1. What is the projected Compound Annual Growth Rate (CAGR) of the Personalized 3D Printed Implant?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Personalized 3D Printed Implant

Personalized 3D Printed ImplantPersonalized 3D Printed Implant by Application (Hospital, Clinic, Others, World Personalized 3D Printed Implant Production ), by Type (Cranial Plates, Hip Joints, Shoulder Implants, Others, World Personalized 3D Printed Implant Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

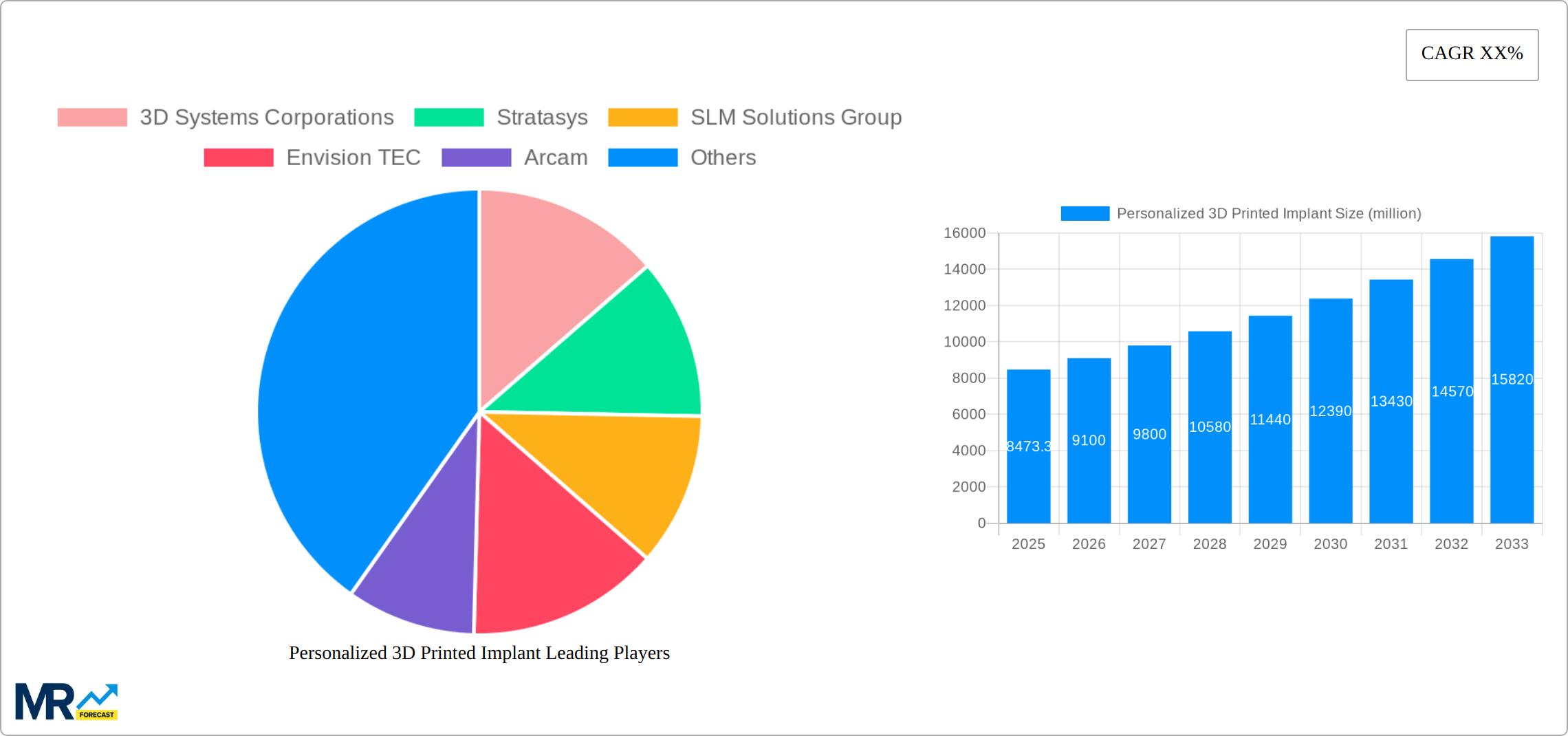

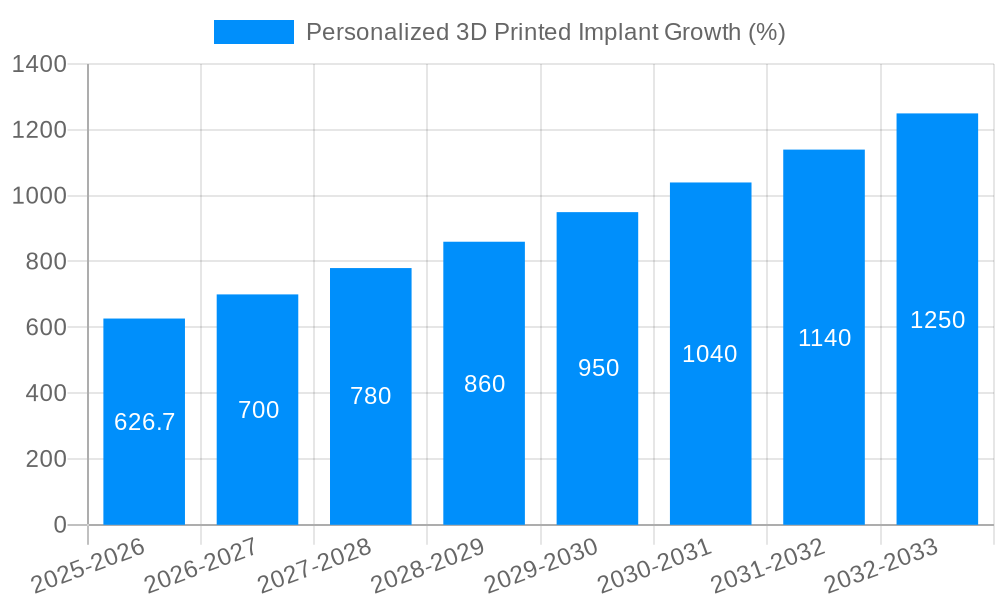

The personalized 3D printed implant market is experiencing significant growth, driven by advancements in 3D printing technology, increasing demand for customized medical solutions, and the rising prevalence of chronic diseases requiring surgical interventions. The market size, estimated at $8.47 billion in 2025, is projected to expand considerably over the forecast period (2025-2033). This growth is fueled by several key factors. Firstly, the ability to create highly precise and patient-specific implants leads to improved surgical outcomes, faster recovery times, and reduced complications. Secondly, the increasing adoption of minimally invasive surgical techniques enhances the demand for customized implants that can be precisely positioned during the procedure. Thirdly, the ongoing development of biocompatible and bioresorbable materials is expanding the range of applications for 3D printed implants, further propelling market expansion. Finally, the growing investment in research and development by both established medical device companies and emerging technology firms is accelerating innovation and creating new market opportunities.

Despite these positive drivers, the market faces some challenges. The high initial investment required for 3D printing equipment and the need for skilled professionals can limit market penetration, particularly in developing regions. Additionally, regulatory approvals and reimbursement policies can vary significantly across different countries, potentially impacting market growth. However, the long-term outlook remains positive, as technological advancements continue to address these challenges, making personalized 3D printed implants increasingly accessible and cost-effective. The competitive landscape is dynamic, with key players such as 3D Systems, Stratasys, and Materialise constantly innovating to enhance their product offerings and expand their market share. The ongoing focus on improving the accuracy, biocompatibility, and cost-effectiveness of 3D printed implants will be pivotal in shaping the future of this rapidly expanding market.

