1. What is the projected Compound Annual Growth Rate (CAGR) of the Industrial Belt System Maintenance?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Industrial Belt System Maintenance

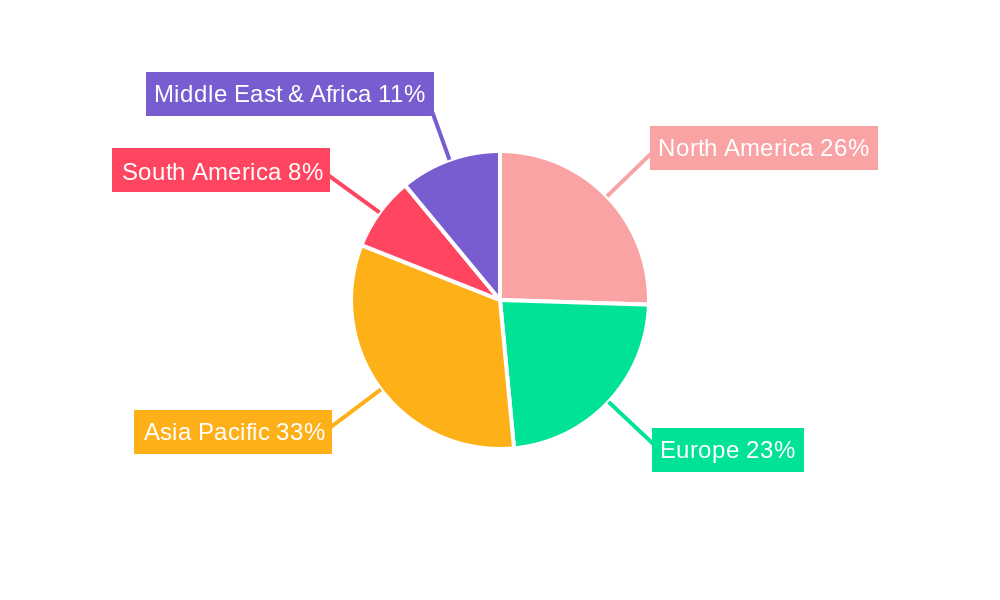

Industrial Belt System MaintenanceIndustrial Belt System Maintenance by Type (/> Maintenance System, Cleaning System), by Application (/> Mining, Automotive, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

