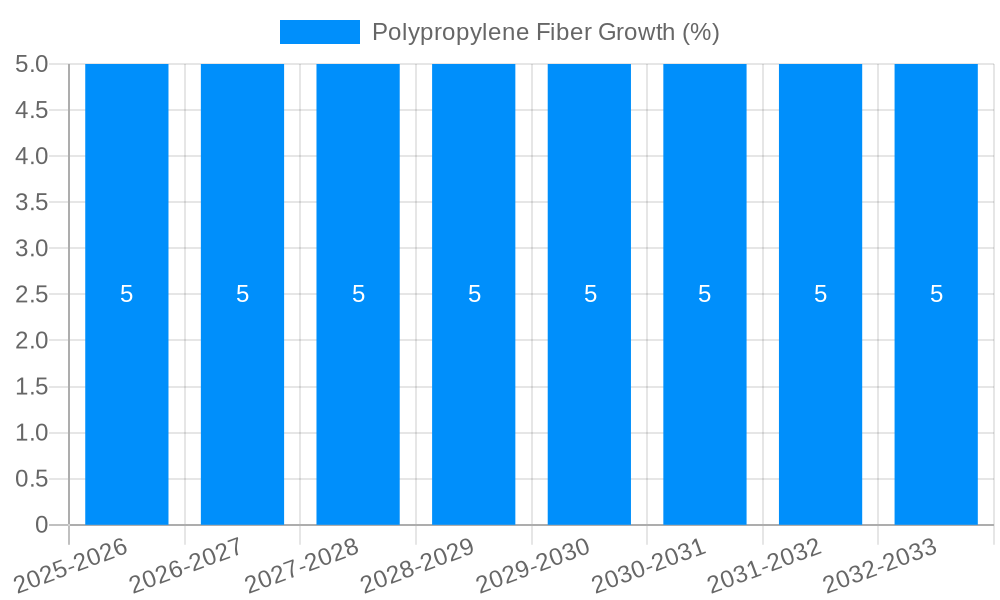

1. What is the projected Compound Annual Growth Rate (CAGR) of the Polypropylene Fiber?

The projected CAGR is approximately 5.0%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Polypropylene Fiber

Polypropylene FiberPolypropylene Fiber by Type (Long Fiber, Staple Fiber, Others), by Application (Construction, Pharmaceutical, Electrical and Electronics, Automotive, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

