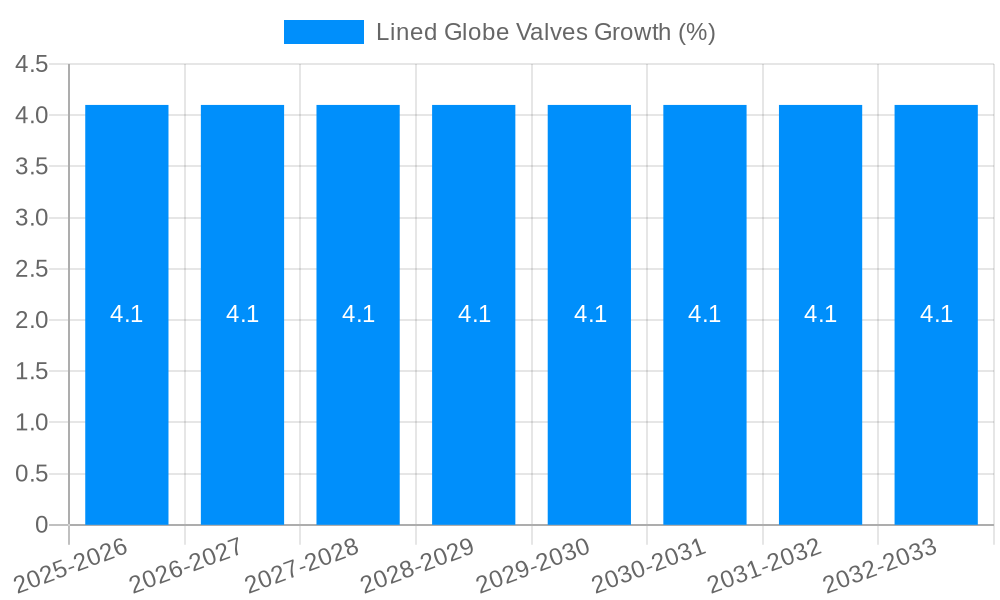

1. What is the projected Compound Annual Growth Rate (CAGR) of the Lined Globe Valves?

The projected CAGR is approximately 4.1%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Lined Globe Valves

Lined Globe ValvesLined Globe Valves by Type (PFA Lined, PTFE Lined, FEP Lined, Others), by Application (Chemical, Petrochemical, Pharmaceutical Industry, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

