1. What is the projected Compound Annual Growth Rate (CAGR) of the Manual Boring Milling Machine?

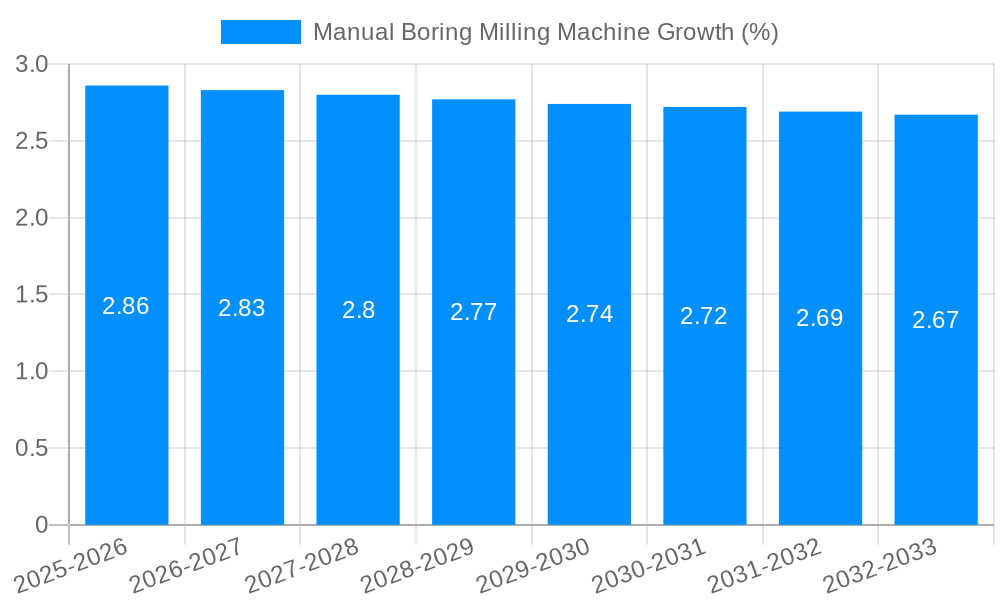

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Manual Boring Milling Machine

Manual Boring Milling MachineManual Boring Milling Machine by Type (Horizontal, Vertical, World Manual Boring Milling Machine Production ), by Application (General Manufacturing, Automotive, Medical, Aerospace, World Manual Boring Milling Machine Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

