1. What is the projected Compound Annual Growth Rate (CAGR) of the Industrial Additive Manufacturing Software?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Industrial Additive Manufacturing Software

Industrial Additive Manufacturing SoftwareIndustrial Additive Manufacturing Software by Application (Oil and Gas, Aerospace and Defense, Machinery and Tool, Automotive, Rail, Others), by Type (Cloud-based, On Premises), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

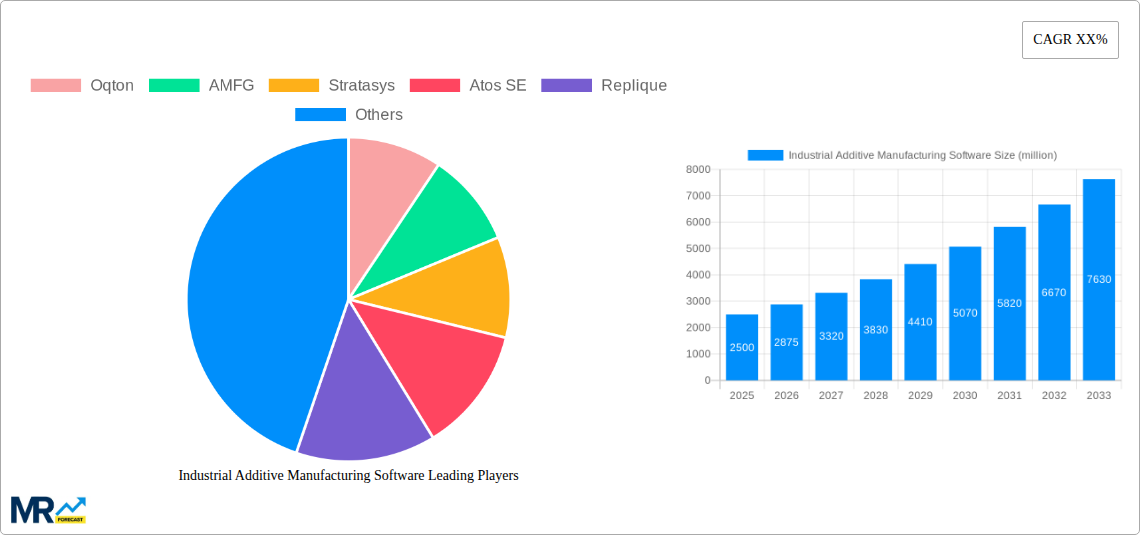

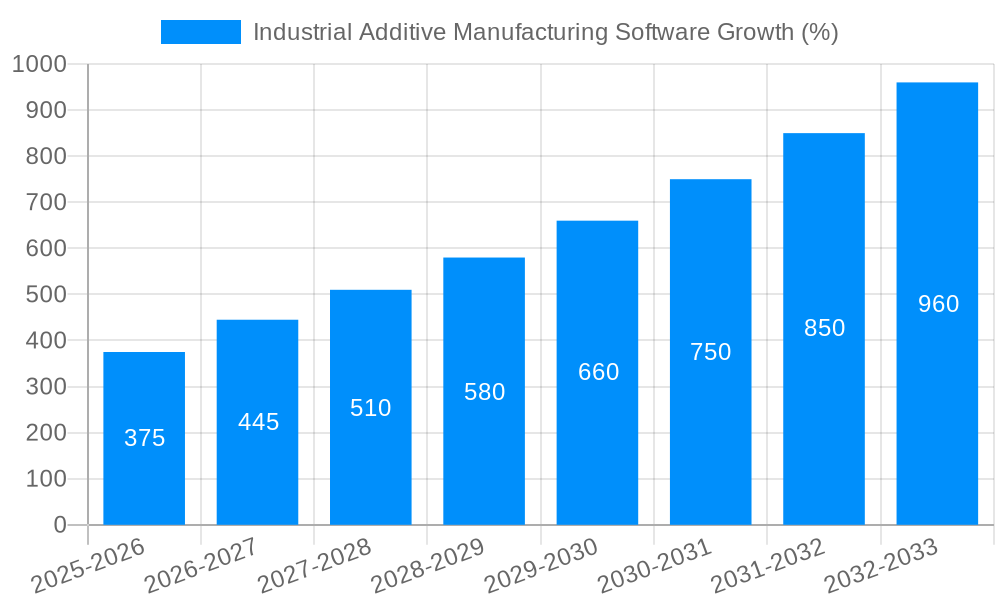

The Industrial Additive Manufacturing (IAM) software market is experiencing robust growth, driven by the increasing adoption of 3D printing technologies across various industries. The market, estimated at $1.5 billion in 2025, is projected to exhibit a Compound Annual Growth Rate (CAGR) of 15% from 2025 to 2033, reaching approximately $5 billion by 2033. This expansion is fueled by several key factors. Firstly, the rising demand for customized and lightweight components in sectors like aerospace and automotive is pushing the need for sophisticated software solutions to optimize the design and manufacturing process. Secondly, the increasing complexity of 3D printing techniques necessitates advanced software for simulation, process optimization, and quality control. Cloud-based solutions are gaining significant traction due to their scalability, accessibility, and cost-effectiveness. Finally, ongoing technological advancements, such as Artificial Intelligence (AI) integration for process automation and predictive maintenance, are further propelling market growth. The competitive landscape is characterized by a mix of established players and innovative startups, fostering innovation and competition.

