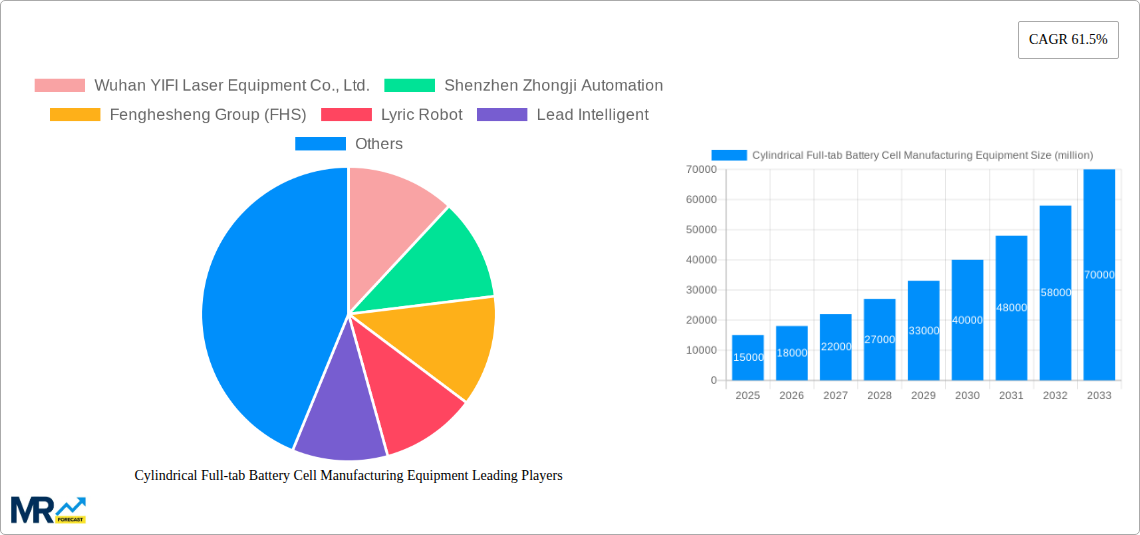

1. What is the projected Compound Annual Growth Rate (CAGR) of the Cylindrical Full-tab Battery Cell Manufacturing Equipment?

The projected CAGR is approximately 61.5%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Cylindrical Full-tab Battery Cell Manufacturing Equipment

Cylindrical Full-tab Battery Cell Manufacturing EquipmentCylindrical Full-tab Battery Cell Manufacturing Equipment by Type (Linear Type, Turret Type, Other), by Application (Large Cylindrical Battery, Small Cylindrical Battery), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

