1. What is the projected Compound Annual Growth Rate (CAGR) of the Static Mixing Nozzle?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Static Mixing Nozzle

Static Mixing NozzleStatic Mixing Nozzle by Type (Plastic Housing, Metal Housing, World Static Mixing Nozzle Production ), by Application (Residential, Commercial, World Static Mixing Nozzle Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

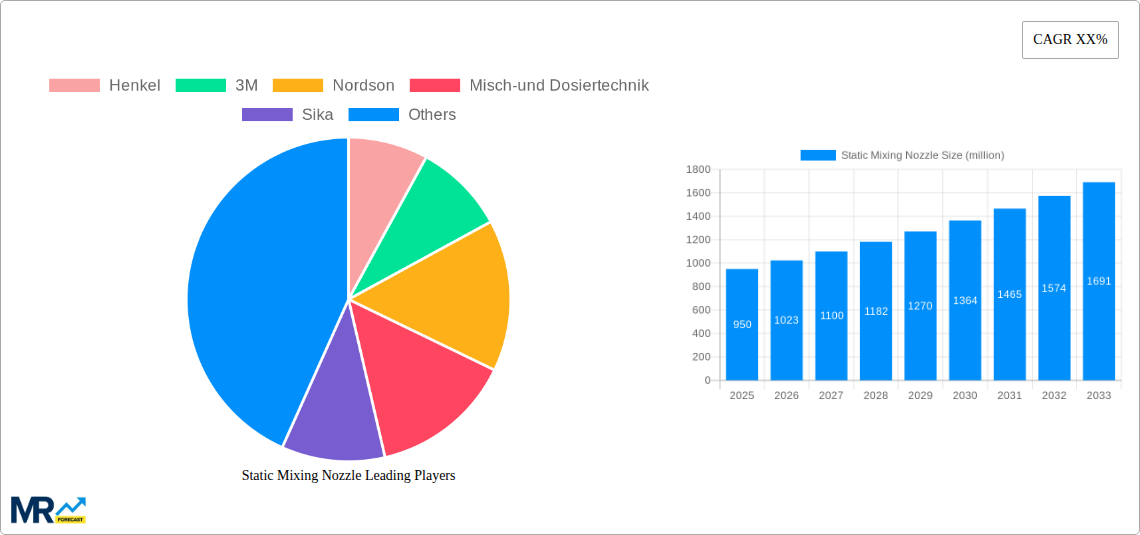

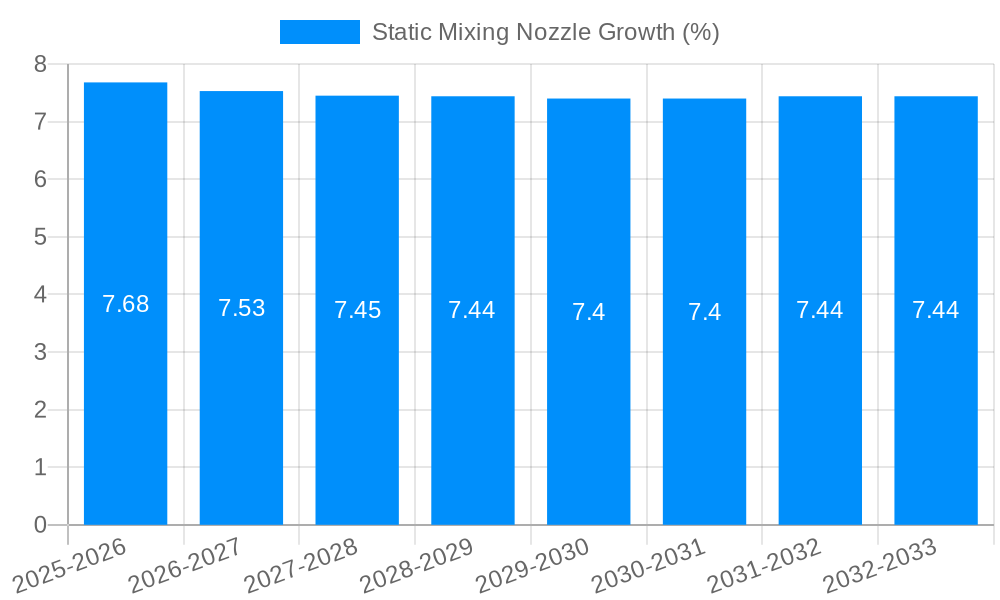

The global Static Mixing Nozzle market is poised for significant expansion, projected to reach a substantial market size of approximately USD 950 million by 2025 and grow at a Compound Annual Growth Rate (CAGR) of roughly 7.8% through 2033. This robust growth is primarily fueled by increasing demand across various industrial applications, particularly in the automotive, construction, and electronics sectors, where precision dispensing of adhesives, sealants, and encapsulants is critical. Advancements in material science and the development of specialized nozzle designs tailored for high-viscosity fluids and specific mixing ratios are further driving market adoption. The residential and commercial segments are expected to witness consistent demand, with the commercial sector showing a slightly higher growth trajectory due to infrastructure development and renovation projects globally.

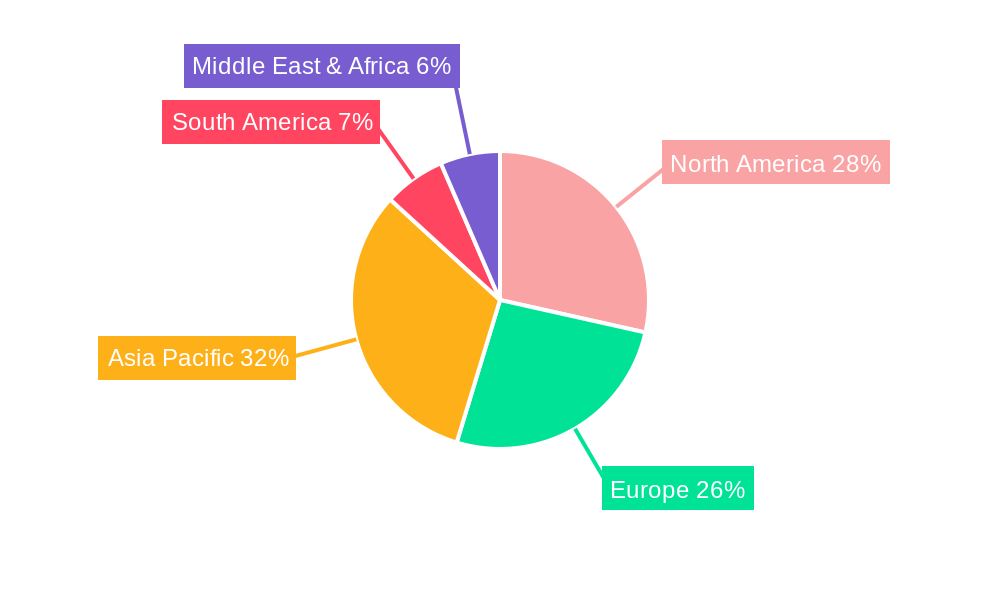