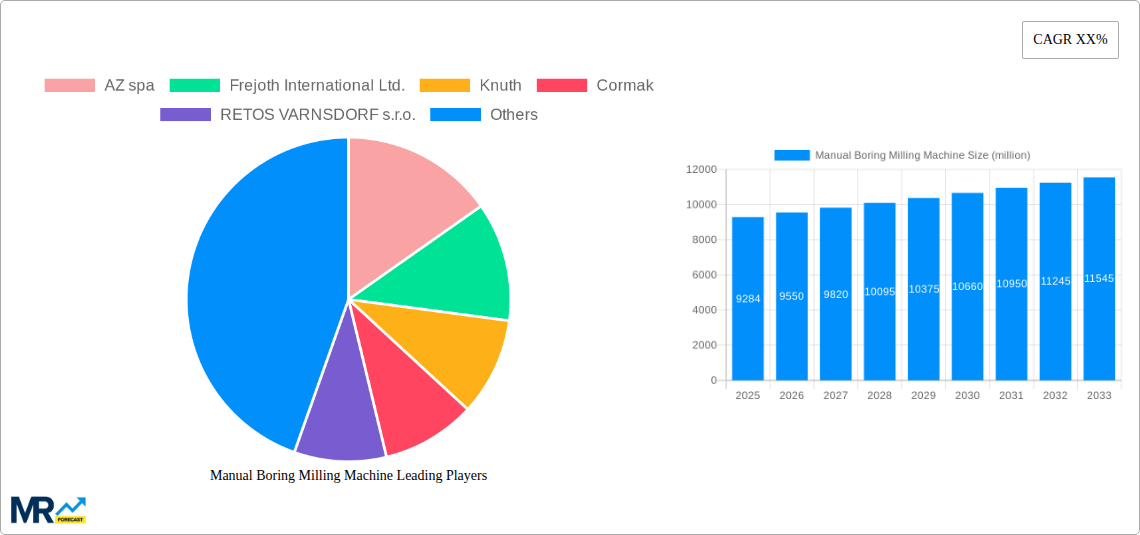

The global Manual Boring Milling Machine market is poised for significant growth, projected to reach an estimated market size of approximately $9,284 million by 2025. This expansion is fueled by the inherent precision, versatility, and cost-effectiveness that manual boring milling machines offer, particularly in specialized applications where intricate machining and a high degree of operator control are paramount. The market's growth is intrinsically linked to the steady demand from general manufacturing sectors, where these machines remain essential for their adaptability to diverse tasks and lower initial investment compared to highly automated alternatives. Furthermore, the increasing need for precision components in sectors like automotive, aerospace, and medical device manufacturing, even amidst the rise of advanced CNC technologies, provides a robust foundation for continued market relevance. The ability of manual machines to handle unique or low-volume production runs without the extensive programming overhead of CNC systems also contributes to their enduring appeal, especially for small and medium-sized enterprises (SMEs) and custom fabrication shops.

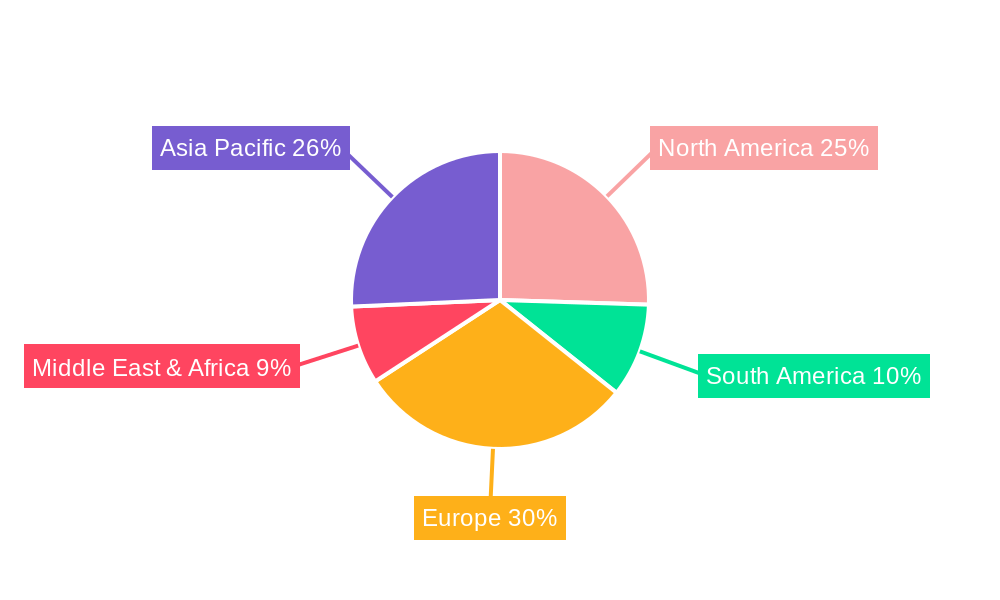

The market's trajectory will be further shaped by key trends focusing on enhanced operator ergonomics, improved machine rigidity, and the integration of digital measurement tools for greater accuracy. While advanced automation and CNC machines represent a significant technological advancement, the manual boring milling machine market is not diminishing but rather evolving to serve specific niches. Restraints, such as the increasing complexity and skilled labor requirements for operating these machines, coupled with the pervasive trend towards automation in high-volume production environments, will present challenges. However, the inherent advantages in terms of initial cost, operational flexibility, and the unique capabilities for intricate manual manipulation will ensure sustained demand. The Asia Pacific region, driven by its vast manufacturing base and growing industrialization, is expected to be a dominant force, while North America and Europe will continue to represent mature yet substantial markets due to their established industries and focus on high-precision applications.

