1. What is the projected Compound Annual Growth Rate (CAGR) of the Hose Test Systems?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Hose Test Systems

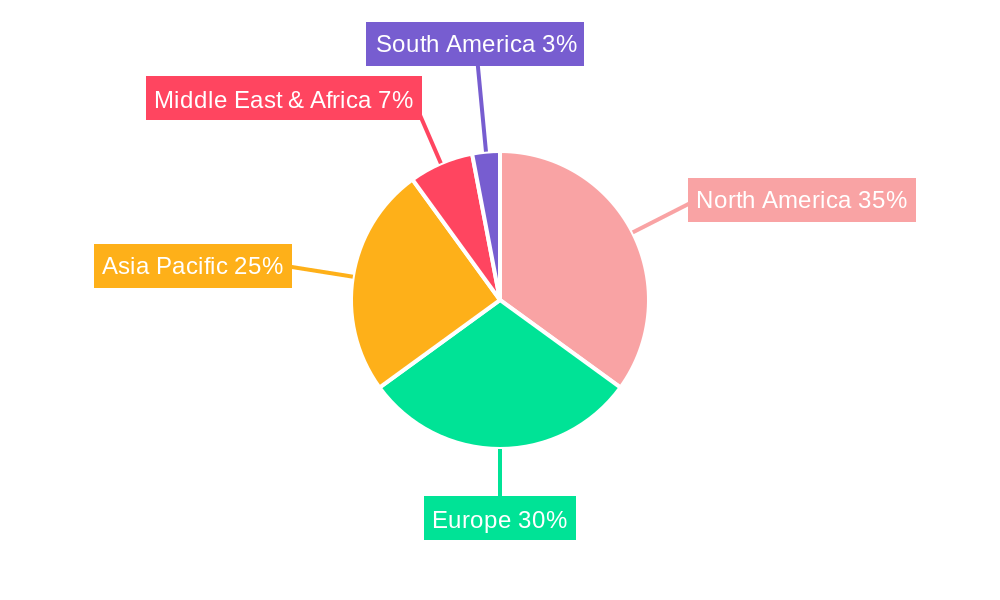

Hose Test SystemsHose Test Systems by Type (Manual, Automatic), by Application (Oil & Gas, Offshore Industry, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