Key market drivers include the escalating need for automation in manufacturing processes, enhancing efficiency and reducing material waste. The growing adoption of advanced composite materials in industries like aerospace and renewable energy, requiring precise application of resins and adhesives, also contributes significantly to market expansion. Emerging economies, particularly in the Asia Pacific region, are demonstrating a strong appetite for static mixing nozzle technology due to rapid industrialization and a burgeoning manufacturing base. However, the market faces certain restraints, including the initial capital investment for sophisticated dispensing systems and the availability of alternative mixing technologies in niche applications. Nonetheless, the ongoing innovation in nozzle design, material compatibility, and integrated dispensing solutions is expected to overcome these challenges, paving the way for sustained market growth. The market is segmented into Plastic Housing and Metal Housing types, with Plastic Housing expected to capture a larger share due to its cost-effectiveness and versatility, while Metal Housing offers superior durability for demanding environments. Prominent players like Henkel, 3M, and Nordson are actively involved in research and development, introducing innovative products to cater to evolving market needs.

This report provides an in-depth analysis of the global Static Mixing Nozzle market, offering insights into its historical performance, current trends, and future projections. Covering the Study Period from 2019 to 2033, with a Base Year and Estimated Year of 2025, and a Forecast Period from 2025 to 2033, this study delves into the intricate dynamics shaping this vital industrial component. The Historical Period of 2019-2024 is meticulously examined to establish a baseline understanding.