This comprehensive report delves into the intricacies of the global Manual Boring Milling Machine market, offering a detailed analysis of trends, drivers, challenges, and future prospects. The study encompasses a robust Study Period from 2019 to 2033, with a Base Year of 2025, providing a clear snapshot of the market's current standing and its trajectory. The Forecast Period of 2025-2033 meticulously outlines anticipated growth patterns, supported by insightful projections based on the Estimated Year of 2025. The Historical Period (2019-2024) lays the foundation, showcasing past performance and providing context for future estimations.

The report meticulously analyzes various segments within the Manual Boring Milling Machine market, including:

Furthermore, it assesses World Manual Boring Milling Machine Production and related Industry Developments, offering a holistic view of the global landscape. The report is enriched with data from leading manufacturers such as AZ spa, Frejoth International Ltd., Knuth, Cormak, RETOS VARNSDORF s.r.o., AMC-SCHOU, TOS VARNSDORF, Kent Industrial USA, Inc., Summit Machine Tool, and KAAST USA, providing valuable insights into their market presence and strategies.

The global Manual Boring Milling Machine market is currently navigating a dynamic phase, characterized by a steady but evolving demand. While the advent of advanced automated machinery has undeniably influenced the manufacturing landscape, manual boring milling machines continue to hold their ground due to their inherent advantages in specific applications. The market is observing a gradual but persistent demand from sectors requiring precision and versatility in smaller-scale operations or specialized repair work. A significant trend is the sustained demand from small and medium-sized enterprises (SMEs) and independent workshops that find manual machines to be a cost-effective and efficient solution for their production needs. These users often prioritize the tactile control and adaptability offered by manual machines, enabling them to achieve intricate finishes and handle unique job requirements that might be cumbersome or uneconomical with highly automated systems. Furthermore, the market is seeing a niche resurgence in demand for older, well-maintained manual machines due to their robust construction and repairability, which can be a significant advantage in regions with limited access to advanced technical support or spare parts for newer, complex automated machinery. The World Manual Boring Milling Machine Production figures, while not reaching the scale of automated systems, indicate a resilient segment catering to these specific needs. Moreover, there’s a growing emphasis on the integration of digital measurement tools and readouts with manual machines to enhance accuracy and operational efficiency, bridging the gap between traditional methods and modern technology. This hybridization allows operators to leverage the familiarity and control of manual operation while benefiting from digital precision. The medical and aerospace industries, in particular, continue to rely on manual boring milling machines for critical component manufacturing and intricate prototyping, where precision, operator judgment, and the ability to make on-the-fly adjustments are paramount. The overall market sentiment suggests a stabilization, with growth driven by these specialized demands and the enduring value proposition of manual machinery in certain manufacturing ecosystems.

Several key factors are underpinning the continued relevance and demand for manual boring milling machines. Foremost among these is their inherent cost-effectiveness, particularly for small to medium-sized enterprises (SMEs) and specialized workshops. The initial capital investment for a manual boring milling machine is significantly lower compared to its automated counterparts, making it an accessible option for businesses with tighter budgets. This economic advantage extends to operational costs, as manual machines generally require less complex maintenance and fewer specialized technicians for operation and repair, contributing to a lower total cost of ownership. Secondly, the simplicity and intuitiveness of operation remain a significant draw. Operators can quickly become proficient with manual machines, and the direct control over cutting parameters allows for a high degree of customization and immediate feedback, which is crucial for intricate or one-off jobs. This tactile engagement enables machinists to develop a deep understanding of the material and the machining process, leading to superior finishes and fewer errors in complex scenarios. Thirdly, the versatility and adaptability of manual boring milling machines are invaluable. They can be readily adapted for a wide range of tasks, from intricate boring and facing operations to milling and drilling, often with simple tool changes. This flexibility is particularly beneficial in job shops that handle a diverse array of projects with varying specifications. The robustness and durability of many manual machines, often built with heavy-duty components, ensure a long operational lifespan, further enhancing their economic appeal. Finally, in specific sectors like medical device manufacturing and aerospace, where extreme precision and the ability for an experienced operator to exert fine control are non-negotiable, manual boring milling machines remain a preferred choice for critical operations, ensuring the integrity and quality of high-value components.

