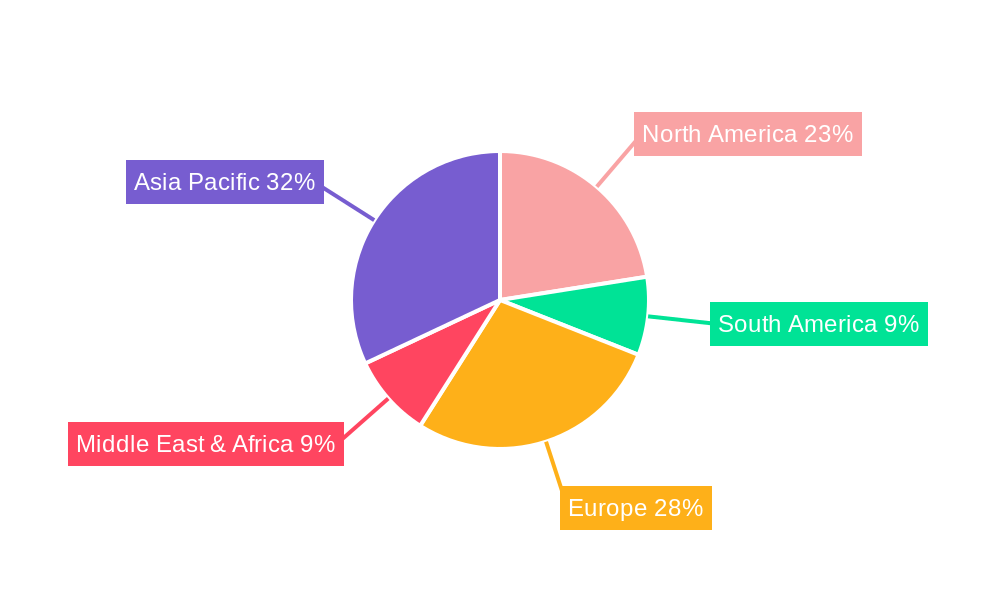

The market's trajectory is further shaped by key trends, including the rising adoption of automation and Industry 4.0 technologies within extrusion processes, leading to increased efficiency and precision. The development of multi-layer extrusion heads, catering to the demand for specialized pipes with distinct functional layers, is a notable trend. Furthermore, the increasing focus on sustainable manufacturing practices and the development of extrusion heads that can process recycled materials are gaining traction. However, the market also faces certain restraints, such as the high initial investment costs associated with advanced extrusion machinery and the fluctuating prices of raw materials, which can impact profitability. Despite these challenges, the overarching demand from diverse end-use industries, coupled with ongoing technological advancements, positions the Pipe Extrusion Head market for sustained and significant growth in the coming years, with Asia Pacific expected to emerge as a dominant regional force due to rapid industrialization and burgeoning infrastructure development.

Here is a comprehensive report description for Pipe Extrusion Heads, incorporating your specified elements:

The global pipe extrusion head market is poised for robust growth, projected to reach a valuation of over $2,000 million by 2033, exhibiting a compound annual growth rate (CAGR) of approximately 5.8% during the study period (2019-2033). The base year, 2025, is estimated to see market activity exceeding $1,500 million. This upward trajectory is underpinned by a confluence of factors, including escalating demand for high-performance piping solutions across various industries and continuous technological advancements in extrusion head design. The historical period (2019-2024) witnessed steady market expansion, driven by infrastructure development and a growing need for durable and efficient fluid transportation systems. The forecast period (2025-2033) is expected to accelerate this growth, fueled by innovations in multilayer extrusion technology, catering to specialized applications that demand enhanced chemical resistance, barrier properties, and structural integrity. Single-layer extrusion heads, while a mature segment, will continue to hold a significant share due to their cost-effectiveness and widespread use in general-purpose piping. Emerging economies are also playing a crucial role, with increased investment in construction and industrial infrastructure, thereby boosting the demand for advanced extrusion equipment. The market's dynamism is further characterized by a shift towards more sustainable and energy-efficient extrusion processes, encouraging manufacturers to invest in R&D for lighter, more precise, and environmentally friendly pipe extrusion heads. This evolving landscape presents a fertile ground for innovation and market penetration, promising substantial opportunities for stakeholders in the coming years. The increasing complexity of material science, with the advent of novel polymer blends and composites, is also pushing the boundaries of extrusion head capabilities, leading to the development of specialized dies capable of handling these advanced materials for niche applications.