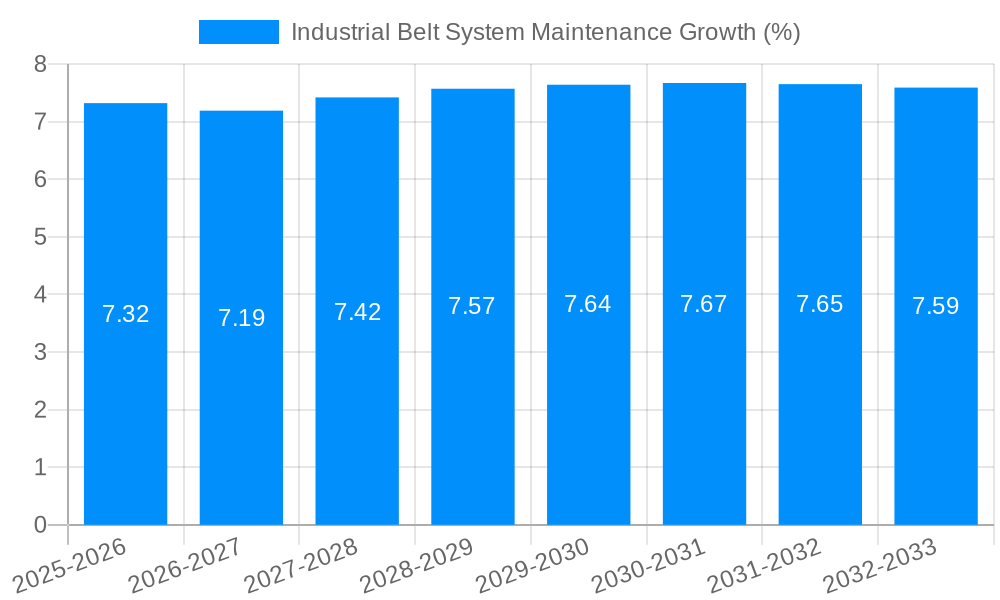

The Industrial Belt System Maintenance market is poised for robust growth, projected to reach an estimated USD 12.3 billion in 2025, driven by a Compound Annual Growth Rate (CAGR) of approximately 7.5% through 2033. This expansion is primarily fueled by the increasing adoption of automated and sophisticated belt systems across core industries such as mining and automotive, where downtime is a significant cost. The continuous demand for enhanced operational efficiency, reduced maintenance expenditure, and prolonged equipment lifespan necessitates advanced maintenance solutions. Key drivers include the growing emphasis on predictive maintenance technologies, the integration of IoT sensors for real-time monitoring, and the development of specialized cleaning systems designed to optimize belt performance and prevent premature wear. Furthermore, the expanding industrial infrastructure globally, particularly in emerging economies, is creating new avenues for market penetration.

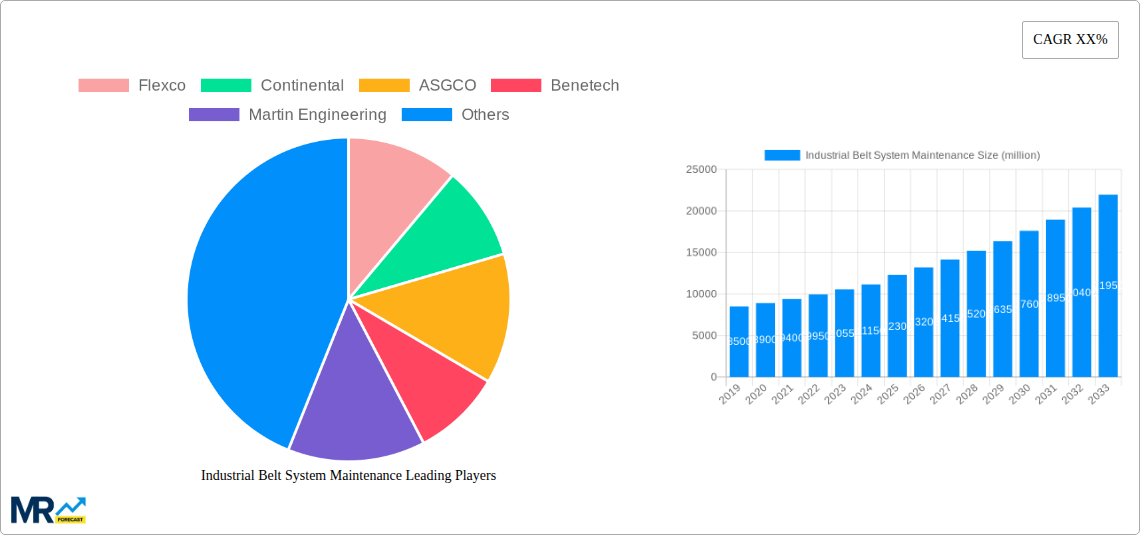

The market is segmented into Maintenance Systems and Cleaning Systems, with Maintenance Systems likely holding a larger share due to the comprehensive nature of proactive and reactive upkeep strategies. Applications in mining are expected to dominate owing to the harsh operating conditions and the critical role of conveyor belts in material handling. While the market exhibits strong growth potential, certain restraints may influence the pace of expansion. These include the initial capital investment required for advanced maintenance systems and the availability of skilled technicians capable of operating and servicing these technologies. However, the long-term benefits of reduced operational costs and improved safety standards are expected to outweigh these challenges. Key players like Flexco, Continental, and Martin Engineering are actively innovating, introducing smart maintenance solutions and eco-friendly cleaning technologies to cater to evolving industry demands and maintain a competitive edge.

Here's a unique report description on Industrial Belt System Maintenance, incorporating your specified details, company names, segments, and dates:

The global industrial belt system maintenance market is poised for significant expansion, driven by an increasing emphasis on operational efficiency, asset longevity, and stringent safety regulations across diverse industrial sectors. The market is projected to witness a robust Compound Annual Growth Rate (CAGR) of XX.XX% from the Base Year of 2025, reaching an estimated market size of $XX.XX million by the end of the Forecast Period in 2033. This growth trajectory is largely attributed to the proactive adoption of advanced maintenance strategies, moving beyond reactive repairs to predictive and preventative approaches. The historical period between 2019 and 2024 laid the groundwork for this evolution, with early adopters recognizing the substantial cost savings and production uptime benefits associated with well-maintained belt systems. The Study Period, spanning from 2019 to 2033, encapsulates this dynamic shift. The increasing complexity of industrial operations and the escalating cost of unscheduled downtime are compelling organizations to invest heavily in sophisticated belt maintenance solutions, including specialized cleaning systems and integrated monitoring technologies. Furthermore, the continuous innovation in belt materials and the development of more durable and efficient conveyor systems are indirectly fueling the demand for specialized maintenance services that can keep pace with these advancements. The integration of IoT sensors and data analytics for real-time performance monitoring is a key trend, allowing for early detection of potential issues and minimizing the risk of catastrophic failures. This proactive approach is not only reducing maintenance costs but also significantly enhancing overall productivity and safety standards within industries such as mining, automotive, and numerous others. The market is also witnessing a growing trend towards specialized maintenance service providers who offer end-to-end solutions, from routine inspections and cleaning to component replacement and system upgrades, further solidifying the market's growth trajectory. The sheer volume of conveyor belt systems operating globally, coupled with the increasing lifespan expectations and the drive for sustainability, ensures a sustained demand for effective maintenance practices. The market is also seeing a geographical shift, with emerging economies gradually adopting these advanced maintenance practices, mirroring the trends observed in more developed industrial regions.

The escalating demand for enhanced operational efficiency stands as a primary catalyst for the industrial belt system maintenance market. In an era where every minute of downtime translates into substantial financial losses, companies across sectors like mining, automotive, and various manufacturing industries are prioritizing strategies that minimize production interruptions. Advanced maintenance systems and cleaning solutions are instrumental in achieving this, ensuring the continuous and reliable operation of critical conveyor belt infrastructure. Secondly, the increasing lifespan and cost of industrial belt systems themselves necessitate robust maintenance practices. Replacing worn-out or damaged belts is a significant capital expenditure, and regular, proactive maintenance extends their operational life, offering considerable cost savings. This economic imperative is driving investment in preventative and predictive maintenance technologies. Moreover, stringent safety regulations across industries are playing a pivotal role. Malfunctioning belt systems can pose serious safety hazards to personnel, leading to accidents and injuries. Consequently, companies are investing in maintenance solutions that guarantee the integrity and safe operation of their belt systems, aligning with compliance requirements and fostering a safer working environment. The continuous technological advancements in belt materials and monitoring systems are also contributing significantly. The introduction of more durable, high-performance belts, coupled with the development of intelligent sensors and data analytics platforms, creates a fertile ground for sophisticated maintenance services that can leverage these innovations to optimize performance and predict potential failures.

Despite the promising growth trajectory, the industrial belt system maintenance market faces several significant challenges and restraints. A primary hurdle is the initial capital investment required for advanced maintenance systems and technologies. Many small and medium-sized enterprises (SMEs) may find the upfront costs of sophisticated cleaning equipment, monitoring sensors, and specialized training programs prohibitive, opting for more traditional, less effective maintenance approaches. Secondly, a shortage of skilled labor trained in the operation and maintenance of modern belt systems presents a considerable restraint. The complexity of new technologies, such as IoT-enabled sensors and data analytics, requires a highly skilled workforce, and a lack of qualified technicians can hinder the widespread adoption of best-in-class maintenance practices. Furthermore, resistance to change and a lack of awareness regarding the long-term benefits of proactive maintenance can also impede market growth. Some organizations may still adhere to outdated, reactive maintenance strategies, failing to recognize the substantial cost savings and efficiency gains that can be achieved through predictive and preventative approaches. The fragmented nature of the market, with a multitude of smaller service providers, can also lead to inconsistencies in service quality and a lack of standardized maintenance protocols, potentially impacting customer confidence. Finally, geographical limitations and accessibility to specialized maintenance services in remote industrial locations can pose challenges, especially in the mining sector where operations are often situated in hard-to-reach areas.

The Maintenance System segment, particularly within the Mining application, is poised to be a dominant force in the industrial belt system maintenance market throughout the Study Period (2019-2033).

