1. What is the projected Compound Annual Growth Rate (CAGR) of the Special Epoxy Resin?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Special Epoxy Resin

Special Epoxy ResinSpecial Epoxy Resin by Type (Cycloaliphatic Epoxy Resin, Elastomer Modified Epoxy Resin, Epoxy Phenolic Resin, Epoxy Polyacrylate, Glycidyl Epoxy Resin, Other), by Application (Composite Material, Coating, Electronic and Electrical, Aviation, Other), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

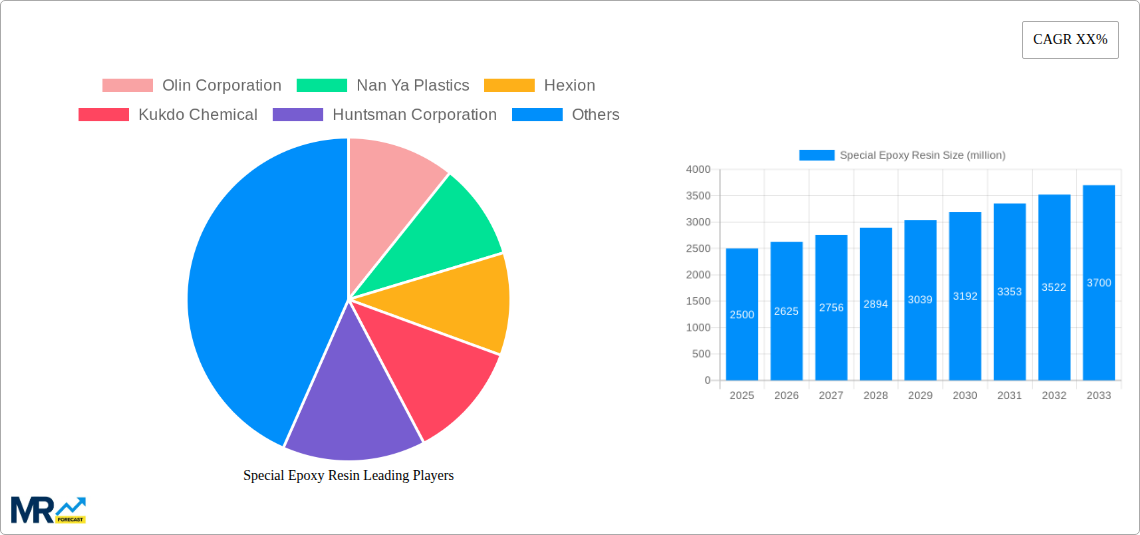

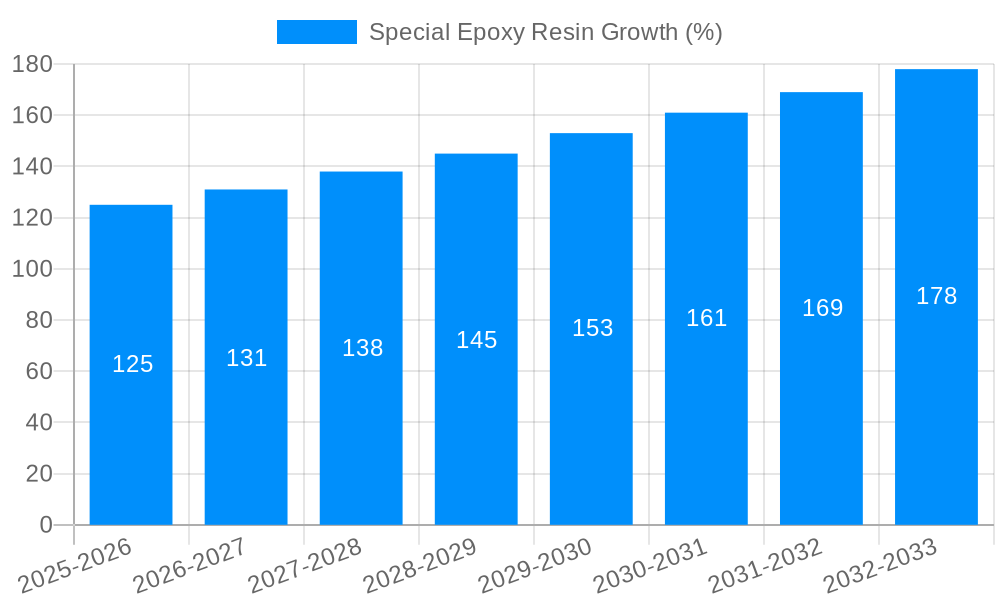

The global Special Epoxy Resin market is poised for significant expansion, projected to reach approximately USD 25,500 million in 2025 and grow at a Compound Annual Growth Rate (CAGR) of around 7.2% through 2033. This robust growth is fueled by escalating demand across diverse high-performance applications, particularly in the burgeoning sectors of composite materials, advanced coatings, and critical electronic and electrical components. The inherent properties of special epoxy resins, such as exceptional mechanical strength, superior chemical resistance, excellent adhesion, and thermal stability, make them indispensable in demanding environments. Key drivers include the continuous innovation in material science, leading to the development of specialized epoxy formulations tailored for specific industrial needs, and the increasing adoption of lightweight and durable materials in industries like automotive and aerospace. Furthermore, the growing emphasis on infrastructure development and the expansion of renewable energy projects, which often utilize epoxy resins for protective coatings and structural components, will continue to propel market growth.

The market's trajectory is further shaped by evolving industry trends and strategic company initiatives. The Elastomer Modified Epoxy Resin segment, known for its enhanced toughness and flexibility, is gaining prominence, catering to applications requiring impact resistance. Similarly, advancements in Cycloaliphatic Epoxy Resins are driving their adoption in applications demanding superior weatherability and UV resistance. While the market exhibits strong growth potential, certain restraints, such as the volatility in raw material prices and stringent environmental regulations impacting production processes, need to be navigated. Leading players like Olin Corporation, Nan Ya Plastics, Hexion, and Huntsman Corporation are actively investing in research and development to innovate product portfolios and expand their global manufacturing footprint. Strategic collaborations and mergers are also expected to play a crucial role in consolidating market share and driving technological advancements within the special epoxy resin landscape. The Asia Pacific region, led by China and India, is anticipated to remain a dominant force, driven by rapid industrialization and a substantial manufacturing base.

