1. What is the projected Compound Annual Growth Rate (CAGR) of the Electrostatic Discharge Packaging?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Electrostatic Discharge Packaging

Electrostatic Discharge PackagingElectrostatic Discharge Packaging by Type (Bags, Trays, Boxes & Containers, ESD Foams, Others), by Application (Communication Network Infrastructure, Consumer Electronics, Computer Peripherals, Automotive Industry, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

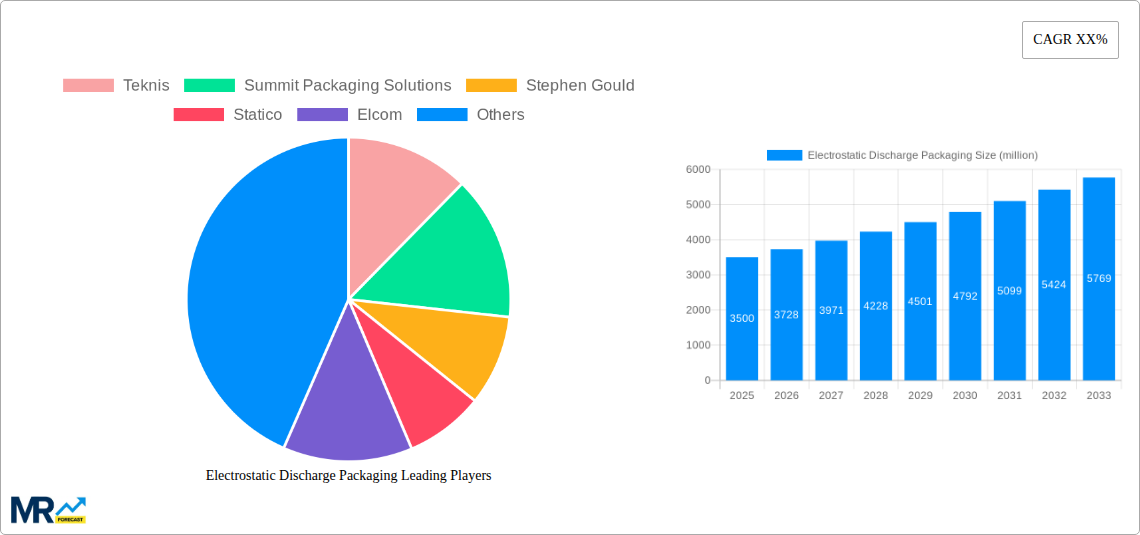

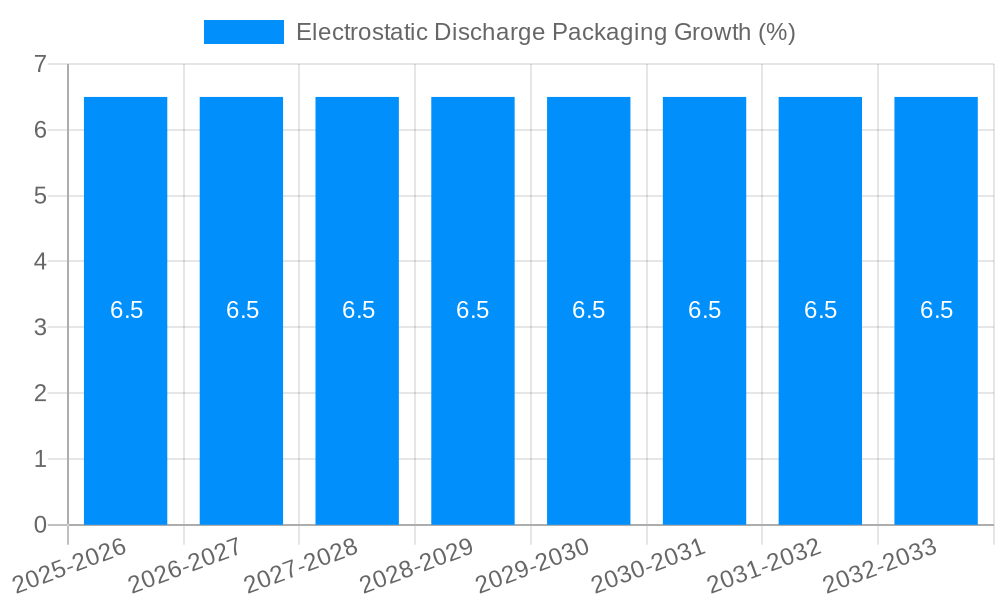

The Electrostatic Discharge (ESD) packaging market is experiencing robust growth, driven by the increasing proliferation of sensitive electronic components across a multitude of industries. With a current market size estimated at approximately $3,500 million in 2025 and projected to expand at a Compound Annual Growth Rate (CAGR) of 6.5%, the market is poised for significant expansion through 2033. This upward trajectory is fundamentally fueled by the escalating demand for sophisticated communication network infrastructure, the ever-growing consumer electronics sector, and the critical need for reliable protection in the automotive industry. As electronic devices become more intricate and powerful, so too does their susceptibility to electrostatic discharge, making advanced ESD packaging solutions indispensable for safeguarding these valuable components during manufacturing, storage, and transit. The increasing adoption of automation and smart manufacturing processes further amplifies the need for high-performance ESD packaging to prevent costly product failures and ensure supply chain integrity.

The market's expansion is further supported by key trends such as the development of sustainable and recyclable ESD packaging materials, offering manufacturers a more environmentally conscious alternative without compromising on protective capabilities. Innovations in material science are leading to lighter, more durable, and cost-effective ESD solutions. However, the market faces certain restraints, including the initial high cost of specialized ESD packaging for some applications and the potential for supply chain disruptions impacting raw material availability. Despite these challenges, the expanding range of applications beyond traditional electronics, including medical devices and aerospace, alongside the increasing awareness of the importance of ESD protection, will continue to propel the market forward. Key players such as Teknis, Summit Packaging Solutions, and Desco Industries are at the forefront of innovation, developing advanced solutions to meet the evolving needs of a dynamic global market.

Here's a comprehensive report description for Electrostatic Discharge (ESD) Packaging, incorporating your specified elements:

This in-depth market analysis delves into the Electrostatic Discharge (ESD) Packaging sector, offering a detailed examination of its dynamics, trends, and future trajectory. The report spans a comprehensive Study Period of 2019-2033, with a Base Year and Estimated Year of 2025, and a robust Forecast Period from 2025-2033, building upon insights from the Historical Period of 2019-2024. The report aims to equip stakeholders with actionable intelligence by dissecting market drivers, identifying inherent challenges, and pinpointing areas of significant growth potential. Leveraging extensive primary and secondary research, this report quantifies market opportunities, with projections often exceeding several million units, providing a tangible understanding of scale and demand.

The global Electrostatic Discharge (ESD) Packaging market is poised for substantial growth, driven by an escalating awareness of the detrimental effects of electrostatic discharge on sensitive electronic components. This surge in demand is intrinsically linked to the ubiquitous presence of electronics across various industries and the increasing complexity of these devices. The market is experiencing a significant shift towards advanced ESD packaging solutions that offer superior protection and compliance with stringent industry standards. Innovations in materials science are leading to the development of more sustainable and high-performance ESD packaging, addressing both functional requirements and environmental concerns. Furthermore, the growing adoption of serialized and trackable ESD packaging is enhancing supply chain integrity and product traceability, a crucial aspect for high-value electronic goods. The market is witnessing a progressive move away from traditional, less effective packaging to more specialized solutions tailored to the specific needs of diverse electronic products. The increasing miniaturization of electronic components also necessitates more precise and robust ESD protection, further fueling the demand for sophisticated packaging designs and materials. As industries like telecommunications and automotive continue to integrate more sensitive electronics, the reliance on reliable ESD packaging will only intensify, creating a sustained upward trend in market value and volume. The ongoing evolution of electronic manufacturing processes, characterized by automation and higher throughputs, also demands packaging solutions that can seamlessly integrate into these workflows while ensuring consistent protection against ESD events. The increasing emphasis on product reliability and longevity, coupled with the high cost of component failure due to ESD, positions ESD packaging as an indispensable element of the modern electronics supply chain. The market is also seeing a greater emphasis on customized ESD packaging solutions, moving beyond one-size-fits-all approaches to cater to the unique form factors and sensitivity levels of various electronic devices and components. This personalized approach is a key trend that will shape the market's evolution in the coming years, ensuring optimal protection and efficiency. The increasing regulatory scrutiny and industry-specific standards are also a significant driver, compelling manufacturers to invest in compliant and effective ESD packaging.

