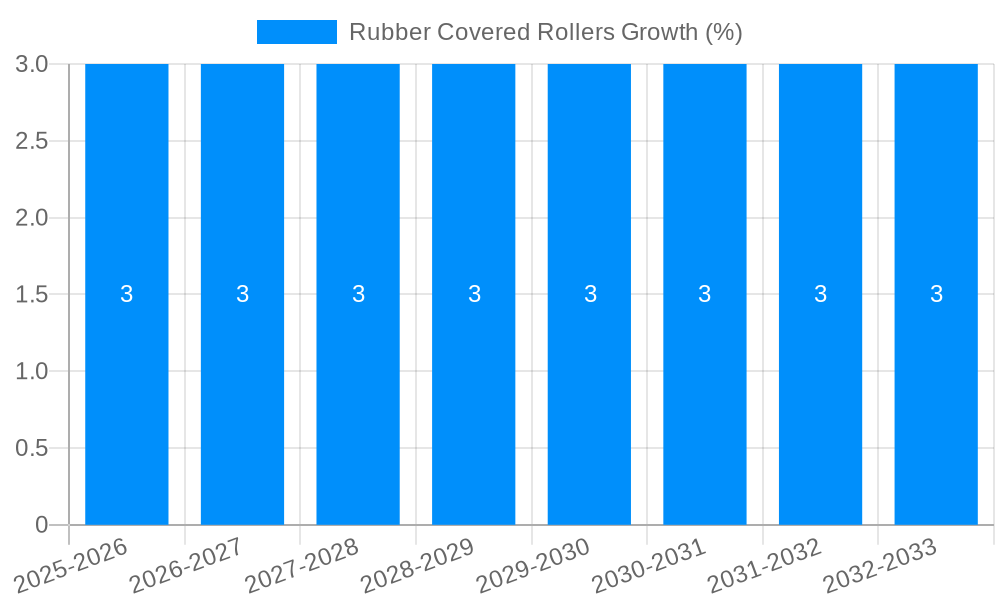

1. What is the projected Compound Annual Growth Rate (CAGR) of the Rubber Covered Rollers?

The projected CAGR is approximately 3.0%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Rubber Covered Rollers

Rubber Covered RollersRubber Covered Rollers by Type (Synthetic Rubber Roller, Natural Rubber Roller, Epdm Rubber Roller, Silicone Rubber Roller, Neoprene Roller, Other Rubber Rollers), by Application (Textile Industry, Paper Industry, Iron and Steel Industry, Food Processing Industry, Quarrying Industry, Other), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

