1. What is the projected Compound Annual Growth Rate (CAGR) of the Portable Magnetic Powder Detector?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Portable Magnetic Powder Detector

Portable Magnetic Powder DetectorPortable Magnetic Powder Detector by Type (Fully Automatic Portable Magnetic Powder Detector, Semi-Automatic Portable Magnetic Powder Detector), by Application (Mechanical, Aerospace, Petrochemical, Other), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

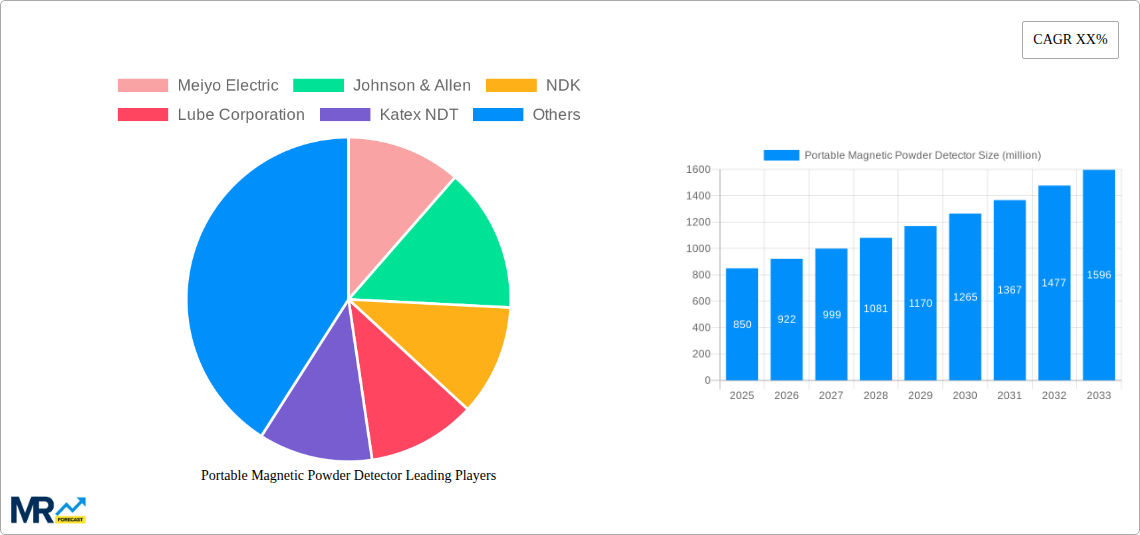

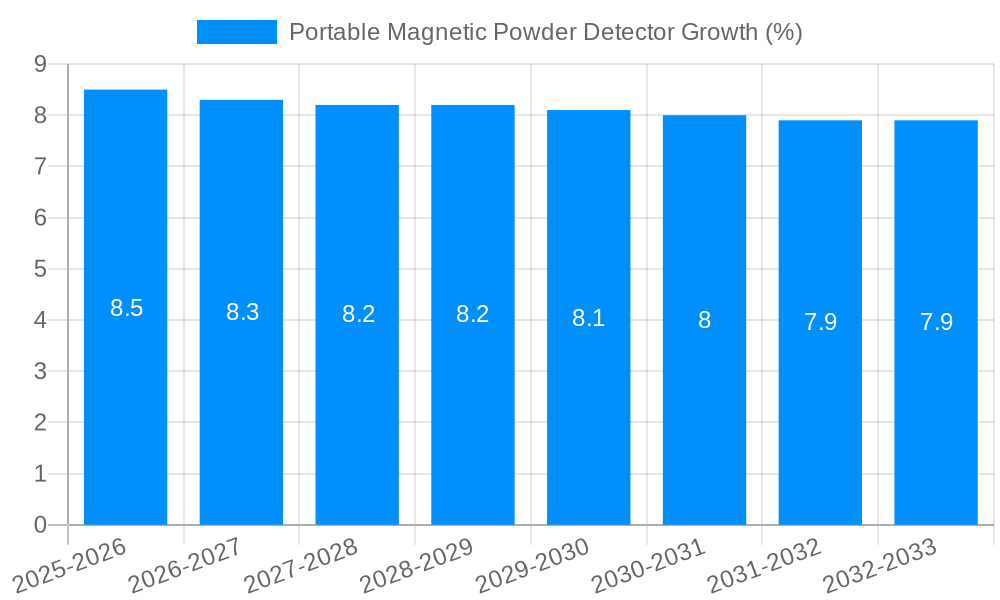

The global market for Portable Magnetic Powder Detectors is experiencing robust growth, projected to reach an estimated $850 million by 2025. This surge is driven by the increasing demand for stringent quality control and non-destructive testing (NDT) across a wide array of industries, including mechanical, aerospace, and petrochemical. The market's Compound Annual Growth Rate (CAGR) is estimated at a healthy 8.5% for the forecast period of 2025-2033. This sustained expansion is fueled by technological advancements in detector sensitivity and portability, making these devices more accessible and efficient for field inspections. The growing emphasis on safety regulations and the need to prevent catastrophic failures in critical infrastructure further bolster the adoption of these essential inspection tools.

