1. What is the projected Compound Annual Growth Rate (CAGR) of the Servo-driven Packaging Machine?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Servo-driven Packaging Machine

Servo-driven Packaging MachineServo-driven Packaging Machine by Type (Semi-automatic Type, Fully Automatic Type, World Servo-driven Packaging Machine Production ), by Application (Food Industry, Pharmaceutical Industry, Others, World Servo-driven Packaging Machine Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

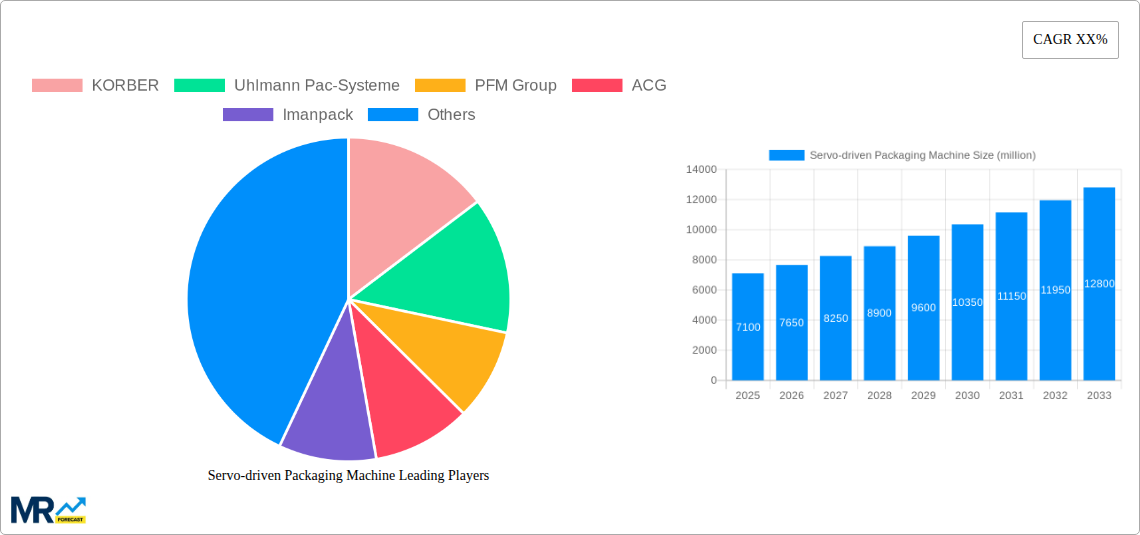

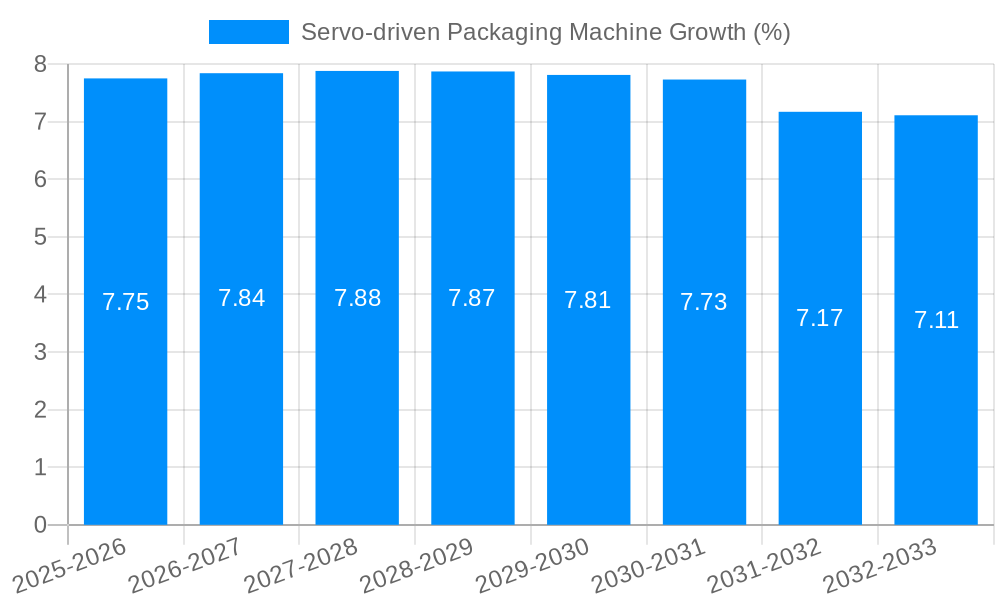

The global Servo-driven Packaging Machine market is poised for significant expansion, projected to reach approximately $11,500 million by 2033, with a robust Compound Annual Growth Rate (CAGR) of around 7.5% during the forecast period of 2025-2033. This growth is primarily fueled by the increasing demand for high-speed, precision, and energy-efficient packaging solutions across various industries. The food and pharmaceutical sectors are leading this surge, driven by stringent quality control standards, the need for enhanced product shelf-life, and the growing consumer preference for convenience and safety. The technological advancements in servo motor technology, enabling greater control, flexibility, and reduced maintenance, are key enablers of this market expansion. Manufacturers are investing in advanced robotics and automation, further propelling the adoption of servo-driven machines.

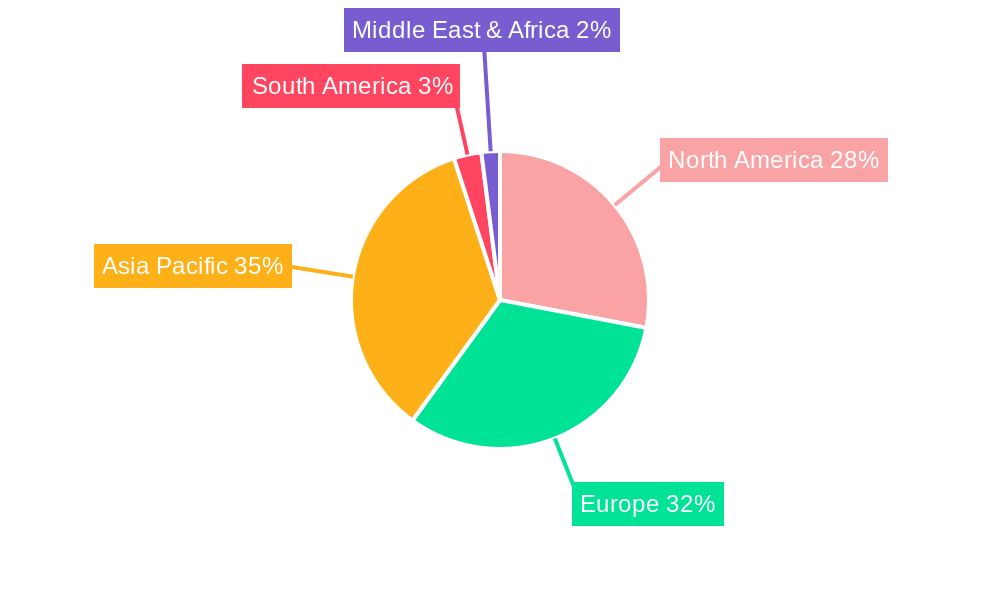

The market is segmented by type into Semi-automatic and Fully Automatic categories, with Fully Automatic machines capturing a larger share due to their superior efficiency and throughput capabilities. The World Servo-driven Packaging Machine Production is also influenced by regional dynamics, with Asia Pacific, particularly China and India, emerging as a dominant force due to rapid industrialization and a growing manufacturing base. North America and Europe remain mature but significant markets, characterized by a strong focus on innovation and sophisticated automation. Restraints such as the high initial investment cost for advanced servo-driven systems and the need for skilled labor to operate and maintain them are present, but are increasingly being offset by the long-term benefits of increased productivity, reduced waste, and compliance with evolving regulatory landscapes. Key players like KORBER, Uhlmann Pac-Systeme, and PFM Group are at the forefront, driving innovation and market growth through strategic investments and product development.

This report delves into the dynamic global market for servo-driven packaging machines, offering a comprehensive analysis from the historical period of 2019-2024 to an extensive forecast period of 2025-2033, with a strong emphasis on the Base Year: 2025. We project a significant global production of servo-driven packaging machines reaching several million units annually by the end of the forecast period. This detailed report will equip stakeholders with critical insights into market trends, driving forces, challenges, regional dominance, growth catalysts, and the leading players shaping this vital industry.

