1. What is the projected Compound Annual Growth Rate (CAGR) of the AGV Handling Robot?

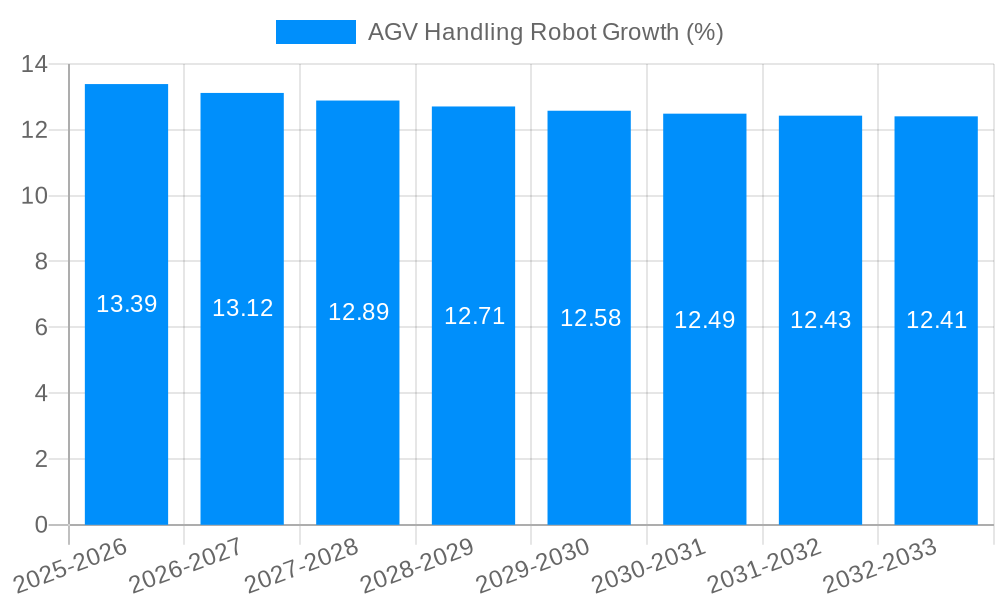

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

AGV Handling Robot

AGV Handling RobotAGV Handling Robot by Type (Jack-up Type AGV, Fork Type AGV, World AGV Handling Robot Production ), by Application (Warehousing Industry, logistics Industry, Construction Site, World AGV Handling Robot Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