The primary driving force behind the robust growth of the Electrostatic Discharge (ESD) Packaging market is the rapid proliferation of electronic devices and their increasing susceptibility to electrostatic damage. As the world becomes more digitally connected, the demand for sophisticated and sensitive electronic components in sectors such as communication network infrastructure, consumer electronics, and computer peripherals continues to skyrocket. Each of these sensitive components requires stringent protection against ESD events throughout their lifecycle – from manufacturing and assembly to shipping and storage. Furthermore, the automotive industry's significant push towards electrification and advanced driver-assistance systems (ADAS) relies heavily on intricate electronic control units, making them prime candidates for ESD-sensitive components that necessitate specialized packaging. The growing complexity and miniaturization of electronics also play a crucial role, as smaller components often possess higher surface resistivity and are therefore more vulnerable to static charges. This trend necessitates the development of advanced ESD packaging materials and designs capable of providing effective shielding. Moreover, increasing regulatory compliance and industry standards regarding the safe handling and transportation of electronic components are compelling manufacturers to adopt certified ESD packaging solutions, thereby bolstering market demand. The economic impact of component failure due to ESD, which can lead to costly rework, product recalls, and reputational damage, further incentivizes businesses to invest in preventative ESD packaging.

Despite the promising growth trajectory, the Electrostatic Discharge (ESD) Packaging market faces several challenges and restraints that could impede its full potential. One significant hurdle is the cost of specialized ESD packaging materials and solutions. While offering superior protection, these often come at a premium compared to conventional packaging, which can be a deterrent for price-sensitive manufacturers, especially in emerging markets. The lack of standardized regulations across all regions and industries can also create confusion and hinder widespread adoption, as manufacturers may struggle to comply with varying requirements. Furthermore, the availability and cost of raw materials used in the production of high-quality ESD packaging can fluctuate, impacting production costs and the final price for consumers. Educating end-users about the importance and proper use of ESD packaging remains a continuous challenge. Many smaller businesses or those new to handling sensitive electronics may not fully grasp the risks associated with ESD and the benefits of employing appropriate packaging, leading to underutilization. The development of truly sustainable and biodegradable ESD packaging solutions that offer equivalent or superior protective properties to traditional options is also an ongoing area of research and development, and currently, the market faces limitations in this regard. Finally, scalability and production capacity can become a challenge during periods of rapid demand surges, requiring significant investment in manufacturing infrastructure.

