1. What is the projected Compound Annual Growth Rate (CAGR) of the PCTFE Material?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

PCTFE Material

PCTFE MaterialPCTFE Material by Type (298K (25°C), 144K (-129°C), 21K (-252°C), World PCTFE Material Production ), by Application (Seals, Semi-conductor, Electrical Components, High Vacuum Plant, Other), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

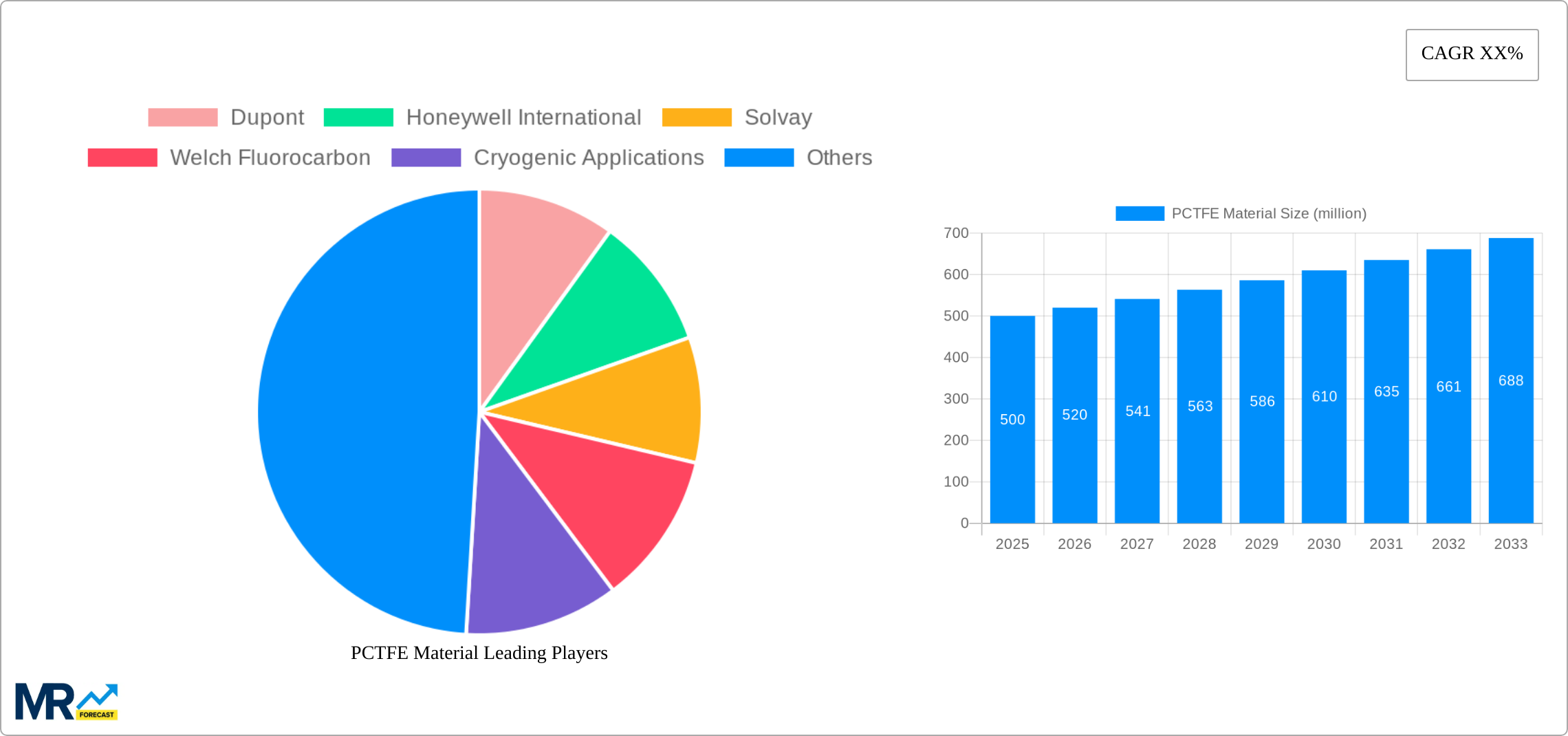

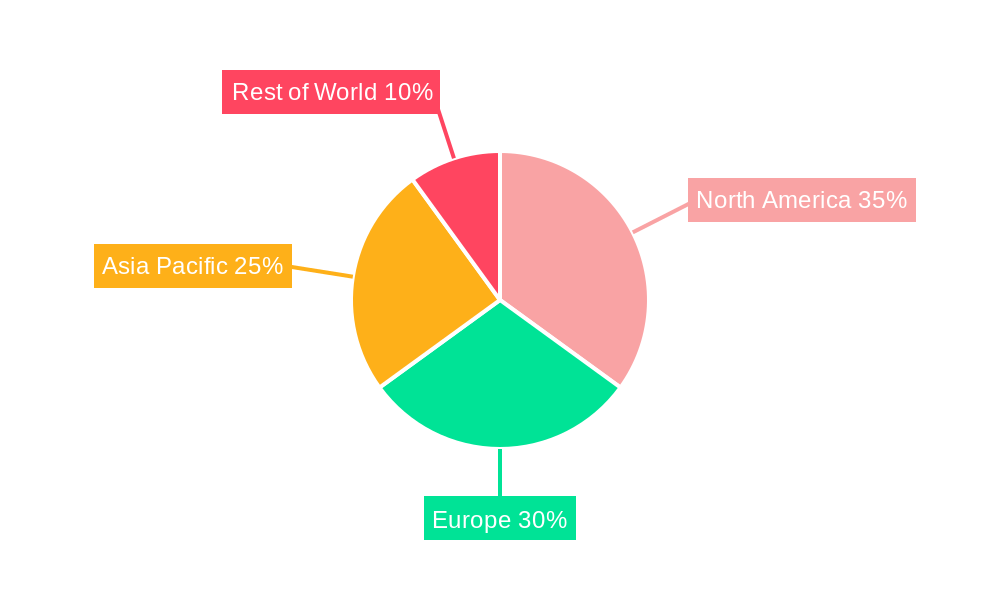

The global PCTFE (polychlorotrifluoroethylene) material market is experiencing steady growth, driven by its unique properties such as high chemical resistance, excellent dielectric strength, and exceptional thermal stability. These characteristics make PCTFE ideal for demanding applications in diverse sectors including semiconductors, aerospace, and cryogenics. The market is segmented by temperature classifications (298K, 144K, and 252K), reflecting the material's versatility across various operating conditions. Key applications include seals, semiconductors, electrical components, and high-vacuum plants. While the precise market size for 2025 is unavailable, a reasonable estimation, considering the provided segment data and typical industry growth rates for specialized materials, would place the overall market value at approximately $500 million. This estimate reflects a balanced distribution across segments with seals and semiconductor applications comprising the largest shares. Major players like DuPont, Honeywell, and Solvay dominate the market, leveraging their established manufacturing capabilities and strong brand reputations. The market's growth is projected to be fueled by increasing demand in electronics manufacturing and advancements in cryogenic technologies. However, restraints include the relatively high cost of PCTFE compared to alternative materials and the potential environmental concerns related to its chemical composition. Future market expansion will hinge on advancements in sustainable production methods and the development of new applications leveraging PCTFE's unique properties. Regional analysis suggests North America and Europe currently hold significant market share due to strong industrial infrastructure and established technological presence. Asia-Pacific, however, is anticipated to experience the most rapid growth in the coming years driven by expanding manufacturing activity and increasing demand from electronics and chemical processing industries.