The personalized 3D printed implant market is experiencing explosive growth, projected to reach multi-million unit sales by 2033. This surge is driven by a confluence of factors, including advancements in 3D printing technologies, a rising demand for customized medical solutions, and a growing awareness of the benefits of personalized medicine. The market's evolution from niche applications to widespread adoption across various medical specialties reflects a significant paradigm shift in how implants are designed, manufactured, and delivered. The historical period (2019-2024) showcased significant technological advancements paving the way for increased adoption. The estimated year 2025 marks a pivotal point, revealing a substantial market expansion fueled by increased investments and wider regulatory approvals. This upward trajectory is expected to continue throughout the forecast period (2025-2033), with millions of units projected to be utilized annually by the end of this decade. Key market insights point towards a steady increase in the adoption of biocompatible materials, the development of more sophisticated software for implant design and patient-specific modeling, and a growing interest in integrating AI and machine learning for improved accuracy and efficiency. This trend is further strengthened by the continuous development of new printing techniques and the exploration of various biomaterials, leading to a wider range of applications across orthopedics, craniomaxillofacial surgery, dentistry, and cardiovascular procedures. The market's success hinges on collaborations between medical professionals, material scientists, and 3D printing specialists, collectively driving innovation and paving the way for even more intricate and personalized implants in the future. The shift towards value-based healthcare further incentivizes the adoption of personalized implants, demonstrating cost-effectiveness in the long run compared to traditional methods, particularly in cases requiring complex surgical interventions. Furthermore, the potential for reduced surgical time and improved patient outcomes further fuels the market's expansion.

Several key factors are propelling the rapid growth of the personalized 3D printed implant market. Firstly, the advancement of 3D printing technologies enables the creation of highly intricate and customized implants tailored to individual patient anatomy and needs. This precision surpasses the capabilities of traditional manufacturing methods, leading to improved fit, function, and overall patient outcomes. Secondly, the increasing prevalence of chronic diseases and the aging global population are driving demand for sophisticated medical solutions, including personalized implants. The demand for improved quality of life alongside an increasing number of trauma cases requiring complex reconstruction is a significant driver. Thirdly, the growing adoption of personalized medicine emphasizes the importance of tailored treatments, further reinforcing the need for customized medical devices. This trend is accelerating investment in research and development within this sector. Fourthly, regulatory approvals are facilitating market entry for new products, with ongoing efforts to streamline the approval processes for 3D-printed medical devices. Lastly, the declining cost of 3D printing technology and materials is making personalized implants more accessible and affordable, ultimately driving wider adoption across various healthcare settings. The combined impact of these factors creates a powerful synergy that significantly boosts the market's expansion, promising substantial growth in the coming years.

Despite the significant growth potential, the personalized 3D printed implant market faces certain challenges and restraints. One major hurdle is the high initial investment required for 3D printing equipment and specialized materials, which can pose a barrier to entry for smaller companies and healthcare providers. Furthermore, ensuring the long-term biocompatibility and durability of 3D-printed implants remains a critical concern. Rigorous testing and clinical trials are necessary to establish the safety and efficacy of these implants, adding to the development timeline and cost. The regulatory landscape for 3D-printed medical devices is still evolving, with varying regulations across different countries, potentially hindering global market expansion. Additionally, skilled professionals trained in designing, manufacturing, and implanting personalized 3D-printed devices are in high demand, creating a talent shortage that can limit the market's capacity for growth. The complexity of the manufacturing process and the need for highly skilled technicians can result in longer production times compared to traditional methods. Moreover, the relatively high cost of personalized implants can limit accessibility for patients in developing countries, hindering global market penetration. Addressing these challenges requires collaborative efforts from researchers, regulatory bodies, manufacturers, and healthcare providers to overcome technical hurdles, streamline regulations, and ensure widespread access to this transformative technology.