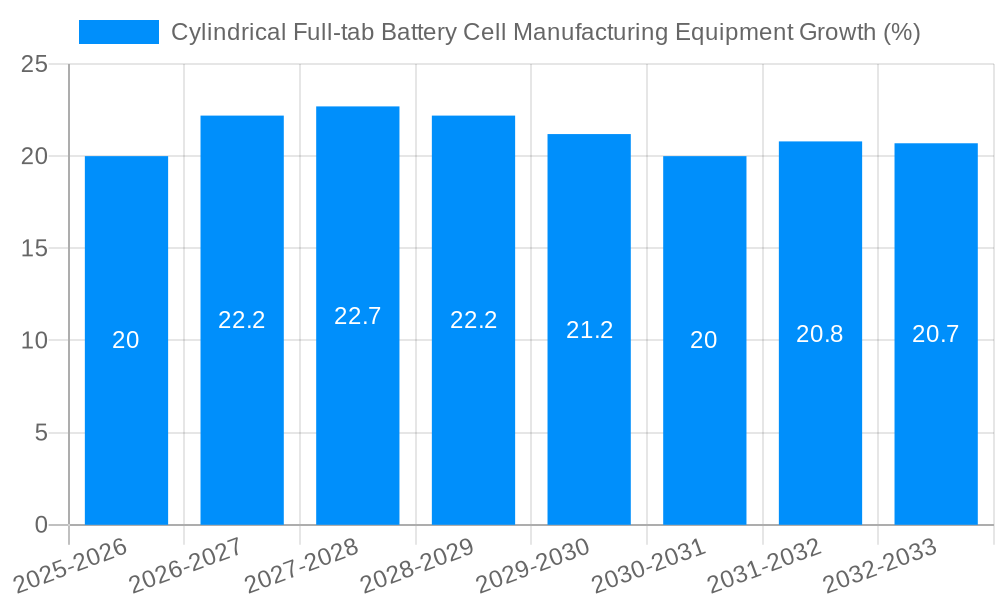

The Cylindrical Full-tab Battery Cell Manufacturing Equipment market is poised for substantial expansion, driven by the burgeoning demand for electric vehicles (EVs) and energy storage solutions. With a historical market value of $1992 million in 1992, the industry has witnessed a remarkable trajectory. Projecting forward, the market is expected to experience a Compound Annual Growth Rate (CAGR) of 61.5% between the study period of 2019 and 2033, with the base and estimated year of 2025 serving as a critical juncture. This aggressive growth signals a significant increase in production capacity and technological advancements within the cylindrical full-tab battery cell manufacturing sector. The market's expansion is underpinned by the increasing adoption of lithium-ion batteries, especially cylindrical variants, which are favored for their robustness, cost-effectiveness, and established manufacturing processes. The transition towards sustainable energy and electrified transportation is directly fueling the need for advanced and efficient manufacturing equipment capable of producing these high-demand battery cells at scale.

Key drivers for this robust growth include the escalating global adoption of electric vehicles, the increasing deployment of renewable energy projects requiring sophisticated battery storage systems, and the continuous innovation in battery technology leading to higher energy densities and improved performance. The market is segmented by Type, with Linear Type and Turret Type equipment being prominent, catering to different production efficiencies and scales. Application-wise, both Large Cylindrical Battery and Small Cylindrical Battery segments are experiencing significant demand, reflecting the diverse uses of cylindrical cells across EVs, consumer electronics, and grid-scale storage. Emerging trends point towards increased automation, precision engineering, and the integration of smart manufacturing technologies to optimize production yields and reduce costs. Companies such as Wuhan YIFI Laser Equipment Co., Ltd., Shenzhen Zhongji Automation, and Lead Intelligent are at the forefront of this innovation, competing to provide cutting-edge solutions to meet the growing global appetite for cylindrical full-tab battery cells.

Here's a unique report description on Cylindrical Full-tab Battery Cell Manufacturing Equipment, incorporating your specific requirements:

This comprehensive report delves into the dynamic global market for Cylindrical Full-tab Battery Cell Manufacturing Equipment, offering an in-depth analysis of its trajectory from the historical period of 2019-2024, through the base year of 2025, and projecting future growth until 2033. With the Study Period encompassing 2019-2033 and the Estimated Year also set at 2025, this research provides critical insights into market shifts and opportunities. The report meticulously examines the manufacturing equipment essential for producing full-tab cylindrical battery cells, a critical component in the rapidly expanding electric vehicle (EV) and energy storage systems (ESS) sectors. We project the market to see a substantial compound annual growth rate (CAGR) over the Forecast Period (2025-2033), driven by burgeoning demand for advanced battery technologies. The global market size for this specialized equipment is expected to reach several hundred million units in the coming years, with significant investments anticipated from both established battery manufacturers and emerging players. Our analysis covers the competitive landscape, identifying key manufacturers and their contributions, as well as regional market dynamics and emerging technological trends.

XXX has witnessed a significant evolution in the manufacturing of cylindrical full-tab battery cells, driven by an insatiable global demand for higher energy density, faster charging capabilities, and enhanced safety. The shift towards full-tab designs, which offer improved current collection and thermal management compared to traditional tab designs, has spurred innovation in manufacturing equipment. Linear Type equipment, characterized by its sequential processing steps and high throughput for mass production, is becoming increasingly prevalent. This type of equipment is favored for its scalability and ability to handle large volumes, directly contributing to the millions of units of cylindrical cells required annually for EV batteries and consumer electronics. Conversely, Turret Type equipment, while potentially offering greater flexibility and adaptability for smaller batch production or specialized cell configurations, is finding its niche in research and development or highly customized manufacturing scenarios. The market is also seeing the emergence of Other specialized equipment, including advanced laser welding systems, automated assembly lines, and sophisticated quality control machinery, all designed to meet the exacting standards of full-tab cell production. The adoption of Industry 4.0 principles, such as automation, AI-driven quality assurance, and real-time data analytics, is no longer a luxury but a necessity. This trend is reshaping how these machines are designed and operated, leading to increased efficiency, reduced waste, and ultimately, a more cost-effective production of battery cells. The drive for greater precision in welding, sealing, and assembly processes, critical for the performance and safety of full-tab cells, is also pushing manufacturers to invest in next-generation equipment. Furthermore, the increasing focus on sustainability within the battery manufacturing sector is influencing equipment design towards energy efficiency and minimized environmental impact. As the industry gears up to produce tens of millions of cylindrical cells annually, the demand for robust, high-precision, and cost-effective manufacturing equipment will only intensify.

