1. What is the projected Compound Annual Growth Rate (CAGR) of the Multi-material Packaging?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Multi-material Packaging

Multi-material PackagingMulti-material Packaging by Type (Polyethylene (PE), Polypropylene (PP), Polyamide (PA), EVOH, Polyethylene Terephthalate (PET)), by Application (Pharmaceutical, Electric and Electronics, Food and Beverages, Medical Devices, Transportation and Logistics, E-commerce, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

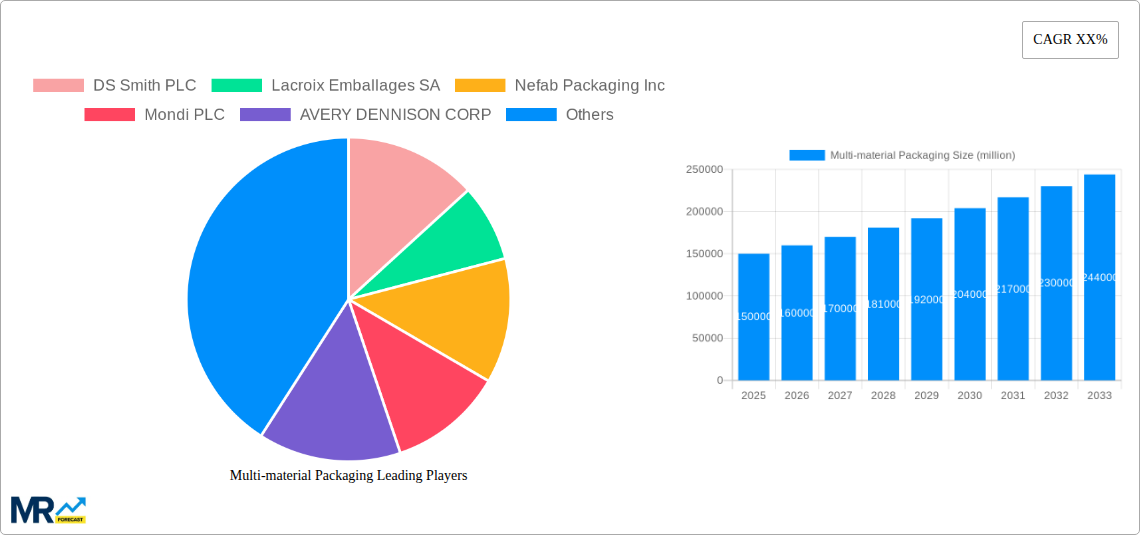

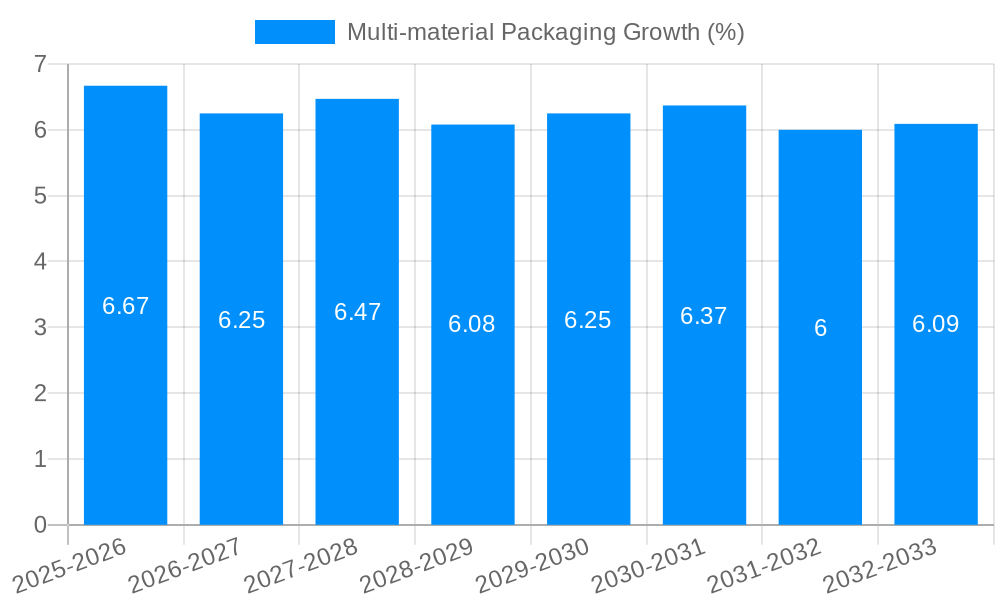

The global Multi-material Packaging market is projected to witness substantial growth, driven by an increasing demand for advanced packaging solutions that offer superior protection, extended shelf life, and enhanced functionality across diverse industries. With a market size estimated at approximately $150 billion in 2025 and a projected Compound Annual Growth Rate (CAGR) of around 6.5%, the market is set to expand significantly. Key drivers include the rising need for sophisticated packaging in the pharmaceutical sector to ensure drug integrity, the burgeoning e-commerce industry's requirement for durable and protective shipping materials, and the growing consumer preference for packaged food and beverages with extended freshness. Innovations in material science, particularly the development of advanced polymers and barrier technologies, are enabling the creation of multi-layered packaging that combines the benefits of different materials, such as high barrier properties, flexibility, and printability. This advancement is crucial for meeting stringent regulatory requirements and consumer expectations for sustainable and high-performance packaging.