However, the market faces certain challenges. High initial investment costs associated with IAM software and the need for skilled professionals to operate these systems can hinder widespread adoption, particularly among small and medium-sized enterprises (SMEs). Furthermore, data security concerns related to cloud-based solutions and the complexities of integrating IAM software with existing manufacturing workflows also represent potential restraints. Despite these challenges, the long-term outlook for the IAM software market remains positive, fueled by continuous technological improvements, increasing industry awareness of the benefits of 3D printing, and growing government support for advanced manufacturing initiatives. Segment-wise, the cloud-based software segment is expected to dominate owing to its flexibility and scalability, while the oil and gas, aerospace and defense, and automotive sectors are projected to be the largest application segments due to their high demand for customized and high-performance parts.

The industrial additive manufacturing (AM) software market is experiencing explosive growth, projected to reach hundreds of millions of dollars by 2033. Driven by increasing adoption across diverse sectors and technological advancements, the market showcases a compelling blend of cloud-based and on-premises solutions catering to specific industry needs. From 2019 to 2024 (the historical period), the market witnessed significant expansion, laying the groundwork for even more substantial growth during the forecast period (2025-2033). The estimated market value in 2025 stands at a substantial figure in the millions, demonstrating the industry's maturity and potential. Key market insights reveal a strong preference for cloud-based solutions due to their scalability, accessibility, and cost-effectiveness. However, on-premises solutions remain relevant for organizations prioritizing data security and control. The aerospace and defense, and automotive sectors are currently leading in AM software adoption, driven by the need for lightweighting, complex part design, and rapid prototyping. However, growth is rapidly expanding into other sectors like oil and gas and machinery and tooling as the benefits of AM become more widely understood. The increasing complexity of AM processes necessitates sophisticated software solutions capable of handling design optimization, process simulation, and production monitoring. This trend is driving the development of advanced AI-powered features within AM software, enabling greater efficiency and precision. The market is also witnessing increased integration with other manufacturing software, facilitating seamless data exchange and streamlined workflows. This holistic approach to manufacturing software is enhancing overall productivity and contributing to the sustained growth of the market. The competitive landscape is dynamic, with a mix of established players and emerging startups vying for market share, further propelling innovation and competition within the market.

Several factors are driving the rapid expansion of the industrial additive manufacturing software market. The increasing demand for customized and complex components across various industries is a primary driver. Additive manufacturing allows for the creation of intricate designs previously impossible with traditional subtractive methods, and specialized software is essential for designing, simulating, and managing these complex processes. The growing need for improved efficiency and reduced production costs is another significant catalyst. AM software optimizes the entire AM workflow, from design to post-processing, resulting in faster turnaround times, reduced material waste, and lower overall production expenses. Furthermore, advancements in software capabilities, such as AI-powered design optimization and predictive maintenance tools, enhance productivity and reliability, making the technology even more attractive to industries seeking improved operational efficiency. The rising adoption of Industry 4.0 principles, emphasizing data-driven decision making and automation, necessitates sophisticated software solutions capable of integrating seamlessly with existing manufacturing systems. Finally, government initiatives and funding aimed at promoting AM technology further stimulate growth within the market by fostering innovation and encouraging widespread adoption across diverse sectors. The convergence of these factors contributes to the continuous expansion of the industrial additive manufacturing software market.

Despite significant growth, the industrial additive manufacturing software market faces challenges. The high initial investment cost of both the software and necessary hardware can deter smaller companies from adopting the technology. Furthermore, the complexity of AM processes and software interfaces can pose a barrier to entry for users lacking specialized training or expertise. This highlights the need for user-friendly interfaces and comprehensive training programs to facilitate wider adoption. The lack of standardization across different AM systems and software platforms creates interoperability issues, hindering seamless data exchange and integration. Ensuring data security and protecting intellectual property also remain important considerations for businesses, especially concerning cloud-based solutions. Competition among existing and emerging software providers is fierce, requiring continuous innovation and adaptation to stay ahead. Finally, the relatively immature nature of some AM technologies and the potential for unforeseen technical issues can create uncertainty and reluctance for potential adopters. Addressing these challenges requires collaborative efforts from software developers, hardware manufacturers, and industry stakeholders to enhance usability, improve standardization, and build trust in the technology.

