1. What is the projected Compound Annual Growth Rate (CAGR) of the Metal Processing Outsourcing Services?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Metal Processing Outsourcing Services

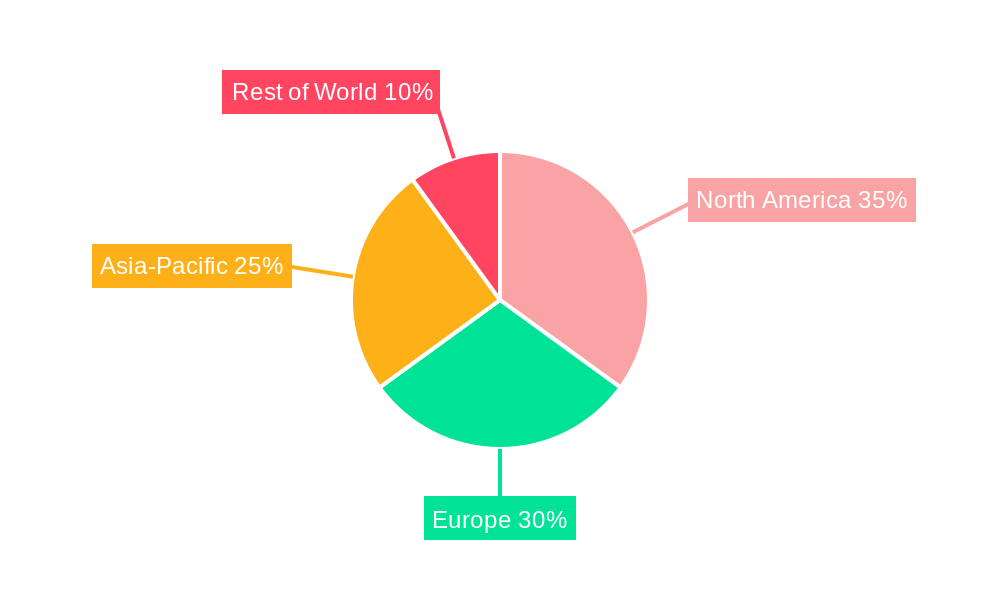

Metal Processing Outsourcing ServicesMetal Processing Outsourcing Services by Type (Domestic Service Outsourcing, Offshore Service Outsourcing), by Application (Communications Industry, Automobile Industry, Machinery Industry, Aerospace Industry), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