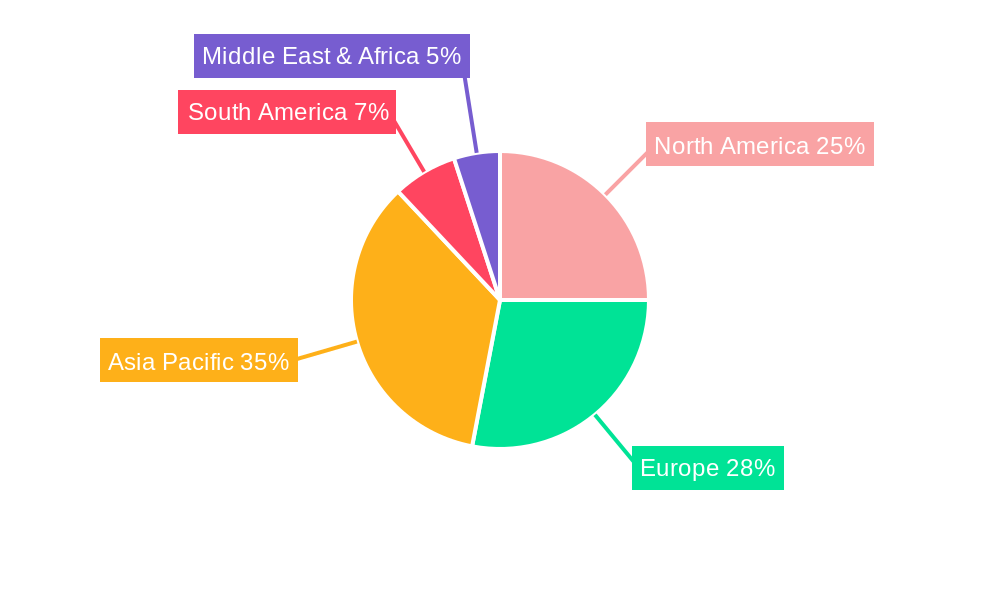

The market segmentation reveals a strong preference for Fully Automatic Portable Magnetic Powder Detectors, which currently hold the dominant share due to their speed, accuracy, and reduced labor requirements. However, the Semi-Automatic Portable Magnetic Powder Detector segment is also poised for steady growth, offering a cost-effective solution for certain applications. Geographically, Asia Pacific, led by China and India, is emerging as a significant growth engine, attributed to rapid industrialization and infrastructure development. North America and Europe remain mature but stable markets, driven by high adoption rates in their established aerospace and manufacturing sectors. Key players such as Meiyo Electric, Johnson & Allen, and NDK are actively innovating, introducing smarter and more integrated NDT solutions to meet evolving industry needs.

This report offers an in-depth analysis of the global Portable Magnetic Powder Detector market, providing a detailed outlook for the period of 2019-2033. Focusing on the base year of 2025 and the forecast period of 2025-2033, with historical data from 2019-2024, this study leverages market insights and data valued in the millions. The report meticulously examines market trends, driving forces, challenges, regional dominance, key players, and significant developments shaping the industry.

The global Portable Magnetic Powder Detector market is poised for substantial growth, projected to reach hundreds of millions of dollars by the end of the forecast period. This upward trajectory is underpinned by an increasing emphasis on non-destructive testing (NDT) methodologies across a wide array of industries. The inherent advantages of magnetic particle testing, such as its cost-effectiveness, sensitivity to surface and near-surface defects in ferromagnetic materials, and portability, make these detectors indispensable tools. We are witnessing a discernible shift towards more sophisticated and automated detection systems, driven by the demand for higher accuracy, faster inspection times, and reduced human error. Fully automatic portable magnetic powder detectors are gaining traction, particularly in high-volume manufacturing and critical infrastructure sectors where precision and efficiency are paramount. This trend is further amplified by stringent quality control regulations and the growing need to ensure the structural integrity and safety of components and structures, especially in demanding environments like aerospace and petrochemical facilities. The market is also experiencing a surge in demand for compact, lightweight, and user-friendly devices that can be easily deployed in challenging field conditions. Advancements in digital imaging and data logging capabilities are also contributing to the evolution of these detectors, enabling better analysis and record-keeping of inspection results. The increasing adoption of these advanced NDT solutions directly correlates with a reduction in potential failures and costly downtime, thus showcasing a strong return on investment for end-users. Furthermore, the global expansion of manufacturing bases, coupled with the growing emphasis on product reliability and lifespan, is creating a sustained demand for portable magnetic powder detectors across emerging economies. The market is dynamic, with ongoing innovation focused on enhancing sensitivity to finer cracks, improving detection of subsurface flaws, and integrating smart features for enhanced connectivity and remote diagnostics. The overall sentiment within the market is one of robust expansion, fueled by both technological advancements and the unwavering commitment to safety and quality assurance.

