1. What is the projected Compound Annual Growth Rate (CAGR) of the Pharmaceutical Granulator?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Pharmaceutical Granulator

Pharmaceutical GranulatorPharmaceutical Granulator by Type (Dry Granulation, Moist Granulation), by Application (Capsule Medicine, Granular Medicine), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

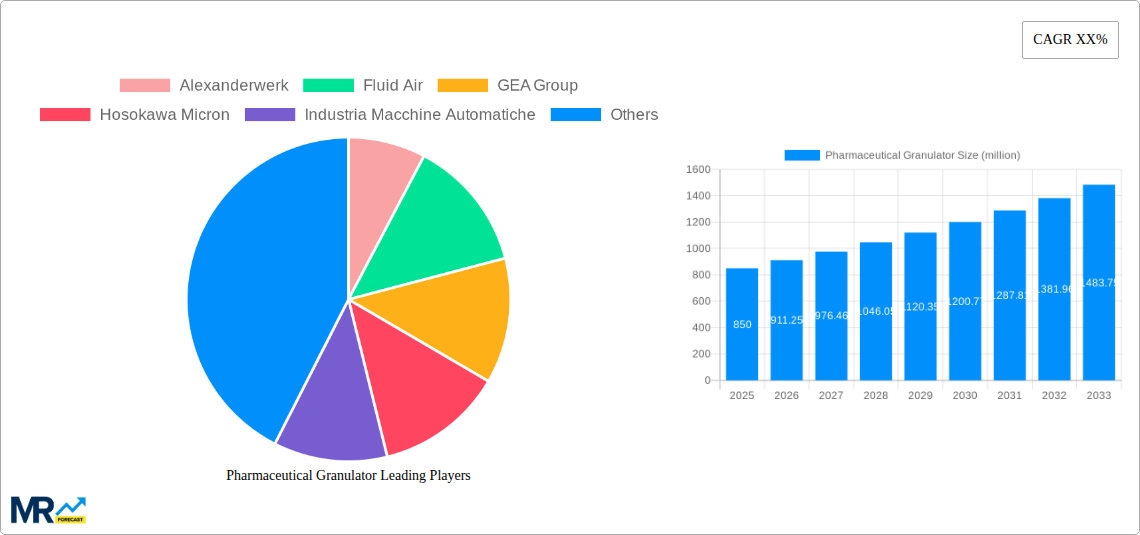

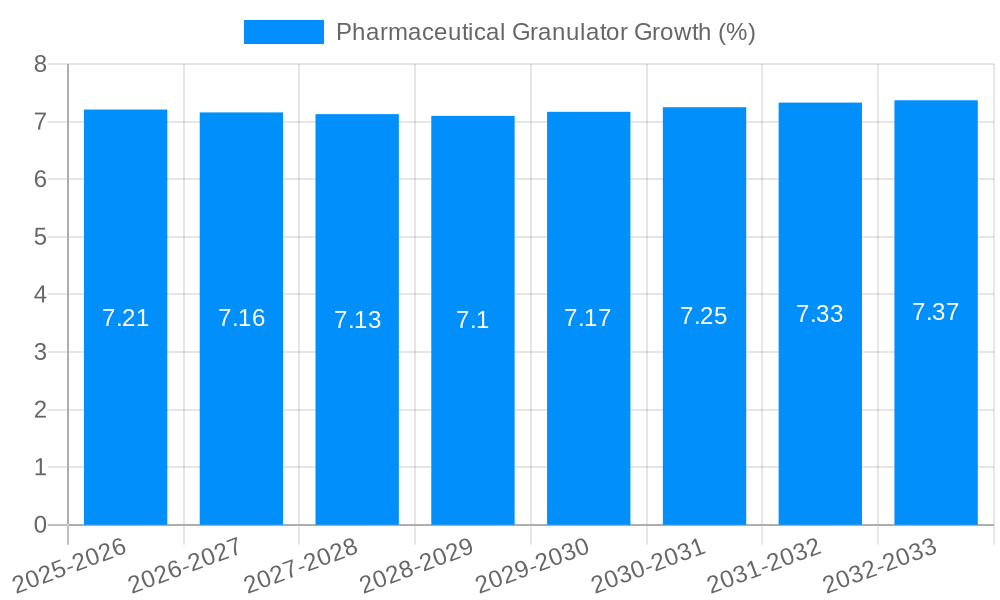

The global Pharmaceutical Granulator market is projected to experience robust growth, driven by the increasing demand for advanced drug delivery systems and the continuous expansion of the pharmaceutical industry. With an estimated market size of approximately $850 million in 2025, and a projected Compound Annual Growth Rate (CAGR) of around 7.5% throughout the forecast period (2025-2033), the market is poised for significant expansion. This growth is fueled by key drivers such as the rising prevalence of chronic diseases, necessitating a larger volume of pharmaceutical production, and the growing emphasis on developing highly effective and patient-compliant dosage forms. Granulation technology plays a pivotal role in improving the flowability, compressibility, and uniformity of powders, essential for manufacturing tablets and capsules, thereby directly contributing to enhanced drug efficacy and safety. Furthermore, the increasing investment in research and development by pharmaceutical companies to innovate and produce novel therapeutics further propels the demand for sophisticated granulation equipment.

