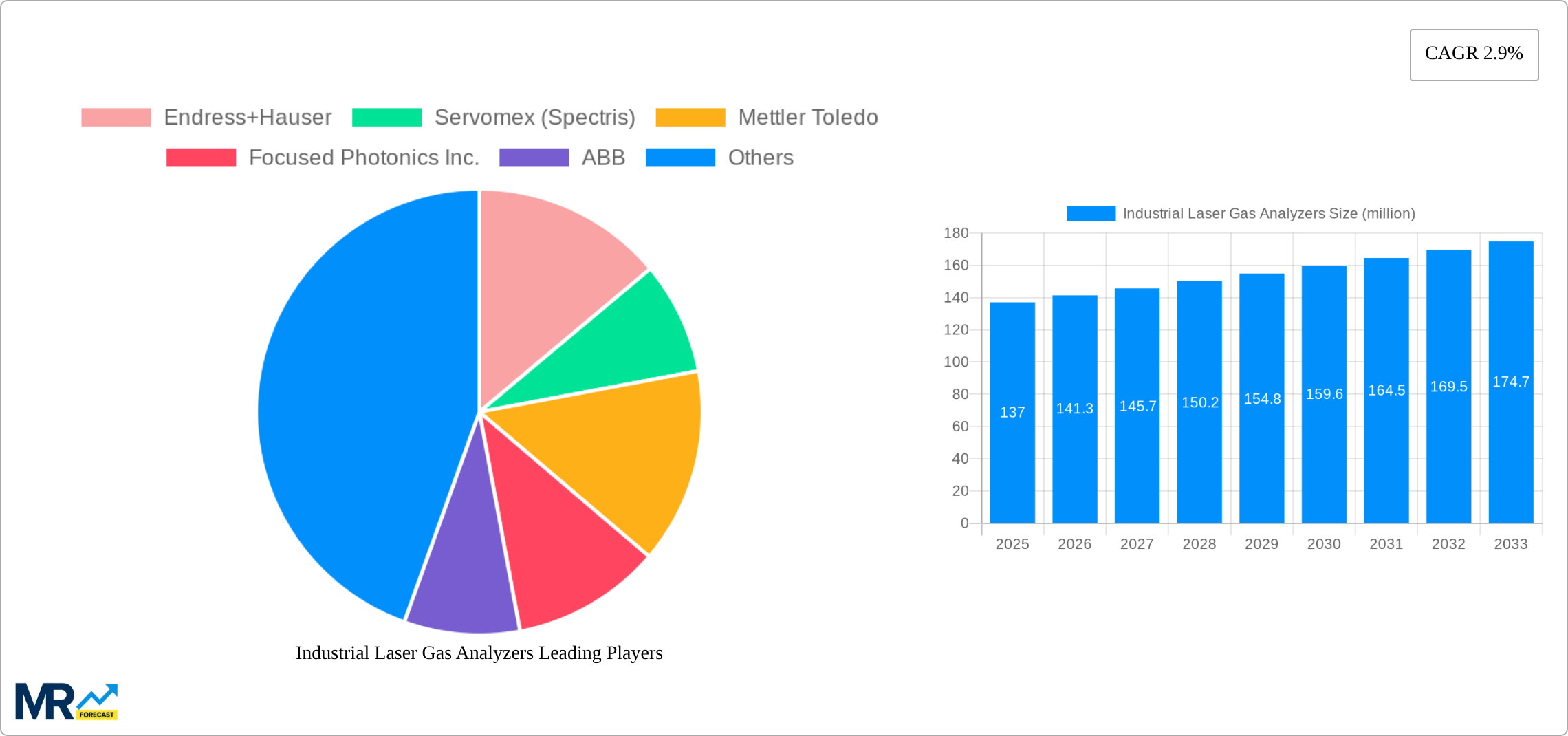

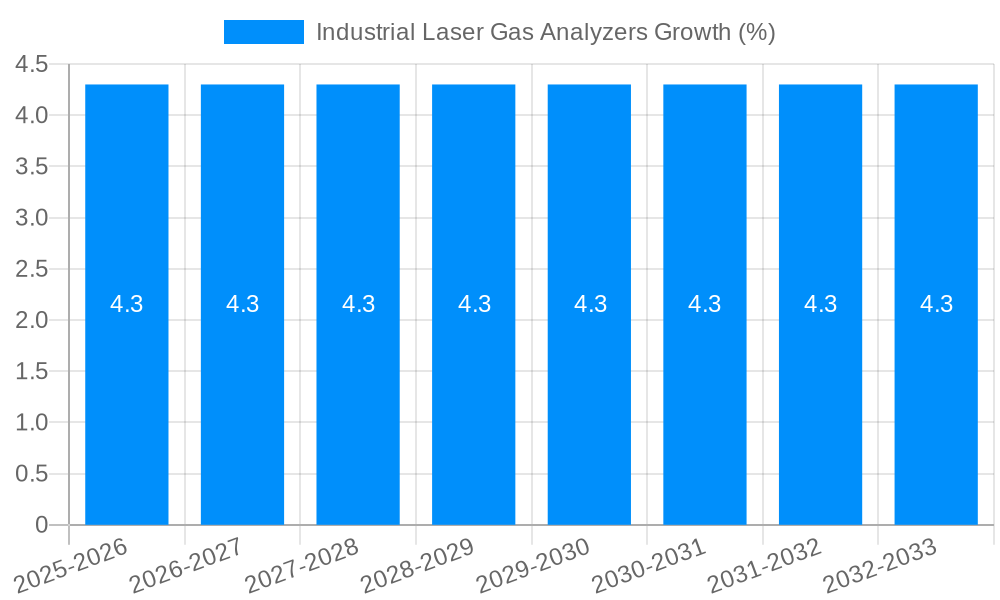

1. What is the projected Compound Annual Growth Rate (CAGR) of the Industrial Laser Gas Analyzers?

The projected CAGR is approximately 2.9%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Industrial Laser Gas Analyzers

Industrial Laser Gas AnalyzersIndustrial Laser Gas Analyzers by Type (In-Situ, Extractive), by Application (Oil & Gas, Power Industry, Metal & Mining, Fertilizer, Cement, Chemical & Pharmaceutical, Pulp & Paper, Steel Industry, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

The global Industrial Laser Gas Analyzers market is projected to reach a substantial value of USD 106.3 million, demonstrating a steady Compound Annual Growth Rate (CAGR) of 2.9% from 2025 to 2033. This growth is propelled by the increasing demand for precise and reliable gas analysis across a wide spectrum of industrial applications. The oil and gas sector, power generation, and the metal and mining industries are identified as key end-users, driven by stringent environmental regulations and the continuous need for operational efficiency and safety. The rising adoption of advanced laser spectroscopy techniques, such as Tunable Diode Laser Absorption Spectroscopy (TDLAS), for in-situ monitoring, contributes significantly to market expansion. These technologies offer advantages like real-time data, non-contact measurement, and enhanced accuracy, making them indispensable for emissions monitoring, process control, and safety applications. The market's trajectory is further supported by ongoing technological advancements leading to more compact, cost-effective, and versatile laser gas analyzer solutions.