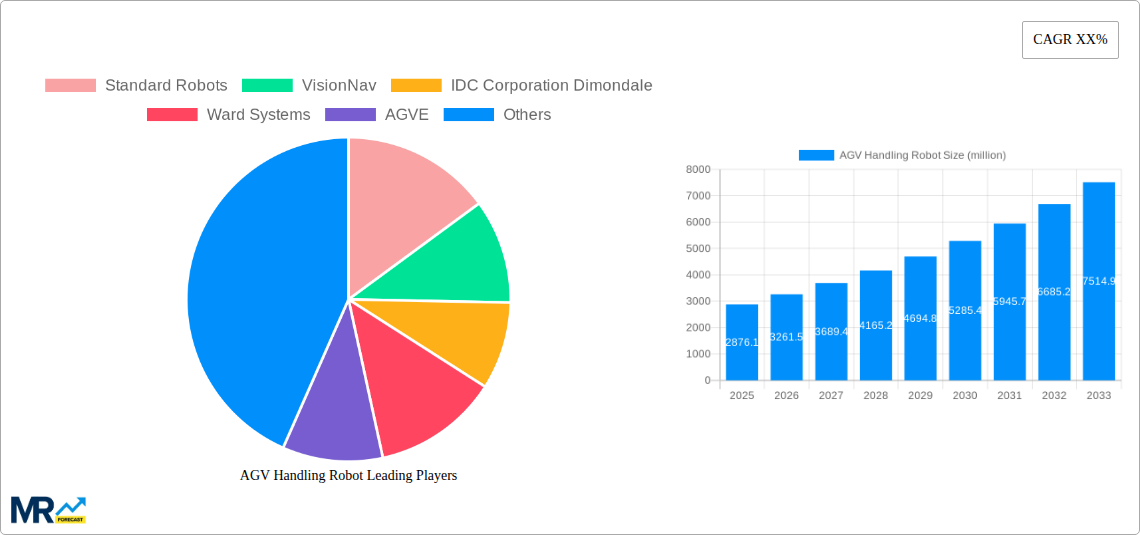

The global AGV (Automated Guided Vehicle) Handling Robot market is poised for substantial expansion, projected to reach a valuation of USD 2876.1 million. This growth is driven by an intensifying demand for enhanced operational efficiency and automation across various industrial sectors. Key drivers fueling this market surge include the relentless pursuit of reduced labor costs, the imperative for improved workplace safety, and the escalating need for precise and consistent material handling. Industries like warehousing and logistics are at the forefront of AGV adoption, leveraging these robots to streamline inventory management, optimize order fulfillment, and minimize errors. Furthermore, the construction sector is increasingly recognizing the potential of AGVs for tasks such as transporting materials on-site, thereby enhancing productivity and reducing the risks associated with manual labor in hazardous environments. The market's trajectory is further bolstered by technological advancements, including improved navigation systems, enhanced sensor technologies, and greater integration capabilities with existing enterprise resource planning (ERP) and warehouse management systems (WMS). This evolution allows AGVs to perform more complex tasks and operate seamlessly within dynamic operational landscapes, solidifying their position as indispensable tools for modern industrial operations.

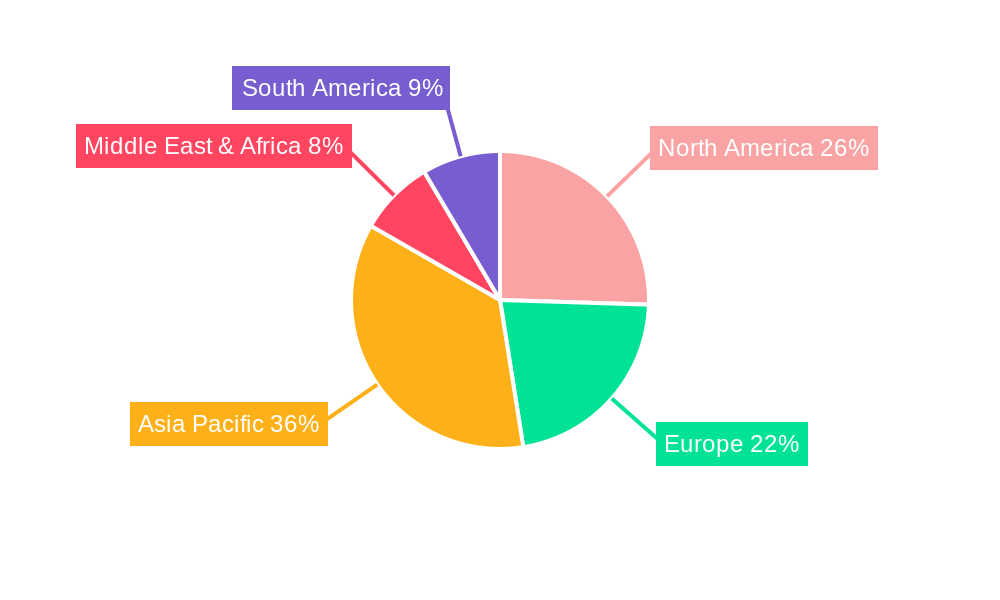

The AGV Handling Robot market is segmented by type, with Jack-up Type AGVs and Fork Type AGVs leading the charge in production. These distinct configurations cater to a wide array of material handling requirements, from lifting and transporting pallets to delicate placement of goods. Regionally, Asia Pacific, particularly China and India, is emerging as a dominant force, fueled by robust manufacturing activities, significant investments in industrial automation, and government initiatives promoting smart manufacturing. North America and Europe continue to exhibit strong market presence due to the established presence of advanced manufacturing facilities and a mature understanding of the benefits of automation. Emerging economies in South America and the Middle East & Africa are also showing promising growth as they increasingly embrace automation to boost their industrial output and global competitiveness. Despite the overwhelmingly positive outlook, certain restraints, such as the high initial investment costs and the need for specialized maintenance and training, may pose challenges. However, the long-term benefits in terms of productivity gains, reduced operational expenses, and enhanced safety are expected to outweigh these initial hurdles, paving the way for sustained and accelerated market growth throughout the forecast period.