The global special epoxy resin market is poised for significant expansion, projecting a valuation that will reach an impressive $50 million by the year 2033. This robust growth trajectory is underpinned by a confluence of factors, including escalating demand from high-performance applications and continuous innovation in product development. During the study period of 2019-2033, with a base year of 2025 and an estimated year also of 2025, the market has witnessed dynamic shifts. The historical period from 2019 to 2024 laid the groundwork for this anticipated surge, with key trends emerging that will shape the forecast period of 2025-2033. A critical observation is the increasing preference for advanced epoxy formulations that offer enhanced mechanical properties, superior chemical resistance, and improved thermal stability. These attributes are particularly sought after in burgeoning sectors like aerospace, automotive, and electronics, where material performance is paramount. Furthermore, the market is experiencing a notable shift towards eco-friendly and sustainable epoxy resin solutions, driven by stringent environmental regulations and a growing consumer consciousness. Manufacturers are actively investing in research and development to produce bio-based epoxies and resins with reduced volatile organic compounds (VOCs). The growing adoption of composite materials across various industries, from wind energy to sporting goods, is also a significant trend. Special epoxy resins serve as indispensable binders and matrices for these composites, imparting the necessary strength and durability. The evolution of coating technologies, demanding specialized epoxy formulations for corrosion protection, abrasion resistance, and aesthetic appeal, further fuels market expansion. The electronics sector, with its insatiable need for advanced encapsulants and adhesives that offer excellent electrical insulation and thermal management, represents another substantial growth avenue. The diversification of product portfolios by leading players, catering to niche applications and specific performance requirements, is also a defining trend. This strategic approach allows companies to capture a larger market share and address the evolving needs of a diverse customer base. The market is also seeing a gradual but impactful increase in the adoption of novel curing agents and additives that enhance the processing characteristics and final properties of epoxy resins. The integration of nanotechnology into epoxy formulations, leading to materials with enhanced stiffness, toughness, and conductivity, is an emerging trend with immense potential. Overall, the special epoxy resin market is characterized by a dynamic interplay of technological advancements, evolving application demands, and a growing emphasis on sustainability, all contributing to a projected market size well within the multi-million dollar range.