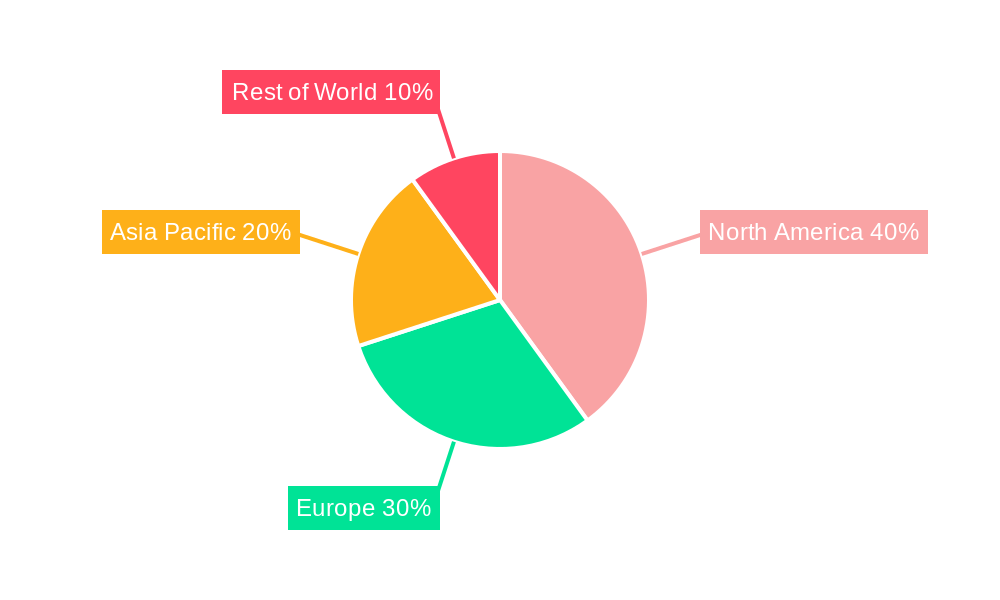

The personalized 3D printed implant market is expected to witness significant growth across several key regions and segments.

North America: The region holds a substantial market share due to the presence of major players, advanced healthcare infrastructure, and high adoption rates of innovative medical technologies. The US, in particular, is expected to drive the majority of the market growth owing to high R&D investments and increasing demand for advanced medical implants.

Europe: The European market is also witnessing significant growth, driven by increasing investment in healthcare infrastructure, rising prevalence of chronic diseases, and favorable regulatory environments in some countries. Germany and France are expected to be major contributors to this regional market growth.

Asia-Pacific: This region displays promising growth potential owing to a rapidly expanding healthcare sector, increasing disposable incomes, and a growing awareness of personalized medicine. Countries like Japan, China, and India are anticipated to witness significant expansion in the coming years.

Segments:

Orthopedics: This segment is currently dominating the market due to the high demand for personalized implants in joint replacements, bone grafts, and fracture fixation. The ability to create customized implants that precisely match patient anatomy leads to improved surgical outcomes and faster recovery times.

Craniomaxillofacial: This segment shows promising growth, with 3D printing enabling the creation of customized implants for facial reconstruction, skull repair, and dental applications. The precision and complexity achievable through 3D printing provide significant advantages over traditional methods.

Cardiovascular: The cardiovascular segment is also experiencing growth, with 3D printing being used to create customized stents, heart valves, and other implants. The ability to create personalized implants with optimal geometries for individual patients has led to better outcomes in cardiovascular procedures.

Dental: The dental segment is showing rapid growth due to the increasing use of 3D printing for creating customized dental crowns, bridges, and implants. The precision and speed offered by 3D printing result in more efficient and comfortable procedures for patients.

The overall dominance of these segments is primarily due to the high volume of procedures and the significant advantages of personalized implants in terms of improved patient outcomes and reduced complications. Further growth is anticipated as 3D printing technologies advance and new applications are developed.

The personalized 3D printed implant industry's growth is fueled by several key catalysts. Advancements in biocompatible materials, enabling the creation of implants that seamlessly integrate with the body, are paramount. The development of sophisticated software for implant design and patient-specific modeling also enhances precision and accuracy. Furthermore, the increasing adoption of AI and machine learning algorithms for improved design and manufacturing processes are streamlining efficiency and effectiveness. Finally, expanding regulatory approvals and favorable reimbursement policies are creating a more favorable market environment. These factors, collectively, contribute to the market's rapid expansion.

This report provides a comprehensive overview of the personalized 3D printed implant market, encompassing historical data, current market trends, and future projections. It delves into the key driving forces, challenges, and growth opportunities within the industry. The report also profiles leading market players, highlighting their strategies, technologies, and market positions. This detailed analysis assists stakeholders in making informed decisions regarding investments, product development, and market entry strategies within this rapidly evolving sector. The report covers a detailed analysis of the various segments and geographies, providing a granular understanding of the market dynamics.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include 3D Systems Corporations, Stratasys, SLM Solutions Group, Envision TEC, Arcam, Organovo, Oxford Performance Materials, Materialise, Bio3D Technologies, Cyfuse Medical, Stryker, BioBots, ANDREAS STIHL AG & Co. KG, Aspect Biosystems, Formlabs, Medprin, Rokit, Materialise N.V., .

The market segments include Application, Type.

The market size is estimated to be USD 8473.3 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Personalized 3D Printed Implant," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Personalized 3D Printed Implant, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.