Several potent forces are collectively driving the expansion of the pipe extrusion head market. The burgeoning construction industry worldwide stands as a primary catalyst. The ever-increasing global population and rapid urbanization necessitate continuous investment in infrastructure, including water supply and sanitation networks, gas pipelines, and drainage systems. These applications heavily rely on the consistent production of high-quality pipes, directly fueling the demand for advanced extrusion heads. Furthermore, the automotive industry's growing emphasis on lightweight materials and complex fluid management systems is creating significant opportunities for specialized pipe extrusion heads. The medical industry, with its stringent requirements for sterile and biocompatible tubing for devices and drug delivery systems, also represents a crucial growth segment. Advancements in materials science, leading to the development of new polymer composites and reinforced plastics, are pushing the capabilities of extrusion heads, enabling the production of pipes with superior strength, flexibility, and chemical resistance. The persistent drive for operational efficiency and reduced manufacturing costs within the plastics processing sector also compels manufacturers to adopt newer, more efficient extrusion head technologies that offer better melt distribution, reduced scrap rates, and enhanced product consistency. This continuous pursuit of improvement and innovation is fundamental to the market's sustained growth.

Despite the promising growth outlook, the pipe extrusion head market faces several significant challenges and restraints that could impede its full potential. One of the foremost challenges is the intense price competition among manufacturers, especially in the single-layer segment, which can squeeze profit margins and limit investment in research and development. The high initial capital investment required for advanced extrusion head technologies can also be a deterrent for smaller manufacturers or those in developing economies, restricting market access and adoption. Moreover, the stringent regulatory landscape surrounding material safety and environmental compliance, particularly in sensitive applications like the medical and food industries, necessitates significant investment in compliance and product validation, adding to manufacturing costs. Fluctuations in raw material prices, particularly for the polymers used in pipe production, can also impact the overall cost-effectiveness of extrusion processes and, consequently, the demand for new equipment. The specialized nature of some extrusion heads, designed for niche applications, can lead to limited market volume, making it challenging for manufacturers to achieve economies of scale. Finally, the need for skilled labor to operate and maintain sophisticated extrusion equipment can be a bottleneck in certain regions, hindering the widespread adoption of advanced technologies.

The Multilayer segment, particularly within the Construction Industry and the Automobile Industry, is poised to dominate the pipe extrusion head market. This dominance is projected to be most pronounced in the Asia-Pacific region, driven by robust economic growth, significant infrastructure development projects, and a rapidly expanding manufacturing base.

Dominating Segment: Multilayer Pipe Extrusion Heads

The increasing demand for pipes with enhanced performance characteristics, such as superior barrier properties, improved chemical resistance, and greater structural integrity, is propelling the growth of the multilayer pipe extrusion head segment. These heads are essential for producing pipes that consist of multiple layers of different materials, each serving a specific function. For instance, in the construction industry, multilayer pipes are increasingly being used for potable water distribution, where an inner layer made of inert material ensures water purity, while an outer layer provides structural support and protection against environmental factors. Similarly, in agricultural applications, multilayer pipes are crucial for irrigation systems, offering longevity and resistance to UV radiation and soil chemicals. The automotive sector is a significant consumer of multilayered pipes for fuel lines, brake fluid lines, and coolant systems, where resistance to specific chemicals, high temperatures, and pressure is paramount. The ability of multilayer extrusion heads to precisely control the thickness and placement of each layer allows for the creation of highly engineered pipes that meet stringent performance requirements and offer extended service life. The ongoing innovation in polymer science, leading to new combinations of materials that can be co-extruded, further fuels the demand for advanced multilayer extrusion heads capable of handling these complex structures.

