1. What is the projected Compound Annual Growth Rate (CAGR) of the FRP Reactor?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

FRP Reactor

FRP ReactorFRP Reactor by Type (Electric Heating Type, Liquid Heating Type, Others), by Application (Petroleum, Chemical, Medicine, Food, Pesticides, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

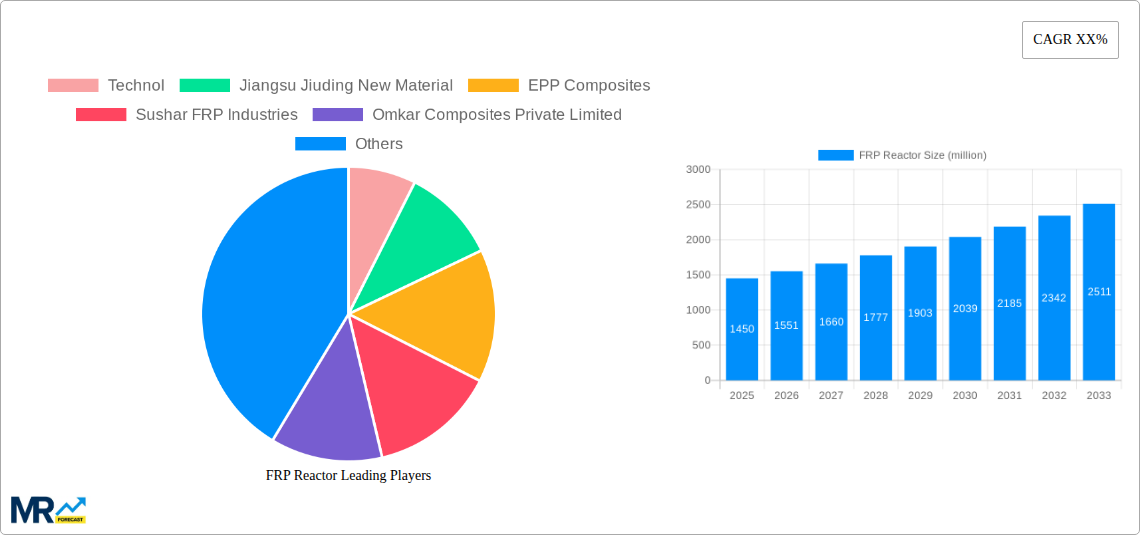

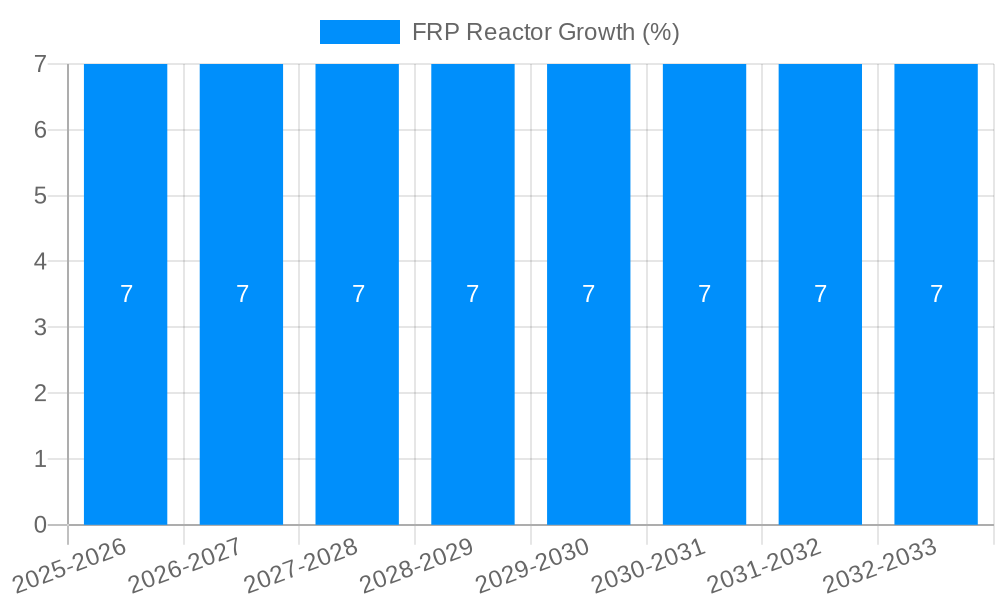

The global FRP Reactor market is projected for substantial growth, anticipated to reach an estimated value of approximately $1,450 million by 2025. This robust expansion is driven by the increasing demand for corrosion-resistant and lightweight materials across various industries, including petroleum, chemical, and medicine. The market is expected to witness a Compound Annual Growth Rate (CAGR) of around 7.5% from 2025 to 2033, indicating a sustained upward trajectory. Key growth enablers include the superior chemical resistance and durability offered by FRP (Fiber Reinforced Polymer) reactors compared to traditional materials like steel and glass-lined steel. Furthermore, the growing emphasis on operational safety and reduced maintenance costs in hazardous industrial environments significantly contributes to the adoption of FRP reactors. Technological advancements in composite manufacturing processes and the development of specialized resin systems are also fueling market expansion by enhancing the performance and application range of these reactors.

