1. What is the projected Compound Annual Growth Rate (CAGR) of the Pneumatic Dosing Pump?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Pneumatic Dosing Pump

Pneumatic Dosing PumpPneumatic Dosing Pump by Type (Compressed Air Operated, Compressed Natural Gas Operated, World Pneumatic Dosing Pump Production ), by Application (Chemical, Oil and Gas, Water Treatment, Food, Agriculture, Others, World Pneumatic Dosing Pump Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

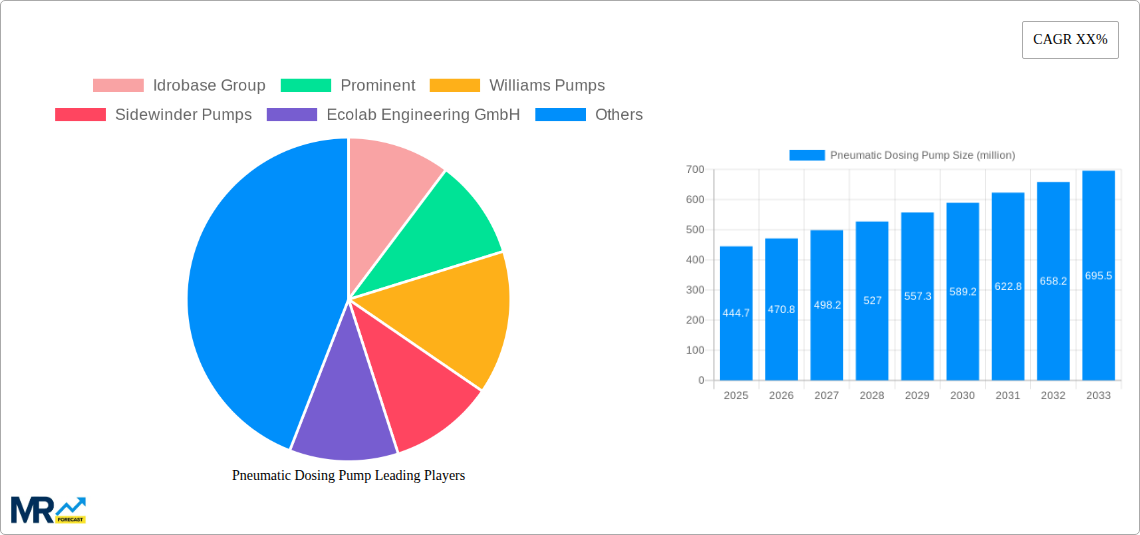

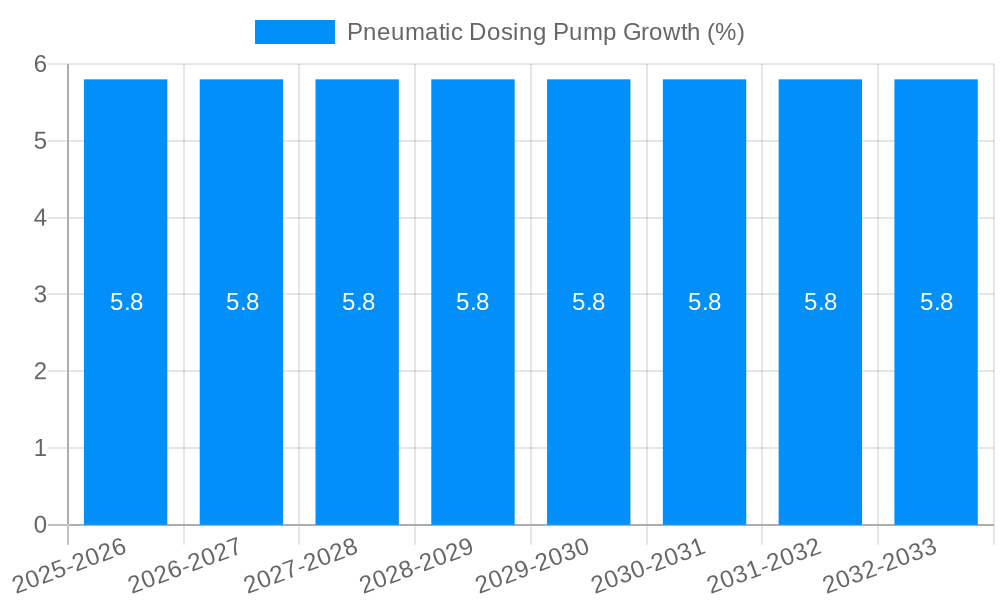

The global pneumatic dosing pump market is poised for robust growth, with an estimated market size of USD 444.7 million in 2025. This growth is underpinned by a Compound Annual Growth Rate (CAGR) of approximately 5.8% projected from 2019 to 2033, indicating a steady and sustained expansion of the market. Key drivers fueling this upward trajectory include the increasing demand for precise fluid handling in critical industrial applications such as chemical processing, oil and gas exploration, and water treatment. The inherent advantages of pneumatic dosing pumps, such as their reliability, inherent safety in hazardous environments, and cost-effectiveness compared to electrically powered counterparts, further bolster their adoption. The market is segmented by type into Compressed Air Operated and Compressed Natural Gas Operated pumps, with the former likely dominating due to widespread availability of compressed air infrastructure. Applications span across chemical, oil and gas, water treatment, food, and agriculture sectors, showcasing the diverse utility of these pumps.

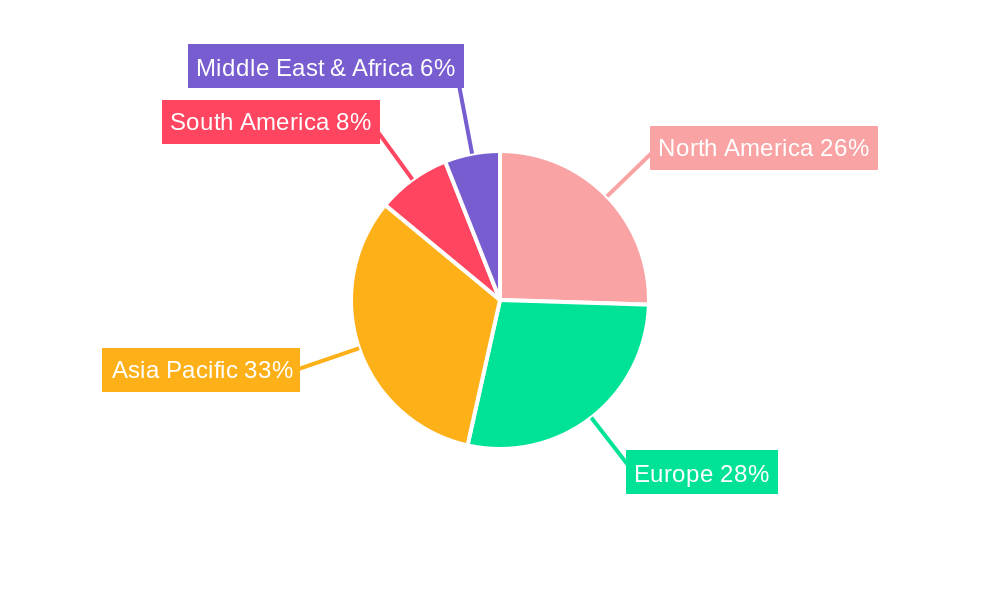

The market is experiencing significant trends such as the development of more energy-efficient and smart pneumatic dosing pump technologies, alongside a growing emphasis on leak-proof designs and enhanced material compatibility for handling corrosive or sensitive fluids. Regionally, Asia Pacific is anticipated to emerge as a leading market due to rapid industrialization