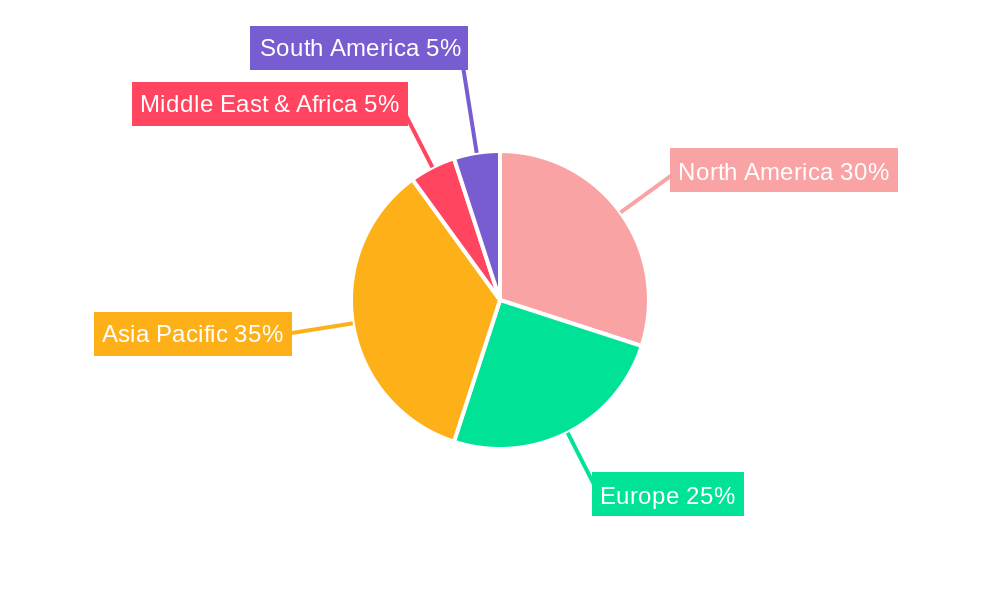

The market's expansion is primarily fueled by the critical role these analyzers play in ensuring compliance with environmental mandates, particularly concerning greenhouse gas emissions and air quality. Industries like cement, chemical, pharmaceutical, and pulp and paper are increasingly investing in these advanced analytical tools to optimize their production processes and minimize their environmental footprint. While the market exhibits robust growth, certain factors could influence its pace. High initial investment costs for sophisticated laser-based systems and the availability of alternative, though often less precise, gas analysis technologies present potential restraints. However, the long-term benefits of improved accuracy, reduced maintenance, and enhanced safety are expected to outweigh these challenges. The competitive landscape features prominent global players, including Endress+Hauser, Servomex (Spectris), Mettler Toledo, ABB, and Siemens, actively engaged in research and development to introduce innovative products and expand their market reach. North America and Europe currently lead the market, with Asia Pacific showing significant growth potential due to rapid industrialization and stricter environmental policies.

The global Industrial Laser Gas Analyzers market is poised for substantial growth, projected to reach an impressive $4,500 million by 2033. This trajectory is driven by an escalating demand for precise and real-time gas monitoring across a multitude of industrial sectors. The study period, spanning from 2019 to 2033, with a base year of 2025, highlights a consistent upward trend. During the historical period of 2019-2024, the market witnessed steady adoption, laying the groundwork for accelerated expansion. The estimated year of 2025 signifies a critical juncture, where existing market dynamics are projected to solidify, leading into a robust forecast period from 2025-2033. A key insight into market trends reveals a significant shift towards In-Situ laser gas analyzers. Their inherent advantages, such as direct measurement without sample conditioning, reduced response times, and lower maintenance requirements, are increasingly appealing to industries striving for operational efficiency and immediate process control. This preference for in-situ technology is a dominant theme shaping the market's evolution. Furthermore, the growing emphasis on stringent environmental regulations globally is a powerful catalyst, compelling industries to invest in advanced gas analysis solutions to ensure compliance and minimize their ecological footprint. This regulatory push is not only driving the adoption of existing technologies but also spurring innovation in developing analyzers capable of detecting a wider range of gases with higher sensitivity. The Oil & Gas sector continues to be a primary consumer of industrial laser gas analyzers, driven by the critical need for safety, process optimization, and emissions monitoring throughout upstream, midstream, and downstream operations. However, the report also identifies burgeoning demand in sectors like Power Industry and Chemical & Pharmaceutical, where precise gas composition analysis is paramount for energy efficiency, product quality, and worker safety. The increasing adoption of Industry 4.0 principles, with a focus on data-driven decision-making and automation, further fuels the demand for sophisticated analytical instruments like laser gas analyzers that can seamlessly integrate into smart manufacturing environments. The market is also characterized by a growing trend towards multi-component analyzers, offering the capability to simultaneously detect and quantify multiple gases, thereby enhancing cost-effectiveness and operational convenience for end-users. This comprehensive approach to gas analysis is a significant evolutionary step within the industry.