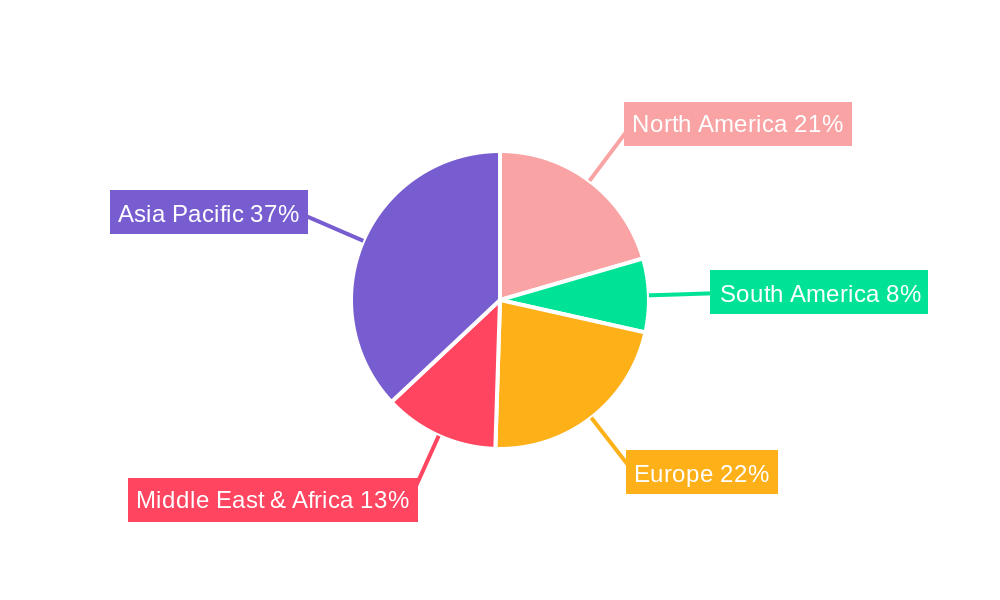

The market is segmented by type into Electric Heating Type, Liquid Heating Type, and Others. The Electric Heating Type and Liquid Heating Type segments are expected to see significant demand due to their specialized applications in controlled heating processes within chemical and pharmaceutical manufacturing. In terms of applications, the Petroleum and Chemical sectors are leading the adoption of FRP reactors, driven by their inherent resistance to aggressive chemicals and high-pressure environments. The Medicine and Food industries are also emerging as key growth areas, owing to stringent regulatory requirements for hygienic and inert materials. Geographically, the Asia Pacific region, particularly China and India, is anticipated to dominate the market, driven by rapid industrialization and significant investments in manufacturing infrastructure. North America and Europe also represent mature markets with consistent demand from established chemical and petroleum industries. Restraints such as the initial high cost of manufacturing and the need for specialized installation expertise are being mitigated by the long-term cost benefits and superior performance characteristics of FRP reactors.