and expanding infrastructure in countries like China and India. North America and Europe, with their well-established industrial bases and stringent regulatory requirements for chemical handling, will also represent substantial market shares. Restraints, such as the initial cost of installation for some advanced systems and the availability of alternative pumping technologies, are present. However, the overall outlook remains highly positive, driven by continuous innovation and the persistent need for accurate and safe fluid dispensing across a multitude of industries. Prominent players like Idrobase Group, Prominent, and Ecolab Engineering GmbH are actively contributing to market dynamics through their product development and strategic initiatives.

Here's a unique report description for the Pneumatic Dosing Pump market, incorporating your specified elements and word counts:

This report provides an in-depth analysis of the global Pneumatic Dosing Pump market, spanning the historical period of 2019-2024, the base and estimated year of 2025, and a robust forecast period extending to 2033. The study meticulously examines market dynamics, technological advancements, and key industry trends, offering valuable insights for stakeholders seeking to navigate this evolving landscape. With an estimated global production value of over 800 million units in the base year of 2025, the market is poised for significant expansion. The report delves into the intricacies of both Compressed Air Operated and Compressed Natural Gas Operated pneumatic dosing pumps, dissecting their individual growth trajectories and market share within the broader World Pneumatic Dosing Pump Production. Furthermore, it offers a granular view of application segments, including Chemical, Oil and Gas, Water Treatment, Food, Agriculture, and Others, highlighting the dominant sectors and emerging opportunities. The World Pneumatic Dosing Pump Production and Industry Developments section offers a forward-looking perspective on innovation and market expansion.