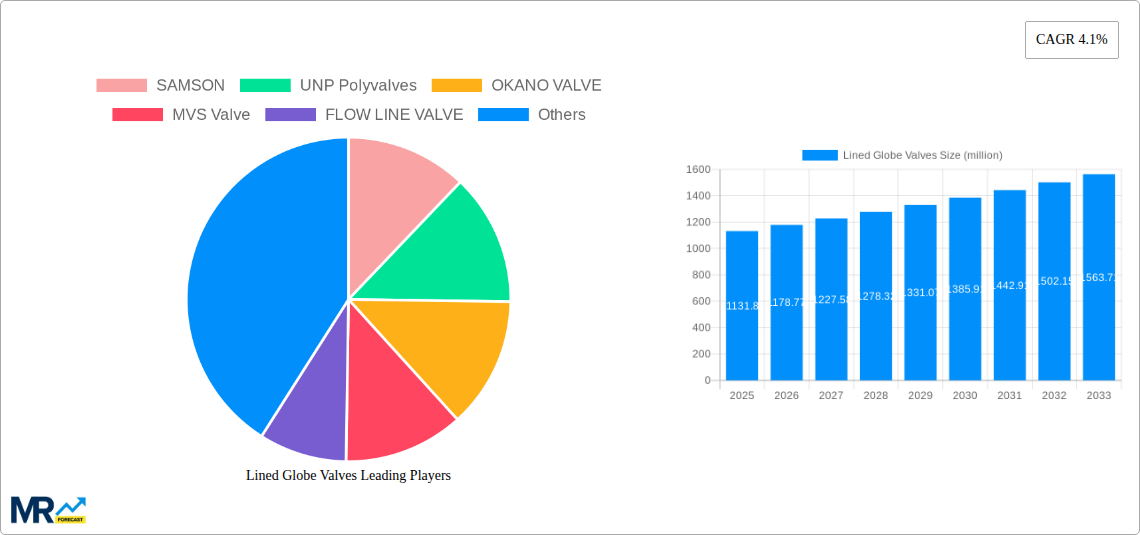

The global Lined Globe Valves market is poised for substantial growth, projected to reach approximately $1131.8 million in 2025 and expand at a Compound Annual Growth Rate (CAGR) of 4.1% through 2033. This upward trajectory is driven by the increasing demand for corrosion-resistant and chemically inert valve solutions across critical industries. The chemical and petrochemical sectors, in particular, are major contributors, necessitating robust valve performance in aggressive processing environments. The pharmaceutical industry also presents a significant growth avenue, driven by stringent quality standards and the need for contamination-free operations. Advancements in lining technologies, such as enhanced PFA, PTFE, and FEP materials, are crucial in meeting these evolving industrial requirements, offering superior chemical resistance and extended service life.

The market is characterized by a strong emphasis on product innovation and strategic collaborations among leading manufacturers like SAMSON, UNP Polyvalves, and OKANO VALVE. These companies are focusing on developing valves with improved sealing capabilities, higher pressure and temperature ratings, and specialized applications. Emerging economies, especially in the Asia Pacific region, are expected to witness accelerated growth due to rapid industrialization and increasing investments in manufacturing infrastructure. However, the market may face challenges related to the initial high cost of specialized lined valves and the need for skilled installation and maintenance. Despite these potential hurdles, the growing need for reliable fluid control in harsh industrial settings, coupled with continuous technological advancements, firmly positions the Lined Globe Valves market for a period of sustained and profitable expansion.

This comprehensive report delves into the global Lined Globe Valves market, offering an in-depth analysis of trends, drivers, challenges, and future prospects. Spanning a study period from 2019 to 2033, with a base year of 2025 and an estimated year of 2025, this report provides valuable insights for stakeholders across the chemical, petrochemical, and pharmaceutical industries, among others. The historical period of 2019-2024 is meticulously examined to establish foundational market dynamics, while the forecast period of 2025-2033 projects future growth trajectories. The report quantifies market values in the millions, offering a clear understanding of the economic landscape.

XXX The global Lined Globe Valves market is poised for robust expansion, driven by an escalating demand for corrosion-resistant and chemically inert flow control solutions across a multitude of industrial applications. During the study period of 2019-2033, the market has witnessed a significant upward trajectory, with the base year of 2025 serving as a crucial benchmark for future projections. The historical performance from 2019 to 2024 has laid a strong foundation, characterized by increasing adoption in stringent processing environments. The estimated year of 2025 reflects a market segment that is maturing, yet still presents substantial opportunities for innovation and growth. The forecast period, from 2025 to 2033, anticipates a sustained and accelerated expansion, fueled by technological advancements, stringent environmental regulations, and the continuous need for reliable fluid handling in critical industries.

Key market insights indicate a growing preference for advanced lining materials such as PFA and FEP, owing to their superior chemical resistance and wider operating temperature ranges compared to traditional PTFE. The chemical industry, a perennial powerhouse in the demand for lined globe valves, continues to be the primary consumer, owing to the highly corrosive nature of many chemical compounds processed. However, the petrochemical sector is increasingly adopting these valves for specialized applications involving aggressive hydrocarbons and sour gas environments, contributing significantly to market value estimated in the millions. Furthermore, the pharmaceutical industry, with its stringent purity requirements and demand for inert materials, represents a rapidly growing segment. The "Others" segment, encompassing industries like wastewater treatment and mining, is also contributing to the overall market value, demonstrating the versatility and broad applicability of lined globe valves. The market is also observing a trend towards more sophisticated valve designs, including enhanced sealing mechanisms and intelligent monitoring capabilities, to ensure operational efficiency and safety. The overall market value is projected to reach significant figures in the millions, underscoring the critical role of lined globe valves in modern industrial operations. The development of specialized lining technologies and materials is expected to further diversify the market and cater to niche applications with extreme performance demands. The interplay between evolving industrial processes and the continuous innovation in valve manufacturing is shaping a dynamic and promising future for the lined globe valve sector.