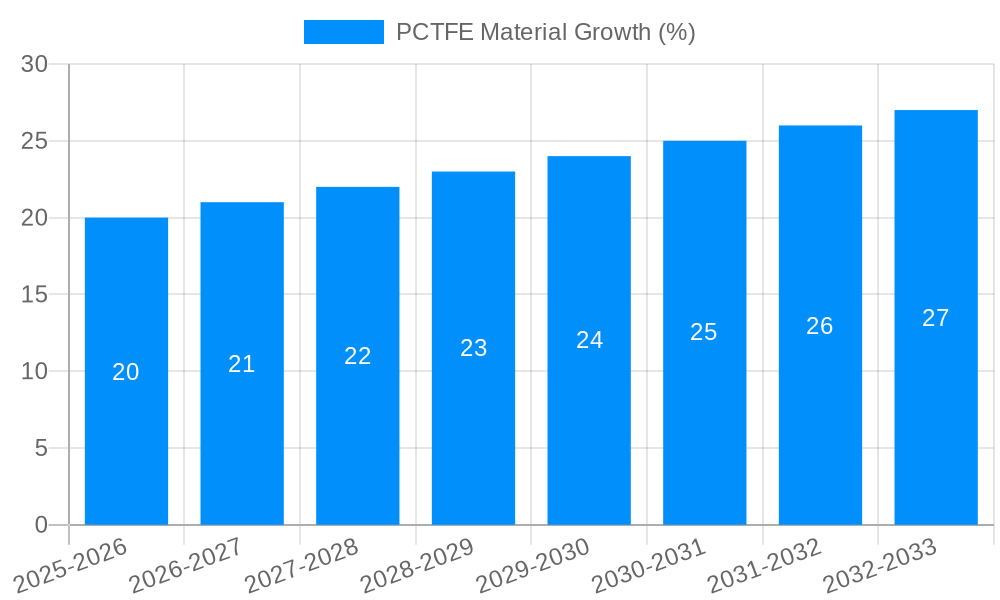

The forecast period (2025-2033) anticipates a continued rise in PCTFE demand, driven by the ongoing technological advancements in sectors reliant on its unique features. The CAGR, while not explicitly stated, is likely within the range of 4-6%, a reasonable estimate considering the market’s niche nature and its dependence on specific high-growth sectors. This growth will be influenced by factors such as the increasing use of PCTFE in demanding applications requiring high performance and long-term durability. Competitive pressures from emerging material alternatives will require manufacturers to prioritize innovation, improved cost-efficiency and sustainable production processes to maintain market share and achieve continued expansion. The ongoing focus on enhanced material properties and broadening applications is projected to sustain market growth throughout the forecast period.

The global PCTFE (polychlorotrifluoroethylene) material market exhibited robust growth during the historical period (2019-2024), exceeding several million units in production. This upward trajectory is projected to continue throughout the forecast period (2025-2033), driven by a confluence of factors, including increasing demand across diverse applications and advancements in material properties. The estimated market value for 2025 sits at a significant figure, with further substantial growth anticipated. Key market insights reveal a strong correlation between the rising adoption of PCTFE in specialized industries like semiconductors and high-vacuum applications, and the material's unique properties such as its exceptional chemical resistance, high thermal stability, and low permeability. This has fostered a considerable expansion in market size, particularly in regions with thriving technological sectors. The market is also witnessing innovation in PCTFE formulations, leading to enhanced performance characteristics and broadening its applicability. Competition among major players remains intense, driving continuous improvement and the introduction of new products tailored to specific market needs. The report provides a detailed analysis of these trends, offering insights into regional variations, application-specific growth patterns, and the evolving competitive landscape. The study period covered (2019-2033), with a base year of 2025, allows for a comprehensive understanding of the past, present, and future trajectory of the PCTFE market.