This comprehensive report delves into the dynamic landscape of the AGV (Automated Guided Vehicle) Handling Robot market, providing an in-depth analysis from its nascent stages to its projected dominance. With a Study Period spanning 2019-2033, including a Base Year of 2025, an Estimated Year of 2025, and a robust Forecast Period of 2025-2033, this report equips stakeholders with unparalleled insights. The analysis is further enriched by a detailed examination of the Historical Period from 2019-2024, tracing the market's evolution and laying the groundwork for future projections.

The global AGV Handling Robot market is poised for monumental growth, with projections indicating a substantial increase in market value. Our research forecasts the market to reach an estimated USD 8.5 million in 2025, demonstrating a significant upward trajectory. This growth is fueled by an increasing demand for automation across various industrial sectors. The report meticulously dissects market segmentation, identifying key product types such as Jack-up Type AGV and Fork Type AGV, alongside broader market categories like World AGV Handling Robot Production. Furthermore, it analyzes the penetration and future potential within critical application segments including the Warehousing Industry, Logistics Industry, and the burgeoning Construction Site applications. The report also examines the overarching trends within World AGV Handling Robot Production and Industry Developments.

The methodology employed ensures a data-driven approach, incorporating primary and secondary research, expert interviews, and sophisticated analytical models. The report aims to provide strategic recommendations for businesses looking to capitalize on emerging opportunities, mitigate potential risks, and secure a competitive edge in this rapidly evolving sector.

The AGV Handling Robot market is experiencing a profound metamorphosis, driven by an insatiable appetite for enhanced operational efficiency and reduced labor costs across industries. The prevailing trend is a decisive shift towards intelligent automation, moving beyond simple pick-and-place functionalities to sophisticated, AI-powered systems capable of complex decision-making and dynamic path planning. This evolution is particularly evident in the Warehousing Industry and Logistics Industry, where the sheer volume of goods movement necessitates advanced solutions to maintain competitiveness. We are witnessing a significant uptick in the adoption of AGVs that integrate advanced sensor technologies, including LiDAR, vision systems, and ultrasonic sensors, enabling them to navigate dynamic environments with unprecedented precision and safety. The integration of machine learning algorithms allows these robots to learn from their surroundings, optimize routes in real-time, and collaborate seamlessly with human workers, a concept often referred to as "cobots" in the context of AGVs. Furthermore, the modularity and scalability of modern AGV systems are becoming crucial differentiators, allowing businesses to adapt their automation strategies to fluctuating demands without substantial upfront capital investment. The emergence of specialized AGV types, such as the Jack-up Type AGV for pallet manipulation and the Fork Type AGV for versatile load handling, reflects a growing demand for tailored solutions that address specific operational pain points. The market is also seeing a rise in collaborative AGV fleets, where multiple vehicles can coordinate their movements and tasks, leading to synergistic operational gains. The future trajectory points towards greater autonomy, increased connectivity through 5G technology for enhanced real-time communication and control, and a deeper integration with overarching enterprise resource planning (ERP) and warehouse management systems (WMS). This comprehensive integration promises a holistic view of operations, enabling predictive maintenance, optimized inventory management, and ultimately, a more resilient and responsive supply chain. The growing awareness of worker safety, coupled with the inherent limitations of manual material handling in terms of strain and repetitive motion injuries, further accelerates the adoption of these advanced robotic solutions. The projected market value of USD 8.5 million in 2025 is merely a waypoint in a journey towards a fully automated material handling ecosystem.

The relentless surge in demand for AGV Handling Robots is underpinned by a confluence of powerful economic and technological drivers. Foremost among these is the escalating need for enhanced productivity and operational efficiency. Businesses across sectors are actively seeking ways to streamline their material handling processes, reduce cycle times, and minimize errors, all of which directly contribute to cost savings and improved profitability. The rising global labor costs and the persistent shortage of skilled labor in manufacturing and logistics further amplify the appeal of automated solutions. AGVs offer a consistent, reliable, and predictable workforce that can operate 24/7 without fatigue, directly addressing these challenges. Technological advancements play a pivotal role, with continuous innovation in areas such as artificial intelligence, machine learning, robotics, and sensor technology significantly enhancing the capabilities and affordability of AGVs. The decreasing cost of these technologies makes advanced automation more accessible to a broader range of businesses, including small and medium-sized enterprises (SMEs). Moreover, the growing emphasis on workplace safety is a significant catalyst. AGVs can perform hazardous tasks in environments that are unsafe for humans, such as areas with heavy machinery, extreme temperatures, or the presence of dangerous materials, thereby reducing the risk of accidents and injuries. The increasing adoption of Industry 4.0 principles, which advocate for the interconnectedness and automation of industrial processes, naturally leads to the integration of AGVs as a key component of smart factories and intelligent supply chains. The competitive pressure to deliver goods faster and more efficiently, particularly in e-commerce, is also pushing companies to invest in automated material handling solutions to meet customer expectations for rapid fulfillment and delivery.

