1. What is the projected Compound Annual Growth Rate (CAGR) of the Wafer Saw Dicing Blades?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Wafer Saw Dicing Blades

Wafer Saw Dicing BladesWafer Saw Dicing Blades by Application (Semiconductors, Glass, Ceramics, Crystals, Others, World Wafer Saw Dicing Blades Production ), by Type (Resin-Bond Blades, Metal-Bond Blades, Nickel-Bond Blades, Others, World Wafer Saw Dicing Blades Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

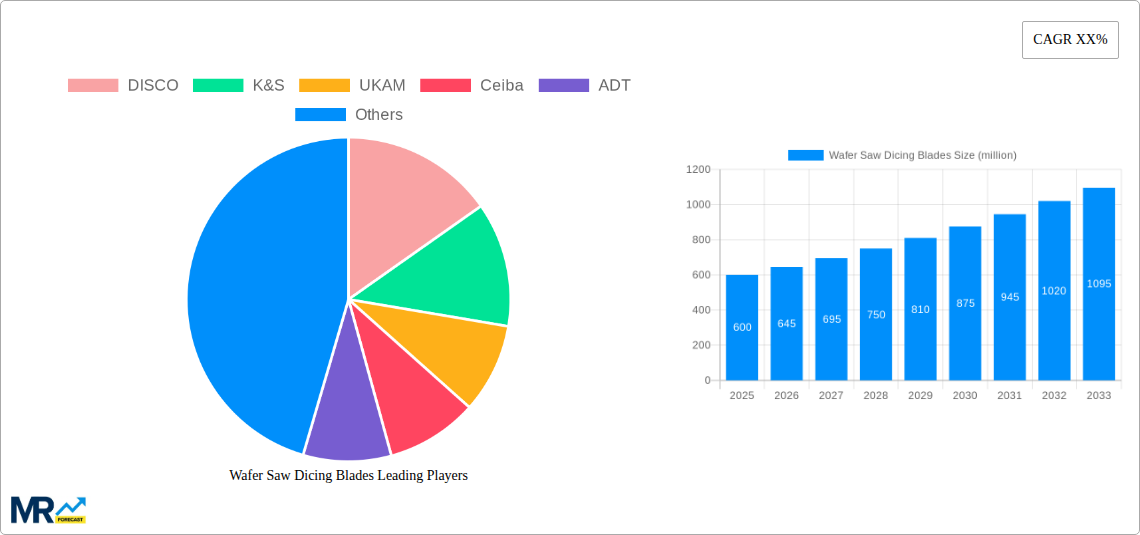

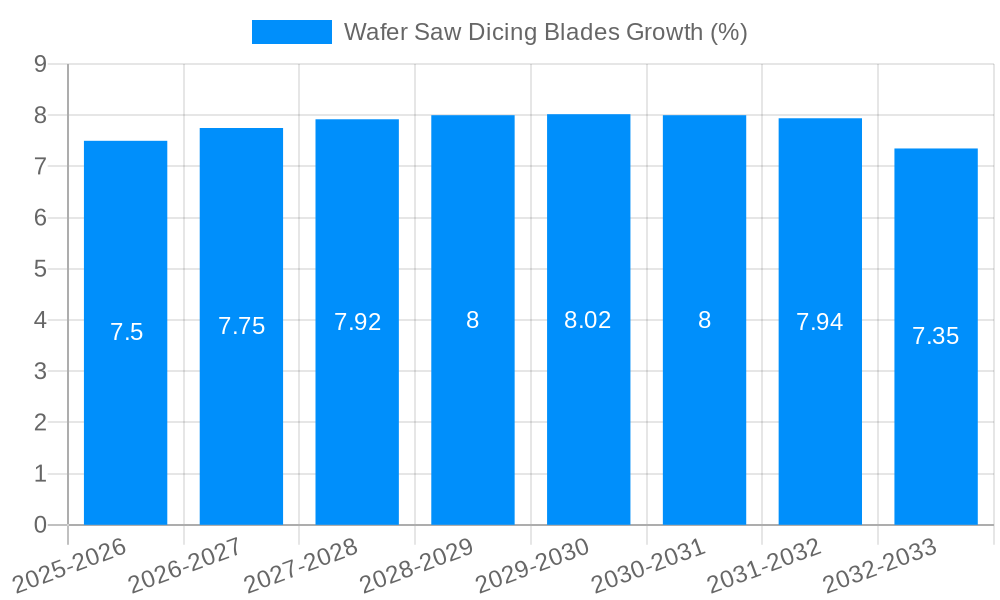

The global wafer saw dicing blades market is poised for significant expansion, projected to reach an estimated value of $600 million by 2025, with a robust Compound Annual Growth Rate (CAGR) of 7.5% anticipated to drive its valuation to approximately $850 million by 2033. This growth trajectory is primarily fueled by the insatiable demand for semiconductors, a critical component in virtually every modern electronic device, from smartphones and computers to advanced automotive systems and artificial intelligence infrastructure. The escalating complexity and miniaturization of integrated circuits necessitate increasingly precise and efficient dicing processes, directly translating into a higher demand for advanced wafer saw dicing blades. Furthermore, the burgeoning electronics manufacturing sectors in Asia Pacific, particularly in China and South Korea, are acting as significant growth engines, bolstered by government initiatives and the presence of major semiconductor fabrication plants. The glass and ceramics industries also contribute substantially, with applications in specialized optics, advanced materials, and consumer electronics requiring high-quality dicing solutions.

The market's expansion is further supported by continuous technological advancements in blade composition, bonding technologies, and manufacturing techniques. Resin-bond blades, known for their flexibility and ability to produce smooth surface finishes, are seeing sustained demand for delicate wafer types. Metal-bond blades offer superior durability and faster cutting speeds, making them ideal for harder materials and high-volume production environments. Nickel-bond blades are emerging as a strong contender, offering a balance of performance and cost-effectiveness. However, the market faces certain restraints, including the high initial investment costs for advanced dicing equipment and the skilled labor required for operation and maintenance. Fluctuations in raw material prices, particularly for specialized abrasive materials like diamond, can also impact production costs. Despite these challenges, the overarching trend towards increased semiconductor content in emerging technologies like 5G, IoT, and electric vehicles ensures a sustained and upward market trajectory for wafer saw dicing blades.

