1. What is the projected Compound Annual Growth Rate (CAGR) of the Polyurethane Adhesives for Electronic Equipments?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Polyurethane Adhesives for Electronic Equipments

Polyurethane Adhesives for Electronic EquipmentsPolyurethane Adhesives for Electronic Equipments by Type (Water-based Polyurethane Adhesive, Solvent-based Polyurethane Adhesive), by Application (Surface Mounting, Conformal Coatings, Other), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

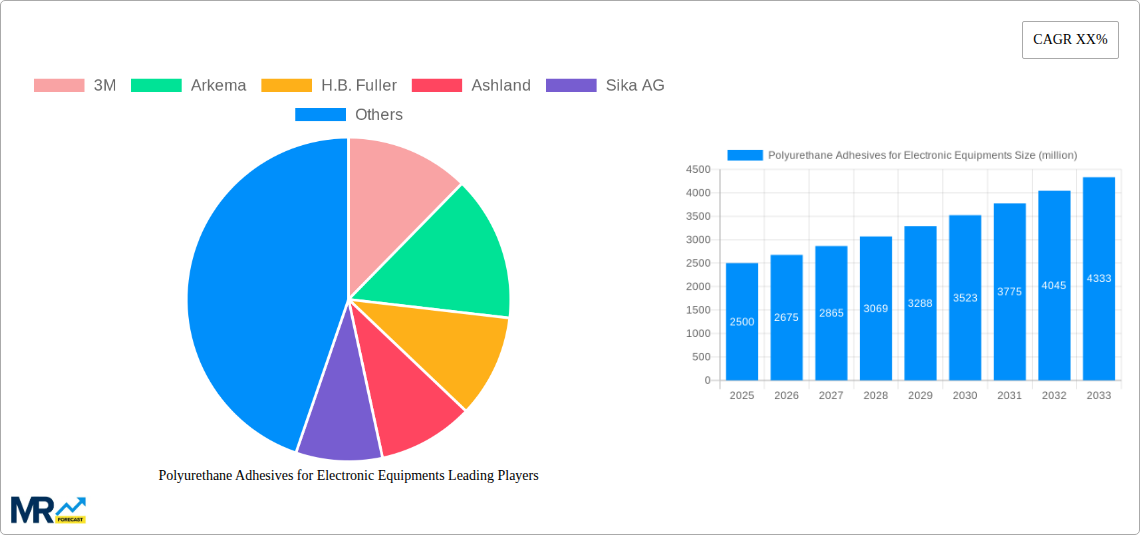

The global market for polyurethane adhesives in electronic equipment is experiencing robust growth, driven by the increasing demand for miniaturized and high-performance electronics. The market's expansion is fueled by several key factors. Firstly, the rising adoption of smartphones, wearables, and other consumer electronics necessitates advanced adhesive solutions for reliable component bonding and assembly. Secondly, the automotive and aerospace industries' increasing reliance on lightweight and durable electronic components is bolstering demand for high-strength, environmentally friendly polyurethane adhesives. Water-based polyurethane adhesives are gaining traction due to their low VOC emissions and environmental benefits, aligning with growing sustainability concerns within the electronics manufacturing sector. Solvent-based adhesives, however, still hold a significant market share due to their superior performance characteristics in specific applications. The market is segmented by adhesive type (water-based and solvent-based) and application (surface mounting, conformal coatings, and others), with surface mounting currently dominating due to its widespread use in printed circuit board (PCB) assembly. Major players like 3M, Henkel, and Dow are investing heavily in R&D to develop innovative polyurethane adhesives with enhanced properties, such as improved thermal stability, higher bond strength, and better resistance to chemicals and moisture. Geographic growth is expected across all regions, with Asia-Pacific leading due to its burgeoning electronics manufacturing industry, followed by North America and Europe.