The global servo-driven packaging machine market is characterized by a profound shift towards enhanced automation, precision, and flexibility, fundamentally reshaping manufacturing processes across diverse sectors. XXX This transformation is driven by an insatiable demand for increased production efficiency, reduced waste, and the ability to handle a wider array of product types and packaging formats. Servo technology, with its unparalleled accuracy in motion control, torque management, and speed regulation, has become indispensable for modern packaging operations. For instance, in the Food Industry, the need for hygienic, high-speed filling and sealing of delicate food products, such as snacks, dairy, and ready-to-eat meals, has propelled the adoption of servo-driven solutions. These machines offer precise dosing, gentle handling, and the ability to adapt to varying package sizes and materials, ensuring product integrity and extending shelf life. Similarly, the Pharmaceutical Industry demands stringent control over packaging processes to maintain sterility, prevent contamination, and ensure tamper-evident seals. Servo-driven blister packaging machines, cartoners, and bottle filling lines provide the necessary precision and repeatability for these critical applications. The ability of servo systems to execute complex movements with exceptional accuracy reduces errors, minimizes material wastage, and allows for quick changeovers between different product runs, thereby boosting overall equipment effectiveness (OEE). Furthermore, the growing trend of personalized and smaller batch production, particularly evident in consumer goods and specialized food products, necessitates packaging machinery that can be rapidly reconfigured. Servo-driven machines excel in this regard, offering programmable motion profiles that can be adjusted on the fly, eliminating the need for extensive mechanical adjustments. The integration of advanced sensor technologies and intelligent control systems further enhances their capabilities, enabling real-time monitoring, predictive maintenance, and seamless integration into Industry 4.0 environments. The continuous innovation in servo motor design, drive technology, and control software is further reducing power consumption and footprint, making these machines more energy-efficient and space-saving, a crucial consideration for manufacturing facilities facing space constraints. The market is also witnessing a growing preference for collaborative robotic solutions integrated with servo-driven packaging machines, enabling human-robot interaction for tasks requiring dexterity and adaptability, further streamlining the packaging workflow and enhancing worker safety. The overarching trend is a move towards smarter, more agile, and more connected packaging lines, where servo technology acts as the central nervous system, orchestrating a symphony of precise movements and efficient operations, ultimately contributing to a competitive edge for businesses in the global marketplace.

The relentless pursuit of operational excellence and evolving consumer demands are the primary architects of the servo-driven packaging machine market's robust growth. Businesses are increasingly recognizing the tangible benefits derived from servo technology, translating directly into enhanced productivity and profitability. The Food Industry, for example, faces escalating pressure to optimize production lines for speed, hygiene, and waste reduction, especially with the rise of e-commerce and the demand for tamper-evident and premium packaging. Servo-driven machines address these needs by offering superior control over filling, sealing, and labeling processes, minimizing product loss and ensuring consistent quality. In the Pharmaceutical Industry, regulatory compliance and product integrity are paramount. Servo technology's inherent precision and repeatability are vital for accurate dosage dispensing, sterile packaging, and the creation of secure, tamper-proof seals on blister packs and bottles. This not only safeguards patient health but also mitigates the risk of costly recalls. Beyond these core industries, the broader manufacturing landscape is experiencing a paradigm shift towards automation and smart manufacturing. The ability of servo-driven machines to integrate seamlessly with other automated systems, such as robotic pick-and-place arms and vision inspection systems, is creating highly efficient and flexible production lines. This interconnectedness, a cornerstone of Industry 4.0, allows for real-time data collection and analysis, enabling predictive maintenance, process optimization, and agile responses to market fluctuations. The increasing complexity of product portfolios and the growing demand for customized packaging solutions further amplify the need for adaptable machinery. Servo-driven machines, with their programmable motion control, can be quickly reconfigured for different product sizes, shapes, and packaging materials, significantly reducing changeover times and improving overall equipment effectiveness. This agility is crucial for companies seeking to cater to niche markets and rapidly evolving consumer preferences.