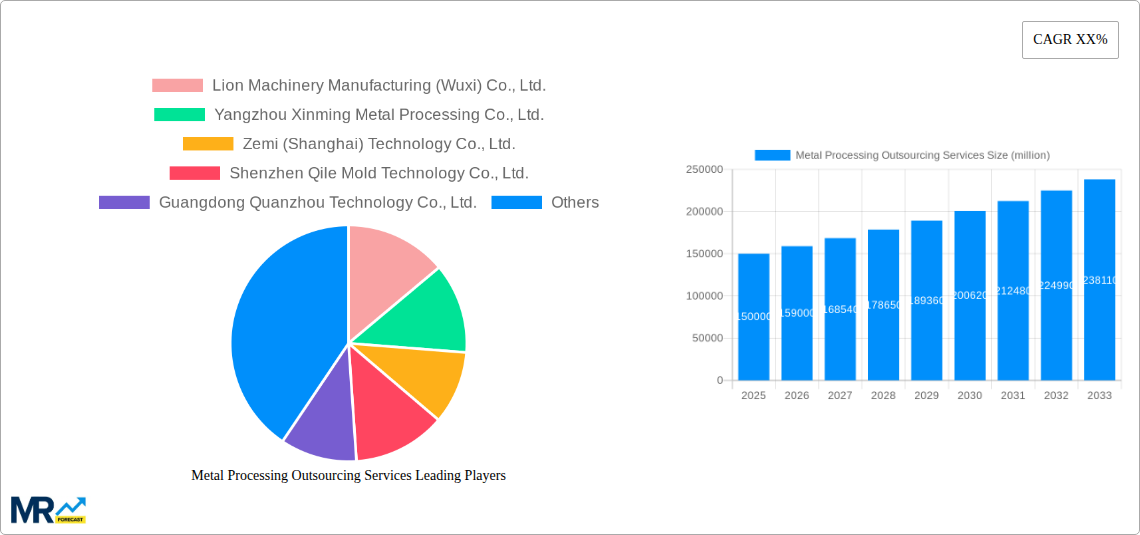

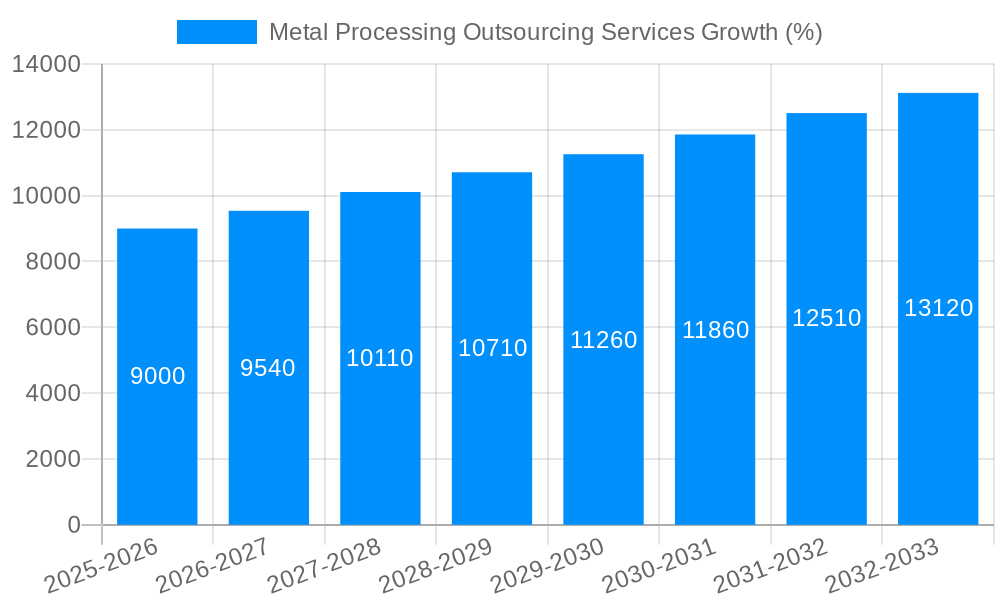

The Metal Processing Outsourcing Services market, valued at XXX million in 2025, is projected to reach XXX million by 2033, exhibiting a CAGR of XX% during the forecast period. The market growth is driven by factors such as rising manufacturing costs, growing demand for customized products, and increasing adoption of digital technologies in manufacturing processes.

Key market trends include the increasing preference for offshore service outsourcing due to lower labor costs and access to skilled labor, the adoption of automation and robotics to enhance efficiency and reduce costs, and the growing demand for metal processing services from industries such as automotive, aerospace, and machinery. Prominent market players include Lion Machinery Manufacturing (Wuxi) Co. Ltd., Yangzhou Xinming Metal Processing Co. Ltd., Zemi (Shanghai) Technology Co. Ltd., and Shenzhen Qile Mold Technology Co. Ltd. The market is geographically distributed across North America, Europe, Asia-Pacific, Middle East & Africa, and South America, with Asia-Pacific accounting for the largest market share.

The global metal processing outsourcing services market is projected to witness a remarkable surge in the coming years. This growth can be attributed to several key factors, including the rising demand for outsourced manufacturing services, the increasing adoption of advanced technologies, and the growing complexity of metal processing operations.

