1. What is the projected Compound Annual Growth Rate (CAGR) of the Horizontal Piston Compressor?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Horizontal Piston Compressor

Horizontal Piston CompressorHorizontal Piston Compressor by Type (Single Phase, 2 Phase, 3 Phase, Others), by Application (Oil & Gas, Chemical, PET Industry, General Industry, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

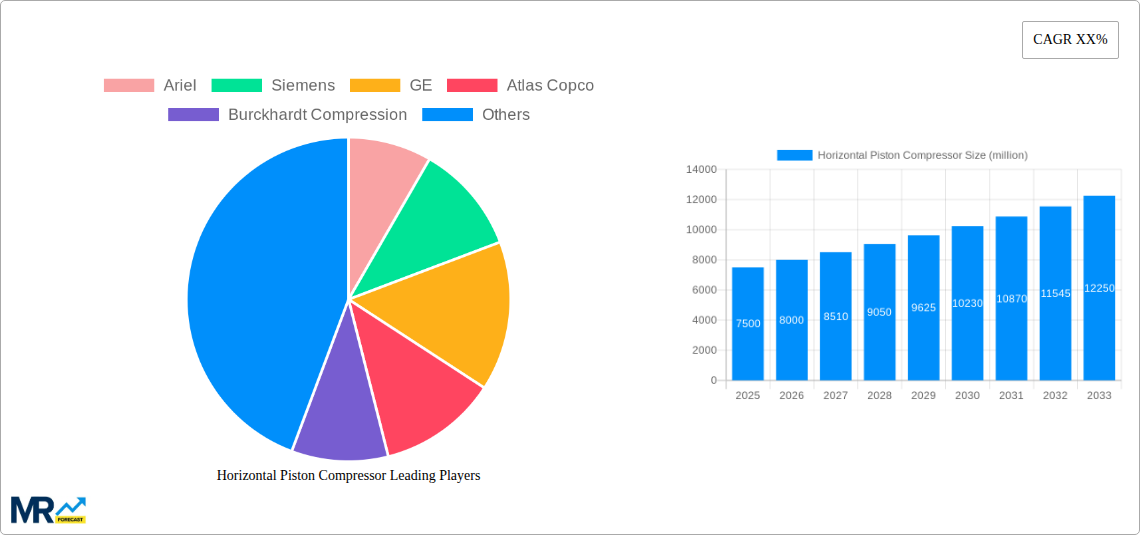

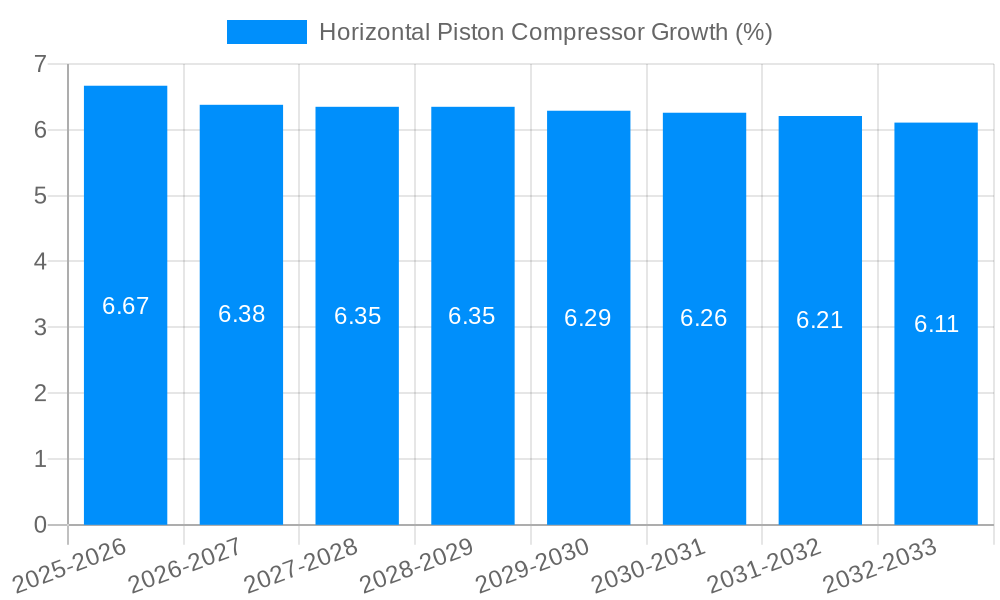

The global horizontal piston compressor market is poised for robust expansion, projected to reach an estimated market size of approximately USD 7,500 million by 2025, with a commendable Compound Annual Growth Rate (CAGR) of around 6.5%. This growth trajectory is primarily fueled by the escalating demand from critical industrial sectors such as Oil & Gas, Chemical, and the PET industry, where the reliability and efficiency of horizontal piston compressors are paramount for processes like gas transportation, chemical synthesis, and plastic manufacturing. The inherent advantages of these compressors, including their durability, ability to handle high pressures, and suitability for continuous operation, make them indispensable for a wide array of industrial applications. Furthermore, ongoing technological advancements, focusing on energy efficiency, reduced emissions, and smart monitoring capabilities, are expected to enhance their appeal and adoption rates across diverse industries.

The market dynamics are further shaped by a confluence of driving forces and emerging trends. Key drivers include the increasing global energy demand, the ongoing expansion of petrochemical facilities, and stringent environmental regulations that necessitate the use of efficient compression technologies. The Asia Pacific region, particularly China and India, is anticipated to emerge as a significant growth engine, driven by rapid industrialization and substantial investments in infrastructure development. While the market presents a promising outlook, certain restraints, such as the high initial capital investment and the availability of alternative compressor technologies, may pose challenges. However, the continuous innovation in materials and design, along with the growing emphasis on lifecycle cost reduction and predictive maintenance, is expected to mitigate these restraints, paving the way for sustained market growth and increasing penetration across both established and nascent industrial landscapes.

The global horizontal piston compressor market, poised for significant expansion between 2019 and 2033, is undergoing a transformative phase driven by evolving industrial demands and technological advancements. Our comprehensive report, with a base year of 2025 and an estimated valuation exceeding 2,500 million USD in the same year, forecasts robust growth throughout the forecast period of 2025-2033. During the historical period (2019-2024), the market exhibited steady progress, laying the foundation for the projected upswing. The core of this trend lies in the increasing adoption of horizontal piston compressors across a spectrum of applications, particularly within the Oil & Gas and Chemical sectors, where their reliability and efficiency are paramount for critical processes such as gas processing, transportation, and chemical synthesis.