The global wafer saw dicing blades market is undergoing a significant transformation, driven by the relentless innovation in the semiconductor industry and the increasing demand for precision manufacturing across various sectors. The market, valued at an estimated \$2,150 million in the Base Year of 2025, is poised for robust expansion, projected to reach \$3,920 million by the end of the Forecast Period in 2033. This upward trajectory is underpinned by the increasing complexity and miniaturization of electronic components, necessitating finer and more accurate dicing techniques. The Historical Period (2019-2024) witnessed a steady growth, fueled by the burgeoning demand for smartphones, advanced computing, and the Internet of Things (IoT) devices. As we move into the Estimated Year of 2025, the market continues to benefit from the ongoing digital transformation, with a particular surge in demand from the automotive sector for advanced driver-assistance systems (ADAS) and electric vehicle (EV) components. The rise of Artificial Intelligence (AI) and High-Performance Computing (HPC) further amplifies the need for high-yield and high-precision wafer dicing, thereby propelling the market forward.

Furthermore, the market's evolution is marked by a discernible shift towards specialized blade types. While Resin-Bond blades have historically dominated due to their cost-effectiveness and versatility, there is a growing preference for Metal-Bond and Nickel-Bond blades, especially in applications demanding extreme precision and reduced chipping. These advanced bonding technologies enable finer grit sizes and sharper cutting edges, crucial for dicing fragile materials and achieving ultra-thin wafers. The application segment of Semiconductors remains the undisputed leader, accounting for a substantial portion of the market share. However, the burgeoning demand from industries such as advanced ceramics for medical implants, specialized glass for display technologies, and high-purity crystals for optical applications is gradually diversifying the market landscape. The market is also witnessing an increased focus on sustainability, with manufacturers exploring eco-friendly materials and production processes for dicing blades. This includes research into recyclable bonding agents and reduced material waste during the dicing process. The study period (2019-2033) encapsulates these dynamic shifts, offering a detailed analysis of market size, segmentation, regional dynamics, and future growth prospects.

The wafer saw dicing blades market is experiencing an unprecedented surge, primarily fueled by the insatiable demand from the semiconductor industry. The relentless miniaturization and increasing complexity of integrated circuits (ICs) for next-generation electronic devices necessitate ever-finer and more precise dicing capabilities. This trend is prominently observed in the booming markets for 5G infrastructure, AI accelerators, and advanced automotive electronics, where high-density packaging and intricate wafer designs are paramount. As the world embraces digital transformation, the sheer volume of semiconductor production continues to climb, directly translating into a greater need for high-performance dicing blades that ensure minimal kerf loss and maximum die yield. The Estimated Year of 2025 sees the semiconductor application segment alone contributing significantly to the market's overall value of an estimated \$2,150 million.