Here is a unique report description for FRP Reactors, incorporating your specific requirements:

The FRP (Fiber Reinforced Polymer) Reactor market is poised for significant expansion, driven by its inherent advantages in corrosion resistance, lightweight construction, and cost-effectiveness compared to traditional materials. Over the Study Period of 2019-2033, the market is expected to witness a compound annual growth rate (CAGR) of approximately 7.5%, with the Base Year of 2025 setting a robust valuation of roughly $2.8 billion. This trajectory is fueled by escalating demand from crucial industrial sectors that are increasingly prioritizing durable and low-maintenance infrastructure. The Forecast Period of 2025-2033 anticipates a market value soaring to an estimated $4.9 billion, reflecting sustained innovation and adoption. During the Historical Period of 2019-2024, the market already demonstrated promising growth, averaging around 6.2% CAGR, laying a strong foundation for future acceleration. Key market insights reveal a discernible shift towards advanced composite materials offering superior performance in aggressive chemical environments, particularly in the Petroleum and Chemical industries, which are projected to collectively hold over 60% of the market share. Furthermore, the increasing focus on stringent environmental regulations and the need for safer operational processes are acting as indirect catalysts, pushing manufacturers to invest in reliable and long-lasting equipment like FRP reactors. The market is also experiencing diversification, with emerging applications in the Medicine and Food industries gaining traction, albeit at a smaller scale, contributing an estimated 15% and 10% respectively to the overall market. The evolution of manufacturing techniques, including filament winding and pultrusion, is enhancing the structural integrity and application breadth of FRP reactors, making them a compelling alternative for a wider array of industrial needs. The penetration of electric heating types and liquid heating types is also expected to grow, with advancements in insulation and heating element integration further solidifying their market presence. The overarching trend is towards tailored solutions, with manufacturers increasingly offering customized FRP reactor designs to meet specific process requirements.

The FRP Reactor market's upward trajectory is propelled by a confluence of powerful factors. Foremost among these is the escalating global demand for corrosion-resistant materials across a spectrum of heavy industries. Traditional materials like steel and stainless steel, while robust, often succumb to aggressive chemicals, leading to frequent replacements and costly downtime. FRP reactors, with their superior chemical inertness and resistance to a wide range of acids, bases, and solvents, offer a significantly longer lifespan and reduced maintenance expenditure. This inherent durability translates into substantial cost savings for end-users, particularly in sectors such as petroleum refining, chemical processing, and wastewater treatment, which are characterized by highly corrosive environments. Furthermore, the increasing stringency of environmental regulations worldwide is indirectly bolstering the demand for FRP reactors. These regulations often mandate the use of safer and more reliable equipment to prevent leaks and spills, minimizing environmental contamination. FRP reactors, with their seamless construction and inherent resistance to degradation, align perfectly with these safety and environmental imperatives. The lightweight nature of FRP materials also contributes to ease of installation and transportation, leading to reduced project costs and faster deployment times. This is particularly advantageous in remote locations or where infrastructure is a constraint. The continuous innovation in composite material science and manufacturing processes is further enhancing the performance and versatility of FRP reactors, opening up new application avenues and solidifying their competitive edge against conventional materials. The projected market valuation of approximately $4.9 billion by 2033 is a testament to these strong underlying growth drivers.

Despite the promising growth outlook, the FRP Reactor market is not without its hurdles. One significant challenge is the perception and awareness gap that still exists in certain traditional industries. While the benefits of FRP are becoming more widely recognized, some sectors remain hesitant to transition away from established materials like stainless steel due to historical familiarity and ingrained procurement practices. Educating these potential adopters about the long-term cost-effectiveness and superior performance of FRP reactors is an ongoing task. Another restraint arises from the initial capital investment. Although FRP reactors offer lower lifecycle costs, the upfront purchase price can sometimes be higher than equivalent reactors made from less advanced materials, posing a barrier for smaller enterprises or those with limited capital budgets. The complexity of manufacturing and quality control also presents a challenge. Ensuring consistent product quality and adherence to stringent industry standards requires specialized expertise and advanced manufacturing facilities, which can limit the number of capable manufacturers. Furthermore, the development of robust repair and maintenance protocols for FRP reactors is still evolving. While they are inherently durable, unforeseen damage can occur, and the specialized techniques required for effective repairs may not be as readily available or understood as those for metal reactors. Extreme temperature applications, especially those exceeding 200°C, can also pose a limitation for certain types of FRP resins, necessitating careful material selection and design considerations, which can add to the overall cost and complexity. The market's reliance on specific raw material supply chains, such as fiberglass and resins, can also be subject to price volatility, impacting production costs and market pricing.