The burgeoning demand for electric vehicles (EVs) stands as the foremost driver for the Cylindrical Full-tab Battery Cell Manufacturing Equipment market. As governments worldwide implement stricter emission regulations and consumers increasingly embrace sustainable transportation, the need for high-performance, reliable, and cost-effective batteries for EVs has never been greater. Cylindrical cells, particularly those employing full-tab designs, offer a compelling balance of energy density, cycle life, and thermal management, making them a preferred choice for many EV manufacturers. This surge in EV production directly translates into a colossal demand for the specialized machinery required to manufacture these cells at scale, potentially reaching hundreds of millions of units annually. Beyond EVs, the rapidly expanding energy storage systems (ESS) sector, vital for grid stabilization and renewable energy integration, also represents a significant growth catalyst. As the world transitions towards cleaner energy sources, the need for large-scale battery storage solutions is skyrocketing, further fueling the demand for cylindrical full-tab battery cells and, consequently, their manufacturing equipment. Furthermore, the persistent growth in consumer electronics, from laptops and power tools to portable chargers, which extensively utilize cylindrical battery cells, contributes to the sustained demand for this manufacturing equipment. The continuous pursuit of battery technologies that offer improved performance, faster charging, and enhanced safety across all these applications necessitates ongoing innovation and investment in advanced manufacturing processes and equipment.

Despite the robust growth, the Cylindrical Full-tab Battery Cell Manufacturing Equipment market faces several significant challenges. The rapid pace of technological advancement within the battery industry itself presents a continuous need for equipment upgrades and adaptations. Manufacturers must invest heavily to keep pace with evolving cell chemistries, form factors, and performance requirements, which can strain capital budgets. The development and implementation of highly sophisticated Linear Type and Turret Type equipment require substantial R&D investment, leading to high initial costs that can be a barrier for smaller companies or those in emerging markets. Furthermore, the precision demanded for full-tab battery cell manufacturing is exceptionally high. Any deviation in welding, sealing, or assembly processes can lead to performance degradation or safety issues, necessitating stringent quality control measures and advanced automation, which further increases equipment complexity and cost. Supply chain disruptions, particularly for specialized components and raw materials used in high-tech manufacturing equipment, can also impede production and lead to delivery delays. The intense competition within the equipment manufacturing sector, with numerous players vying for market share, can also lead to price pressures, potentially impacting profit margins. Finally, the skilled labor shortage for operating and maintaining these complex automated systems is another significant hurdle. The need for highly trained technicians and engineers to manage and optimize these advanced manufacturing lines can slow down adoption and scalability in certain regions.