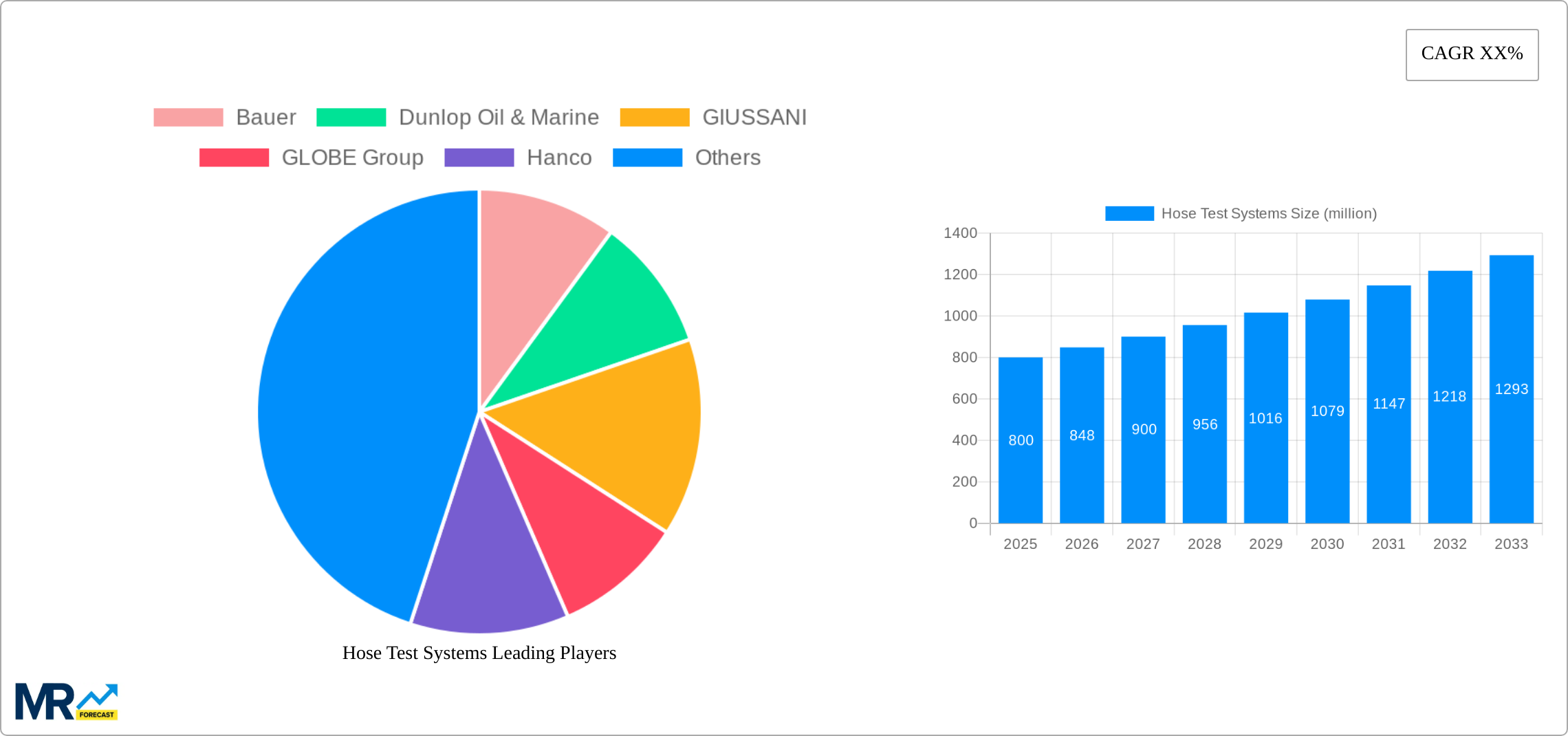

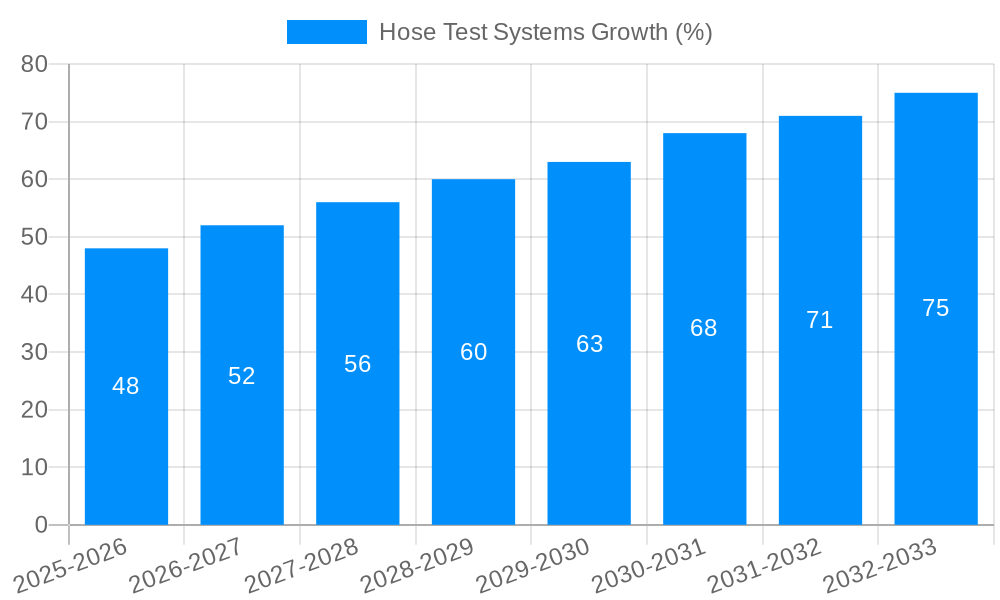

The global Hose Test Systems market is projected to reach a substantial size, estimated at approximately USD 750 million by 2025, with a robust Compound Annual Growth Rate (CAGR) of around 6.5% expected throughout the forecast period of 2025-2033. This expansion is primarily fueled by the escalating demand for safety and reliability in critical industrial applications. The Oil & Gas sector, particularly offshore operations, represents a significant driver due to stringent regulatory compliance and the inherent risks associated with high-pressure fluid transfer. As industries increasingly prioritize the integrity of their fluid conveyance systems, the need for advanced hose testing solutions to prevent failures, ensure operational efficiency, and minimize environmental hazards becomes paramount. The market's growth trajectory is further supported by technological advancements in automated testing equipment, offering enhanced precision, speed, and data management capabilities, thereby appealing to a wider range of industrial clients.