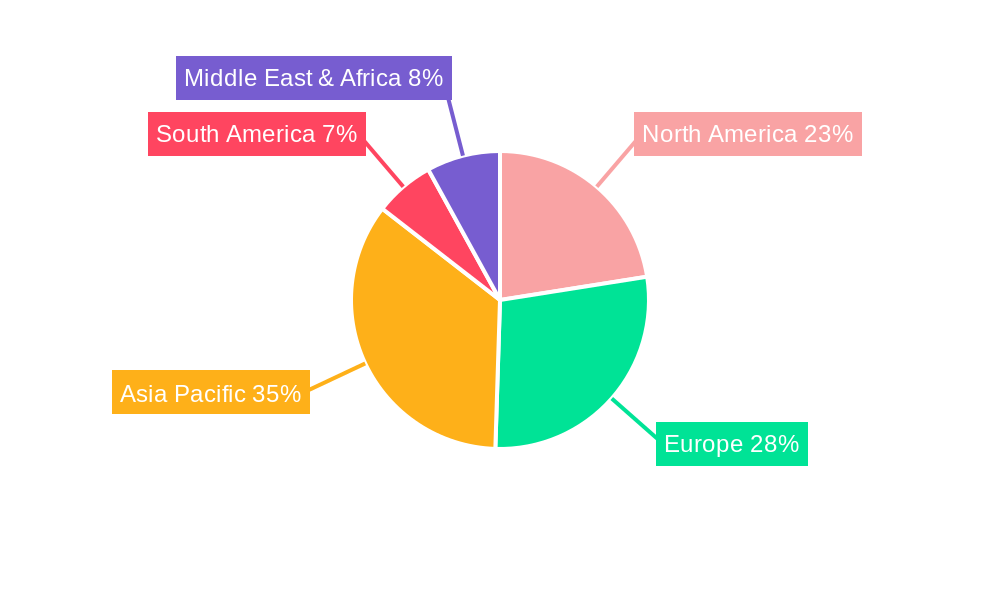

The market segmentation reveals a dynamic landscape, with Dry Granulation and Moist Granulation being the primary types, catering to diverse formulation needs. Capsule Medicine and Granular Medicine represent key applications, highlighting the broad utility of these machines across various pharmaceutical manufacturing processes. Prominent players like GEA Group, Syntegon Technology, and Alexanderwerk are at the forefront, continually innovating to offer advanced solutions. Geographically, the Asia Pacific region, particularly China and India, is emerging as a substantial growth engine due to its expanding pharmaceutical manufacturing base and increasing healthcare expenditure. North America and Europe remain significant markets, driven by established pharmaceutical industries and stringent quality control standards. Challenges such as high initial investment costs and the need for specialized technical expertise might pose restraints, but the overall outlook for the pharmaceutical granulator market remains exceptionally positive, supported by ongoing technological advancements and the unwavering demand for high-quality pharmaceuticals globally.