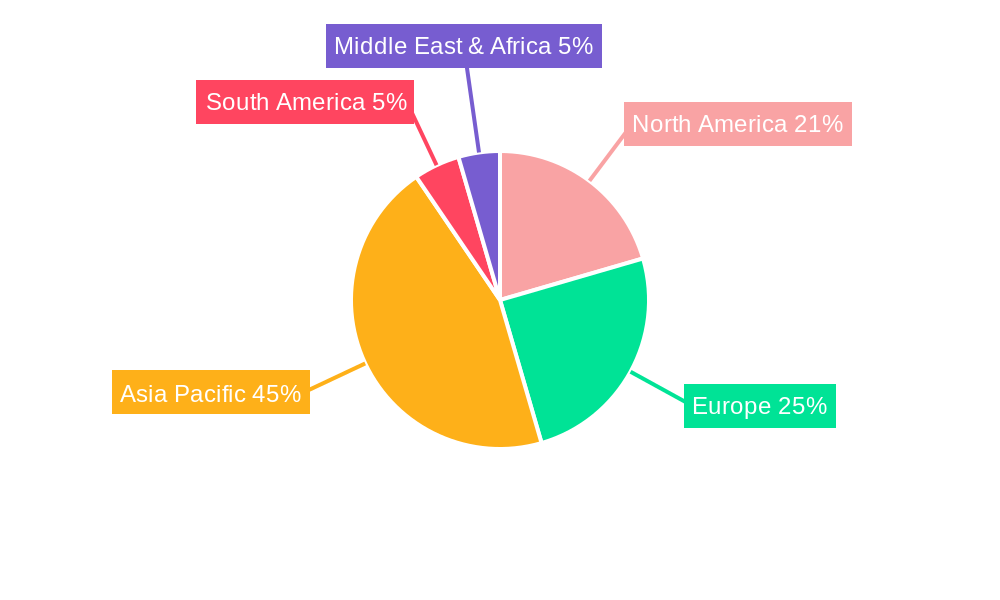

The global Cylindrical Full-tab Battery Cell Manufacturing Equipment market is poised for significant growth, with particular dominance expected from Asia-Pacific, driven by China's unparalleled manufacturing capabilities and its leading position in both EV production and battery manufacturing. The region's proactive government policies, substantial investments in the new energy sector, and a vast network of battery manufacturers are creating an enormous appetite for advanced manufacturing equipment. Specifically, the Small Cylindrical Battery segment is anticipated to lead the charge in terms of equipment demand within Asia-Pacific. This is due to the widespread application of small cylindrical cells in a multitude of consumer electronics, including smartphones, laptops, power banks, and electric toothbrushes. The sheer volume of these devices produced globally, with hundreds of millions of units manufactured annually, necessitates highly efficient and high-throughput manufacturing equipment. The Linear Type equipment, with its inherent suitability for mass production and scalability, is expected to be the dominant type of machinery in this segment. Manufacturers in Asia-Pacific are investing heavily in linear production lines to meet the consistent and massive demand for small cylindrical cells. China, in particular, boasts a robust ecosystem of both battery cell manufacturers and equipment suppliers, creating a virtuous cycle of innovation and adoption. This region is not only a major consumer of this equipment but also a significant exporter of both batteries and the machinery to produce them.

Furthermore, while the Small Cylindrical Battery segment is currently dominant, there is a rapidly growing emphasis on Large Cylindrical Battery applications, especially for EVs and grid-scale energy storage. This segment, while still smaller in terms of unit volume compared to small cylindrical cells, is experiencing a much higher growth rate in terms of equipment investment. Countries like South Korea and Japan, alongside China, are significant players in the development and production of large cylindrical batteries, necessitating advanced and often more specialized manufacturing equipment. The adoption of Turret Type equipment might see a gradual increase in this segment for pilot lines and customized production of specific large-format cells, though Linear Type equipment will likely remain the backbone for large-scale production due to efficiency demands. The increasing global push towards electrification and renewable energy adoption ensures that both segments, small and large cylindrical batteries, will continue to drive substantial demand for the respective manufacturing equipment, with Asia-Pacific firmly positioned as the epicentre of this industrial revolution. The scale of production in this region, aiming for millions of units across various applications, directly translates into a colossal demand for sophisticated and high-volume manufacturing solutions.

The rapid advancements in battery technology, leading to higher energy density and faster charging capabilities in cylindrical full-tab cells, are a significant growth catalyst. The burgeoning electric vehicle (EV) market, coupled with the expanding energy storage systems (ESS) sector, is creating an unprecedented demand for these cells. Government incentives and stringent environmental regulations worldwide are further accelerating the adoption of EVs and renewable energy solutions, thereby boosting the need for battery manufacturing equipment. Continued innovation in automation and artificial intelligence is enhancing the efficiency, precision, and cost-effectiveness of manufacturing processes, making the equipment more attractive to investors.

This report offers an exhaustive analysis of the Cylindrical Full-tab Battery Cell Manufacturing Equipment market, providing a granular breakdown of market size, segmentation, and growth projections. It details the key market drivers, including the explosive growth of the electric vehicle (EV) sector and the increasing demand for energy storage solutions (ESS). The report also critically assesses the challenges and restraints, such as high capital investment, technological obsolescence, and supply chain complexities. Furthermore, it identifies the dominant regions and segments, with a focus on the pivotal role of Asia-Pacific and the significant demand generated by both Large Cylindrical Battery and Small Cylindrical Battery applications. The report underscores the impact of Linear Type and Turret Type equipment on production efficiency and market dynamics. Finally, it presents a comprehensive overview of leading players and their strategic initiatives, along with an outlook on future technological developments, providing stakeholders with the essential intelligence to navigate this rapidly evolving market.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 61.5% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 61.5%.

Key companies in the market include Wuhan YIFI Laser Equipment Co., Ltd., Shenzhen Zhongji Automation, Fenghesheng Group (FHS), Lyric Robot, Lead Intelligent, Ruisheng New Energy.

The market segments include Type, Application.

The market size is estimated to be USD 1992 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million.

Yes, the market keyword associated with the report is "Cylindrical Full-tab Battery Cell Manufacturing Equipment," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Cylindrical Full-tab Battery Cell Manufacturing Equipment, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.