1. What is the projected Compound Annual Growth Rate (CAGR) of the Vacuum Gauges for PVD Equipment?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Vacuum Gauges for PVD Equipment

Vacuum Gauges for PVD EquipmentVacuum Gauges for PVD Equipment by Type (Hot-cathode Ionization Vacuum Gauges, Cold-cathode Ionization Vacuum Gauges, Pirani Compound Vacuum Gauges, Capacitive Vacuum Gauges, Compound Pressure Gauges, Others), by Application (Programmable Logic Device, Storage Device), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

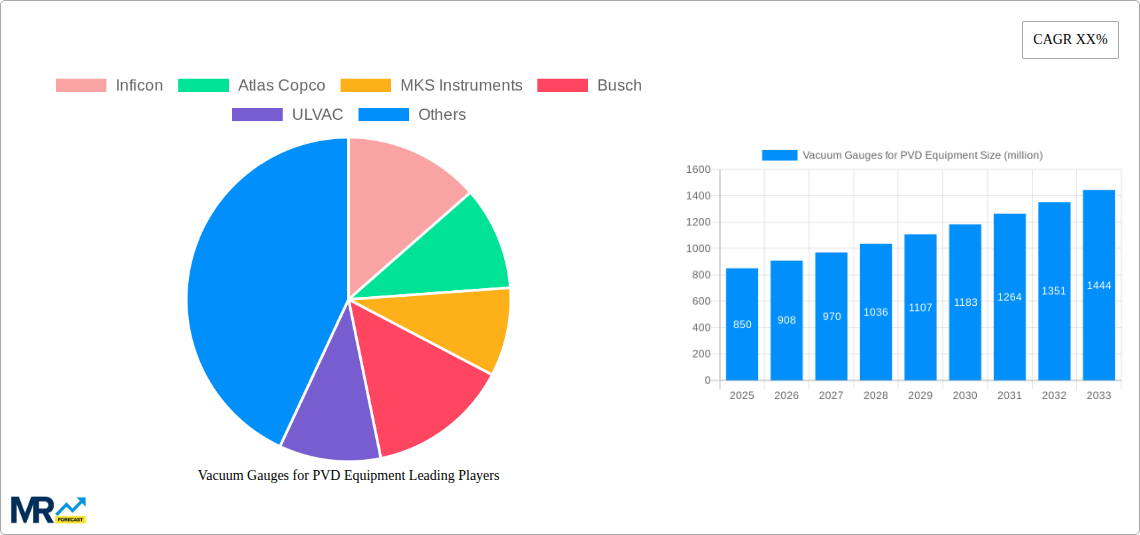

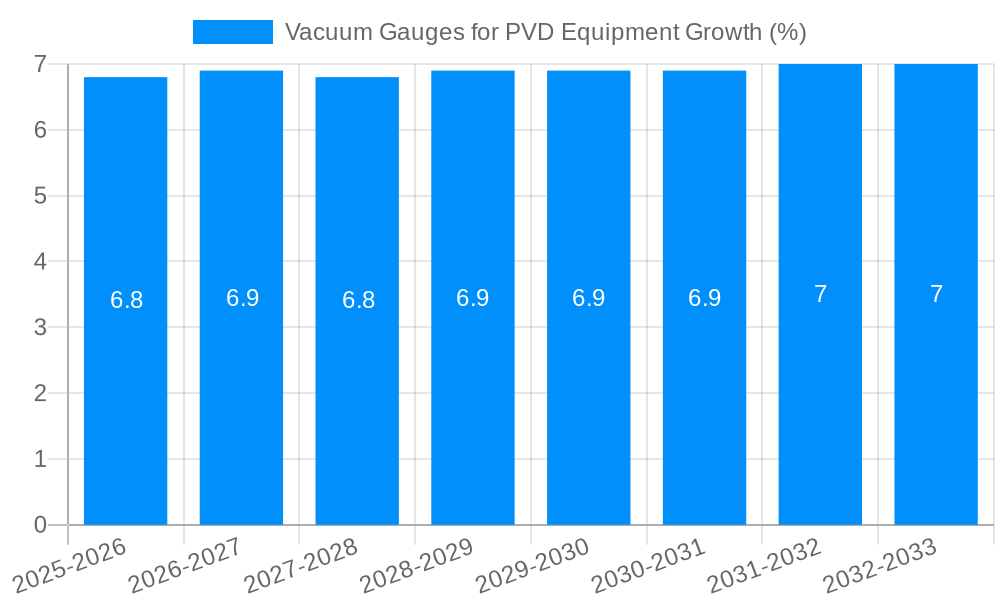

The global Vacuum Gauges for PVD Equipment market is projected for robust expansion, driven by the escalating demand for advanced semiconductor devices and the increasing adoption of Physical Vapor Deposition (PVD) technology across diverse industries. With a projected market size of approximately USD 850 million in 2025 and a Compound Annual Growth Rate (CAGR) of around 6.5% between 2025 and 2033, the market is poised for significant value creation. Key drivers include the burgeoning demand for Programmable Logic Devices (PLDs) and Storage Devices, which heavily rely on precise vacuum conditions for their fabrication. Furthermore, advancements in PVD techniques, leading to enhanced thin-film deposition accuracy and efficiency, are fueling the uptake of sophisticated vacuum gauging