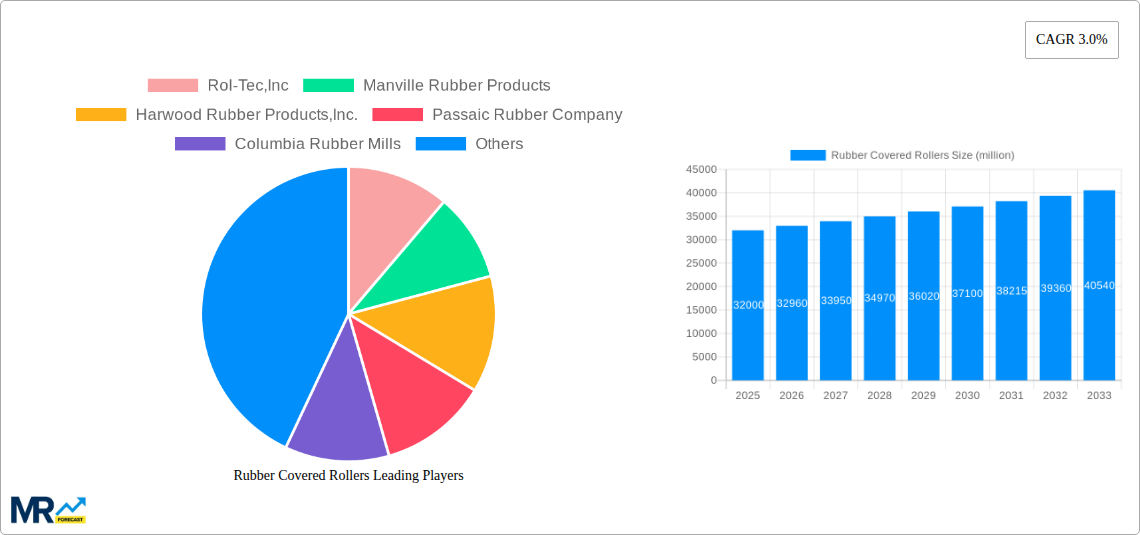

The global Rubber Covered Rollers market is poised for steady growth, projected to reach approximately USD 32,000 million by 2025, with an anticipated Compound Annual Growth Rate (CAGR) of 3.0% during the forecast period of 2025-2033. This expansion is primarily fueled by the increasing demand across a diverse range of industrial applications, including the textile, paper, and iron and steel sectors, which rely heavily on specialized rollers for their manufacturing processes. The growing need for enhanced efficiency, precision, and durability in these industries necessitates the use of high-performance rubber-covered rollers. Furthermore, advancements in material science leading to the development of more resilient and application-specific rubber compounds, such as advanced synthetic and silicone variants, are also contributing to market momentum. The integration of these advanced rollers improves operational output and reduces downtime, making them indispensable components.

The market's trajectory is further influenced by emerging trends in automation and industrial modernization. As industries embrace Industry 4.0 principles, the demand for intelligent and custom-engineered rubber rollers that can withstand extreme conditions and integrate with sophisticated machinery is expected to rise. While the market exhibits robust growth drivers, potential restraints such as fluctuating raw material prices, particularly for natural rubber, and the capital intensity associated with specialized roller manufacturing could pose challenges. However, the continuous innovation in product development, focusing on longevity, chemical resistance, and tailored surface properties, is expected to mitigate these concerns and sustain the positive growth outlook for the rubber-covered rollers market globally. The diverse segmentation by type, including Synthetic Rubber Rollers and Natural Rubber Rollers, and by application, such as the Textile Industry and Paper Industry, underscores the market's broad appeal and its critical role in modern manufacturing.

The global Rubber Covered Rollers market is poised for robust growth, projected to reach an estimated value of XXX million USD by 2025, and further expanding to XXX million USD by 2033. This upward trajectory is underpinned by a confluence of evolving industrial demands and technological advancements. The historical period from 2019-2024 has witnessed a steady increase in adoption, driven by the inherent advantages of rubber-covered rollers, including their superior grip, dampening capabilities, and resistance to abrasion and chemicals. These properties make them indispensable across a wide array of critical manufacturing sectors. The study period spanning 2019-2033, with 2025 serving as the base and estimated year, provides a comprehensive outlook on this dynamic market. The forecast period of 2025-2033 is expected to be particularly significant, as industries increasingly invest in upgrading their machinery and optimizing their production processes. Key trends include a growing preference for specialized rubber compounds tailored to specific application needs, leading to a diversification in the types of rubber used. Furthermore, advancements in manufacturing techniques, such as precision molding and advanced curing processes, are enhancing the performance and lifespan of these rollers, thereby driving market expansion. The integration of smart technologies for monitoring roller performance and predicting maintenance needs is also emerging as a significant trend, promising to revolutionize operational efficiency and reduce downtime. The inherent versatility and adaptability of rubber-covered rollers ensure their continued relevance and demand, making them a cornerstone of modern industrial operations worldwide. The market's growth is further stimulated by the increasing global emphasis on product quality and efficiency, where the reliable performance of rubber-covered rollers plays a crucial role in achieving these objectives. As industries continue to innovate and expand, the demand for customized and high-performance rubber solutions is set to escalate, further solidifying the market's growth prospects. The report will delve into the granular details of these trends, providing actionable insights for stakeholders.