The global Lined Globe Valves market is experiencing a significant surge, propelled by several potent driving forces. Foremost among these is the ever-increasing demand for corrosion-resistant and chemically inert fluid handling solutions. Industries such as chemical processing, petrochemical refining, and pharmaceuticals routinely handle aggressive media that can rapidly degrade standard valve materials. Lined globe valves, with their robust polymeric linings like PFA, PTFE, and FEP, offer an exceptional barrier against such corrosive substances, ensuring longer service life, reduced maintenance costs, and preventing product contamination. This inherent characteristic makes them indispensable in safeguarding operational integrity and product quality, contributing to market values in the millions.

Furthermore, the stringent regulatory landscape surrounding environmental protection and industrial safety plays a crucial role. As governments worldwide implement stricter guidelines for emissions control and the safe handling of hazardous materials, the adoption of high-integrity valves like lined globe valves becomes imperative. These valves minimize the risk of leaks and fugitive emissions, directly contributing to compliance with environmental standards and enhancing workplace safety. The growing emphasis on process efficiency and automation also drives demand. Lined globe valves offer precise flow control, crucial for optimizing complex industrial processes and reducing operational inefficiencies, thereby bolstering their market value. The continuous innovation in material science, leading to the development of more durable and specialized linings, further expands their application scope and market penetration.

Despite the promising growth trajectory of the Lined Globe Valves market, certain challenges and restraints could potentially impede its full potential. A primary concern is the inherent complexity and cost associated with the lining process. Applying these specialized polymer linings, particularly PFA and FEP, requires specialized equipment and expertise, leading to higher manufacturing costs compared to conventional metal valves. This can translate into a higher upfront investment for end-users, potentially limiting adoption in cost-sensitive applications or smaller enterprises. The limitations in operating temperature and pressure for some lining materials also present a restraint. While advancements are continuously being made, certain extreme conditions may still necessitate the use of alternative, more robust, or exotic alloy valves, thereby capping the market size for standard lined globe valves.

Moreover, the potential for lining damage due to mechanical abrasion or improper handling remains a significant concern. While the linings offer excellent chemical resistance, they can be susceptible to scratching or wear from abrasive particles in the fluid stream or during maintenance procedures. This can lead to premature failure and necessitate costly repairs or replacements, impacting the total cost of ownership and customer satisfaction. The availability of skilled technicians for installation and maintenance can also be a bottleneck in certain regions, as specialized knowledge is required to ensure the longevity and optimal performance of lined globe valves. Lastly, competition from other valve technologies, such as ceramic-lined valves or advanced alloy valves designed for highly corrosive environments, poses a threat, particularly in niche applications where specific performance characteristics are paramount. These challenges, while significant, are being addressed through ongoing research and development efforts aimed at improving lining techniques, material properties, and user education.

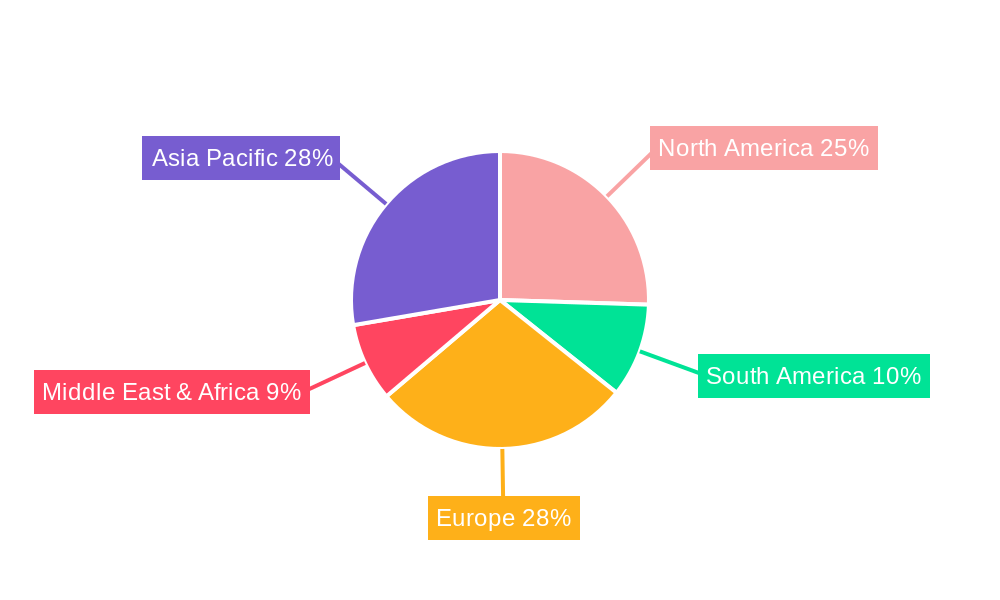

The global Lined Globe Valves market is poised for significant expansion, with specific regions and segments emerging as dominant forces, contributing substantially to market values estimated in the millions.