solutions. The market is witnessing a surge in demand for high-precision and reliable vacuum measurement instruments capable of operating under extreme conditions, thereby supporting the continuous innovation and miniaturization trends in the electronics sector.

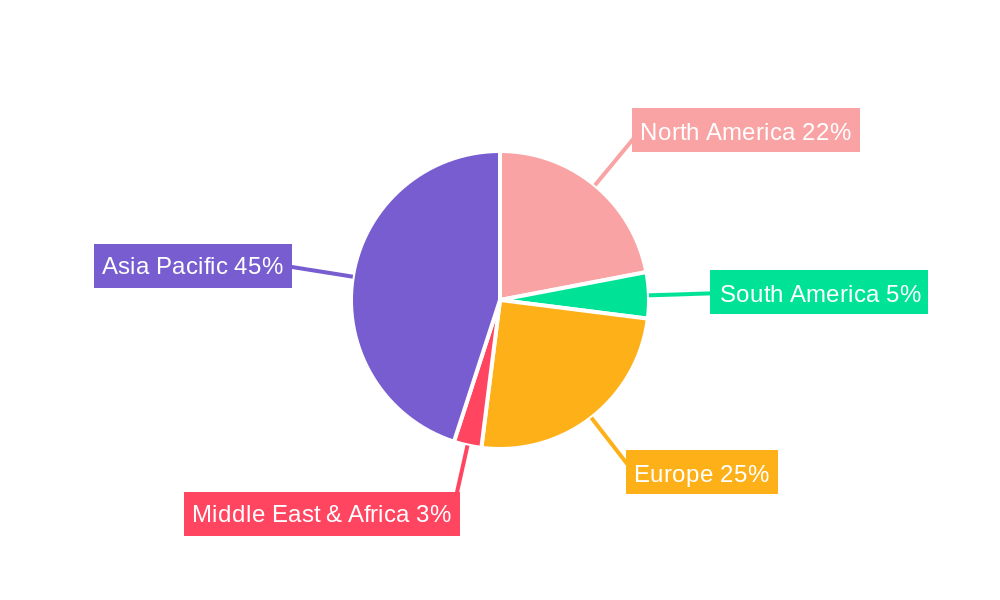

The market is segmented into various types of vacuum gauges, with Hot-cathode Ionization Vacuum Gauges and Pirani Compound Vacuum Gauges likely to dominate due to their established performance and versatility in PVD applications. Cold-cathode Ionization Vacuum Gauges are also gaining traction for specific high-vacuum requirements. Capacitive Vacuum Gauges and Compound Pressure Gauges cater to specialized needs for broad pressure range monitoring. Geographically, Asia Pacific, led by China, Japan, and South Korea, is expected to be the largest and fastest-growing market, owing to its extensive semiconductor manufacturing base and increasing investments in R&D. North America and Europe, with their established PVD equipment manufacturers and strong focus on technological innovation, will also represent significant markets. While the market is characterized by intense competition from established players like Inficon, Atlas Copco, and MKS Instruments, the growing complexity of PVD processes and the need for specialized vacuum solutions present opportunities for both innovation and market expansion.