Despite the clear advantages and robust growth trajectory, the servo-driven packaging machine market is not without its hurdles. A primary challenge revolves around the initial investment cost. Servo-driven systems, due to their sophisticated components and advanced control capabilities, generally command a higher upfront price compared to traditional pneumatic or mechanical packaging machines. This can be a significant barrier for small and medium-sized enterprises (SMEs) or businesses in emerging economies with limited capital budgets. The complexity of these systems also necessitates a skilled workforce for operation, maintenance, and troubleshooting. Manufacturers and end-users alike face the challenge of finding and retaining adequately trained technicians who can effectively manage and service servo-driven machinery, leading to potential operational downtime if expertise is lacking. Furthermore, the integration of new servo systems into existing manufacturing lines can sometimes be complex. Ensuring compatibility with legacy equipment and seamlessly integrating the new technology without disrupting ongoing production requires careful planning, expertise, and often, custom engineering solutions. While servo technology offers superior precision, it can also be more sensitive to environmental factors such as dust, moisture, and temperature fluctuations. Maintaining optimal operating conditions to ensure the longevity and performance of servo components is an ongoing concern for users, particularly in less controlled manufacturing environments. Finally, the rapid pace of technological advancement can lead to concerns about obsolescence. As newer and more advanced servo technologies emerge, businesses may face the dilemma of investing in the latest systems or risking their current investments becoming outdated, impacting their long-term competitiveness. Addressing these challenges through training initiatives, accessible financing options, and robust after-sales support will be crucial for sustained market penetration.

The global servo-driven packaging machine market is poised for significant growth, with certain regions and segments demonstrating exceptional dominance and potential.

Fully Automatic Type Segment: This segment is expected to be the leading force in the market.

Dominant Regions:

The interplay between the strong demand for fully automatic systems and the technological sophistication and market size of regions like North America, Europe, and Asia Pacific will dictate the overall market landscape for servo-driven packaging machines.

The servo-driven packaging machine industry is fueled by several potent growth catalysts. The escalating global demand for packaged goods, driven by population growth and changing consumer lifestyles, directly translates into increased need for efficient packaging solutions. Furthermore, the stringent regulatory landscape in sectors like pharmaceuticals, mandating high levels of precision and safety, compels manufacturers to invest in advanced servo technology. The relentless pursuit of operational efficiency, waste reduction, and cost optimization by businesses across various industries also acts as a significant propellant. The ongoing digital transformation and the adoption of Industry 4.0 principles are further driving the integration of servo-driven machines into smart factories, enabling enhanced automation and data-driven decision-making.

The global servo-driven packaging machine market is characterized by the presence of several key players who are instrumental in driving innovation and shaping market trends. These companies are at the forefront of technological advancements and offer a wide range of solutions to cater to diverse industry needs.

The servo-driven packaging machine sector has witnessed several significant developments that have shaped its evolution and market dynamics:

This report provides an in-depth analysis of the global servo-driven packaging machine market, offering valuable insights for stakeholders across the value chain. We meticulously examine market dynamics, including production volumes, technological advancements, and regulatory impacts, from the historical period of 2019-2024 to an extensive forecast period extending to 2033, with a specific focus on the Base Year: 2025. The report details market segmentation by type (Semi-automatic, Fully Automatic) and application (Food Industry, Pharmaceutical Industry, Others), providing granular data and forecasts for each segment. We highlight the key driving forces and challenges that are shaping the market, along with the critical regions and countries poised for significant growth. Furthermore, the report identifies key growth catalysts and provides a comprehensive overview of the leading players and their contributions to the industry, along with significant developments that have occurred. This report is designed to be an indispensable resource for manufacturers, suppliers, investors, and end-users seeking to navigate and capitalize on the evolving landscape of servo-driven packaging machinery.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include KORBER, Uhlmann Pac-Systeme, PFM Group, ACG, Imanpack, ILLIG Maschinenbau, Romaco, SOLLAS HOLLAND, Maripak, Jornen Machinery, General Measure Technology, Guangzhou Leiwest Pak, Gachn Technology, Shanghai Joso Packaging Machinery, Taizhou Funengda Industry, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Servo-driven Packaging Machine," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Servo-driven Packaging Machine, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.