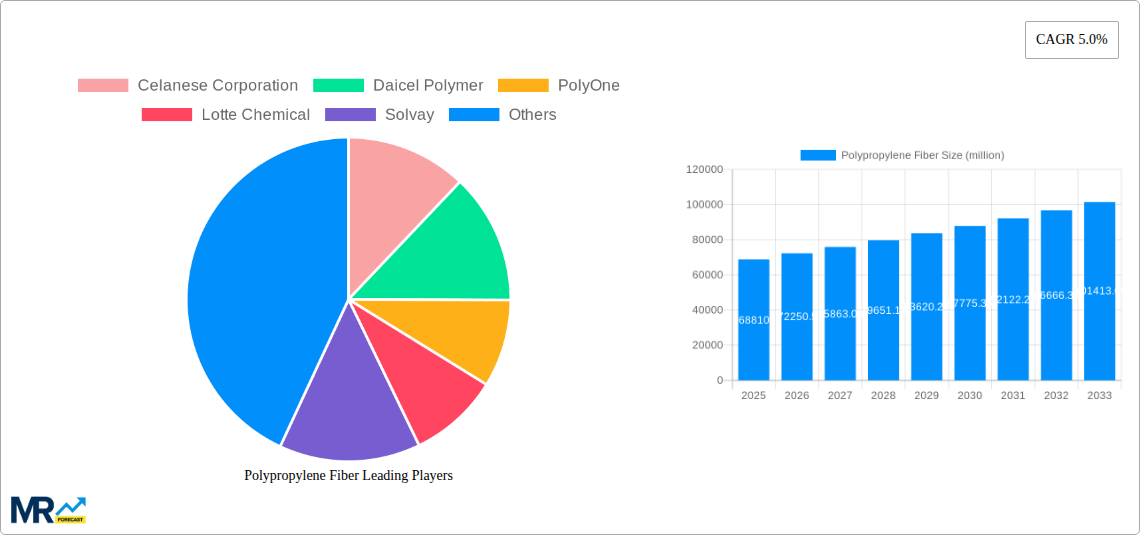

The global Polypropylene Fiber market is poised for significant expansion, projected to reach a substantial market size of $68,810 million. This growth is underpinned by a robust Compound Annual Growth Rate (CAGR) of 5.0% over the forecast period of 2025-2033, indicating a dynamic and expanding industry. Key drivers fueling this upward trajectory include the increasing demand for lightweight and durable materials across various sectors, the growing adoption of advanced manufacturing techniques, and the inherent cost-effectiveness and versatility of polypropylene fibers. The market's expansion is further stimulated by its widespread application in critical industries such as construction, where its use in concrete reinforcement and geotextiles is becoming standard practice. In the automotive sector, polypropylene fibers contribute to reducing vehicle weight, thereby enhancing fuel efficiency. Furthermore, the pharmaceutical and electrical and electronics industries are increasingly recognizing the unique properties of these fibers, leading to novel applications and sustained demand.

The market is segmented into distinct product types, namely Long Fiber and Staple Fiber, each catering to specific end-use requirements. Staple fibers, known for their ease of processing, are widely used in textiles and non-wovens, while long fibers offer enhanced strength and rigidity for composite applications. The diverse applications, ranging from construction and automotive to pharmaceuticals and electrical components, highlight the broad utility and market penetration of polypropylene fibers. Major global players like Celanese Corporation, Daicel Polymer, Solvay, and Toray are actively investing in research and development, expanding production capacities, and forging strategic partnerships to capitalize on emerging opportunities. These efforts, coupled with a growing emphasis on sustainable and recyclable materials, are expected to further propel the market's growth, making polypropylene fibers an indispensable material in the modern industrial landscape.

The global Polypropylene (PP) Fiber market is on an upward trajectory, exhibiting robust growth across various applications. The study period of 2019-2033, with a base year of 2025, highlights a dynamic landscape shaped by evolving consumer demands and technological advancements. The estimated market size for 2025 is projected to reach approximately 5.8 million units in revenue, with a significant portion of this growth anticipated during the forecast period of 2025-2033. The historical period of 2019-2024 laid the groundwork for this expansion, demonstrating consistent demand, particularly in the automotive and construction sectors. The increasing preference for lightweight yet durable materials in these industries, coupled with advancements in fiber manufacturing techniques, has been instrumental.

The versatility of PP fibers, stemming from their inherent properties like chemical resistance, low density, and high tensile strength, makes them indispensable in a wide array of end-use industries. The growing emphasis on sustainable and recyclable materials is also a key trend, with manufacturers investing in developing eco-friendly PP fiber variants. Furthermore, the pharmaceutical sector's demand for non-woven PP fabrics in protective gear and medical disposables is experiencing a surge, driven by heightened health awareness and stringent regulatory requirements. The electrical and electronics sector, while a smaller segment, is also witnessing a steady increase in demand for PP fibers in insulation and cable protection applications. The market's resilience is further evidenced by its ability to adapt to fluctuating raw material prices, with companies actively exploring innovative cost-management strategies. The overall outlook for the PP Fiber market remains exceptionally positive, with continuous innovation and market expansion expected in the coming years. The market is poised to witness a Compound Annual Growth Rate (CAGR) of approximately 4.5% between 2025 and 2033, further solidifying its position as a critical material in various industrial applications. The projected market size by the end of the forecast period (2033) is estimated to reach around 8.3 million units in revenue, underscoring the significant growth potential.

The polypropylene fiber market's robust growth is underpinned by a confluence of powerful driving forces. Foremost among these is the escalating demand from the automotive industry. PP fibers are increasingly utilized in vehicle interiors, such as carpets, upholstery, and headliners, due to their lightweight nature, durability, and cost-effectiveness. This trend is amplified by the global push for fuel efficiency, which necessitates the use of lighter materials in vehicle construction. The construction sector is another significant contributor, with PP fibers finding widespread application in concrete reinforcement, geosynthetics for soil stabilization, and roofing materials. Their ability to enhance the structural integrity and longevity of construction projects makes them a preferred choice.