The 3 Phase power type segment is anticipated to maintain its dominance, reflecting the significant power requirements of industrial operations that necessitate these robust compressors. Furthermore, the report highlights a growing demand for specialized, high-pressure horizontal piston compressors engineered for challenging environments and demanding gas compositions. Innovation in material science and compressor design is leading to enhanced operational lifespans, reduced maintenance requirements, and improved energy efficiency, all contributing to a more sustainable industrial landscape. The integration of smart technologies, including advanced control systems and remote monitoring capabilities, is also a burgeoning trend, enabling predictive maintenance and optimizing operational performance. This report delves into these intricate trends, providing an in-depth understanding of the market dynamics that are shaping the future of horizontal piston compressors. We project the market to reach a staggering 4,200 million USD by 2033, signifying a compound annual growth rate (CAGR) of approximately 5.0% during the forecast period.

Several key factors are acting as powerful accelerators for the global horizontal piston compressor market. Foremost among these is the continuous expansion and modernization of the Oil & Gas industry. As exploration and production activities intensify, particularly in emerging economies, the need for reliable and high-capacity compressors for natural gas gathering, processing, and transportation becomes increasingly critical. These compressors are indispensable for maintaining pipeline pressures and facilitating the efficient movement of hydrocarbons. Complementing this is the sustained growth within the Chemical industry. The synthesis of various chemicals, petrochemicals, and fertilizers often involves processes that require precise gas compression for reactions and material handling. The inherent robustness and adaptability of horizontal piston compressors make them ideal for these demanding chemical applications, even with corrosive or toxic gases.

Furthermore, the ongoing industrialization and manufacturing boom in developing regions are creating substantial demand for general industrial applications, from large-scale manufacturing plants to specialized processing facilities. This broad-based industrial activity fuels the need for versatile and dependable compression solutions. Coupled with these sector-specific drivers, a broader trend towards enhancing operational efficiency and reducing energy consumption across industries plays a vital role. Horizontal piston compressors, particularly those with advanced designs and control systems, offer a compelling solution for companies looking to optimize their energy footprints and lower operating costs. The report's analysis, based on extensive data from 2019-2024 and projecting through 2033, underscores the cumulative impact of these forces, projecting a dynamic and upward trajectory for the market.