Beyond semiconductors, the expanding applications in advanced ceramics, particularly for biocompatible medical implants and wear-resistant industrial components, are creating new avenues for growth. Similarly, the demand for specialized glass with enhanced optical properties for augmented reality (AR) and virtual reality (VR) devices, as well as high-resolution displays, is indirectly boosting the market for dicing blades capable of handling these delicate materials. The continuous innovation in bonding technologies, such as the increasing adoption of Metal-Bond and Nickel-Bond blades, allows for the use of finer diamond grits and sharper cutting edges, catering to these increasingly sophisticated material requirements. This technological advancement, coupled with the growing manufacturing capabilities across various regions, is a significant propellant for the global wafer saw dicing blades market throughout the study period (2019-2033).

Despite the robust growth trajectory, the wafer saw dicing blades market faces several significant challenges that could temper its expansion. A primary concern is the increasing cost of raw materials, particularly industrial diamonds and the specialized bonding agents used in high-performance blades. Fluctuations in the supply and pricing of these essential components can directly impact the manufacturing costs of dicing blades, potentially leading to higher prices for end-users. The Estimated Year of 2025, with its projected market value of \$2,150 million, is not immune to these cost pressures. Furthermore, the development and adoption of alternative dicing technologies, such as laser dicing or plasma dicing, pose a potential threat. While these technologies may not yet offer the same level of cost-effectiveness or material versatility as traditional sawing, their ongoing advancements could gradually erode the market share of wafer saw dicing blades in certain niche applications.

The stringent quality control requirements and the need for extremely high precision in semiconductor fabrication also present a challenge. Manufacturers must continually invest in research and development to meet ever-evolving specifications for die size, kerf width, and surface finish. This necessitates substantial capital expenditure and can be a barrier to entry for smaller players. Moreover, the global supply chain disruptions, exacerbated by geopolitical events and the ongoing impact of the pandemic, can affect the availability of both raw materials and finished products, leading to production delays and increased lead times. The intense competition among established players like DISCO and K&S, alongside emerging manufacturers, also exerts downward pressure on profit margins, forcing companies to optimize their production processes and seek cost efficiencies to remain competitive. The study period (2019-2033) will likely see these challenges persist and evolve as the market matures.