Furthermore, the expanding textile industry, particularly in the production of non-woven fabrics, is a major growth propeller. These fabrics are integral to diverse applications ranging from hygiene products like diapers and sanitary napkins to industrial filters and geotextiles. The inherent properties of PP fibers, such as their resistance to moisture and chemicals, and their hypoallergenic nature, make them ideal for these sensitive applications. Moreover, ongoing advancements in manufacturing technologies have led to the development of specialized PP fibers with enhanced properties, catering to niche market demands and expanding the application spectrum. The growing awareness and adoption of recyclable and sustainable materials are also playing a crucial role, as PP is a recyclable polymer. This aligns with global environmental initiatives and regulatory pressures, encouraging the use of PP fibers as a more sustainable alternative to other synthetic fibers.

Despite the promising growth trajectory, the polypropylene fiber market is not without its challenges. One of the most prominent restraints is the volatility of raw material prices, primarily linked to crude oil. Fluctuations in crude oil prices directly impact the cost of polypropylene, leading to price instability for fiber manufacturers and potentially affecting their profit margins. This dependency on petrochemical feedstocks makes the market susceptible to geopolitical events and global supply chain disruptions. Another significant challenge is the growing environmental concern surrounding plastic waste. While polypropylene is recyclable, the sheer volume of plastic production and disposal poses environmental challenges. This can lead to increased regulatory scrutiny and public pressure, potentially impacting the demand for virgin PP fibers and driving the adoption of recycled or alternative materials.

The competition from alternative materials also poses a threat. While PP fibers offer a unique combination of properties, other synthetic and natural fibers can compete in specific applications. For instance, polyester fibers compete in some textile applications, and natural fibers like cotton or jute might be preferred in certain eco-conscious markets. Moreover, the capital-intensive nature of manufacturing can be a barrier to entry for new players, and established companies require significant investments for capacity expansion and technological upgrades. Finally, technical limitations in certain high-performance applications might also restrict the widespread adoption of PP fibers, requiring further research and development to enhance properties like flame retardancy or UV resistance for more demanding end-uses.

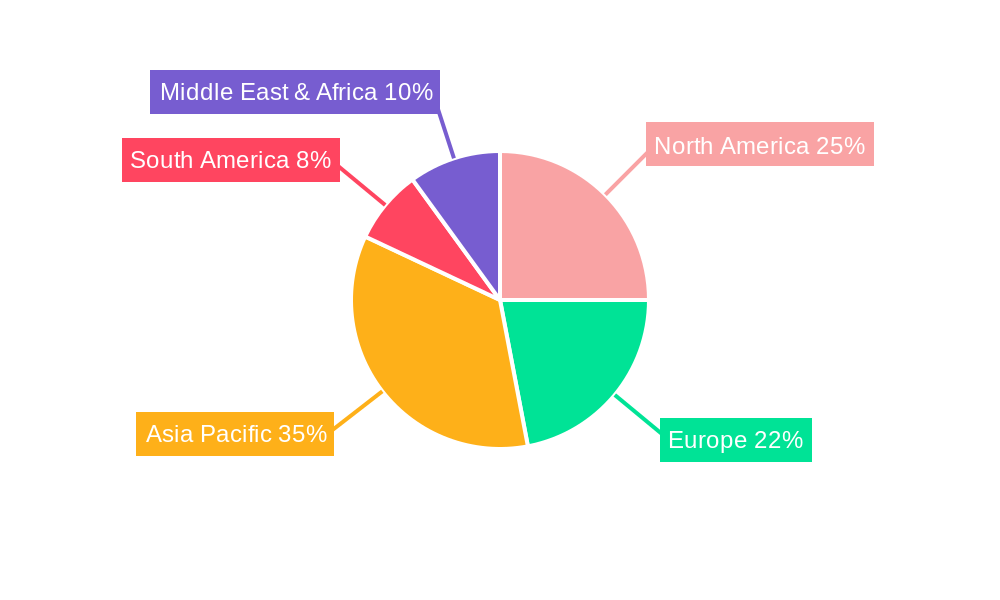

The global polypropylene fiber market is characterized by a dynamic interplay of regional dominance and segment popularity. However, certain regions and segments are poised to exert a more significant influence on market expansion and revenue generation.