Here's a comprehensive report description on Pharmaceutical Granulators, incorporating your specified details and formatting:

The global pharmaceutical granulator market is poised for significant expansion, projected to reach approximately $1.2 million in the Base Year of 2025 and subsequently surge to an estimated $1.9 million by 2033. This robust growth trajectory, spanning the Study Period of 2019-2033, is underpinned by an increasing demand for advanced and efficient drug manufacturing processes. During the Historical Period of 2019-2024, the market witnessed steady progress, driven by the pharmaceutical industry's continuous need for improved granulation techniques that enhance drug bioavailability, stability, and ease of handling. The Forecast Period of 2025-2033 anticipates an acceleration in this trend, fueled by technological innovations and a growing focus on precision manufacturing within the pharmaceutical sector. Key market insights reveal a rising preference for sophisticated granulation equipment that can accommodate a wider range of formulations, including complex drug molecules and specialized delivery systems. The emphasis on particulate properties, such as particle size distribution, bulk density, and flowability, is paramount for optimizing downstream processes like tablet compression and capsule filling. Furthermore, the market is experiencing a shift towards automation and integrated solutions, where granulators are seamlessly incorporated into larger, end-to-end manufacturing lines. This trend reflects the industry's pursuit of higher throughput, reduced operational costs, and enhanced product consistency. The advent of advanced control systems and process analytical technology (PAT) is also playing a crucial role in optimizing granulation parameters in real-time, leading to improved product quality and regulatory compliance. The expanding global pharmaceutical market, coupled with the increasing prevalence of chronic diseases and an aging population, further bolsters the demand for efficient and scalable granulation solutions. The development of specialized granulators designed for specific therapeutic areas or formulation types is also contributing to market diversification. As manufacturers increasingly prioritize miniaturization and the production of potent and highly active pharmaceutical ingredients (HPAPIs), the demand for compact, contained, and highly efficient granulators is expected to rise. The ongoing research and development efforts aimed at improving the energy efficiency and sustainability of granulation processes are also shaping market trends.

Several potent forces are collectively propelling the pharmaceutical granulator market forward. A primary driver is the ever-increasing global demand for pharmaceuticals. With a growing and aging population worldwide, coupled with the rising incidence of chronic diseases, the need for effective and accessible medications continues to escalate. This surge in demand directly translates into a higher requirement for efficient drug manufacturing processes, where granulation plays a pivotal role in preparing active pharmaceutical ingredients (APIs) and excipients for dosage form production. Furthermore, the growing emphasis on drug bioavailability and efficacy is a significant catalyst. Granulation techniques are critical for improving the flow properties of powders, ensuring uniform tablet hardness, and enhancing the dissolution rates of drugs. This directly impacts how well a medication is absorbed by the body and its overall therapeutic effectiveness. The continuous innovation in pharmaceutical formulations, including the development of novel drug delivery systems and complex molecules, necessitates advanced granulation equipment capable of handling diverse materials and achieving specific particle characteristics. Manufacturers are constantly seeking solutions that can precisely control particle size, shape, and density to optimize drug performance. The stringent regulatory landscape governing pharmaceutical manufacturing also acts as a driving force. Regulatory bodies demand consistent product quality, robust manufacturing processes, and thorough documentation. Granulators that offer advanced control, reproducibility, and containment features are therefore highly sought after, as they help companies meet these rigorous standards and ensure patient safety.

Despite the promising growth outlook, the pharmaceutical granulator market is not without its challenges and restraints. One significant hurdle is the high initial investment cost associated with acquiring advanced granulation equipment. These sophisticated machines, equipped with cutting-edge technology and automation, represent a substantial capital expenditure, which can be a deterrent for smaller pharmaceutical manufacturers or those operating in price-sensitive markets. Another challenge lies in the complexity of certain pharmaceutical formulations. Some APIs and excipients are inherently difficult to granulate due to their poor flow properties, sticky nature, or high sensitivity to heat and moisture. Developing and optimizing granulation processes for such challenging materials can require extensive research and development, specialized equipment, and expert knowledge. The ever-evolving regulatory environment can also pose a restraint. While regulations drive innovation, frequent changes in guidelines and compliance requirements can necessitate costly upgrades and modifications to existing granulation machinery, impacting manufacturers' ability to adapt quickly. Energy consumption and environmental concerns associated with some granulation processes are also gaining attention. Traditional granulation methods can be energy-intensive, and the industry is increasingly under pressure to adopt more sustainable and eco-friendly manufacturing practices. Finding cost-effective and efficient granulation solutions that minimize energy usage and waste generation is an ongoing challenge. Finally, the shortage of skilled labor capable of operating and maintaining complex granulation equipment can also limit market growth in certain regions, as specialized training and expertise are required for optimal performance and troubleshooting.