The Chemical segment, projected to account for over 45% of the FRP Reactor market by 2033, is set to be a dominant force, driven by its extensive and demanding applications. Within this segment, the Liquid Heating Type FRP reactors are expected to lead, capturing an estimated 30% of the overall market share due to their widespread use in chemical synthesis, distillation, and various heat transfer processes. These reactors are indispensable for managing exothermic and endothermic reactions, where precise temperature control is paramount. The inherent corrosion resistance of FRP makes it ideal for handling a vast array of aggressive chemicals commonly found in the chemical industry, from strong acids like sulfuric acid and hydrochloric acid to alkaline solutions and organic solvents, which would rapidly degrade traditional metal reactors. The significant market value attributed to this segment, estimated to contribute well over $2.0 billion to the total market by 2033, underscores its criticality.

Regions such as Asia Pacific are poised to emerge as the dominant geographical market, driven by rapid industrialization, significant investments in manufacturing infrastructure, and a growing focus on developing advanced materials. Countries like China and India, with their burgeoning chemical, petroleum, and pharmaceutical industries, represent substantial consumption hubs. The Petroleum industry, another major application, is also a key driver, with FRP reactors being employed in various stages of oil and gas processing, including storage, refining, and transportation of corrosive hydrocarbons. The need for robust and long-lasting equipment in these challenging environments further amplifies the demand for FRP solutions.

In terms of specific segments, the Liquid Heating Type reactors are expected to witness substantial growth across all major applications due to their versatility in maintaining specific process temperatures. For instance, in the Medicine industry, precise temperature control is critical for pharmaceutical synthesis and sterilization processes, where contamination from corroded materials is unacceptable. Similarly, the Food industry relies on these reactors for pasteurization, sterilization, and ingredient processing, demanding hygienic and non-reactive containment. The Electric Heating Type is also anticipated to see consistent growth, particularly in niche applications requiring localized and efficient heating. The overall market is expected to reach an estimated $4.9 billion by 2033, with the Chemical and Petroleum segments forming the bedrock of this valuation.

The FRP Reactor industry is being catalyzed by several key advancements. The continuous innovation in composite materials, leading to enhanced mechanical strength, higher temperature resistance, and improved chemical compatibility, is a primary growth catalyst. Furthermore, the increasing adoption of sophisticated manufacturing techniques like filament winding and pultrusion allows for the production of larger, more complex, and highly engineered FRP reactors, expanding their application scope. The growing emphasis on sustainability and the circular economy is also indirectly driving demand, as FRP reactors are often more energy-efficient to produce and have a longer service life, reducing waste.

This report offers a comprehensive analysis of the FRP Reactor market, providing in-depth insights into market dynamics, growth drivers, and challenges. It meticulously forecasts market size and growth rates for the Study Period of 2019-2033, with a Base Year of 2025 and a detailed breakdown of the Forecast Period of 2025-2033. The report delves into the strategic initiatives and competitive landscape, featuring an exhaustive list of leading players and their key developments. Through detailed segmentation by type, application, and region, it identifies lucrative opportunities and emerging trends, offering a holistic view for stakeholders seeking to navigate and capitalize on this expanding market. The projected market valuation of approximately $4.9 billion by 2033 highlights the significant economic potential and the strategic importance of understanding the forces shaping this industry.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Technol, Jiangsu Jiuding New Material, EPP Composites, Sushar FRP Industries, Omkar Composites Private Limited, Hunan Huanan, Huadong Chemical Equipment, Zhejiang Huanxing, Global Fibre Glass Co, Shandong Kepai, Shandong Wenshuo, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "FRP Reactor," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the FRP Reactor, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.