Dominant Regions:

Asia-Pacific: This region stands out as a dominant force in the polypropylene fiber market. Driven by rapid industrialization, a burgeoning population, and significant investments in infrastructure and manufacturing, countries like China and India are major consumers and producers of PP fibers. The booming construction industry, coupled with a massive textile manufacturing base, fuels a substantial demand for staple and long fibers. Furthermore, the increasing disposable income in these nations translates to a higher demand for automotive products and consumer goods incorporating PP fibers. The region's proactive approach to adopting new manufacturing technologies and its cost-effective production capabilities further solidify its leading position.

North America: The North American region, particularly the United States, plays a crucial role in the PP fiber market, largely driven by its advanced automotive industry and robust construction sector. The increasing adoption of lightweight materials in vehicles for improved fuel efficiency, alongside the ongoing infrastructure development and renovation projects, significantly bolsters the demand for PP fibers. The region also benefits from a well-established manufacturing base for specialty PP fibers catering to high-value applications in filtration, medical textiles, and industrial fabrics.

Dominant Segments:

Staple Fiber: The Staple Fiber segment is a key contributor to the polypropylene fiber market's growth. These short-length fibers are highly versatile and find extensive use in the production of non-woven fabrics, which are critical for hygiene products (diapers, sanitary napkins), medical disposables (masks, gowns), and various industrial applications like filters and geotextiles. The high volume production and diverse applications of staple fibers make it a cornerstone of the PP fiber market. The demand is further propelled by the increasing global focus on hygiene and healthcare, especially post-pandemic. The estimated market share for staple fibers in 2025 is projected to be around 3.5 million units in revenue.

Construction Application: Within the application landscape, the Construction segment is a major driver of PP fiber demand. PP fibers are extensively used as concrete reinforcement to improve tensile strength, reduce cracking, and enhance durability. They are also vital in the production of geosynthetics, which are used for soil stabilization, erosion control, and drainage systems in civil engineering projects. The ongoing global urbanization and infrastructure development initiatives, especially in emerging economies, are creating a sustained demand for these materials. The estimated market size for PP fibers in construction applications in 2025 is projected to be approximately 1.8 million units in revenue. The continuous need for cost-effective and performance-enhancing building materials ensures the sustained dominance of this application.

The interplay between these dominant regions and segments creates a powerful engine for the global polypropylene fiber market. The continuous innovation in fiber production and application development, coupled with favorable economic conditions and regulatory support, will further solidify the growth and importance of these key market players and segments.

The polypropylene fiber industry is experiencing accelerated growth driven by several key catalysts. The increasing demand for lightweight and durable materials in the automotive sector, aimed at improving fuel efficiency, is a significant growth driver. Similarly, the construction industry's reliance on PP fibers for concrete reinforcement, geosynthetics, and insulation materials, due to their enhanced structural integrity and cost-effectiveness, fuels market expansion. Furthermore, the burgeoning non-woven fabric market, propelled by hygiene and medical applications, especially in the wake of global health concerns, provides a substantial avenue for PP fiber consumption.

This report provides a comprehensive analysis of the global polypropylene fiber market, spanning from the historical period of 2019-2024 to a detailed forecast extending to 2033, with a pivotal base year of 2025. It delves into the intricate trends shaping the market, identifying key growth drivers such as the increasing demand from the automotive and construction industries, alongside the burgeoning non-woven fabric sector. The report also meticulously examines the challenges and restraints, including raw material price volatility and environmental concerns surrounding plastic waste. Furthermore, it highlights the dominant regions and segments, with a particular focus on the Asia-Pacific region and the staple fiber and construction application segments, which are projected to lead market expansion.

The analysis incorporates insights into significant industry developments and leading players, providing a holistic view of the competitive landscape. The projected market size for 2025 is estimated at approximately 5.8 million units in revenue, with a projected CAGR of around 4.5% during the forecast period, reaching an estimated 8.3 million units by 2033. This detailed report is essential for stakeholders seeking to understand the current market dynamics, anticipate future trends, and make informed strategic decisions within the dynamic polypropylene fiber industry.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 5.0% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 5.0%.

Key companies in the market include Celanese Corporation, Daicel Polymer, PolyOne, Lotte Chemical, Solvay, PPG Fiber Glass, RTP, Core Molding Technologies, PlastiComp, Toray, Mitsubishi Rayon, Teijin, .

The market segments include Type, Application.

The market size is estimated to be USD 68810 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Polypropylene Fiber," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Polypropylene Fiber, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.