1. What is the projected Compound Annual Growth Rate (CAGR) of the Automotive Low Voltage Harness?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Automotive Low Voltage Harness

Automotive Low Voltage HarnessAutomotive Low Voltage Harness by Type (Main, Engine Wiring Harness, E-motor Harness, Others, World Automotive Low Voltage Harness Production ), by Application (Passenger Car, Commercial Car, World Automotive Low Voltage Harness Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

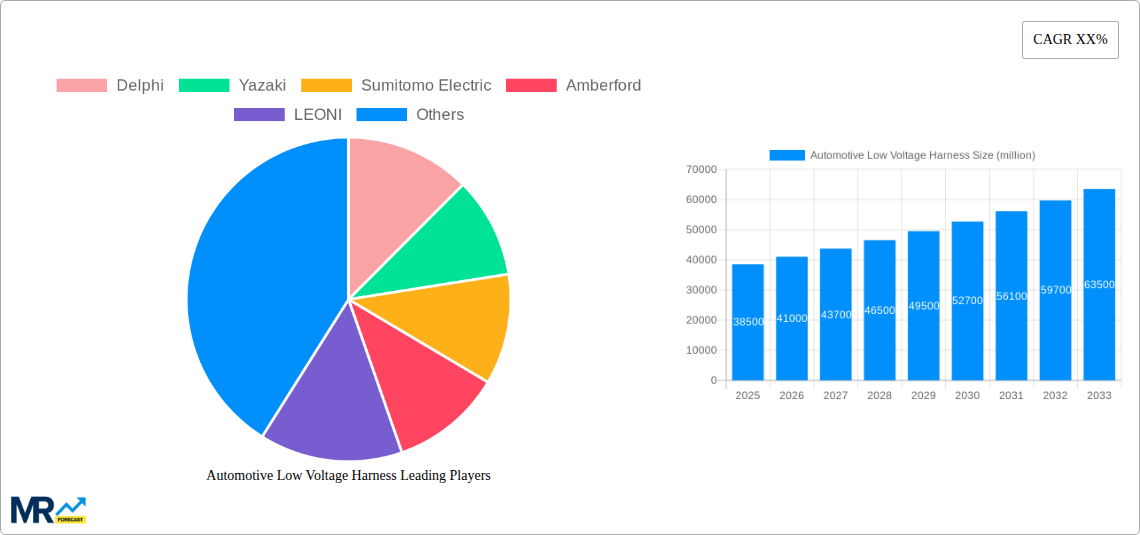

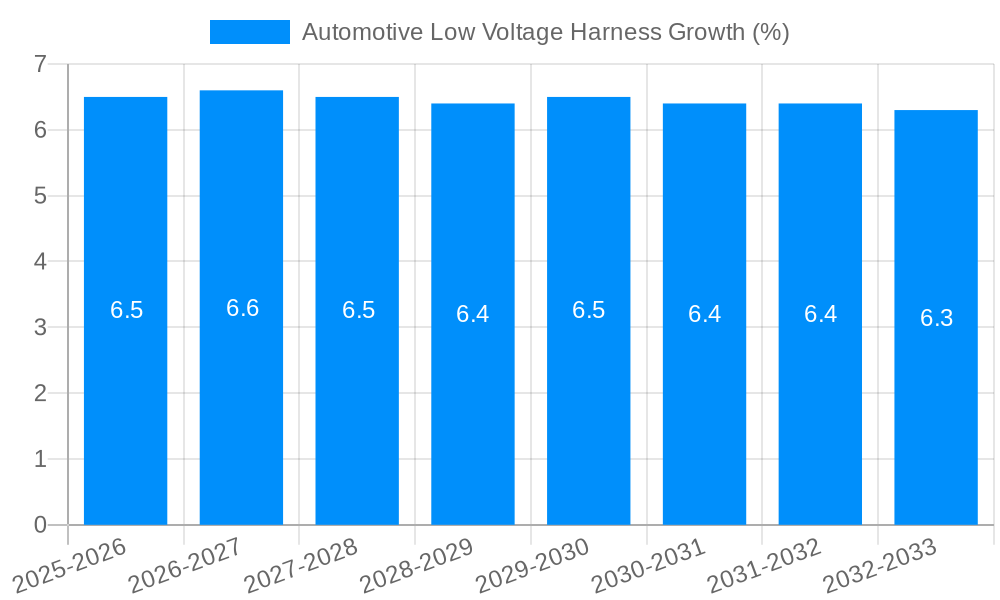

The global automotive low voltage harness market is experiencing significant growth, driven by the increasing complexity of vehicle electronics and the rising demand for electric and hybrid vehicles. With an estimated market size of approximately $38,500 million in 2025, this sector is projected to expand at a Compound Annual Growth Rate (CAGR) of around 6.5% through 2033. This robust expansion is fueled by the continuous integration of advanced driver-assistance systems (ADAS), in-car infotainment, and connectivity features, all of which necessitate more sophisticated and higher-performing wiring solutions. The proliferation of electric vehicles (EVs) and hybrid electric vehicles (HEVs) is a particularly strong catalyst, as these vehicles require specialized high-voltage and low-voltage harnesses to manage their intricate power distribution and control systems, contributing significantly to the overall market value in millions.