Dominating Application: Construction Industry

The construction industry remains a bedrock for pipe extrusion head demand. As global populations grow and urbanization accelerates, the need for robust infrastructure for water supply, sewage systems, gas distribution, and telecommunications cabling continues to escalate. Multilayer pipes, in particular, are gaining traction due to their superior durability, leak-proof capabilities, and resistance to corrosion, making them ideal for long-term underground installations. Single-layer pipes, however, continue to be vital for less demanding applications within construction, offering cost-effectiveness and ease of installation for tasks like drainage and conduit systems. The increasing focus on sustainable building practices is also driving the adoption of plastic pipes over traditional materials like metal, due to their lower energy consumption during production and their recyclability.

Dominating Application: Automobile Industry

The automobile industry presents a significant growth avenue for pipe extrusion heads, driven by the increasing complexity of vehicle designs and the continuous pursuit of weight reduction and enhanced performance. Multilayered pipe extrusion heads are indispensable for producing specialized tubing required for fuel systems, brake lines, cooling systems, and emission control systems. These applications demand pipes that can withstand high pressures, extreme temperatures, and exposure to various automotive fluids, including fuels, oils, and coolants. The trend towards electric vehicles (EVs) is also creating new demands for specialized piping solutions for battery cooling systems and charging infrastructure. The ability to produce complex profiles and multi-lumen tubes is becoming increasingly important, pushing the innovation envelope for extrusion head manufacturers.

Dominating Region: Asia-Pacific

The Asia-Pacific region is expected to lead the global pipe extrusion head market. This dominance is attributed to several factors:

Companies operating in this region benefit from a large and growing domestic market, coupled with export opportunities to other parts of the world. The presence of key players and a competitive manufacturing landscape also fosters innovation and cost efficiency.

The pipe extrusion head industry is propelled by several key growth catalysts. The relentless global demand for improved infrastructure, particularly in emerging economies, for water, gas, and sewage systems is a primary driver. Furthermore, the automotive industry's continuous innovation in lightweighting and advanced fluid management systems necessitates specialized, high-performance extruded pipes. The medical sector's stringent requirements for sterile, biocompatible tubing for critical applications like catheters and drug delivery systems also fuels demand for precision extrusion heads. Lastly, advancements in polymer science are enabling the development of novel materials that require sophisticated extrusion technology, creating new market opportunities.

This comprehensive report offers an in-depth analysis of the global pipe extrusion head market, providing critical insights for stakeholders. The study encompasses a detailed examination of market size and forecasts for the period 2019-2033, with a focus on the base year 2025 and the forecast period 2025-2033, supported by historical data from 2019-2024. It delves into the intricate trends shaping the market, including technological advancements in multilayer and single-layer extrusion, and analyzes the key driving forces such as infrastructure development and automotive industry demands. Crucially, the report identifies and elaborates on the challenges and restraints impacting market growth, offering strategic perspectives on overcoming these hurdles. A significant portion of the report is dedicated to identifying and detailing the key regions and dominant market segments, with a particular focus on the Multilayer segment within the Construction and Automobile Industries. Furthermore, it highlights the crucial growth catalysts and provides an exhaustive list of leading players in the industry, along with significant developments observed in recent years. The report's comprehensive coverage aims to equip businesses with the knowledge necessary to navigate this dynamic market and capitalize on emerging opportunities.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 5.8% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 5.8%.

Key companies in the market include Bausano & Figli SpA, Krauss-Maffei Berstorff, Tecnomatic, Maillefer, PREVEN MECCANICA SRL, KUATRO PLAST, HF TireTech Group, BOCO PARDUBICE, Guill Tool & Engineering, Bausano & Figli, KraussMaffei Berstorff, Cincinnati Extrusion, Conair Group, Kabra Extrusiontechnik, Theysohn Extrusionstechnik, Allied Dies, .

The market segments include Type, Application.

The market size is estimated to be USD 597.8 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Pipe Extrusion Head," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Pipe Extrusion Head, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.