Despite their enduring strengths, the manual boring milling machine market faces notable challenges and restraints that temper its growth potential. The most significant is the increasing dominance of automation and CNC technology. As automated machinery becomes more sophisticated, affordable, and widely adopted, it inherently draws demand away from manual alternatives, especially for high-volume production runs where efficiency and consistency are paramount. The inherent limitations in speed and precision compared to advanced CNC machines also pose a considerable restraint. Manual operations are inherently slower and more susceptible to operator fatigue or inconsistencies, which can impact production output and the uniformity of finished parts, particularly for large-scale manufacturing. Furthermore, the shrinking pool of skilled manual machinists is a growing concern. The focus of modern technical education and training has shifted towards automated systems, leading to a decline in individuals with the specialized skills and experience required to operate manual boring milling machines effectively. This skills gap can hinder adoption and limit the operational capacity of businesses relying on these machines. Maintenance and spare parts availability for older manual models can also become a challenge over time, potentially leading to extended downtime if specialized components are difficult to source. The perceived lack of advanced features such as integrated digital diagnostics, real-time data logging, and automated tool changing, which are standard in modern CNC machines, can also make manual machines appear less attractive to businesses seeking to optimize their operations with Industry 4.0 principles. Lastly, while the initial cost is an advantage, the ongoing labor costs associated with manual operation can, over the long term, become a disadvantage compared to the reduced labor requirements of automated systems.

The global Manual Boring Milling Machine market, while not experiencing explosive growth, is characterized by distinct regional and segmental dominance.

Key Regions/Countries:

Key Segments:

These regions and segments are expected to continue driving the World Manual Boring Milling Machine Production landscape, with a focus on quality, precision, and cost-effective solutions for specialized manufacturing needs.

Several factors are acting as growth catalysts, ensuring the continued relevance of the Manual Boring Milling Machine industry. A primary driver is the persistent need for cost-effective precision machining solutions, especially for SMEs and emerging economies. The relatively lower capital expenditure and operational costs compared to advanced automated systems make manual machines an accessible entry point for many manufacturers. Furthermore, the demand for specialized repairs and refurbishment of existing machinery, particularly in industries with long equipment lifecycles, creates a steady market. The increasing emphasis on operator skill development and hands-on training in technical institutions, recognizing the enduring value of manual expertise, also supports this sector. Finally, niche applications within sectors like medical device manufacturing and aerospace, where operator intuition and fine-tuned control are paramount for critical component integrity, continue to fuel demand.

This report offers an unparalleled depth of analysis for the Manual Boring Milling Machine market, extending its coverage beyond mere statistics. It provides critical insights into the strategic positioning of key players like AZ spa, Frejoth International Ltd., Knuth, Cormak, RETOS VARNSDORF s.r.o., AMC-SCHOU, TOS VARNSDORF, Kent Industrial USA, Inc., Summit Machine Tool, and KAAST USA. The report meticulously dissects the World Manual Boring Milling Machine Production trends, offering granular details on both Horizontal and Vertical types, and their specific applications across General Manufacturing, Automotive, Medical, and Aerospace. Furthermore, it thoroughly examines Industry Developments and future market trajectories from 2019 to 2033, with a strong focus on the 2025-2033 forecast period. This comprehensive approach ensures stakeholders are equipped with the knowledge to navigate the evolving landscape of manual boring milling machinery, from understanding market drivers and challenges to identifying lucrative opportunities.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include AZ spa, Frejoth International Ltd., Knuth, Cormak, RETOS VARNSDORF s.r.o., AMC-SCHOU, TOS VARNSDORF, Kent Industrial USA, Inc., Summit Machine Tool, KAAST USA, .

The market segments include Type, Application.

The market size is estimated to be USD 9284 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Manual Boring Milling Machine," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Manual Boring Milling Machine, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.