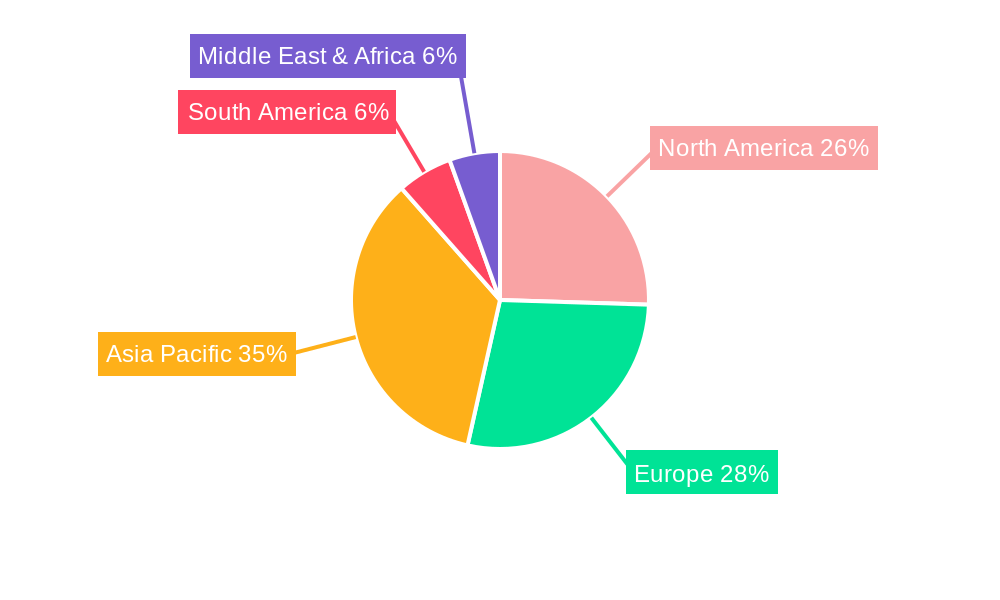

The market segmentation reveals key areas of opportunity and demand. The "Engine Wiring Harness" and "E-motor Harness" segments are expected to witness substantial growth due to the electrification trend and the ongoing evolution of internal combustion engine technologies. Passenger cars represent the largest application segment, accounting for a dominant share of the market, while commercial vehicles are also showing a steady increase in demand for advanced low voltage harness solutions. Geographically, Asia Pacific, led by China, is anticipated to remain the largest and fastest-growing regional market, owing to its massive automotive production base and the rapid adoption of new automotive technologies. North America and Europe also represent significant markets, driven by stringent safety regulations and the increasing consumer preference for feature-rich vehicles. Key market restraints include the volatile raw material prices, such as copper, and intense competition among established and emerging players, which can impact profit margins.

This report provides an in-depth analysis of the global Automotive Low Voltage Harness market, examining trends, drivers, challenges, regional dynamics, and key industry players from the historical period of 2019-2024 to a projected forecast up to 2033. The Base Year for estimation is 2025. The report delves into the intricate workings of this critical automotive component, projecting a significant production volume reaching into the hundreds of millions of units by the end of the study period.