The global Static Mixing Nozzle market is experiencing a robust and dynamic evolution, driven by an increasing demand for precise and efficient fluid mixing across a multitude of industrial applications. Over the Study Period (2019-2033), the market has demonstrated a consistent upward trajectory, with significant growth anticipated in the Forecast Period (2025-2033). Key trends indicate a growing preference for advanced material compositions, particularly in the Plastic Housing segment, owing to their enhanced chemical resistance, lightweight properties, and cost-effectiveness. This has led to a substantial shift away from traditional metal housings in certain applications, though Metal Housing solutions continue to hold strong in high-pressure and extreme temperature environments where durability and robustness are paramount. The market is also witnessing a significant push towards miniaturization and customization of static mixers to cater to niche applications and evolving manufacturing processes. Furthermore, the integration of smart technologies and IoT capabilities into static mixing systems, while still nascent, is emerging as a notable trend, promising real-time monitoring and automated adjustments for optimal mixing efficiency. The sheer volume of World Static Mixing Nozzle Production is projected to escalate, propelled by the expanding industrial base in emerging economies and the continuous need for process optimization in established ones. The increasing adoption of static mixers in sectors like adhesives, sealants, and composites is further fueling market expansion. The Report will highlight how innovations in mixing element design, leading to improved laminar and turbulent flow characteristics, are becoming critical differentiators. This focus on performance enhancement is not only about achieving homogeneity but also about minimizing material waste and energy consumption, aligning with global sustainability initiatives. The study will explore how the market is responding to stringent regulatory requirements regarding product consistency and safety, making reliable mixing solutions indispensable.

The burgeoning demand for static mixing nozzles is intrinsically linked to the escalating need for efficient and consistent material processing across a wide spectrum of industries. In the Application segment, the Residential and Commercial sectors are witnessing a surge in the use of adhesives, sealants, and coatings, all of which rely heavily on static mixers for accurate two-component dispensing. This directly translates to increased production volumes of these materials, thereby driving the demand for the nozzles themselves. Furthermore, the ever-present quest for enhanced product quality and reduced manufacturing costs acts as a significant impetus. Static mixers eliminate the inconsistencies and potential contamination associated with manual mixing, leading to a more uniform end-product and minimizing material waste. This efficiency gain is particularly critical in high-volume manufacturing environments. The growing complexity of chemical formulations also plays a crucial role; as new and more specialized materials are developed, the requirement for precise and controlled mixing becomes more pronounced. The ability of static mixers to handle a wide range of viscosities and reaction rates, from low-viscosity resins to high-viscosity epoxies, further broadens their applicability and adoption. The continuous innovation in manufacturing processes, particularly in industries like electronics and automotive, where the precise application of bonding agents and encapsulants is critical, is another key driver. As these industries push the boundaries of material science and miniaturization, the demand for highly accurate and reliable static mixing solutions is set to grow exponentially.

Despite the robust growth trajectory, the static mixing nozzle market is not without its hurdles. One of the primary challenges revolves around the initial capital investment required for acquiring advanced static mixing systems, which can be a deterrent for small and medium-sized enterprises (SMEs). While the long-term cost savings are evident, the upfront expenditure can be a significant barrier to adoption. Another restraint lies in the technical expertise required for selecting the optimal static mixer for a specific application. Incorrect selection can lead to inefficient mixing, increased waste, and potential damage to equipment, necessitating specialized knowledge that may not be readily available in all organizations. Furthermore, the compatibility of materials with the static mixer is a critical consideration. Certain highly corrosive or abrasive substances can degrade the mixing elements over time, leading to premature wear and the need for frequent replacement, thus increasing operational costs. The market also faces competition from alternative mixing technologies, such as dynamic mixers, which, in certain specialized applications, might offer advantages in terms of speed or mixing intensity. The global supply chain disruptions and fluctuations in raw material prices, particularly for metals used in some housing types, can also impact production costs and lead times, posing a challenge to market stability. Lastly, the lack of standardization in certain sub-segments can lead to interoperability issues and complicate the selection process for end-users, thereby slowing down the adoption of new technologies.

The Plastic Housing segment is poised to exhibit remarkable dominance within the global Static Mixing Nozzle market during the Study Period (2019-2033), with a significant surge expected in the Forecast Period (2025-2033). This ascendancy is driven by several interconnected factors that align with evolving industrial demands and technological advancements.