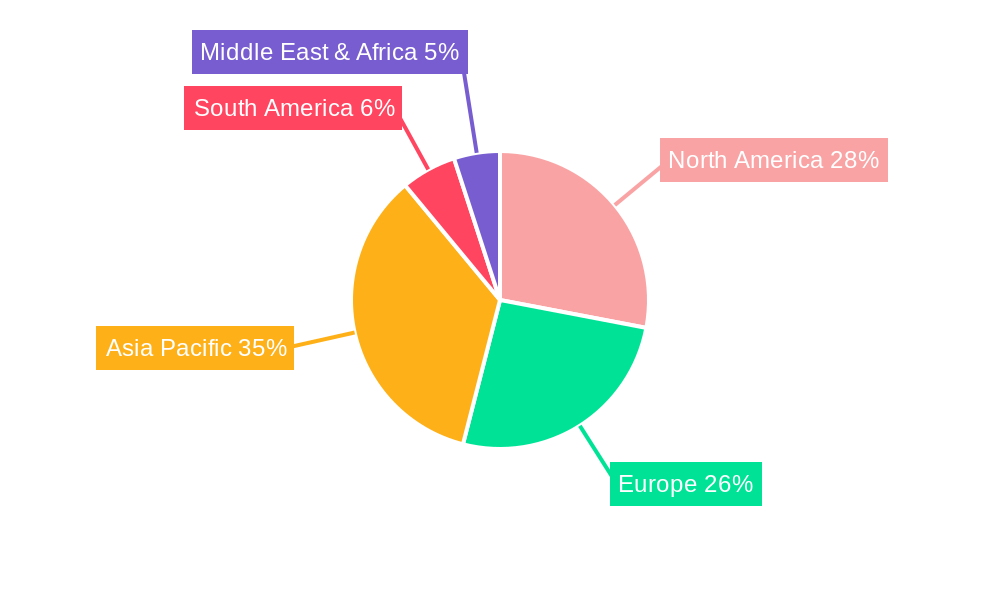

The market's trajectory is further shaped by several key trends, including the increasing adoption of advanced printing technologies for enhanced branding and consumer engagement, the growing emphasis on recyclability and the circular economy, and the integration of smart packaging solutions for traceability and authenticity. While the market presents significant opportunities, certain restraints could influence its pace. These include the higher cost associated with some advanced multi-material solutions compared to traditional packaging, the complexities involved in recycling multi-material structures, and potential regulatory hurdles related to material composition and disposal. Key segments driving growth include Polyethylene (PE) and Polypropylene (PP) due to their versatility and cost-effectiveness, alongside specialized materials like EVOH for high barrier applications. The pharmaceutical and food and beverage sectors are expected to remain dominant application areas, with rapid expansion anticipated in e-commerce and electric and electronics. Geographically, Asia Pacific, particularly China and India, is poised to lead the market in terms of growth, owing to rapid industrialization and a growing consumer base, while North America and Europe will continue to be significant markets with a strong focus on innovation and sustainability.