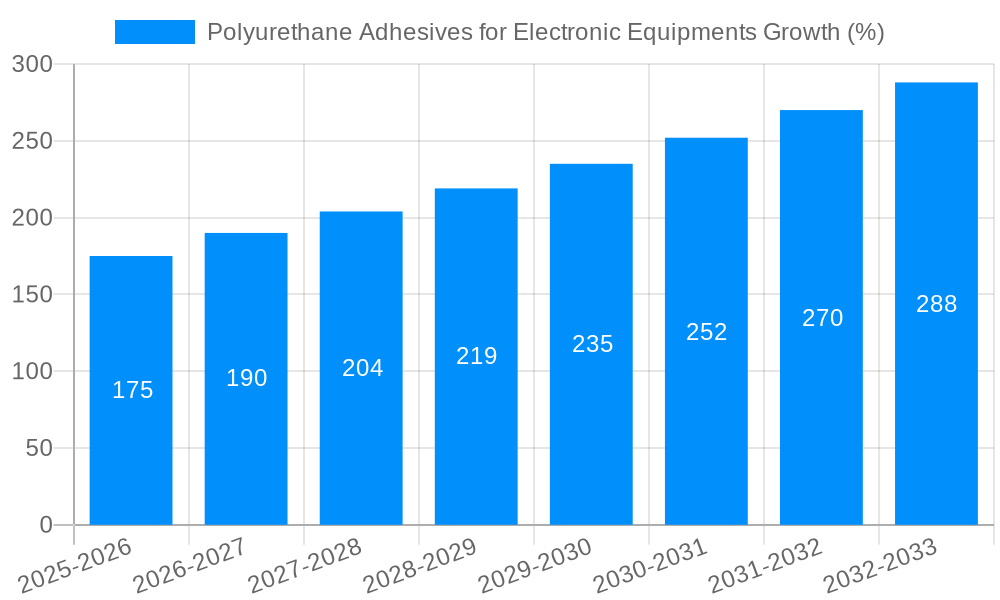

Despite the positive outlook, challenges remain. Fluctuations in raw material prices, particularly isocyanates, can impact profitability. Stricter environmental regulations in certain regions are driving the need for manufacturers to adopt more sustainable manufacturing processes and formulations. Competition from other adhesive technologies, such as epoxy and acrylic adhesives, also presents a challenge. However, the ongoing innovation in polyurethane adhesive technology, coupled with its superior performance in many applications, is expected to ensure sustained market growth throughout the forecast period. We estimate the market size in 2025 to be approximately $2.5 billion, based on observed growth trends and considering the influence of industry giants and emerging regional markets. A conservative Compound Annual Growth Rate (CAGR) of 6% is projected from 2025 to 2033. This estimation factors in expected technological advancements and market penetration in developing economies.

The global market for polyurethane adhesives in electronic equipment experienced robust growth during the historical period (2019-2024), driven by the increasing demand for advanced electronic devices and the inherent advantages of polyurethane adhesives in these applications. The estimated market value in 2025 is projected to be in the billions of units, reflecting a strong upward trajectory. This growth is anticipated to continue throughout the forecast period (2025-2033), albeit at a potentially moderated pace. Key market insights reveal a shift towards water-based polyurethane adhesives due to growing environmental concerns and stricter regulations. Solvent-based adhesives, however, still retain a significant market share, particularly in applications requiring high-performance bonding characteristics. The application segment dominated by surface mounting is expected to maintain its leading position, fueled by the rising popularity of surface-mount technology (SMT) in the electronics industry. Conformal coatings, another significant application, are witnessing increasing adoption for protecting sensitive electronic components from environmental hazards. Overall, the market is characterized by intense competition among numerous established players and emerging companies, leading to continuous product innovation and improvements in adhesive performance and cost-effectiveness. The market is also witnessing a growing focus on developing specialized adhesives tailored to meet the unique demands of different electronic components and applications, further driving market expansion. The report comprehensively analyzes these trends, providing granular insights into consumption value, market segmentation, regional performance, and competitive landscape, facilitating informed strategic decision-making for stakeholders across the value chain.

Several factors are propelling the growth of the polyurethane adhesives market for electronic equipment. The miniaturization trend in electronics necessitates adhesives offering high strength, flexibility, and thermal stability in compact spaces. Polyurethane adhesives excel in meeting these demands, facilitating the production of smaller, more powerful devices. The increasing demand for consumer electronics, including smartphones, wearables, and other portable devices, directly translates into higher demand for adhesives. Furthermore, the automotive industry's incorporation of advanced electronics, such as driver-assistance systems and infotainment units, creates a significant demand for high-performance adhesives capable of withstanding extreme temperatures and vibrations. The growing adoption of 5G technology and the Internet of Things (IoT) further accelerates the need for robust and reliable adhesives in electronic devices. Finally, the ongoing development of new polyurethane formulations with enhanced properties, such as improved adhesion to various substrates, increased flexibility, and higher resistance to chemicals and moisture, further strengthens the market's growth trajectory. These innovations cater to the increasingly stringent performance requirements of modern electronics.