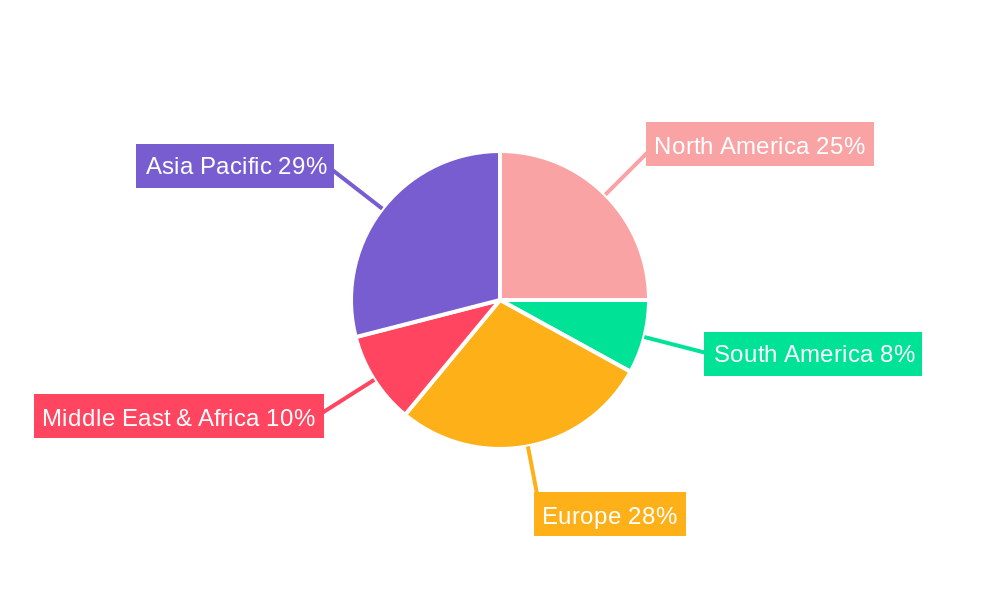

The Asia Pacific region is projected to be a dominant force in the Electrostatic Discharge (ESD) Packaging market during the Forecast Period (2025-2033). This dominance is fueled by the region's status as a global manufacturing hub for electronics, encompassing a vast array of companies involved in the production of consumer electronics, computer peripherals, and communication network infrastructure components. Countries like China, South Korea, Taiwan, and Vietnam are at the forefront of this manufacturing prowess, necessitating large volumes of reliable ESD packaging to protect sensitive components throughout their intricate supply chains. The presence of major electronics manufacturers, coupled with the continuous expansion of the semiconductor industry within Asia Pacific, directly translates into a substantial and sustained demand for various ESD packaging types. The increasing domestic consumption of electronic devices within these nations further amplifies this demand.

Within the Type segmentation, Bags are expected to hold a significant market share due to their versatility, cost-effectiveness, and ease of use across a wide range of electronic components. ESD bags, including metallized, anti-static, and conductive bags, offer robust protection against static discharge and tribocharging, making them indispensable for individual component packaging. They are widely adopted in the manufacturing and assembly processes of almost all electronic device categories.

When considering Application, the Communication Network Infrastructure segment is anticipated to exhibit remarkable growth and contribute significantly to the market's dominance in the Asia Pacific region. The relentless expansion of 5G networks, the ongoing deployment of fiber optic cables, and the continuous innovation in telecommunication hardware necessitate the protection of highly sensitive and often high-value electronic components. These components, integral to routers, switches, base stations, and data centers, are extremely vulnerable to ESD, making specialized ESD packaging a critical requirement. The growth in cloud computing and the increasing demand for high-speed data transmission further underscore the importance of robust ESD protection for the infrastructure that underpins these services.

The Automotive Industry also presents a substantial growth opportunity, particularly with the increasing integration of advanced electronics in modern vehicles, from infotainment systems to sophisticated ADAS and EV powertrains. These components require stringent ESD protection during their manufacturing and installation phases. The growing adoption of electric vehicles (EVs) and their complex battery management systems, power electronics, and control units will further drive the demand for specialized ESD packaging solutions in this sector. The continuous advancements in automotive electronics, coupled with the stringent quality and reliability standards of the automotive sector, ensure a sustained demand for high-performance ESD packaging. The global automotive supply chain, with its significant presence in Asia, further solidifies the region's dominance.

Several key factors are acting as significant growth catalysts for the Electrostatic Discharge (ESD) Packaging industry. The accelerating pace of technological innovation across the electronics sector, leading to increasingly miniaturized and sensitive components, directly fuels the need for advanced ESD protection. Furthermore, the growing awareness among manufacturers regarding the significant financial implications of ESD-induced component failures is driving proactive investment in protective packaging solutions. The expansion of e-commerce and the global reach of supply chains also necessitate robust packaging to ensure product integrity during transit.

This report offers a granular view of the Electrostatic Discharge (ESD) Packaging market, providing comprehensive insights into its present state and future potential. It details market size estimations in millions of units, analyzes key trends influencing the sector, and dissects the driving forces and challenges that shape its trajectory. The report also provides an in-depth examination of the dominant regions and segments, offering strategic insights for market players. Furthermore, it highlights critical growth catalysts and profiles the leading companies, alongside a chronological overview of significant industry developments. This holistic approach ensures a thorough understanding of the ESD Packaging landscape, empowering stakeholders to make informed decisions and capitalize on emerging opportunities within this vital market.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Teknis, Summit Packaging Solutions, Stephen Gould, Statico, Elcom, Protektive Pak, GWP Group, Desco Industries, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Electrostatic Discharge Packaging," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Electrostatic Discharge Packaging, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.