Cost-Effectiveness and Lightweight Properties: Plastic housing static mixers offer a substantial cost advantage over their metal counterparts. The manufacturing processes for plastic components are generally more economical, leading to lower unit prices for static mixers. Furthermore, the inherent lightweight nature of plastics significantly reduces transportation and handling costs, making them an attractive option, particularly for high-volume applications and for manufacturers prioritizing logistical efficiency.

Chemical Resistance and Durability: Advancements in polymer science have led to the development of highly specialized plastics that exhibit exceptional resistance to a wide range of chemicals, solvents, and corrosive agents. This makes plastic housing static mixers ideal for applications involving aggressive fluids, where traditional materials might degrade or react. This enhanced durability translates to a longer service life and reduced maintenance requirements.

Versatility and Customization: Plastic materials lend themselves to intricate molding processes, allowing for the creation of complex and highly customized internal geometries within the mixing elements. This enables static mixer manufacturers to precisely tailor the internal design to optimize flow patterns and achieve superior mixing performance for specific viscosities and material combinations. This level of customization is often more challenging and expensive to achieve with metal housings.

Growing Applications in Adhesives and Sealants: The residential and commercial sectors are significant consumers of adhesives and sealants for construction, automotive assembly, and consumer goods. The increasing use of advanced polymer-based adhesives and sealants, which often require precise two-component mixing, directly fuels the demand for static mixing nozzles. Plastic housing solutions are particularly well-suited for these applications due to their compatibility with these materials and their disposable nature, eliminating the need for cleaning.

Industry Developments and Innovation: Companies like Henkel, 3M, and Sika are heavily involved in the formulation and application of adhesives and sealants, driving innovation in their dispensing technologies. This often involves the development of integrated static mixing solutions where plastic housings are prevalent. The continuous research and development in polymer formulations by these leading companies, aiming for enhanced performance and application-specific solutions, further solidifies the position of plastic housing static mixers.

Regional Demand: The Asia-Pacific region, with its burgeoning manufacturing sector and increasing adoption of advanced materials in construction and automotive industries, is a major contributor to the demand for plastic housing static mixers. Similarly, North America and Europe, with their established industries and focus on process optimization and sustainability, also represent significant markets.

While Metal Housing static mixers will continue to be relevant in high-temperature and high-pressure environments where extreme durability is paramount, the overall trend and projected growth strongly favor the Plastic Housing segment due to its superior balance of cost, performance, and adaptability to evolving industrial needs. The World Static Mixing Nozzle Production volume, across all types, is expected to grow, but the plastic housing segment is anticipated to capture a larger share of this growth.

The static mixing nozzle industry is experiencing significant growth catalyzed by several key factors. The increasing demand for high-performance adhesives, sealants, and coatings, particularly in the automotive and construction sectors, necessitates precise and consistent material mixing, a role static mixers excel at. Furthermore, the global emphasis on process efficiency and waste reduction in manufacturing operations is driving the adoption of static mixers as they minimize material waste and energy consumption compared to traditional methods. The continuous innovation in material science, leading to the development of new formulations requiring specialized mixing, also fuels market expansion.

The global static mixing nozzle market is characterized by the presence of several leading manufacturers. These companies are at the forefront of innovation, offering a diverse range of products to cater to various industrial needs.

The static mixing nozzle sector has witnessed several key developments that have shaped its growth and evolution:

This report offers a comprehensive overview of the static mixing nozzle market, delving into its intricate dynamics from 2019 to 2033. It meticulously analyzes historical data, identifies prevailing trends, and provides expert forecasts for the future. The report covers key aspects such as market segmentation by type (Plastic Housing, Metal Housing) and application (Residential, Commercial), providing detailed insights into World Static Mixing Nozzle Production volumes and industry developments. It also examines the driving forces, challenges, and growth catalysts shaping the market, alongside a thorough assessment of leading players and their contributions. This in-depth analysis equips stakeholders with the critical information needed to navigate and capitalize on the evolving static mixing nozzle landscape.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Henkel, 3M, Nordson, Misch-und Dosiertechnik, Sika, Sulzer, Promix Solutions, Struers, Hermann Otto, SEM Products, Euclid Chemical, REDO-BOND, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Static Mixing Nozzle," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Static Mixing Nozzle, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.