The global market for Vacuum Gauges for PVD (Physical Vapor Deposition) Equipment is projected to witness substantial growth, driven by the escalating demand for advanced semiconductor devices and the continuous evolution of PVD technologies. The market, estimated to be valued in the hundreds of millions of US dollars in the base year of 2025, is expected to follow a robust growth trajectory throughout the forecast period of 2025-2033. The historical period (2019-2024) has laid a strong foundation, characterized by steady adoption rates in established PVD applications. Moving forward, the study period of 2019-2033 will encompass a dynamic landscape where innovation and market expansion will be key themes.

The PVD process is critical in the manufacturing of a wide array of electronic components, including microprocessors, memory chips, displays, and optical coatings. As the complexity and miniaturization of these components increase, so does the requirement for precise and reliable vacuum control. This necessitates the use of high-performance vacuum gauges that can accurately measure and monitor the ultra-high vacuum (UHV) and high vacuum (HV) conditions essential for achieving desired film properties and process yields. The market is observing a discernible shift towards digital and smart vacuum measurement solutions, offering enhanced data logging, remote monitoring, and integration capabilities with PVD equipment control systems. Furthermore, the growing adoption of PVD techniques in emerging sectors such as advanced packaging, flexible electronics, and specialized thin-film solar cells is opening up new avenues for market expansion. The increasing investments in research and development by key players are leading to the introduction of novel gauge technologies that offer improved accuracy, wider measurement ranges, and greater resilience in harsh PVD environments. The overall market sentiment points towards a sustained demand fueled by technological advancements and the expanding application spectrum of PVD.

The relentless pursuit of miniaturization and enhanced performance in semiconductor devices stands as a primary propellant for the vacuum gauges for PVD equipment market. As transistors shrink and chip densities increase, the precision required during the PVD process becomes paramount. Even minute deviations in vacuum pressure can lead to defects, impacting device yield and functionality. This demand for meticulous process control directly translates into a higher requirement for accurate and responsive vacuum gauges. Moreover, the rapid advancement and widespread adoption of PVD in the manufacturing of advanced displays, such as OLEDs and micro-LEDs, are significantly boosting market growth. These display technologies demand extremely low vacuum levels to deposit thin films with exceptional optical and electrical properties, thereby creating a substantial demand for sophisticated vacuum measurement solutions.

The growing prominence of 3D NAND flash memory, which involves complex etching and deposition steps requiring precise vacuum control, further amplifies the need for reliable vacuum gauges. The transition to higher layer counts in 3D NAND inherently increases the complexity of the PVD process, necessitating more robust and precise vacuum monitoring. Furthermore, the increasing global investments in semiconductor manufacturing facilities, particularly in Asia-Pacific, are creating a substantial market for PVD equipment, and consequently, for the vacuum gauges that are integral to their operation. Government initiatives and industry-wide efforts to bolster domestic semiconductor production capabilities are translating into increased capital expenditure, directly benefiting the vacuum gauge sector.

Despite the robust growth prospects, the vacuum gauges for PVD equipment market faces several challenges that could temper its expansion. One significant restraint is the high cost associated with advanced vacuum gauging technologies, particularly those designed for UHV applications. The intricate manufacturing processes, specialized materials, and rigorous calibration required for these gauges contribute to their premium pricing, which can be a barrier for smaller manufacturers or those with limited capital expenditure budgets. This cost factor can lead to a preference for less sophisticated, albeit less accurate, solutions in certain segments, thus impacting the overall market value.

Another critical challenge lies in the inherent complexity of integrating different types of vacuum gauges with diverse PVD equipment platforms. Each PVD system may have unique requirements and interfaces, necessitating customized solutions or significant retrofitting efforts. This interoperability issue can slow down the adoption of new gauging technologies and create additional costs for end-users. Furthermore, the stringent environmental conditions within PVD chambers, such as high temperatures, plasma bombardment, and reactive gas environments, can lead to sensor degradation and reduced lifespan for some vacuum gauges. Maintaining accuracy and reliability under these harsh conditions requires robust sensor design and frequent calibration, adding to the operational expenses and posing a technical hurdle for gauge manufacturers. The market also faces challenges related to the availability of skilled technicians for installation, calibration, and maintenance of these specialized instruments, which can impact the overall efficiency of PVD operations.