Key trends shaping the Hose Test Systems market include the growing adoption of sophisticated automated systems that reduce manual intervention and improve testing accuracy. Innovations in portable and compact testing units are also gaining traction, enabling on-site testing and reducing downtime for industries like offshore exploration and maintenance. However, certain restraints exist, such as the high initial investment cost for advanced systems, which can be a barrier for smaller enterprises. Furthermore, the availability of standardized testing protocols across different regions and industries poses a challenge for widespread adoption. Despite these constraints, the continuous drive for enhanced safety standards, coupled with the increasing complexity of industrial operations, will continue to propel the demand for effective hose testing solutions, ensuring sustained market growth and innovation in the coming years.

This report offers an in-depth analysis of the global Hose Test Systems market, providing a detailed forecast of its trajectory from the historical period of 2019-2024, through the base and estimated year of 2025, and extending to the forecast period of 2025-2033. With a projected market valuation expected to reach several hundred million dollars, the study encompasses key industry players, emerging trends, driving forces, and significant challenges that will shape the market landscape.

XXX The global Hose Test Systems market is poised for substantial growth, driven by an increasing emphasis on safety, regulatory compliance, and operational efficiency across various industrial sectors. The study period from 2019 to 2033 reveals a dynamic evolution, with the base year of 2025 serving as a critical benchmark for understanding current market conditions and future projections. Over the historical period (2019-2024), the market witnessed steady adoption fueled by burgeoning demand from the oil and gas sector. However, the forecast period (2025-2033) is expected to see an accelerated expansion, with market size projected to reach hundreds of millions of dollars by 2033. This growth is underpinned by advancements in technology, leading to more sophisticated and automated testing solutions. The increasing complexity of industrial hoses, designed to withstand extreme pressures and harsh environments, necessitates rigorous testing to prevent catastrophic failures. Consequently, the demand for reliable and accurate hose test systems is escalating. Furthermore, stringent international safety standards and regulations are compelling industries to invest in advanced testing equipment, ensuring the integrity and longevity of their hydraulic and pneumatic systems. The rise of digital integration, with IoT-enabled test systems offering real-time data logging and remote monitoring capabilities, is also a significant trend. This trend caters to the growing need for predictive maintenance and enhanced operational visibility. The offshore industry, in particular, will continue to be a strong contributor, given its reliance on high-performance hoses in challenging marine environments. Moreover, the "Others" segment, encompassing sectors like manufacturing, aerospace, and general engineering, is also showing promising growth as companies increasingly prioritize safety and quality control. The development of portable and compact test systems will further democratize access to advanced testing solutions, driving adoption in smaller enterprises and remote locations.

The expansion of the Hose Test Systems market is propelled by a confluence of critical factors that underscore the paramount importance of hose integrity in modern industrial operations. Foremost among these is the unwavering global commitment to enhancing safety standards and regulatory compliance. Industries across the spectrum, from the critical Oil & Gas sector to the demanding Offshore Industry, are subject to increasingly stringent regulations that mandate rigorous testing of all fluid conveyance systems, including hoses. Failure to comply can result in severe penalties, operational downtime, and reputational damage, thereby driving a consistent demand for reliable testing solutions. Furthermore, the inherent risks associated with hose failures, particularly in high-pressure and hazardous environments, necessitate proactive measures to prevent accidents and environmental incidents. The economic implications of hose failures are also a significant driver. Replacing failed hoses and addressing the resulting damage can incur substantial costs, including repair expenses, lost production, and potential environmental remediation. Investing in advanced hose test systems, therefore, offers a clear return on investment by mitigating these risks and ensuring operational continuity. The continuous evolution of hose technology itself, with hoses becoming more advanced in material science and capable of handling extreme conditions, also fuels the need for sophisticated testing methodologies. These newer, high-performance hoses require specialized testing protocols to ensure their performance under demanding operational parameters. The growing emphasis on predictive maintenance and asset management within industries is another key driver. Hose test systems that can provide accurate data and identify potential weaknesses before failure occurs enable proactive interventions, extending the lifespan of critical components and optimizing maintenance schedules.