Despite the promising growth outlook, the horizontal piston compressor market is not without its significant challenges and restraints that could temper its expansion. One of the primary hurdles is the inherent high initial capital expenditure associated with purchasing and installing horizontal piston compressors. These units are complex pieces of machinery, and their robust construction and specialized engineering contribute to a substantial upfront cost, which can be a deterrent for smaller businesses or those with tight budgetary constraints.

Another considerable challenge is the increasing competition from alternative compressor technologies. While horizontal piston compressors excel in certain applications, centrifugal compressors and screw compressors are gaining traction, particularly in scenarios requiring very high flow rates or specific pressure profiles. These alternatives may offer advantages in terms of energy efficiency for certain operating conditions or lower maintenance costs in some instances, presenting a competitive threat. Furthermore, the complexity of maintenance and repair can pose a significant operational challenge. Horizontal piston compressors often require specialized knowledge and trained personnel for their servicing, and the availability of such expertise, especially in remote industrial locations, can be a limiting factor. Downtime for maintenance can also be considerable, leading to production losses. Environmental regulations and the increasing focus on noise pollution are also becoming more stringent. While advancements are being made, the inherent operational noise of some piston compressors can necessitate additional soundproofing measures, adding to installation costs and complexity. The report's detailed analysis addresses these constraints, providing a balanced perspective on the market's future.

Segments Dominating the Market:

Type: 3 Phase compressors are anticipated to continue their reign as the dominant segment within the horizontal piston compressor market. This is fundamentally due to the significant power demands of the primary industries that rely heavily on these machines. For instance, large-scale Oil & Gas operations, major chemical plants, and extensive manufacturing facilities invariably require the substantial and consistent power output that 3-phase electric motors can provide to drive these robust compressors efficiently. The continuous operation and high-duty cycles inherent in these applications necessitate the reliable and powerful nature of 3-phase driven units. The market share of this segment is projected to remain above 70% throughout the forecast period.

Application: The Oil & Gas and Chemical industries are poised to be the leading application segments driving the demand for horizontal piston compressors. The Oil & Gas sector, encompassing upstream exploration and production, midstream transportation, and downstream refining, presents a vast and consistent demand. Compressors are integral to gas lift operations, pipeline boosting, gas gathering, and vapor recovery. The sheer scale of operations and the critical nature of gas handling in this sector make horizontal piston compressors a preferred choice due to their reliability, durability, and ability to handle a wide range of gas compositions and pressures. In 2025, this segment is estimated to account for over 35% of the total market revenue.

The Chemical industry follows closely, with applications ranging from the production of fertilizers and petrochemicals to the synthesis of specialty chemicals. These processes often involve compressing gases for reactions, separation, and material transfer. The ability of horizontal piston compressors to handle corrosive or toxic gases, coupled with their precision in pressure control, makes them indispensable in this sector. The ongoing expansion of chemical manufacturing, particularly in Asia-Pacific, is a significant growth driver. This segment is expected to contribute approximately 30% to the market's revenue in 2025. The PET Industry, while a smaller but growing segment, also contributes to the demand, particularly in the pre-polymerization stages and for the compression of blowing agents. General Industry applications, though diverse, will collectively represent a notable portion of the market, driven by manufacturing and processing needs across various sub-sectors. The combined revenue from these application segments is expected to reach over 3,700 million USD by 2033.

Key Region/Country Driving Demand:

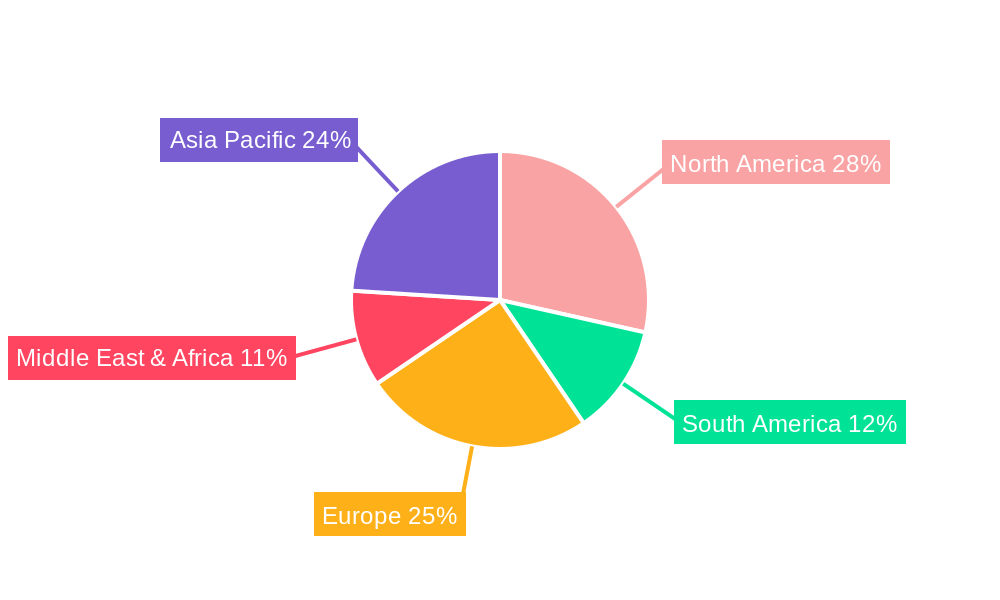

Asia-Pacific: This region is projected to be the most dominant and fastest-growing market for horizontal piston compressors. The robust industrialization, expanding energy infrastructure, and burgeoning chemical manufacturing sectors in countries like China, India, and Southeast Asian nations are key drivers. Significant investments in oil and gas exploration and refining, coupled with a growing demand for petrochemical products, fuel the need for these compressors. China, in particular, with its vast manufacturing base and ambitious industrial policies, represents a substantial portion of the regional demand.

North America: This region will continue to be a significant market, primarily driven by the mature yet active Oil & Gas industry, especially in the United States. Advancements in shale gas extraction and the need for associated gas processing and transportation infrastructure ensure a steady demand. Furthermore, the presence of established chemical manufacturing and general industrial sectors contributes to sustained market growth.

Middle East & Africa: This region is a critical hub for oil and gas production, leading to substantial demand for compressors in upstream and midstream operations. The ongoing development of petrochemical complexes and liquefied natural gas (LNG) facilities further bolsters the market for horizontal piston compressors.

The horizontal piston compressor industry is experiencing several key growth catalysts. A significant driver is the continued expansion of the global Oil & Gas sector, particularly in regions with substantial natural gas reserves and ongoing exploration activities. The increasing demand for cleaner energy sources also fuels the need for compressors in natural gas processing and transportation. Furthermore, the growing chemical and petrochemical industries worldwide, especially in emerging economies, require reliable compression solutions for a multitude of synthesis and processing applications. Technological advancements leading to improved energy efficiency, enhanced durability, and reduced maintenance requirements for horizontal piston compressors are also acting as strong catalysts, making them more attractive to end-users looking to optimize operational costs and sustainability.

This report provides an exhaustive examination of the horizontal piston compressor market, offering unparalleled insights for stakeholders. Our analysis delves deep into market segmentation, meticulously dissecting trends across various compressor types such as single-phase, 2-phase, and 3-phase, with a particular emphasis on the dominant 3-phase segment. We also conduct a granular evaluation of applications, spotlighting the significant contributions and future potential of the Oil & Gas, Chemical, PET Industry, and General Industry sectors. The report meticulously details industry developments, charting the trajectory of technological innovations and market evolution from 2019 through to a projected 2033. Crucially, it identifies the key growth catalysts, including the unwavering expansion of the energy sector and the burgeoning chemical industry, alongside the challenges and restraints that could influence market dynamics. This comprehensive coverage ensures a holistic understanding of the market's current state and future prospects, making it an indispensable resource for strategic decision-making.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Ariel, Siemens, GE, Atlas Copco, Burckhardt Compression, Howden, Ingersoll Rand, Hitachi, Kobelco, Shenyang Yuanda, Neuman & Esser, Gardner Denver, Shenyang Blower, Sundyne, Atelier Francois, ABC COMPRESSORS, KAESER, Mayekawa, Corken, Fusheng, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Horizontal Piston Compressor," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Horizontal Piston Compressor, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.