Several factors are driving the growth of the PCTFE material market. The inherent properties of PCTFE, including its exceptional chemical inertness, outstanding dielectric strength, and broad temperature tolerance, make it highly suitable for demanding applications. This has resulted in its increasing adoption in the semiconductor industry for critical components demanding high reliability and precision. The growth of the high-vacuum technology sector also contributes significantly to the market's expansion, as PCTFE’s low permeability is crucial for maintaining vacuum integrity. Similarly, the increasing demand for durable and chemically resistant seals in various industries further fuels market growth. Furthermore, ongoing research and development efforts are leading to the creation of modified PCTFE formulations with enhanced properties, widening the range of applications and increasing the overall demand. Finally, the rising focus on safety and performance in industries where PCTFE is used—such as chemical processing and aerospace—is encouraging its wider adoption, reinforcing the positive market momentum.

Despite the positive growth outlook, the PCTFE material market faces several challenges. The relatively high cost of PCTFE compared to alternative materials can limit its adoption in applications where cost is a primary concern. Furthermore, the complex manufacturing process and specialized handling requirements can pose logistical and operational complexities for manufacturers. Stringent environmental regulations regarding the use and disposal of fluoropolymers also present a hurdle, necessitating adherence to specific guidelines and potentially increasing production costs. The availability of substitute materials with similar properties, albeit potentially with some performance trade-offs, poses competitive pressure. Additionally, fluctuations in the prices of raw materials used in PCTFE production can impact market stability and profitability. Addressing these challenges effectively will be crucial for sustaining the market's growth trajectory and ensuring its long-term viability.

The semiconductor application segment is expected to dominate the PCTFE market during the forecast period. The demand for high-purity, high-performance materials in semiconductor manufacturing is a key driver of this segment's growth. PCTFE's exceptional dielectric strength, chemical inertness, and ability to withstand high temperatures make it ideal for use in various semiconductor manufacturing processes.

North America and Asia-Pacific are projected to be the leading regions for PCTFE consumption. These regions benefit from strong technological advancement in sectors such as semiconductor manufacturing, aerospace, and chemical processing, all of which are key drivers for PCTFE demand. North America's established industrial base and strong regulatory framework contribute to the region's significant market share. Asia-Pacific's rapidly expanding electronics industry and increasing investments in advanced technologies fuel significant growth in the region.

The 298K (25°C) type PCTFE segment holds a significant market share due to its widespread applicability across various industries. However, the 21K (-252°C) type, while smaller in market size currently, is experiencing notable growth driven by its critical role in cryogenic applications, particularly in the aerospace and scientific research sectors. This segment is poised for faster-than-average growth due to escalating demand from these specialized fields.

The high-vacuum plant application segment, owing to PCTFE's crucial role in maintaining vacuum integrity, is showing strong growth. This segment benefits from advances in high-vacuum technologies and the expanding applications requiring ultra-high vacuum conditions.

Within these regions and segments, individual countries like the United States, Japan, South Korea, and China are major consumers of PCTFE, fueled by their strong manufacturing and technological capabilities.

The PCTFE material industry is experiencing growth fueled by its unique properties and expanding applications in high-value sectors. The increasing demand for advanced materials in the semiconductor and electronics industries, along with the growing need for high-performance seals in various applications, are driving significant growth. Technological advancements leading to improved PCTFE formulations with enhanced properties, coupled with rising investments in R&D, are further accelerating the market's expansion.

This report provides a comprehensive analysis of the PCTFE material market, covering historical data, current market dynamics, and future projections. It offers deep insights into key market trends, driving forces, challenges, regional and segmental breakdowns, and profiles of leading industry players. The detailed analysis presented enables informed decision-making for businesses operating in or seeking entry into this specialized market.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Dupont, Honeywell International, Solvay, Welch Fluorocarbon, Cryogenic Applications, Aetna Plastics, Arkema, Fluorocarbon Group, Afton Plastics, Fluorocarbon, Allied, SABIC, Lima, The Chemours.

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "PCTFE Material," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the PCTFE Material, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.