Despite the robust growth trajectory, the Hose Test Systems market is not without its inherent challenges and restraints that could potentially temper its expansion. A primary concern is the high initial investment cost associated with advanced, automated hose test systems. For small and medium-sized enterprises, particularly within the "Others" segment, the significant capital outlay required for state-of-the-art equipment can be a considerable barrier to adoption, leading to continued reliance on less sophisticated manual testing methods. This can indirectly impact the overall market growth by limiting the reach of cutting-edge technology. Another significant restraint is the lack of standardized testing protocols across all applications and regions. While certain sectors have well-defined standards, variations can lead to confusion and the need for customized solutions, increasing complexity and cost. This fragmentation can hinder widespread adoption and interoperability of testing systems. Skilled labor shortage for operating and maintaining sophisticated automated test systems presents a further challenge. The intricate nature of some advanced systems requires specialized training, and a lack of adequately skilled personnel can impede efficient utilization and adoption. Furthermore, the increasing complexity of hose designs and materials necessitates continuous research and development to create testing systems that can accurately assess their performance under diverse and extreme conditions. Keeping pace with these advancements requires substantial investment in R&D, which can be a bottleneck for some manufacturers. Lastly, economic downturns and geopolitical uncertainties can impact capital expenditure budgets across industries, potentially slowing down the procurement of new testing equipment. Industries might defer investments in non-critical upgrades during periods of economic instability, affecting the overall demand for hose test systems.

The global Hose Test Systems market is characterized by regional variations in demand and adoption, driven by industrial concentration and regulatory landscapes. However, two primary segments are poised to significantly influence and potentially dominate the market's trajectory: Automatic Hose Test Systems and the Oil & Gas Application segment.

Automatic Hose Test Systems are expected to lead the market's dominance due to several compelling factors.

The Oil & Gas Application segment is another critical pillar of market dominance.

While other regions and segments will contribute to the market's overall growth, the synergistic interplay between the technological superiority of automatic test systems and the critical, high-demand nature of the Oil & Gas application is expected to be the primary engine driving market dominance in the coming years. The integration of Industry 4.0 principles, with smart, connected testing solutions becoming more prevalent, will further solidify the position of these dominant segments.

The Hose Test Systems industry is experiencing robust growth, primarily fueled by an escalating global emphasis on safety and regulatory compliance. As industries worldwide grapple with stringent international standards for pressure equipment and fluid transfer, the demand for reliable hose testing solutions has surged. Furthermore, the increasing complexity of industrial hoses, designed to withstand more extreme pressures and challenging environments, necessitates advanced testing methodologies to ensure their integrity and prevent costly failures. The growing trend towards predictive maintenance and proactive asset management within sectors like Oil & Gas and the Offshore Industry is also a significant growth catalyst, as companies seek to minimize downtime and optimize operational efficiency.

This comprehensive report delves into the intricate dynamics of the global Hose Test Systems market, offering a detailed forecast from 2019 to 2033. It meticulously analyzes the market's growth trajectory, driven by an unyielding commitment to safety, stringent regulatory frameworks, and the relentless pursuit of operational efficiency across diverse industrial sectors. The report highlights the critical role of technological innovation in shaping the future of hose testing, with a focus on automated solutions and data-driven insights. By examining key market trends, driving forces, and prevailing challenges, this analysis provides stakeholders with a robust understanding of the opportunities and potential roadblocks within this vital industry. The report is an indispensable resource for anyone seeking to navigate the complexities and capitalize on the promising future of the Hose Test Systems market.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Bauer, Dunlop Oil & Marine, GIUSSANI, GLOBE Group, Hanco, Hydratron, Hydraulic Technology, Itensify BV, Maximator, OP Srl, Poppe + Potthoff, Resato, TECHMAFLEX, Uniflex-Hydraulik GmbH, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Hose Test Systems," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Hose Test Systems, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.