The aerospace and defense segment is poised to dominate the industrial additive manufacturing software market. The industry's demand for lightweight, high-strength components, and complex geometries makes AM an ideal manufacturing process. This drives the need for sophisticated software capable of managing complex designs, optimizing processes, and ensuring quality control.

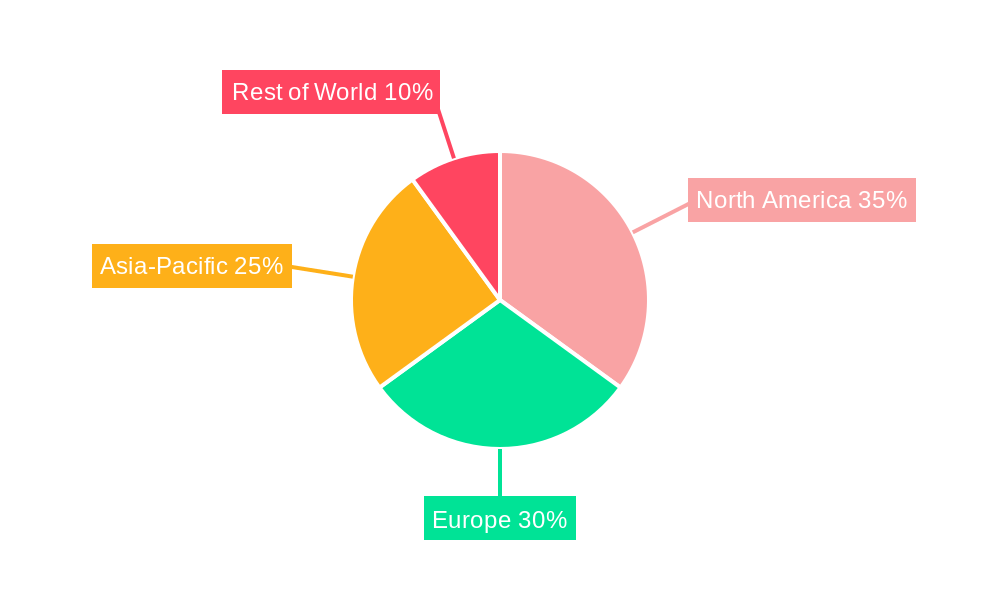

North America and Europe are expected to lead in market share due to their established aerospace and defense industries, significant investment in R&D, and early adoption of advanced manufacturing technologies. These regions' robust economies and supportive regulatory environments further encourage innovation and investment in the sector.

Cloud-based solutions are gaining significant traction across all segments because of their accessibility, scalability, and reduced upfront investment. This type of software is particularly attractive to companies seeking flexibility and cost optimization.

On-premises solutions, however, will continue to hold relevance in industries with stringent data security requirements and a preference for maintaining complete control over their data and processes. This is commonly seen within aerospace and defense, particularly when dealing with sensitive military or government projects.

The high value of aerospace and defense components justifies the investment in sophisticated software, ensuring quality control and compliance with rigorous industry standards. Furthermore, the increasing complexity of modern aircraft designs and the need for lighter, more fuel-efficient components significantly contribute to the segment's dominance. The continuous need for innovation in this sector drives the demand for cutting-edge software with capabilities such as advanced simulation, generative design, and AI-driven optimization. The demand for reduced lead times and improved production efficiency further fuels the growth of the additive manufacturing software market within the aerospace and defense sector, ensuring continued dominance over the forecast period.

Several factors are accelerating growth in the industrial additive manufacturing software industry. The increasing demand for customized and lightweight components across numerous sectors fuels the need for specialized software to manage and optimize complex AM processes. Technological advancements like AI and machine learning are enhancing software capabilities, improving design optimization, process simulation, and predictive maintenance. Government initiatives and funding aimed at promoting AM technology are encouraging innovation and wider adoption across various industries. The integration of AM software with other manufacturing systems is also streamlining workflows and enhancing overall productivity. These combined elements create a powerful synergy, propelling growth within the sector.

This report provides a comprehensive overview of the industrial additive manufacturing software market, covering key trends, growth drivers, challenges, and leading players. Detailed analysis of market segments, regional variations, and future projections offers valuable insights for industry stakeholders, investors, and potential entrants seeking to understand and capitalize on the opportunities within this rapidly expanding sector. The report's robust methodology and data-driven approach provide a clear and accurate picture of the current and future state of the industrial additive manufacturing software market.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Oqton, AMFG, Stratasys, Atos SE, Replique, Nexa3D, Materialise, Tritone, Castor, SIEMENS, AI BUILD, GE Additive, 3D Systems, Ansys, AdditiveLab, 3YourMind, CADS Additive, Spatial, EOS, Renishaw, Tulip, Hexagon, Autodesk, nTOPOLOGY, Fabpilot, HP, Eplus3D Tech, .

The market segments include Application, Type.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million.

Yes, the market keyword associated with the report is "Industrial Additive Manufacturing Software," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Industrial Additive Manufacturing Software, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.