The remarkable growth trajectory of the special epoxy resin market, projected to reach substantial multi-million dollar figures by 2033, is driven by a powerful synergy of technological advancements and escalating industry demands. A primary propellant is the relentless pursuit of lightweight and high-strength materials across critical sectors like aviation and automotive. Special epoxy resins, particularly those formulated for composite applications, offer unparalleled performance characteristics in this regard, enabling fuel efficiency and enhanced structural integrity. The burgeoning renewable energy sector, especially wind turbine manufacturing, represents another significant driver. The immense scale of modern wind turbine blades necessitates robust and durable composite materials, for which special epoxy resins are the backbone, providing the essential binding and structural support. Furthermore, the rapid advancements in the electronics and electrical industry, characterized by miniaturization and the need for superior insulation and thermal management, are fueling demand for specialized epoxy formulations used in encapsulants, adhesives, and printed circuit boards. The increasing need for protective coatings with enhanced durability, chemical resistance, and corrosion prevention capabilities in harsh industrial environments, marine applications, and infrastructure projects also contributes significantly to market propulsion. The continuous innovation by key players in developing epoxy resins with tailored properties, such as improved flexibility, higher temperature resistance, and faster curing times, is expanding their applicability into previously unaddressed market segments. This relentless product development ensures that special epoxy resins remain at the forefront of material science, meeting and exceeding the performance expectations of an increasingly sophisticated industrial landscape. The global push towards more sustainable and environmentally friendly materials is also indirectly driving the market, as companies invest in developing lower VOC and bio-based epoxy alternatives that align with regulatory mandates and consumer preferences, further broadening the market's appeal and reach.

Despite the promising growth prospects for special epoxy resins, the market faces a spectrum of challenges and restraints that could temper its expansion. A significant hurdle is the volatile pricing and availability of raw materials, particularly epichlorohydrin and bisphenol A (BPA), which are crucial precursors for many epoxy resin formulations. Fluctuations in crude oil prices and geopolitical factors can directly impact the cost and supply of these key ingredients, leading to price instability for manufacturers and potentially affecting their profit margins. Another considerable challenge is the growing regulatory scrutiny and health concerns associated with certain epoxy resin components, especially BPA. While efforts are underway to develop BPA-free alternatives, their widespread adoption and cost-effectiveness are still areas of active development, and some industries remain hesitant to transition fully. The skilled labor requirement for handling and processing specialized epoxy resins can also act as a restraint. Many high-performance applications demand precise mixing ratios, controlled curing conditions, and specialized application techniques, necessitating a well-trained workforce, which may not be readily available in all regions. Furthermore, the competition from alternative materials, such as polyurethanes and advanced thermoplastics, in certain application segments poses a constant threat. These materials, in some cases, offer comparable performance at potentially lower costs or with simpler processing methods, requiring special epoxy resin manufacturers to continually innovate and demonstrate their superior value proposition. The lengthy curing times of some traditional epoxy systems can also be a constraint in high-volume manufacturing processes, leading to longer production cycles and increased operational costs. While advancements in faster-curing formulations are being made, they may come with higher price points or compromise other desirable properties. Finally, the initial capital investment required for sophisticated manufacturing facilities and research and development for specialized epoxy resin production can be a barrier to entry for smaller players, potentially limiting market competition and innovation.