Dominant Regions:

North America (specifically the United States): This region stands out due to its highly developed chemical and petrochemical industries, which are major consumers of lined globe valves. Stringent environmental regulations and a strong emphasis on process safety drive the demand for high-performance, corrosion-resistant valves. The presence of major global chemical manufacturers and refineries, coupled with significant investments in infrastructure upgrades and new plant constructions, fuels consistent demand. Furthermore, the advanced manufacturing capabilities and adoption of new technologies within the United States contribute to its market leadership. The pharmaceutical industry's robust growth and stringent quality control requirements also bolster the demand for PFA and PTFE lined globe valves in this region.

Europe (particularly Germany and the UK): Similar to North America, Europe boasts a mature and sophisticated chemical, petrochemical, and pharmaceutical landscape. Germany, with its strong chemical manufacturing base, and the UK, with its significant petrochemical operations, are key markets. The region's commitment to sustainability and reducing industrial emissions further propels the adoption of lined globe valves. Investments in upgrading aging industrial infrastructure and adherence to stringent EU regulations concerning material handling and environmental safety are significant drivers. The increasing focus on specialty chemicals and advanced materials also contributes to the demand for specialized lined valve solutions.

Asia Pacific (led by China and India): While historically a follower, the Asia Pacific region is rapidly emerging as a dominant force in the lined globe valves market. Rapid industrialization, coupled with massive investments in the chemical, petrochemical, and pharmaceutical sectors, is driving unprecedented demand. China, as a global manufacturing hub, and India, with its burgeoning pharmaceutical and chemical industries, represent significant growth opportunities. The increasing adoption of Western manufacturing standards and technologies, along with government initiatives to boost domestic manufacturing capabilities, further accelerates market penetration. The demand here is also driven by the need to replace aging infrastructure and build new capacity to meet growing domestic and international market needs.

Dominant Segments:

Type: PFA Lined and PTFE Lined:

Application: Chemical Industry:

Several key factors are acting as significant growth catalysts for the Lined Globe Valves industry. The continuous push for enhanced process safety and environmental compliance across industries is a primary driver. As regulations become more stringent, the need for reliable, leak-proof, and corrosion-resistant valves becomes paramount. Furthermore, advancements in polymer lining technologies, such as improved adhesion techniques, enhanced material properties (e.g., higher temperature resistance, better abrasion resistance), and the development of specialized composites, are expanding the application scope of lined globe valves. The increasing industrialization and infrastructure development in emerging economies, particularly in the Asia Pacific region, are creating substantial demand for new plant constructions and upgrades, directly benefiting the lined globe valves market. Finally, the growing focus on operational efficiency and cost reduction through longer service life, reduced maintenance, and minimized downtime further encourages the adoption of high-quality lined globe valves.

This comprehensive report offers a deep dive into the global Lined Globe Valves market, providing in-depth analysis and actionable insights for stakeholders. It meticulously covers market trends, driving forces, and challenges, offering a nuanced understanding of the factors shaping the industry. Key regions and dominant segments, including PFA, PTFE, and FEP lined valves, along with their applications in the chemical, petrochemical, and pharmaceutical industries, are thoroughly examined. The report quantifies market values in the millions, presenting a clear economic perspective. With a study period spanning 2019-2033, the report leverages a base year of 2025 and an estimated year of 2025 to provide robust forecasts for the 2025-2033 period, building upon a detailed historical analysis from 2019-2024. The report also identifies leading players and significant industry developments, offering a holistic view of the market landscape and its future trajectory.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 4.1% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 4.1%.

Key companies in the market include SAMSON, UNP Polyvalves, OKANO VALVE, MVS Valve, FLOW LINE VALVE, GMK VALVE, Nutech Applicator, Pfeiffer, Apcon, .

The market segments include Type, Application.

The market size is estimated to be USD 1131.8 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Lined Globe Valves," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Lined Globe Valves, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.