The automotive low voltage harness market is currently experiencing a paradigm shift driven by the relentless pursuit of vehicle electrification, enhanced connectivity, and sophisticated driver-assistance systems. Historically, the focus was on delivering power and data efficiently to traditional internal combustion engine (ICE) components. However, the Base Year of 2025 marks a pivotal point, with the market increasingly shaped by the demands of electric vehicles (EVs) and the proliferation of advanced digital features. The sheer volume of electronic control units (ECUs) and sensors required for modern vehicles, from infotainment systems and ADAS (Advanced Driver-Assistance Systems) to battery management systems and thermal management, necessitates increasingly complex and higher-density wiring harnesses. This complexity translates into a greater number of individual wires, connectors, and specialized routing solutions within a single vehicle. The shift towards modular vehicle architectures and dedicated EV platforms further accentuates this trend, with e-motor harnesses emerging as a distinct and rapidly growing segment within the broader low voltage harness landscape. Furthermore, the industry is witnessing a growing emphasis on lightweighting and space optimization. Manufacturers are constantly seeking innovative materials and design strategies to reduce harness weight, which directly impacts fuel efficiency and EV range. The integration of advanced materials, such as high-performance insulation and miniaturized connectors, is becoming paramount. The increasing adoption of automated manufacturing processes and sophisticated diagnostic tools throughout the Forecast Period of 2025-2033 will also play a crucial role in ensuring the quality and reliability of these complex systems, as the total World Automotive Low Voltage Harness Production continues its upward trajectory, expected to surpass 500 million units annually. The demand for robust electromagnetic compatibility (EMC) solutions is also escalating as vehicles become more connected and susceptible to interference. Consequently, the design and manufacturing of low voltage harnesses are evolving to incorporate better shielding and noise suppression techniques. The integration of data communication protocols like CAN, LIN, and Ethernet is also a defining trend, demanding harnesses that can reliably transmit high volumes of data at increased speeds. The rise of over-the-air (OTA) updates and connected car services further amplifies the need for resilient and high-bandwidth data harnesses. The market is also seeing a bifurcation, with premium vehicles demanding highly sophisticated and integrated solutions, while mass-market segments focus on cost-effectiveness and scalability. The Estimated Year of 2025 sees a significant acceleration in these trends, setting the stage for substantial growth and innovation over the next decade. The increasing adoption of digital twin technology and advanced simulation tools during the Study Period of 2019-2033 are also influencing harness design and validation processes, leading to optimized performance and reduced development cycles.

The automotive low voltage harness market is experiencing robust growth, propelled by a confluence of powerful forces that are fundamentally reshaping the automotive industry. Foremost among these is the unprecedented surge in vehicle electrification. The global transition towards electric vehicles (EVs) is a primary driver, as EVs inherently require extensive and complex low voltage harnesses to manage an array of critical systems, including battery management, charging infrastructure, thermal management for batteries and motors, and the sophisticated electronic controls that govern power distribution. This is significantly increasing the demand for specialized e-motor harnesses and associated wiring. Simultaneously, the relentless advancement in automotive technology, particularly in the realm of Advanced Driver-Assistance Systems (ADAS) and autonomous driving, is creating a burgeoning demand for sophisticated electronic components and, consequently, intricate wiring. Features like adaptive cruise control, lane-keeping assist, automatic emergency braking, and sophisticated sensor arrays necessitate a significantly higher density of sensors and ECUs, each requiring dedicated low voltage harness connections. The increasing integration of in-car connectivity and infotainment systems further fuels this demand. With consumers expecting seamless integration of smartphones, advanced navigation, in-car entertainment, and a host of digital services, the complexity and extent of the low voltage harness are escalating. This drive for a connected and intelligent cabin requires a robust network of wires and connectors to support data transfer, power delivery, and sensor integration. The Base Year of 2025 marks a critical inflection point where these trends are not merely emerging but are becoming dominant forces shaping the market landscape. The continuous innovation in sensor technology and the miniaturization of electronic components, while potentially reducing the number of individual wires in some applications, are simultaneously leading to higher functionality and greater interconnectivity, thereby driving up the overall complexity and demand for harnesses. The expanding automotive electronics market, a direct consequence of these technological advancements, is inextricably linked to the growth of the low voltage harness sector. As more electronic features are integrated into vehicles across all segments, the need for reliable and efficient wiring solutions escalates proportionally. This sustained demand, coupled with the evolution of vehicle architectures towards more integrated and software-defined platforms, ensures a strong and sustained growth trajectory for the automotive low voltage harness market.

Despite the strong growth trajectory, the automotive low voltage harness market faces several significant challenges and restraints that can impact its expansion. One of the primary hurdles is the increasing complexity of vehicle architectures. As vehicles become more sophisticated with the integration of advanced electronics, EVs, and ADAS, the design and manufacturing of low voltage harnesses become exponentially more intricate. This complexity demands highly specialized engineering expertise, advanced simulation tools, and rigorous testing protocols, leading to increased development costs and longer lead times. Maintaining a consistent supply chain for a vast array of specialized components, including connectors, terminals, and wire insulation materials, is another significant challenge. Geopolitical uncertainties, raw material price volatility, and logistical disruptions can impact the availability and cost of these essential components. The push for cost reduction in the highly competitive automotive industry also presents a considerable restraint. While demand for advanced features is high, automakers are constantly striving to optimize costs, putting pressure on harness manufacturers to deliver complex solutions at competitive price points. This often requires significant investment in automation and process optimization. The rigorous quality and reliability standards demanded by the automotive sector are also a constant challenge. Harnesses are critical for vehicle safety and functionality, and any failure can have severe consequences. Ensuring consistent quality across millions of units produced annually, especially with increasingly complex designs, requires stringent quality control measures and adherence to evolving industry standards. Cybersecurity concerns are also beginning to emerge as a restraint, particularly for connected vehicles. While not directly a harness manufacturing issue, the security of data transmitted through harnesses needs to be considered in the overall system design, potentially influencing material choices and shielding requirements. Furthermore, the skilled labor shortage in specialized manufacturing roles can also hinder production capacity and innovation. The need for highly trained technicians and engineers to manage complex automated systems and intricate assembly processes is a growing concern for manufacturers. Finally, evolving environmental regulations concerning the use of certain materials and manufacturing processes can also necessitate costly changes in production methods and material sourcing, posing an ongoing challenge for the industry.