The Asia-Pacific region is poised to be the dominant force in the global Vacuum Gauges for PVD Equipment market, driven by its status as the world's largest hub for semiconductor manufacturing and the burgeoning demand for advanced electronic components. Countries like China, South Korea, Taiwan, and Japan are home to the leading semiconductor fabrication plants, which are the primary consumers of PVD equipment and, consequently, vacuum gauges. The substantial investments being made in expanding existing foundries and building new ones, coupled with government initiatives to foster domestic semiconductor industries, are creating an unprecedented demand for PVD solutions. The increasing production of smartphones, laptops, and other consumer electronics, all heavily reliant on semiconductor chips manufactured using PVD processes, further fuels this regional dominance.

Within this region, the Storage Device segment, particularly the manufacturing of NAND flash memory and DRAM, is expected to be a key driver of market growth. The continuous evolution of storage technologies, such as the transition to higher density 3D NAND architectures and the development of next-generation memory solutions, necessitates sophisticated PVD processes. These processes demand extremely precise vacuum control, thereby driving the demand for high-performance vacuum gauges. The increasing global consumption of data and the proliferation of cloud computing services are directly linked to the demand for more advanced storage devices, creating a sustained need for PVD equipment and the associated vacuum measurement technologies.

Looking at specific vacuum gauge types, Capacitive Vacuum Gauges are expected to exhibit significant growth due to their accuracy, stability, and ability to measure in a wide pressure range, making them indispensable for critical PVD applications in storage device manufacturing. These gauges are less susceptible to contamination and can maintain their calibration for extended periods, offering a cost-effective solution for high-volume production environments. Their reliability in measuring absolute pressure, independent of gas composition, is also a crucial advantage in the diverse process gases used in PVD. The continuous technological advancements in capacitive sensing technology are leading to even higher accuracy and lower detection limits, further solidifying their position in the market.

The adoption of Pirani Compound Vacuum Gauges is also expected to remain strong, particularly in applications where a broader pressure range measurement, from atmospheric pressure down to high vacuum, is required. These gauges offer a cost-effective solution for initial pump-down and process monitoring in less critical stages of PVD. The ability of compound gauges to combine Pirani and a high vacuum sensor (e.g., ionization gauge) in a single unit simplifies system design and reduces installation complexity. The ongoing development of more robust and field-serviceable Pirani sensors is enhancing their appeal in industrial PVD settings. The strong manufacturing base in Asia-Pacific, coupled with the substantial growth in the storage device segment and the preference for accurate and reliable capacitive and compound vacuum gauging technologies, solidifies the region's dominance in the market.

The PVD equipment industry is witnessing several catalysts that are propelling the growth of vacuum gauges. The continuous innovation in semiconductor manufacturing, driven by the demand for smaller, faster, and more power-efficient electronic devices, necessitates increasingly precise PVD processes. This demand for higher performance chips directly translates into a greater need for accurate and reliable vacuum measurement. Furthermore, the expansion of PVD applications beyond traditional electronics into areas like advanced optics, medical devices, and renewable energy sources is creating new market opportunities and driving demand for a wider range of vacuum gauging solutions.

This comprehensive report delves into the intricacies of the Vacuum Gauges for PVD Equipment market, providing an in-depth analysis of market dynamics, technological advancements, and future outlook. The report meticulously covers the study period from 2019 to 2033, with a detailed examination of the historical performance (2019-2024) and a robust forecast for the period 2025-2033. It explores the key driving forces, such as the miniaturization of electronic components and the expansion of PVD applications, alongside the challenges posed by high costs and integration complexities. The report identifies dominant regions and segments, offering strategic insights into market penetration and growth opportunities. Through detailed segmentation by type and application, the report provides a granular understanding of the market landscape. Leading players and their strategic initiatives, along with significant developments and innovations, are comprehensively documented to offer a complete picture of this vital industry.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Inficon, Atlas Copco, MKS Instruments, Busch, ULVAC, Teledyne Hastings Instruments, Azbil Corporation, Canon Anelva, Thyracont Vacuum Instruments, Brooks Instrument, Kurt J. Lesker, Agilent, Shanghai Zhentai, Ebara, Chengdu Zhenghua Electron Instrument, Atovac, Arun Microelectronics, Shanghai Cixi Instrument, Chengdu Ruibao Electronic Technology.

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Vacuum Gauges for PVD Equipment," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Vacuum Gauges for PVD Equipment, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.