Several powerful forces are acting as significant drivers for the Rubber Covered Rollers market. Foremost among these is the relentless demand from the Paper Industry, which relies heavily on these rollers for processes such as pressing, conveying, and coating. The continuous need for high-quality paper products translates into a consistent and substantial demand for robust and precisely engineered rubber-covered rollers. Similarly, the Textile Industry presents another major growth engine. Here, rollers are vital for fabric processing, dyeing, printing, and finishing, where their ability to provide consistent tension and prevent fabric damage is paramount. The ongoing modernization and expansion of textile manufacturing facilities globally are directly fueling the market's expansion. Furthermore, the Iron and Steel Industry, despite its inherent challenges, continues to be a significant consumer of rubber-covered rollers for applications like strip processing, coating, and conveying of hot and cold metal. The increasing global demand for steel in construction, automotive, and infrastructure projects indirectly contributes to the sustained need for these specialized rollers. Beyond these core industries, the Food Processing Industry is witnessing a growing demand for hygienic and durable rubber-covered rollers in various stages of processing, packaging, and material handling, driven by stringent food safety regulations and the need for efficient production. The increasing industrialization across emerging economies also plays a pivotal role, as these regions invest heavily in manufacturing infrastructure, thereby creating new avenues for market growth. The inherent durability, resilience, and cost-effectiveness of rubber-covered rollers in demanding industrial environments make them a preferred choice, ensuring their sustained demand across a broad spectrum of applications.

Despite the promising growth outlook, the Rubber Covered Rollers market is not without its hurdles. A primary challenge stems from the volatility of raw material prices, particularly natural and synthetic rubber. Fluctuations in the global supply and demand dynamics for these essential commodities can significantly impact the production costs and, consequently, the pricing of rubber-covered rollers. This price sensitivity can sometimes lead to a hesitance in large-scale investments for some end-user industries, especially during economic downturns. Another restraint comes from the increasing competition from alternative materials and technologies. While rubber offers unique advantages, certain advanced composite materials and specialized polymer solutions are emerging as viable alternatives for specific high-performance applications, potentially eroding market share in niche segments. Furthermore, the environmental regulations and sustainability concerns associated with the production and disposal of rubber products can pose a challenge. Manufacturers are under increasing pressure to adopt eco-friendly manufacturing processes and develop recyclable or biodegradable rubber compounds, which requires significant investment in research and development. The technical expertise required for manufacturing and maintaining high-quality rubber-covered rollers also acts as a barrier to entry for new players, and a shortage of skilled labor in specialized areas can hinder production capacity and innovation. Lastly, economic uncertainties and geopolitical instability in key regions can disrupt supply chains and dampen industrial investment, indirectly impacting the demand for rubber-covered rollers. Addressing these challenges will be crucial for sustained and profitable growth within the sector.