The global automotive low voltage harness market is characterized by a dynamic interplay between regional manufacturing capabilities and specific segment dominance.

Key Dominating Regions/Countries:

Asia-Pacific (APAC): This region, particularly China, stands out as the undisputed leader in both production volume and market share for automotive low voltage harnesses. Several factors contribute to this dominance:

Europe: While not matching APAC's sheer production volume, Europe remains a crucial and highly influential region, particularly in terms of technological innovation and the production of high-value, complex harnesses.

North America: The North American market, primarily driven by the United States, is another significant player, characterized by a strong automotive industry and a growing focus on technological advancements.

Key Dominating Segments:

Main Wiring Harness: This segment consistently represents the largest share of the global automotive low voltage harness market. It encompasses the primary wiring that distributes power and data throughout the vehicle, connecting essential systems like lighting, interior components, and the power distribution system. The sheer ubiquity of these harnesses across all vehicle types, from passenger cars to commercial vehicles, ensures its dominant position. Its production volume is expected to be well over 200 million units annually by 2025.

Engine Wiring Harness: While the shift towards EVs is impacting the traditional engine wiring harness, it still remains a significant segment, particularly for the ongoing production of internal combustion engine vehicles. This harness connects crucial engine components, sensors, and the powertrain control module. However, its growth is expected to be more moderate compared to other segments.

E-motor Harness: This segment is experiencing the most explosive growth and is projected to be a key growth catalyst in the coming years. As the automotive industry rapidly transitions to electric vehicles, the demand for specialized e-motor harnesses – designed to handle high voltages, temperatures, and electromagnetic interference specific to electric powertrains – is skyrocketing. The intricate nature and specialized requirements of these harnesses, designed to connect the electric motor to the power inverter and battery, are driving innovation and significant market expansion. The World Automotive Low Voltage Harness Production in this segment alone is anticipated to reach tens of millions of units by the end of the study period.

Application:

The interplay of these regions and segments paints a clear picture: Asia-Pacific, driven by China's manufacturing prowess and massive market, will continue to lead in production volume, especially for the foundational Main Wiring Harness. However, the burgeoning demand for E-motor Harnesses, fueled by global EV adoption, will see significant growth across all major automotive manufacturing regions, with Europe and North America playing crucial roles in technological advancements and specialized solutions.

The automotive low voltage harness industry is propelled by several key growth catalysts that ensure its continued expansion. The most significant is the accelerating global transition towards electric vehicles (EVs). As EV production scales up, the demand for specialized e-motor harnesses and the intricate wiring required for battery management systems, charging, and thermal control experiences a substantial surge. Secondly, the increasing integration of Advanced Driver-Assistance Systems (ADAS) and autonomous driving technologies is a major catalyst. These systems rely on a multitude of sensors, cameras, and ECUs, each requiring robust and complex low voltage harness connections, driving higher content per vehicle. Furthermore, the proliferation of in-car connectivity and sophisticated infotainment systems is fueling demand for harnesses capable of supporting high-speed data transfer and powering numerous digital features, enhancing the overall user experience.

This comprehensive report offers an exhaustive analysis of the global Automotive Low Voltage Harness market. It meticulously details market dynamics, including key trends, driving forces, and prevalent challenges, providing a clear understanding of the industry's current landscape and future trajectory. The report delves into the critical segments driving growth, such as the rapidly expanding E-motor Harness segment, and analyzes the market dominance of key regions like Asia-Pacific. With a detailed examination of leading players and significant industry developments from 2019 through 2033, this report equips stakeholders with the essential insights needed to navigate this evolving market and capitalize on emerging opportunities within the multi-million unit production volumes projected.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Delphi, Yazaki, Sumitomo Electric, Amberford, LEONI, Lear, TE Connectivity, PKC Group, Korea Electric Terminal, Nexans Autoelectric, Furukawa Electric, Fujikura, THB Group, Wuhu Bokang Electrical, Yingkou Abe Harness, Liuzhou Shuangfei, Kunshan Huguang Auto Harness, henzhen Uniconn Technology, Shanghai Jinting Automobile Harness, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Automotive Low Voltage Harness," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Automotive Low Voltage Harness, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.