The pharmaceutical granulator market is characterized by a dynamic interplay of regional strengths and segment dominance. Among the various segments, Moist Granulation is expected to maintain its leadership position, driven by its established efficacy in improving powder flowability, compressibility, and dissolution rates for a wide array of oral solid dosage forms. This technique remains a cornerstone in the production of Granular Medicine, which constitutes a substantial portion of the overall pharmaceutical market. The ability of moist granulation to create robust granules that are less prone to segregation and dusting makes it a preferred choice for manufacturers aiming for consistent product quality and simplified downstream processing. Within the application segment, Granular Medicine is projected to continue its market dominance. This is primarily due to the widespread use of granular formulations in oral solid dosage forms like tablets and capsules, which are the most prevalent and cost-effective ways to administer a vast number of medications. The growing global burden of chronic diseases, such as diabetes, cardiovascular disorders, and respiratory ailments, directly fuels the demand for effective treatments delivered in granular forms.

In terms of regional dominance, North America is anticipated to be a key region to lead the market in the coming years. This supremacy is attributed to several factors. Firstly, the region boasts a highly developed pharmaceutical industry with a significant presence of leading drug manufacturers that are continuously investing in advanced manufacturing technologies. The strong emphasis on research and development in the United States and Canada leads to a constant stream of new drug formulations, many of which require sophisticated granulation processes. Secondly, North America has a robust healthcare infrastructure and a high prevalence of chronic diseases, leading to a substantial demand for pharmaceuticals. This, in turn, drives the need for efficient and scalable granulation solutions. The region's stringent regulatory framework, particularly from the Food and Drug Administration (FDA), also encourages manufacturers to adopt state-of-the-art equipment that ensures product quality and patient safety, thereby boosting the adoption of advanced granulators. Furthermore, the presence of major pharmaceutical companies with significant research and manufacturing facilities in North America acts as a key growth catalyst. The region's strong economic standing also allows for substantial investments in capital equipment, including sophisticated pharmaceutical granulators. The continuous drive for innovation and the adoption of Industry 4.0 principles in manufacturing processes further solidify North America's leading position.

The pharmaceutical granulator industry is experiencing significant growth catalysts. The escalating global demand for pharmaceuticals, driven by an aging population and the rise of chronic diseases, directly fuels the need for efficient drug manufacturing processes. Advances in drug formulation, including the development of complex molecules and novel delivery systems, necessitate advanced granulation technologies to achieve desired particle properties. Furthermore, the increasing focus on drug bioavailability, stability, and patient compliance compels manufacturers to adopt granulators that offer precise control over granulation parameters. Stringent regulatory requirements for product quality and consistency also drive the adoption of advanced, automated granulation solutions.

This comprehensive report delves deep into the global pharmaceutical granulator market, providing an in-depth analysis of its current state and future prospects. It offers meticulous forecasts from 2025 to 2033, with 2025 serving as the Base Year and Estimated Year, building upon the Historical Period of 2019-2024. The report meticulously examines key market drivers, including the escalating demand for pharmaceuticals, advancements in drug formulations, and the stringent regulatory landscape. It also identifies and analyzes significant challenges and restraints, such as high initial investment costs and the complexity of certain formulations. Crucially, the report provides detailed insights into the dominance of specific regions and segments, such as North America and the Moist Granulation technique for Granular Medicine applications, offering a granular understanding of market dynamics. Furthermore, it highlights pivotal growth catalysts and provides an exhaustive list of leading global players. The report also documents significant industry developments, offering a timeline of recent innovations and strategic moves by key companies. This comprehensive coverage ensures stakeholders have the necessary data and analysis to make informed strategic decisions within the evolving pharmaceutical granulator landscape.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Alexanderwerk, Fluid Air, GEA Group, Hosokawa Micron, Industria Macchine Automatiche, LB Bohle, LFA Machines, PTK-GB, Romaco Group, Syntegon Technology, Pharmaland Technologies, Yenchen Machinery Co., Ltd.

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Pharmaceutical Granulator," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Pharmaceutical Granulator, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.