Dominance of Maintenance Systems: The inherent nature of mining operations, characterized by vast, continuous conveyor systems transporting heavy and abrasive materials over long distances, necessitates highly robust and specialized maintenance solutions. These systems are the backbone of mining efficiency, and any disruption can lead to catastrophic production losses. Therefore, the demand for comprehensive maintenance systems, encompassing everything from specialized cleaning systems to sophisticated monitoring and diagnostic tools, is exceptionally high. Companies like Metso Outotec, Rulmeca Group, and Superior Industries are key players in providing integrated solutions that address the unique challenges of mining belt maintenance. Their offerings often include automated cleaning mechanisms to prevent material carry-back and pulley lagging, crucial for maintaining belt health and preventing premature wear.

Mining Application as a Growth Engine: The mining industry, by its very nature, relies heavily on continuous material handling through conveyor belts. From extraction at the face to transportation to processing plants or export terminals, belts are in constant use, often under extreme environmental conditions. This relentless usage leads to significant wear and tear, necessitating frequent and effective maintenance. The scale of operations in mining, with kilometers of belting and massive machinery, translates directly into a substantial market for maintenance services and equipment. Furthermore, the increasing global demand for minerals and metals, coupled with the push for greater efficiency and sustainability in mining practices, further amplifies the importance of reliable belt systems. Government regulations concerning environmental impact and worker safety in mining also mandate stringent maintenance protocols. The historical period (2019-2024) saw significant investments in upgrading and maintaining mining infrastructure, a trend expected to continue and accelerate. The Base Year (2025) marks a point where these investments are translating into sustained demand for advanced maintenance.

Synergy with Cleaning Systems: Within the Maintenance System segment, Cleaning Systems will play a particularly crucial role. In mining, preventing material carry-back, a common issue where material adheres to the belt and pulleys, is paramount. Carry-back can lead to belt mistracking, increased wear, and reduced conveying efficiency. Therefore, innovative and effective belt cleaning solutions, offered by companies like Flexco, ASGCO, and Martin Engineering, are integral to the overall maintenance strategy. These systems are constantly evolving, with advancements in scraper technologies, brush cleaners, and impact beds designed to optimize cleaning efficiency while minimizing belt damage.

Technological Integration: The mining sector is increasingly adopting Industry 4.0 principles, integrating IoT sensors, real-time data analytics, and predictive maintenance algorithms into their belt systems. This allows for proactive identification of potential issues such as belt degradation, splice failures, or pulley wear, enabling maintenance teams to intervene before a breakdown occurs. Companies like Benetech and HOSCH are at the forefront of developing these intelligent maintenance solutions, providing the mining industry with the tools to optimize performance and reduce downtime significantly. The Estimated Year (2025) and the subsequent Forecast Period (2025-2033) will witness a surge in the adoption of such integrated maintenance systems within mining operations globally.

The industrial belt system maintenance industry is being propelled by several key growth catalysts. The unrelenting drive for enhanced operational efficiency and reduced downtime across all industrial sectors is paramount. As companies increasingly recognize the direct correlation between effective belt maintenance and their bottom line, investments in advanced maintenance systems and cleaning technologies are on the rise. Furthermore, the growing emphasis on asset longevity and the desire to maximize the lifespan of expensive industrial equipment directly translate into a greater demand for preventative and predictive maintenance strategies. The continuous evolution of belt materials and conveyor technologies also necessitates specialized maintenance solutions to keep pace with these advancements.

This comprehensive report provides an in-depth analysis of the global industrial belt system maintenance market, meticulously examining trends, driving forces, challenges, and future outlooks. It delves into the intricate details of the Maintenance System and Cleaning System segments, with a particular focus on their application within the Mining and Automotive industries. The report offers detailed market sizing and forecasting for the Study Period (2019-2033), including Base Year (2025) and Estimated Year (2025) figures, and a robust Forecast Period (2025-2033). It identifies key regions and countries that are expected to dominate the market and offers strategic insights into the growth catalysts that are shaping the industry's future. The report also provides a detailed overview of the leading players and significant developments, making it an invaluable resource for stakeholders seeking to understand and capitalize on the evolving industrial belt system maintenance landscape.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Flexco, Continental, ASGCO, Benetech, Martin Engineering, Metso Outotec, Rulmeca Group, Richwood Industries, Steinhaus, HOSCH, GURTEC, Multitec, KHD Technology, Airmatic, BMS, Superior Industries, Ransohoff, Fenner Dunlop, GVF Impianti, InduTechnik, STIF, LUTZE, Goodway Technologies, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million.

Yes, the market keyword associated with the report is "Industrial Belt System Maintenance," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Industrial Belt System Maintenance, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.