Despite the burgeoning growth, the AGV Handling Robot market is not without its hurdles. A primary challenge lies in the significant initial capital investment required for the acquisition and implementation of AGV systems, which can be a substantial barrier for smaller businesses. While the long-term return on investment is often compelling, the upfront cost can deter adoption. The complexity of integrating AGVs into existing infrastructure and workflows presents another significant challenge. This often requires substantial modifications to the physical environment, such as specialized flooring, charging stations, and navigation aids, as well as the re-engineering of established operational processes. Furthermore, the need for skilled personnel to manage, maintain, and program these sophisticated robots can be a limiting factor, especially in regions with a shortage of technical expertise. Cybersecurity concerns also loom large, as interconnected AGV systems can be vulnerable to cyber-attacks, which could disrupt operations, compromise data, or even lead to physical damage. The lack of standardization across different AGV manufacturers can also create interoperability issues, making it difficult for businesses to integrate systems from various vendors. Regulatory hurdles and the need for clear safety guidelines and certifications for autonomous systems can also slow down widespread adoption, particularly in industries with stringent safety requirements. Finally, while AGVs are designed to operate autonomously, unexpected environmental changes or unforeseen obstacles can still pose challenges, requiring sophisticated fallback mechanisms and human intervention, which may not always be readily available or efficient.

The global AGV Handling Robot market is characterized by distinct regional strengths and segment dominance, with significant opportunities and growth potential poised to reshape the industry landscape.

Several key factors are acting as powerful catalysts for the sustained growth of the AGV Handling Robot industry. The relentless pursuit of operational efficiency and cost reduction across manufacturing and logistics sectors is a primary driver, as AGVs offer a reliable and cost-effective alternative to manual labor. The rapid advancements in Artificial Intelligence (AI) and Machine Learning (ML) are empowering AGVs with enhanced navigation, decision-making, and collaborative capabilities, making them more adaptable to complex and dynamic environments. The burgeoning growth of e-commerce, with its ever-increasing demand for faster order fulfillment and delivery, is creating a significant need for automated material handling solutions to manage the surge in order volumes and complexity. Furthermore, governments worldwide are actively promoting automation and Industry 4.0 initiatives, offering incentives and regulatory frameworks that encourage the adoption of advanced technologies like AGVs.

This report offers an unparalleled depth of analysis into the global AGV Handling Robot market, providing a holistic view of its current state and future trajectory. The comprehensive coverage extends beyond market sizing and forecasts, delving into the intricate details of market dynamics. It meticulously dissects the driving forces propelling growth, such as the escalating demand for operational efficiency and the relentless pace of technological innovation. Simultaneously, it offers a candid assessment of the challenges and restraints that may impede market expansion, including the significant capital investment and integration complexities. The report also provides a granular examination of key regions and countries poised for dominance, alongside an in-depth analysis of critical market segments like the Warehousing Industry and the versatile Fork Type AGV. Furthermore, it highlights crucial growth catalysts and identifies the leading industry players, offering strategic insights into their contributions and market positioning. The inclusion of significant developments, with projected timelines, ensures that readers are informed about the latest advancements and future trends shaping the AGV landscape. This comprehensive approach ensures that stakeholders are equipped with the knowledge to make informed strategic decisions in this rapidly evolving sector.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Standard Robots, VisionNav, IDC Corporation Dimondale, Ward Systems, AGVE, America In Motion Charlotte, TRAPO AG, Eckhart Warren, RedViking Plymouth, Seaqx NV, .

The market segments include Type, Application.

The market size is estimated to be USD 2876.1 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "AGV Handling Robot," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the AGV Handling Robot, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.