Several interconnected factors are propelling the growth of the Industrial Laser Gas Analyzers market. Foremost among these is the escalating global concern for environmental protection and the subsequent implementation of stricter emission control regulations. Governments worldwide are mandating industries to reduce their greenhouse gas emissions and monitor various pollutants, creating a substantial demand for reliable and accurate gas analysis equipment. Laser gas analyzers, with their inherent precision and ability to detect trace amounts of gases, are well-positioned to meet these stringent requirements. The Oil & Gas industry, in particular, is a significant driver, owing to the inherent risks associated with hydrocarbon exploration, production, and refining. Continuous monitoring of process gases, flare stacks, and fugitive emissions is crucial for ensuring operational safety, preventing accidents, and complying with environmental standards. The Power generation sector is another key contributor, with a need to monitor combustion efficiency, emissions such as NOx, SO2, and CO, and ensure compliance with environmental permits. The increasing global energy demand necessitates optimized power generation, and laser gas analyzers play a vital role in achieving this efficiency. Moreover, advancements in laser spectroscopy technology have led to the development of more compact, robust, and cost-effective laser gas analyzers. These technological innovations have broadened their applicability across a wider range of industrial environments, including challenging and hazardous conditions. The integration of these analyzers with advanced data acquisition and analysis systems, facilitating real-time monitoring and predictive maintenance, further enhances their value proposition and drives market adoption.

Despite the promising growth trajectory, the Industrial Laser Gas Analyzers market faces certain challenges and restraints that could impact its full potential. A primary challenge is the high initial investment cost associated with advanced laser gas analyzer systems. While offering long-term benefits, the upfront capital expenditure can be a deterrent for smaller businesses or those in developing economies with limited budgets. This can lead to a preference for less sophisticated, albeit less accurate, measurement techniques. Furthermore, the complexity of installation and maintenance for some laser gas analyzer systems requires skilled personnel and specialized training, which might not be readily available in all industrial settings. This can translate into higher operational costs and longer downtime if not managed effectively. The lack of awareness and understanding of the full capabilities and benefits of laser gas analyzers in certain niche industrial segments could also hinder adoption. While major industries are well-versed, smaller or emerging sectors might not fully appreciate the return on investment and the enhanced safety and efficiency gains achievable through these advanced solutions. The availability of alternative, less expensive gas measurement technologies, such as electrochemical sensors or non-dispersive infrared (NDIR) analyzers, poses a competitive challenge. While laser analyzers often offer superior performance in terms of specificity, accuracy, and response time, the cost-effectiveness of alternatives can sway purchasing decisions in price-sensitive markets. Lastly, stringent calibration and validation protocols required for laser gas analyzers, especially in regulated industries, can add to the operational burden and require significant time and resources, presenting a logistical hurdle for widespread deployment.

The Industrial Laser Gas Analyzers market is anticipated to witness significant dominance from both regional and segmental perspectives. Regionally, North America and Europe are expected to lead the market share during the forecast period. These regions are characterized by well-established industrial infrastructures, stringent environmental regulations, and a high level of technological adoption. Countries like the United States, Germany, and the United Kingdom are at the forefront, driven by advanced manufacturing capabilities and a strong emphasis on process optimization and emissions control. Asia-Pacific, particularly China and India, is emerging as a rapidly growing market, fueled by industrial expansion, increasing environmental awareness, and government initiatives promoting cleaner manufacturing practices.

From a segment perspective, the In-Situ type of Industrial Laser Gas Analyzers is poised to dominate the market. The inherent advantages of in-situ measurement, such as direct probing of the process stream without the need for sample extraction or conditioning, significantly reduce response times and minimize potential measurement errors. This leads to more accurate and real-time data, crucial for critical process control and safety applications. The ability of in-situ analyzers to operate in harsh and high-temperature environments where extractive systems might struggle further solidifies their leadership.