Here's a unique report description for Multi-material Packaging, incorporating the requested elements:

The multi-material packaging market is on a robust growth trajectory, poised to reach significant milestones in the coming years. Driven by a complex interplay of regulatory pressures, evolving consumer preferences, and technological advancements, the demand for innovative packaging solutions that combine various materials to achieve optimal performance is escalating. In the Base Year of 2025, the market is estimated to be valued in the billions of dollars, with projections indicating a substantial Compound Annual Growth Rate (CAGR) throughout the Forecast Period of 2025-2033. This growth is underpinned by the increasing need for packaging that offers enhanced barrier properties, extended shelf life, improved sustainability profiles, and superior protection for a diverse range of products.

During the Historical Period of 2019-2024, the market demonstrated consistent expansion, fueled by the burgeoning e-commerce sector and a growing awareness of food waste reduction. Key insights reveal a shift towards high-barrier materials like EVOH and specialized polyamides, particularly within the food and beverage and pharmaceutical applications. The Study Period of 2019-2033 will delve deep into these transformative trends, analyzing how the strategic integration of materials such as Polyethylene (PE), Polypropylene (PP), Polyamide (PA), EVOH, and Polyethylene Terephthalate (PET) is reshaping product protection and supply chain efficiency. Furthermore, the report will examine the increasing adoption of multi-material solutions in the electric and electronics, medical devices, and transportation and logistics segments, highlighting the specific material combinations and design innovations that are setting new industry standards. The evolution of recycling technologies and the increasing emphasis on circular economy principles will also be thoroughly explored as critical determinants of future market dynamics.

Several potent forces are collectively propelling the expansion of the multi-material packaging market. Foremost among these is the escalating consumer demand for products with extended shelf life and enhanced freshness, particularly within the food and beverage sector. Multi-material solutions, by strategically layering different polymers and barrier materials like EVOH and specialized polyamides, offer superior protection against oxygen, moisture, and light, thereby significantly reducing spoilage and food waste. Concurrently, stringent regulations across the globe, focusing on product safety, tamper-evidence, and the prevention of counterfeiting, are driving the adoption of sophisticated multi-material packaging designs, especially in the pharmaceutical and medical device industries. The rapid growth of e-commerce, characterized by the need for robust and protective packaging that can withstand the rigmarole of transit, is another significant propellant. The ability of multi-material structures to provide impact resistance and damage prevention without excessive weight or bulk makes them ideal for this segment.

Moreover, a growing environmental consciousness among consumers and businesses is indirectly fueling this market. While the focus often leans towards single-material recyclable solutions, the practical reality is that for certain high-performance applications, multi-material structures remain the most effective. The industry is therefore investing heavily in developing multi-material solutions that can still incorporate recycled content and are designed for improved end-of-life management, thereby addressing sustainability concerns. The inherent versatility of combining different materials to achieve specific functionalities – whether it’s printability, sealability, or chemical resistance – also makes multi-material packaging an attractive proposition for a broad spectrum of industries seeking optimized packaging performance.

Despite its robust growth, the multi-material packaging market faces several significant challenges and restraints. The primary hurdle remains the complex recyclability of multi-material structures. The very nature of combining different types of plastics, or plastics with other materials like aluminum or paper, often makes them difficult and uneconomical to separate and reprocess through existing recycling streams. This poses a considerable challenge to achieving circular economy goals and can lead to negative environmental perceptions, even when the packaging offers superior product protection. Consequently, regulatory bodies and environmental advocacy groups are increasingly scrutinizing multi-material packaging, demanding clearer end-of-life solutions.