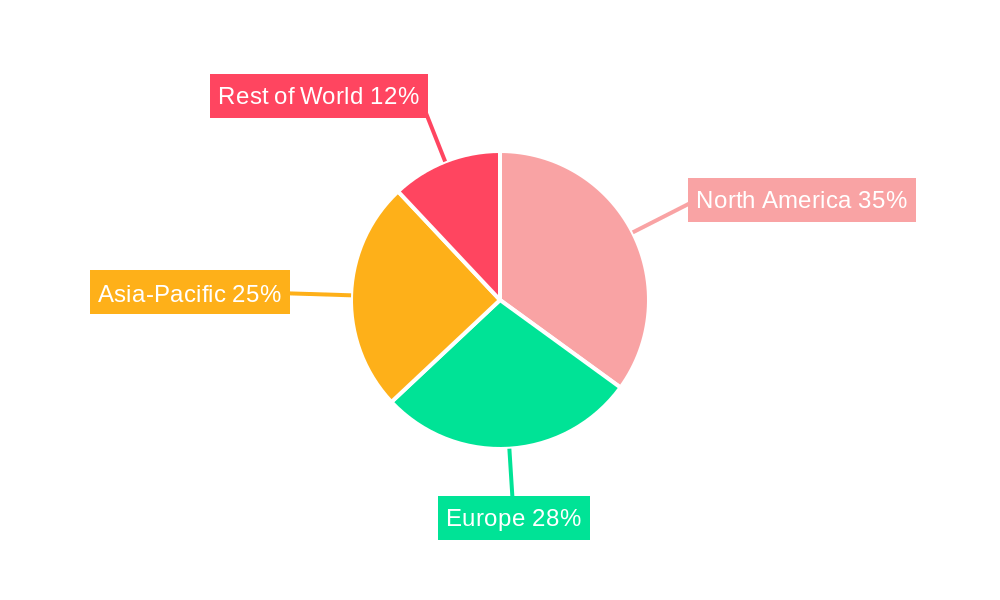

The global special epoxy resin market, projected to reach substantial multi-million dollar valuations, is characterized by distinct regional dominance and segment leadership that will shape its trajectory through 2033.

Dominating Regions/Countries:

Asia Pacific: This region is poised to maintain its leading position, driven by robust industrial growth, particularly in China, Japan, and South Korea.

North America: This region, particularly the United States, will continue to be a significant market, fueled by its advanced manufacturing capabilities, strong aerospace and defense industries, and growing investment in renewable energy infrastructure. The presence of major players like Olin Corporation and Huntsman Corporation underscores its importance.

Dominating Segments:

Within the diverse landscape of special epoxy resins, certain segments are set to command a larger share of the market, driven by specific application demands and technological advancements.

Application: Composite Material: This segment is anticipated to be a dominant force throughout the study period (2019-2033), with its peak influence expected around the estimated year of 2025 and continuing into the forecast period. The escalating demand for lightweight, high-strength, and durable materials across various industries is the primary catalyst.

Type: Glycidyl Epoxy Resin: Among the various types of special epoxy resins, glycidyl epoxy resins are expected to hold a significant market share due to their versatility and widespread use in numerous applications.

The interplay between these dominant regions and segments creates a dynamic market landscape. Asia Pacific's manufacturing strength, coupled with North America's technological advancements, will drive the demand for composite materials and, consequently, glycidyl epoxy resins and other specialized formulations. The continued focus on high-performance applications in aerospace, automotive, and renewable energy will ensure that these segments remain at the forefront of market growth for special epoxy resins throughout the forecast period.

Several key growth catalysts are propelling the special epoxy resin industry towards its projected multi-million dollar valuation by 2033. The escalating demand for high-performance materials in the aerospace and automotive sectors, driven by the need for lightweighting and enhanced fuel efficiency, is a primary catalyst. Furthermore, the booming renewable energy sector, particularly wind turbine manufacturing, requires durable and robust composite materials where special epoxy resins are indispensable. Advancements in electronics and electrical applications, demanding superior insulation and thermal management, are also significant drivers. Continuous innovation in product development, focusing on eco-friendly formulations and resins with tailored properties for niche applications, further fuels market expansion and opens up new avenues for growth.

This comprehensive report delves into the intricate landscape of the special epoxy resin market, providing in-depth analysis and insights into its projected multi-million dollar growth by 2033. Covering the study period from 2019 to 2033, with a base and estimated year of 2025, the report meticulously examines market trends, driving forces, and significant challenges. It offers a detailed breakdown of regional and country-specific market dynamics, highlighting the dominance of Asia Pacific and North America. Furthermore, it scrutinizes the key market segments, with a particular focus on the commanding influence of composite materials and glycidyl epoxy resins. The report also identifies crucial growth catalysts, leading industry players, and significant recent developments, providing a holistic understanding of the market's evolution and future potential.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Olin Corporation, Nan Ya Plastics, Hexion, Kukdo Chemical, Huntsman Corporation, Chang Chun Plastics, Sinopec Corporation, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Special Epoxy Resin," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Special Epoxy Resin, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.