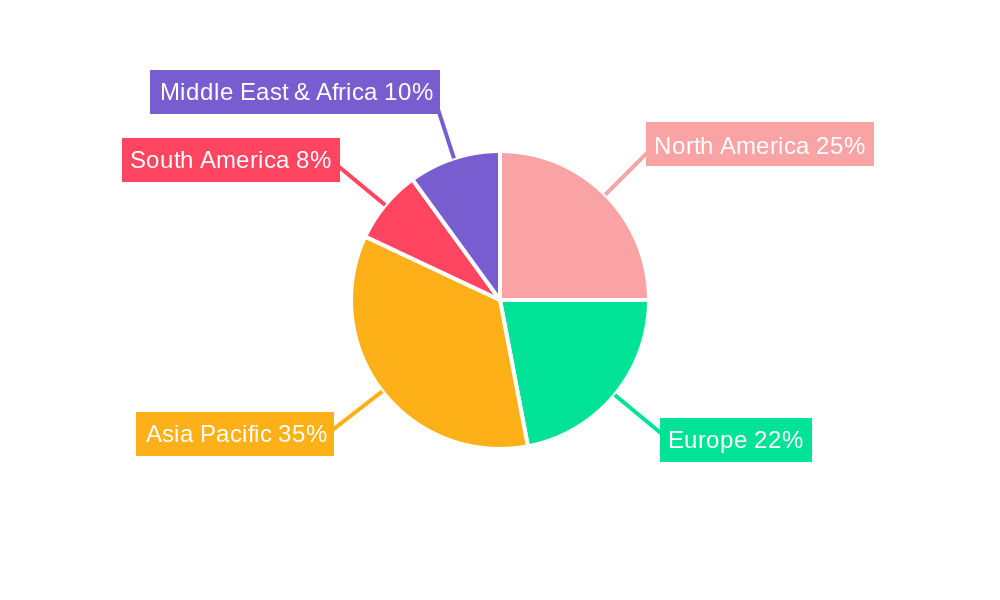

The global Rubber Covered Rollers market is characterized by distinct regional dominance and segment leadership, driven by industrial concentration, technological adoption, and specific application demands.

Dominant Segments:

Type: Synthetic Rubber Roller (specifically Epdm Rubber Roller and Neoprene Roller):

Application: Paper Industry and Textile Industry:

Dominant Regions/Countries:

The Rubber Covered Rollers industry is experiencing significant growth catalysts, primarily driven by the increasing demand for operational efficiency and product quality across diverse industrial sectors. The continuous need for advanced materials that can withstand demanding operational environments, such as high temperatures, corrosive chemicals, and abrasive forces, is fueling innovation in rubber formulations. Furthermore, the growing emphasis on automation and smart manufacturing is creating opportunities for the integration of sensors and advanced monitoring systems into rubber-covered rollers, leading to predictive maintenance and optimized performance. The expansion of manufacturing capabilities in emerging economies, coupled with the upgrade of existing infrastructure in developed nations, provides a consistent pipeline of demand. Finally, the development of specialized rubber compounds tailored to specific industry requirements, such as food-grade compliance or enhanced chemical resistance, is further broadening the market's appeal and driving adoption.

This comprehensive report on the Rubber Covered Rollers market offers an in-depth analysis of market dynamics, trends, and future projections. It meticulously covers the historical period from 2019-2024 and the forecast period of 2025-2033, with 2025 identified as the base and estimated year. The report details market size estimations in the millions of USD for various segments and regions. It examines the key driving forces, such as the sustained demand from the Paper Industry, Textile Industry, and Iron and Steel Industry, alongside emerging applications in Food Processing. The report also critically analyzes the challenges and restraints, including raw material price volatility and competition from alternative materials. Furthermore, it highlights the dominant segments and regions, with a particular focus on the growth potential of Synthetic Rubber Rollers (EPDM, Neoprene, Silicone) and their applications, as well as the market leadership of the Asia-Pacific region. The report also identifies significant growth catalysts, leading players, and recent significant developments, providing a holistic view of the market landscape and offering actionable insights for stakeholders looking to capitalize on the opportunities within this vital industrial sector.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 3.0% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 3.0%.

Key companies in the market include Rol-Tec,Inc, Manville Rubber Products, Harwood Rubber Products,Inc., Passaic Rubber Company, Columbia Rubber Mills, Valley Roller, Rubber Coated Rollers, Krishna Engineering Works, ADVANCE RUBTECH (I) PRIVATE LIMITED, REDCO Rubber Engineering&Development, Vintex Rubber Industries, Warca Rulli Srl, Ames Rubber Manufacturing, Rubber Right Rollers, J.J. Short Associates,Inc, .

The market segments include Type, Application.

The market size is estimated to be USD 32000 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Rubber Covered Rollers," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Rubber Covered Rollers, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.