Within the application segments, the Oil & Gas sector is expected to remain the largest contributor. The inherent hazards and the need for continuous monitoring throughout exploration, production, refining, and petrochemical processes necessitate the use of sophisticated gas analysis. This includes monitoring for hydrocarbons, H2S, CO2, and other critical gases to ensure safety, optimize production, and comply with strict environmental regulations. The increasing focus on shale gas production and the expansion of downstream refining capacities further bolster this segment.

Another significant segment driving market growth is the Power Industry. With the global push for cleaner energy and the need for efficient combustion processes, laser gas analyzers are crucial for monitoring emissions like NOx, SO2, CO, and O2 in power plants. This allows for better control of combustion, improved fuel efficiency, and adherence to environmental standards. The growing investment in renewable energy sources also necessitates monitoring of related processes, though the traditional fossil fuel power generation sector will continue to be a major consumer for the foreseeable future.

The Chemical & Pharmaceutical segment also presents substantial growth opportunities. Precise gas analysis is critical in chemical synthesis, reaction monitoring, and ensuring the purity of pharmaceutical products. The requirement for stringent quality control and adherence to regulatory standards in these industries drives the demand for highly accurate and reliable laser gas analyzers.

The Steel Industry is also a notable segment, where laser gas analyzers are used for monitoring combustion gases, process gases, and emissions to optimize furnace operations, improve energy efficiency, and control air pollution.

List of Dominating Segments:

The Industrial Laser Gas Analyzers industry is experiencing several growth catalysts. A primary driver is the increasing global adoption of Industry 4.0 principles, where real-time data from advanced sensors like laser gas analyzers is crucial for automation, predictive maintenance, and overall operational efficiency. Stringent environmental regulations worldwide are compelling industries to invest in sophisticated monitoring solutions to curb emissions and ensure compliance, directly boosting demand for these analyzers. Furthermore, technological advancements in laser spectroscopy are leading to the development of more accurate, sensitive, and cost-effective instruments, expanding their applicability across diverse industrial sectors. The growing emphasis on process optimization and safety in high-risk industries such as Oil & Gas and Power Generation also acts as a significant growth catalyst.

This comprehensive report offers an in-depth analysis of the Industrial Laser Gas Analyzers market, spanning the period from 2019 to 2033. It delves into the intricate market trends, driven by technological advancements and regulatory mandates, with a projected market value of $4,500 million by 2033. The report meticulously examines the driving forces propelling market growth, including the escalating demand for environmental compliance and process optimization, particularly within the Oil & Gas and Power Industry segments. It also addresses the inherent challenges and restraints, such as high initial costs and the need for skilled personnel, that could influence market dynamics. A key focus is placed on identifying the dominating regions and segments, with North America, Europe, and Asia-Pacific highlighted for their substantial market share, and In-Situ analyzers and applications in Oil & Gas, Power Industry, Chemical & Pharmaceutical, and Steel Industry identified as key growth areas. The report further elaborates on the critical growth catalysts, such as Industry 4.0 adoption and stringent environmental regulations. It provides an exhaustive list of leading global players in the market and details significant technological developments and innovations. This report serves as an indispensable resource for stakeholders seeking to understand the current landscape and future trajectory of the Industrial Laser Gas Analyzers market.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 2.9% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 2.9%.

Key companies in the market include Endress+Hauser, Servomex (Spectris), Mettler Toledo, Focused Photonics Inc., ABB, Siemens, Yokogawa Electric, NEO Monitors, Baker Hughes, SICK, HORIBA, AMETEK, Fuji Electric, Shanghai ChangAi, Emerson, Sinosteel Accurate (WuHan) Technology, Nanjing KELISAIKE, Landun Photoelectron, Chongqing Chuanyi Automation, DEFINE Technology, Teledyne Analytical Instruments, Boreal Laser, AnHui Wanyi Science and Technology, Opsis AB, Hangzhou Zetian Technology, Shanxi Guohui Huaguang, ADEV, .

The market segments include Type, Application.

The market size is estimated to be USD 106.3 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Industrial Laser Gas Analyzers," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Industrial Laser Gas Analyzers, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.