Despite the positive growth outlook, several challenges and restraints could potentially hinder market expansion. Fluctuations in raw material prices, primarily isocyanates and polyols, directly impact the production costs of polyurethane adhesives, affecting profitability and market competitiveness. Stricter environmental regulations regarding volatile organic compounds (VOCs) are prompting manufacturers to develop and adopt more eco-friendly formulations, adding to the complexity and cost of production. The need for specialized adhesives to meet diverse application requirements poses a significant challenge, requiring manufacturers to invest in R&D and maintain high levels of product diversification. Competition from alternative adhesive technologies, such as epoxy and silicone adhesives, further complicates the market landscape. Maintaining high quality and consistency across large production volumes is crucial, as any defects in adhesive application can lead to product failures and reputational damage. Finally, ensuring the long-term reliability and durability of polyurethane adhesives in electronic devices, especially in harsh operating environments, is a crucial consideration.

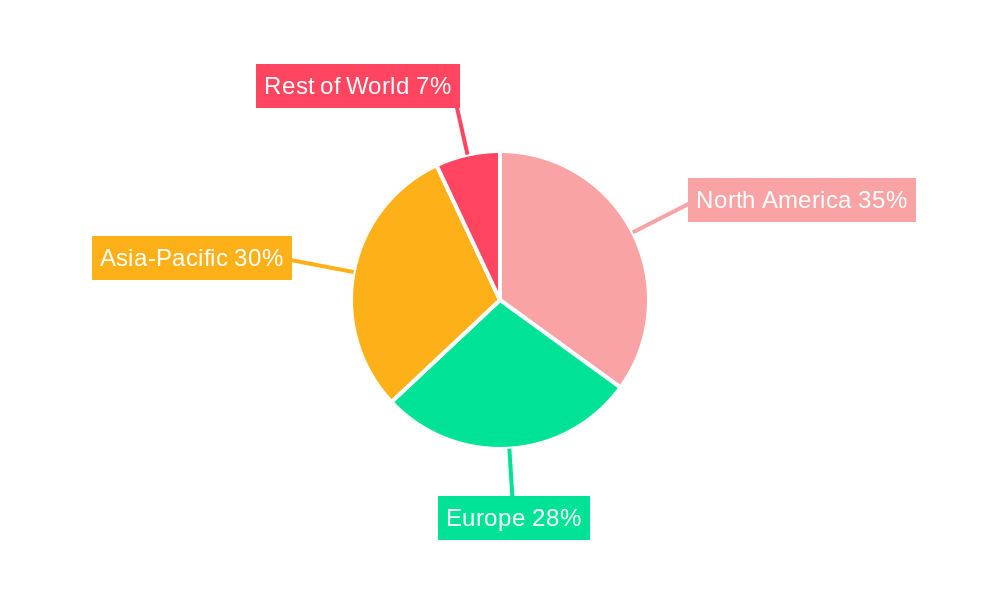

The Asia-Pacific region is expected to dominate the polyurethane adhesives market for electronic equipment due to the high concentration of electronics manufacturing in countries like China, South Korea, Japan, and Taiwan. These regions house major Original Equipment Manufacturers (OEMs) and contract manufacturers, creating substantial demand for adhesives.

Regarding market segmentation, the surface mounting application segment is projected to hold the largest market share. This is due to the widespread use of surface-mount technology (SMT) in electronic device manufacturing. SMT requires adhesives capable of providing reliable bonding, excellent thermal stability, and protection against mechanical stresses. Polyurethane adhesives are well-suited to these demands.

The increasing demand for miniaturized and high-performance electronics, coupled with advancements in polyurethane adhesive formulations offering improved thermal stability, chemical resistance, and flexibility, are key growth catalysts. Stricter environmental regulations are pushing the development and adoption of water-based, eco-friendly options. The expansion of the electronics manufacturing industry in emerging economies, particularly in Asia, further fuels market growth. Government support for technological advancements in electronics also stimulates demand for specialized adhesives.

This report provides a comprehensive overview of the polyurethane adhesives market for electronic equipment, offering detailed insights into market trends, driving forces, challenges, and opportunities. It presents a thorough analysis of market segmentation by type (water-based and solvent-based) and application (surface mounting, conformal coatings, and others), encompassing both historical data (2019-2024) and future projections (2025-2033). The report also profiles leading industry players, providing an in-depth analysis of their competitive strategies and market positions. This report is a valuable resource for stakeholders seeking to understand the dynamics of this rapidly evolving market and make informed business decisions.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include 3M, Arkema, H.B. Fuller, Ashland, Sika AG, Henkel, Dow, Dupont, Dymax Corporation, Franklin International, Huntsman Corporation, Jowat, Mapei, PPG Industries, Wacker Chemie, Avery Dennison.

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Polyurethane Adhesives for Electronic Equipments," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Polyurethane Adhesives for Electronic Equipments, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.