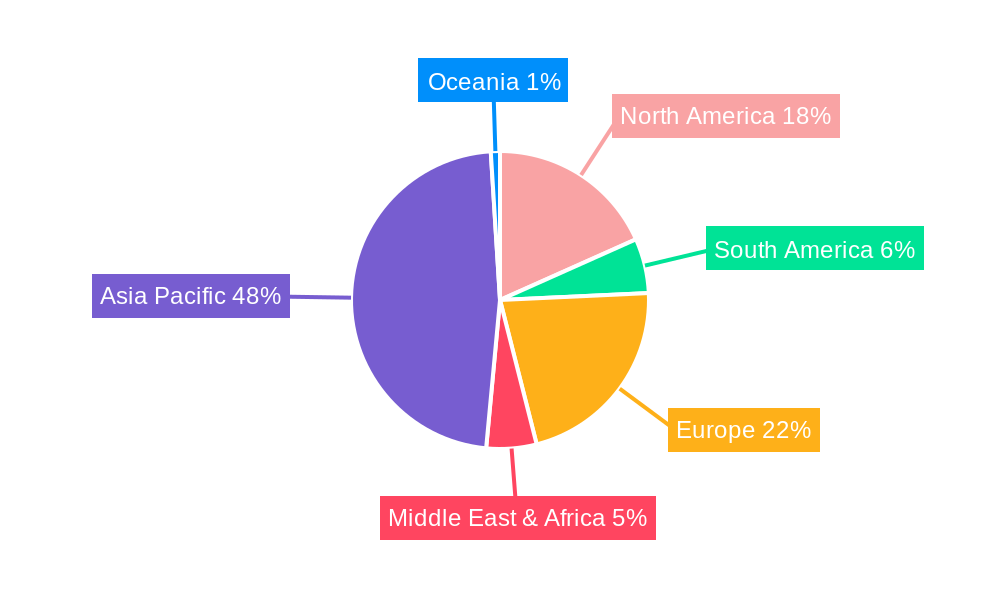

The Semiconductors application segment, coupled with the dominant role of Asia Pacific as a manufacturing hub, is poised to significantly influence and likely dominate the global wafer saw dicing blades market. The sheer scale of semiconductor production concentrated in this region, particularly in countries like Taiwan, South Korea, China, and Japan, makes it the primary driver for demand. These nations are home to some of the world's largest and most advanced semiconductor foundries and assembly facilities, constantly pushing the boundaries of wafer fabrication and requiring a consistent and high-volume supply of dicing blades. The Estimated Year of 2025, with its projected market value of \$2,150 million, sees the semiconductor segment contributing a substantial majority to this figure, largely due to the continued investment in cutting-edge technologies like advanced node manufacturing and high-bandwidth memory (HBM) for AI applications.

Within the Asia Pacific region, the increasing domestic production capabilities in China, driven by government initiatives to achieve semiconductor self-sufficiency, are expected to further bolster demand. This surge in local manufacturing, while potentially impacting global trade dynamics, will undoubtedly fuel the need for a vast quantity of wafer saw dicing blades, whether imported or manufactured regionally. The adoption of advanced blade types, such as Metal-Bond and Nickel-Bond blades, is also prevalent in these technologically advanced regions due to the stringent precision requirements for dicing brittle silicon wafers and compound semiconductors used in high-performance chips. The presence of leading manufacturers like DISCO, K&S, Ceiba, ADT, Kinik, and Shanghai Sinyang, with their strong presence and manufacturing facilities or robust distribution networks in Asia Pacific, further solidifies the region's dominance.

Beyond Semiconductors, the increasing adoption of dicing blades in other emerging applications within Asia Pacific will also contribute to its leading position. For instance, the growing manufacturing of advanced ceramics for the electronics industry and specialized glass for displays in countries like South Korea and Japan will add to the market's regional strength. The Type segment of Resin-Bond Blades will continue to hold a significant market share due to its cost-effectiveness and widespread use in various applications, especially in high-volume production scenarios. However, the growth of Metal-Bond Blades and Nickel-Bond Blades is expected to be more rapid, driven by the increasing demand for higher precision and reduced chipping in critical semiconductor and advanced material applications across the study period (2019-2033). The synergy between the concentrated semiconductor manufacturing in Asia Pacific and the continuous technological advancements in dicing blade types creates a formidable force that is expected to dictate the market's direction.

Several key growth catalysts are propelling the wafer saw dicing blades industry forward. The ever-increasing complexity and miniaturization of semiconductor devices for AI, 5G, and IoT applications are creating an insatiable demand for higher precision dicing. Furthermore, the burgeoning adoption of advanced materials like silicon carbide (SiC) and gallium nitride (GaN) in power electronics and electric vehicles necessitates specialized dicing blades capable of handling these harder and more brittle substrates. The continuous innovation in bonding technologies, leading to finer grit sizes and sharper cutting edges in Metal-Bond and Nickel-Bond blades, directly enhances dicing performance and yield, making them indispensable for critical applications.

This comprehensive report delves deep into the global wafer saw dicing blades market, providing an in-depth analysis of its intricate dynamics. From the Base Year of 2025, with an estimated market valuation of \$2,150 million, the report forecasts a significant expansion to \$3,920 million by 2033. The study meticulously examines key market trends, including the increasing demand for high-precision blades driven by semiconductor advancements and the growing adoption of Metal-Bond and Nickel-Bond technologies. It thoroughly investigates the driving forces, such as the miniaturization of electronic components and the expansion of applications in ceramics and specialized glass. The report also addresses the challenges and restraints faced by the industry, including raw material costs and the emergence of alternative dicing methods. Furthermore, it identifies the dominant regions and segments, highlighting the pivotal role of Asia Pacific and the Semiconductors application. The report concludes by outlining crucial growth catalysts and profiling the leading industry players, offering invaluable insights for stakeholders.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include DISCO, K&S, UKAM, Ceiba, ADT, Kinik, ITI, Shanghai Sinyang, .

The market segments include Application, Type.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Wafer Saw Dicing Blades," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Wafer Saw Dicing Blades, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.