Another restraint stems from the cost factor. The advanced materials and intricate manufacturing processes involved in producing high-performance multi-material packaging can lead to higher unit costs compared to simpler, single-material alternatives. This can be a barrier for price-sensitive industries or for products where cost optimization is paramount. Furthermore, the development and implementation of effective sorting and recycling technologies for mixed materials are still in their nascent stages and require substantial investment and infrastructure development across various regions. The lack of standardized recycling infrastructure globally further complicates the end-of-life management of these complex packaging formats. Consumer confusion and a lack of clear disposal instructions for multi-material products can also hinder effective waste management, leading to increased landfill waste.

The Food and Beverages segment is projected to be a dominant force in the multi-material packaging market throughout the Study Period of 2019-2033, with its global market share anticipated to reach substantial figures in the billions by 2025. This dominance is intrinsically linked to the inherent requirements of food preservation and extending shelf life, where multi-material packaging offers unparalleled advantages. The strategic use of materials like Polyethylene (PE) for its excellent sealing properties and moisture barrier, Polypropylene (PP) for its rigidity and heat resistance, and crucially, EVOH (Ethylene Vinyl Alcohol) and specialized Polyamides (PA) for their exceptional oxygen barrier capabilities, allows for the creation of packaging that significantly reduces spoilage and waste. For instance, flexible pouches for snacks, retort pouches for ready-to-eat meals, and high-barrier films for dairy products all heavily rely on multi-material constructions to maintain product integrity and quality. The increasing global demand for convenience foods, ready-to-drink beverages, and fresh produce further amplifies the need for sophisticated packaging that can withstand diverse transportation and storage conditions while maintaining product safety and appeal.

Within the Type classification, Polyethylene Terephthalate (PET), in combination with other materials, is expected to witness remarkable growth and contribute significantly to market dominance. While PET itself is a widely used single-material packaging component, its integration into multi-material structures, often with barrier layers or as part of composite structures, enhances its functionality. For example, PET bottles with specialized barrier coatings or multi-layer PET films used in flexible packaging offer improved performance for beverages and certain food items. The Application of Pharmaceutical and Medical Devices is another segment poised for significant growth, driven by stringent regulatory requirements for sterility, tamper-evidence, and drug efficacy. Multi-material packaging here ensures protection against moisture, oxygen, and light, critical for sensitive medications and medical equipment. The Region expected to lead the market is North America, largely due to its advanced technological infrastructure, high consumer disposable income, and a well-established industrial base across food and beverage, pharmaceutical, and electric and electronics sectors. The region’s proactive approach to packaging innovation and stringent quality standards further bolster its leading position.

The multi-material packaging industry is experiencing significant growth catalysts, primarily driven by the demand for enhanced product protection and extended shelf life, especially in the food and beverage sector. The rise of e-commerce, requiring robust and damage-resistant packaging, is another major catalyst. Furthermore, increasing regulatory focus on product safety and tamper-evidence, particularly in pharmaceuticals and medical devices, is compelling the adoption of advanced multi-material solutions. Growing consumer awareness regarding sustainability is also a catalyst, pushing for the development of more recyclable multi-material options and those incorporating recycled content, thereby aligning with circular economy principles.

This report offers a comprehensive analysis of the multi-material packaging market, delving into its intricate dynamics from the Historical Period of 2019-2024 through to the Forecast Period of 2025-2033. It provides in-depth insights into market trends, driving forces, and critical challenges, complemented by a detailed examination of key regions and dominating segments. The report meticulously analyzes the strategic importance of various material types like PE, PP, PA, EVOH, and PET, and their applications across vital sectors including pharmaceutical, electric and electronics, food and beverages, medical devices, transportation and logistics, and e-commerce. With a focus on the Base Year of 2025 and projections extending to 2033, this report serves as an indispensable resource for stakeholders seeking to understand and capitalize on the evolving landscape of multi-material packaging solutions.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include DS Smith PLC, Lacroix Emballages SA, Nefab Packaging Inc, Mondi PLC, AVERY DENNISON CORP, Tri-Wall Group, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Multi-material Packaging," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Multi-material Packaging, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.