XXX The global pneumatic dosing pump market is exhibiting a compelling upward trajectory, driven by an increasing demand for precise fluid handling solutions across a multitude of industrial applications. During the study period of 2019-2033, with a base year of 2025 where global production is anticipated to exceed 800 million units, several key trends are shaping market dynamics. A prominent trend is the growing adoption of these pumps in water treatment facilities, necessitated by stringent environmental regulations and the need for efficient chemical injection for purification processes. The Oil and Gas sector continues to be a significant consumer, leveraging pneumatic dosing pumps for accurate chemical additive injection in exploration, extraction, and refining operations, where precision and reliability are paramount even in hazardous environments. The Chemical industry, a foundational pillar of this market, consistently demands high-performance dosing solutions for a wide array of chemical processes, from batch production to continuous manufacturing, reinforcing the need for robust and versatile equipment. Food and beverage applications are also witnessing an upswing, as manufacturers increasingly rely on precise dosing for ingredients, sanitizers, and processing aids, ensuring product quality and safety. The integration of smart technologies and automation is another burgeoning trend. Manufacturers are focusing on developing pneumatic dosing pumps with enhanced digital controls, remote monitoring capabilities, and self-diagnostic features. This shift towards Industry 4.0 principles allows for greater operational efficiency, reduced downtime, and optimized resource utilization, making the pumps more attractive to end-users. Furthermore, there's a discernible trend towards the development of more energy-efficient and environmentally friendly pneumatic dosing pump designs, aligning with global sustainability initiatives and corporate social responsibility goals. The shift towards Compressed Natural Gas (CNG) operated pumps, while still nascent compared to Compressed Air Operated systems, presents a significant future growth avenue, particularly in regions with abundant natural gas infrastructure and a drive to reduce reliance on traditional electricity sources. The overall market sentiment is positive, with expectations of sustained growth driven by technological innovation, increasing industrialization, and a persistent need for accurate and reliable fluid management. The estimated global production value, projected to further escalate beyond 800 million units by the forecast period's end, underscores the market's robust potential.

The pneumatic dosing pump market is experiencing robust growth, propelled by a confluence of powerful drivers. Foremost among these is the increasing stringency of environmental regulations worldwide. These regulations necessitate precise and reliable dosing of chemicals for water and wastewater treatment, air pollution control, and industrial effluent management. Pneumatic dosing pumps, with their inherent accuracy and ability to handle a wide range of fluid viscosities and chemistries, are perfectly positioned to meet these compliance demands. The burgeoning Oil and Gas industry, particularly in emerging economies, is another significant driver. The exploration, extraction, and refining processes require precise injection of various chemicals, including corrosion inhibitors, demulsifiers, and biocides, to optimize operations and ensure asset integrity. Pneumatic pumps are favored for their ability to operate in hazardous and remote locations, often without the need for electrical power. Furthermore, the expanding global Food and Beverage sector, driven by population growth and evolving consumer preferences, fuels the demand for accurate dosing of ingredients, additives, and cleaning agents. Maintaining product quality, consistency, and safety is paramount, making precise volumetric control essential. The growing industrialization and manufacturing activities across diverse sectors, from pharmaceuticals to textiles, also contribute significantly. As production processes become more sophisticated and automated, the need for accurate and repeatable chemical dosing intensifies. Finally, the inherent advantages of pneumatic dosing pumps, such as their simplicity of operation, robust construction, explosion-proof capabilities (crucial in many industrial environments), and cost-effectiveness for certain applications, continue to attract end-users, solidifying their position in the market.

Despite the promising growth prospects, the pneumatic dosing pump market faces several challenges and restraints that could temper its expansion. A primary concern is the dependence on a reliable compressed air supply. For Compressed Air Operated pumps, inconsistent or inadequate air pressure can lead to inaccurate dosing, operational inefficiencies, and potential equipment damage. This reliance on a secondary utility can also increase the overall operational cost for end-users, especially in facilities that do not already possess a well-maintained compressed air infrastructure. The initial capital investment for high-quality pneumatic dosing pumps, particularly those with advanced features and materials for specialized applications, can be a barrier for smaller enterprises or those with limited budgets. While generally cost-effective in the long run, the upfront expense might deter some potential buyers. The availability of alternative dosing technologies also presents a competitive challenge. Electric dosing pumps, for instance, offer greater precision and energy efficiency in some scenarios and may be preferred in applications where a stable electrical supply is readily available and compressed air infrastructure is absent. The maintenance requirements, while generally straightforward for pneumatic pumps, can still be a restraint if specialized knowledge or parts are not readily accessible, especially in remote regions. Furthermore, the development and adoption of new, potentially more efficient or integrated dosing systems could disrupt the market share of traditional pneumatic pumps. Fluctuations in raw material costs for pump manufacturing can also impact pricing and profitability, creating uncertainty for both manufacturers and consumers. Finally, the perception of pneumatic technology as less advanced or sophisticated compared to modern electronic or hydraulic systems might, in some sectors, lead to a preference for alternatives, even if pneumatic pumps offer superior performance for specific tasks.