Many businesses are turning to outsourced manufacturing services to reduce costs, improve efficiency, and gain access to specialized expertise. Metal processing is a complex and specialized field, and outsourcing these services to a reputable provider can help companies to overcome challenges related to skilled labor shortages, equipment maintenance, and production optimization.

Advancements in technology are also driving the growth of the metal processing outsourcing services market. The adoption of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies has enabled manufacturers to streamline their operations, reduce errors, and improve product quality. Outsourcing providers are investing in these technologies to provide their clients with cutting-edge solutions that meet their evolving needs.

The increasing complexity of metal processing operations is another factor contributing to the growing demand for outsourcing services. With the advent of new materials and manufacturing techniques, metal processing has become increasingly specialized and requires a high level of expertise and experience. Outsourcing providers can offer companies access to a pool of skilled professionals who are equipped to handle complex projects and ensure timely delivery of high-quality products.

The metal processing outsourcing services industry is propelled by a range of factors, including:

Cost reduction: Outsourcing metal processing services can help companies to save on labor costs, overhead expenses, and equipment investments. By partnering with an experienced provider, businesses can access a global network of suppliers and tap into economies of scale.

Improved efficiency: Outsourcing providers typically have standardized processes and specialized equipment, which enables them to deliver products efficiently and on time. They can also help companies to optimize their supply chain and reduce lead times.

Access to expertise: Metal processing is a complex and specialized field, and outsourcing providers have the expertise and experience to handle a wide range of projects. They can provide companies with access to the latest technologies and best practices, helping them to improve product quality and reduce risks.

Flexibility: Outsourcing providers offer a flexible workforce that can be scaled up or down as needed. This allows companies to respond quickly to changes in demand and adjust their production capacity accordingly.

Focus on core competencies: By outsourcing metal processing services, companies can focus on their core competencies and invest their resources in developing and marketing their products. This can lead to increased productivity and profitability.

Despite the growing demand for metal processing outsourcing services, there are also some challenges and restraints that businesses need to consider:

Quality control: Companies need to ensure that the outsourced provider meets their quality standards and specifications. Establishing clear communication channels and conducting regular quality inspections are crucial to mitigating risks and maintaining product integrity.

Intellectual property protection: Companies should ensure that their intellectual property (IP) is protected when outsourcing metal processing services. This can be achieved through non-disclosure agreements (NDAs) and other legal agreements that safeguard confidential information and designs.

Communication challenges: Outsourcing providers may be located in different time zones or have different cultural backgrounds, which can lead to communication challenges. Establishing clear communication protocols and fostering a collaborative relationship can help to overcome these challenges.

Transportation costs: Depending on the location of the outsourcing provider, transportation costs can impact the overall cost of outsourcing. Companies need to carefully consider the trade-offs between cost and delivery time.

Loss of control: Outsourcing metal processing services can result in a loss of control over certain aspects of the manufacturing process. Companies need to strike a balance between outsourcing for efficiency and maintaining control over critical aspects of their operations.

Key Regions:

Key Segments:

The growth of the metal processing outsourcing services industry is expected to be further fueled by several factors, including:

Some of the leading players in the metal processing outsourcing services market include:

The metal processing outsourcing services sector is constantly evolving with the emergence of new technologies and market trends. Some of the significant developments in this sector include:

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Lion Machinery Manufacturing (Wuxi) Co., Ltd., Yangzhou Xinming Metal Processing Co., Ltd., Zemi (Shanghai) Technology Co., Ltd., Shenzhen Qile Mold Technology Co., Ltd., Guangdong Quanzhou Technology Co., Ltd., YENA Engineering, Prince Manufacturing, Remaly Manufacturing Company, Leonhardt Manufacturing Co., Inc., United Global Sourcing, Sheet Metal Services, GSM Industrial, East Metal, Fabritex Inc., .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million.

Yes, the market keyword associated with the report is "Metal Processing Outsourcing Services," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Metal Processing Outsourcing Services, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.