The portable magnetic powder detector market is experiencing significant momentum propelled by several key driving forces. Foremost among these is the ever-increasing stringency of safety regulations and quality control standards across various industries. Sectors such as aerospace, petrochemical, and heavy machinery demand the utmost reliability in their components, making non-destructive testing methods like magnetic particle inspection essential for detecting surface and near-surface flaws before they can lead to catastrophic failures. The inherent cost-effectiveness and efficiency of portable magnetic powder detectors compared to other NDT techniques further contribute to their widespread adoption. Their portability allows for on-site inspections, reducing the need to transport large or critical components to specialized testing facilities, thereby saving time and logistical costs. Moreover, the continuous growth in manufacturing activities globally, particularly in developing economies, is creating a larger installed base of machinery and infrastructure that requires regular inspection and maintenance. This expanding industrial landscape directly translates into a heightened demand for portable inspection equipment. Technological advancements are also playing a crucial role. The development of more sensitive magnetic powders, improved magnetic field generation capabilities, and integration of digital technologies for data acquisition and analysis are enhancing the performance and usability of these detectors, making them more attractive to end-users seeking greater accuracy and efficiency. The increasing focus on predictive maintenance strategies within industries further bolsters the demand for portable magnetic powder detectors, as companies aim to identify and rectify potential issues early, preventing costly breakdowns and ensuring operational continuity.

Despite the promising growth trajectory, the portable magnetic powder detector market is not without its challenges and restraints. A significant hurdle is the evolving regulatory landscape, which, while driving adoption, also necessitates continuous adaptation and investment in compliance. Keeping abreast of the latest safety standards and certifications across different regions can be complex and resource-intensive for manufacturers. Furthermore, the market is characterized by intense price competition, particularly from manufacturers in emerging economies, which can exert downward pressure on profit margins for established players. The availability of alternative non-destructive testing technologies, such as eddy current testing and ultrasonic testing, also presents a competitive challenge, as these methods may be preferred for specific applications or material types. Another restraint is the need for skilled personnel to operate these detectors effectively and interpret the results accurately. Inadequate training or lack of qualified technicians can lead to misinterpretations and potentially compromised inspection outcomes, thus limiting the full potential of the technology. Moreover, the initial capital investment for advanced, fully automatic portable magnetic powder detectors can be a barrier for small and medium-sized enterprises (SMEs) with limited budgets, slowing down their adoption of cutting-edge technology. Environmental factors can also pose challenges; for instance, the presence of strong external magnetic fields or extreme temperatures might interfere with the accuracy of some magnetic particle inspections, requiring specialized procedures or equipment. Finally, the relatively longer product lifecycle for certain durable NDT equipment might influence the frequency of replacement purchases, creating a more gradual demand pattern for newer models.

The global Portable Magnetic Powder Detector market is anticipated to witness significant dominance by North America and Europe in terms of revenue and adoption. These regions are characterized by a mature industrial base, stringent regulatory frameworks, and a high emphasis on safety and quality assurance across critical sectors such as aerospace, automotive, and energy. The presence of major aerospace manufacturers, a robust petrochemical industry, and extensive infrastructure development initiatives in countries like the United States, Canada, Germany, and the United Kingdom fuel a consistent demand for reliable NDT solutions. The proactive adoption of advanced technologies and the willingness of these industries to invest in high-performance equipment further solidify the leadership of these regions.

In terms of segments, the Fully Automatic Portable Magnetic Powder Detector is expected to be a key growth driver and potentially dominate specific sub-segments of the market. This dominance stems from several factors:

While the fully automatic segment is poised for significant growth, the Semi-Automatic Portable Magnetic Powder Detector will continue to hold a substantial market share, especially in applications where cost-effectiveness and flexibility are prioritized over complete automation. This segment caters to a broader range of industries and smaller enterprises, offering a good balance between performance and investment.

The Portable Magnetic Powder Detector industry is experiencing robust growth fueled by several catalysts. The relentless pursuit of enhanced safety and reliability across all manufacturing sectors, particularly aerospace and petrochemical, is a primary driver. Increasing global infrastructure development and the need to maintain aging assets further contribute to demand. Technological advancements, such as improved magnetic powder formulations and more sophisticated magnetic field generation, are enhancing detection capabilities. Furthermore, the growing emphasis on predictive maintenance strategies and the cost savings associated with early defect detection are encouraging wider adoption of these portable inspection tools.

This comprehensive report provides an exhaustive analysis of the Portable Magnetic Powder Detector market, covering all critical aspects from market dynamics to future projections. It delves into the intricate interplay of various factors influencing market growth, including technological innovations, regulatory landscapes, and evolving industry demands. The report utilizes a data-driven approach, leveraging market insights valued in the millions, to offer accurate market sizing and forecasting. By dissecting trends, driving forces, and challenges, it provides stakeholders with a clear understanding of the current market scenario and future opportunities. The report also identifies key regions and segments poised for dominance and highlights the strategic initiatives of leading players, offering actionable intelligence for strategic decision-making.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Meiyo Electric, Johnson & Allen, NDK, Lube Corporation, Katex NDT, NEW-COSMOS, Zhongke Innovation, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Portable Magnetic Powder Detector," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Portable Magnetic Powder Detector, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.