The global Pneumatic Dosing Pump market is characterized by regional and segmental dominance, with several key players poised for significant market share. The Compressed Air Operated segment is unequivocally the dominant force within the Type category, accounting for an estimated over 750 million units in global production for the base year of 2025. This dominance stems from its widespread applicability, inherent reliability in hazardous environments, and the extensive existing infrastructure for compressed air in numerous industrial settings. Its robust nature makes it suitable for a broad spectrum of demanding applications.

In terms of regional dominance, Asia-Pacific is emerging as a powerhouse for World Pneumatic Dosing Pump Production. This region is projected to account for a substantial portion of the global production value, estimated to surpass 300 million units by 2025, driven by rapid industrialization, significant investments in infrastructure development, and a growing manufacturing base across countries like China, India, and Southeast Asian nations. The increasing adoption of sophisticated water treatment solutions to combat pollution and manage water scarcity, coupled with the expansion of the Oil and Gas sector in regions like the Middle East and parts of Asia, further propels demand.

Within the Application segments, Water Treatment stands out as a primary driver of market growth and demand. The escalating global concerns regarding water scarcity and pollution, coupled with stringent regulatory frameworks for wastewater discharge and potable water quality, necessitate the precise and reliable dosing of chemicals for purification, disinfection, and pH adjustment. The estimated production volume for pneumatic dosing pumps dedicated to this segment alone is expected to exceed 250 million units in 2025, highlighting its critical importance. The Oil and Gas industry also represents a substantial segment, particularly in exploration and production where the injection of various chemicals for flow assurance, corrosion inhibition, and enhanced oil recovery is essential. While the overall production volume might be slightly lower than water treatment, its high-value applications and consistent demand contribute significantly to the market's economic output. The Chemical industry remains a constant and significant consumer, utilizing pneumatic dosing pumps across a vast array of processes for ingredient addition, reaction control, and product formulation. The Food and Agriculture segments, while individually smaller than the aforementioned, collectively represent a growing demand for precise and hygienic dosing solutions, driven by food safety standards and the need for efficient fertilizer and pesticide application. The Others category, encompassing niche applications in pharmaceuticals, textiles, and research, also contributes to the overall market diversification.

The World Pneumatic Dosing Pump Production and Industry Developments specifically indicate a focus on developing more energy-efficient and intelligent pneumatic dosing systems that can integrate with broader industrial automation platforms. Companies are investing in research and development to enhance the durability, accuracy, and remote monitoring capabilities of their offerings, particularly within the Compressed Air Operated segment, to solidify its market leadership.

The Pneumatic Dosing Pump industry is propelled by several key growth catalysts. The increasing global focus on environmental protection and stringent regulations surrounding water and wastewater treatment significantly boosts demand for accurate chemical injection. The expanding Oil and Gas sector, particularly in upstream and midstream operations, requires reliable dosing for process optimization and asset integrity. Furthermore, the growing adoption of automation and Industry 4.0 principles in manufacturing industries is driving the need for precise and controllable fluid handling solutions. The inherent advantages of pneumatic pumps, such as their explosion-proof nature and suitability for hazardous environments, continue to make them a preferred choice in many critical applications.

This comprehensive report delves into the intricate dynamics of the Pneumatic Dosing Pump market from 2019 to 2033. It provides an exhaustive analysis of market size, segmentation by type (Compressed Air Operated, Compressed Natural Gas Operated), application (Chemical, Oil and Gas, Water Treatment, Food, Agriculture, Others), and regional trends. The study meticulously forecasts global production volumes, estimated to surpass 800 million units in the base year of 2025, and examines the competitive landscape, highlighting key players and their strategic initiatives. Furthermore, it dissects the driving forces, challenges, and growth catalysts shaping the industry, offering actionable insights for stakeholders to capitalize on emerging opportunities and navigate market complexities. The report offers a thorough understanding of the World Pneumatic Dosing Pump Production and Industry Developments, equipping readers with the knowledge to make informed business decisions.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Idrobase Group, Prominent, Williams Pumps, Sidewinder Pumps, Ecolab Engineering GmbH, Iwaki America, White Knight, Linc Pumps, Varicon Pumps & Systems, Adityatech, WRS S.R.L., Depamu, .

The market segments include Type, Application.

The market size is estimated to be USD 444.7 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Pneumatic Dosing Pump," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Pneumatic Dosing Pump, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.