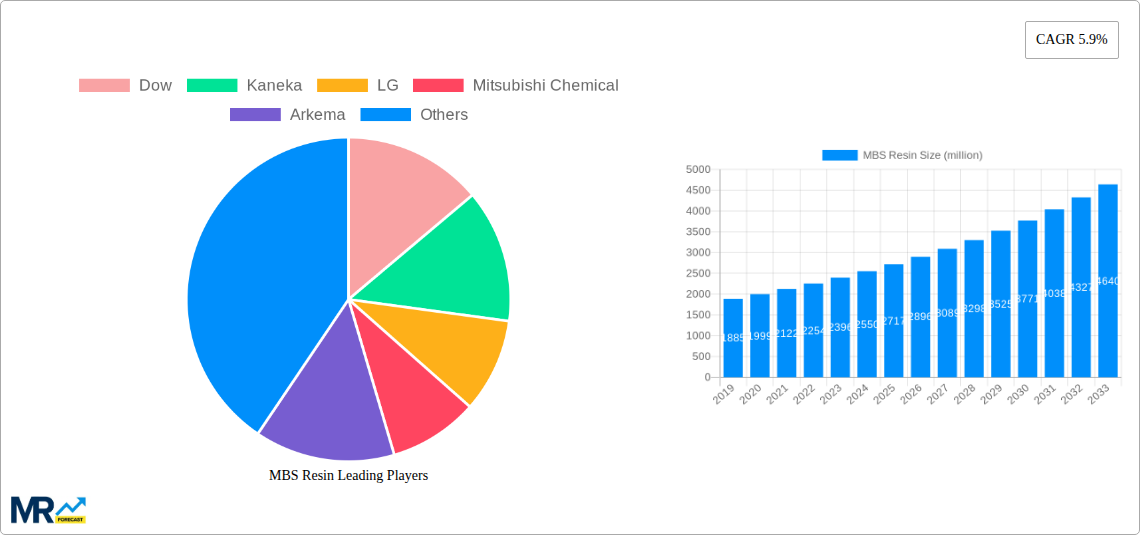

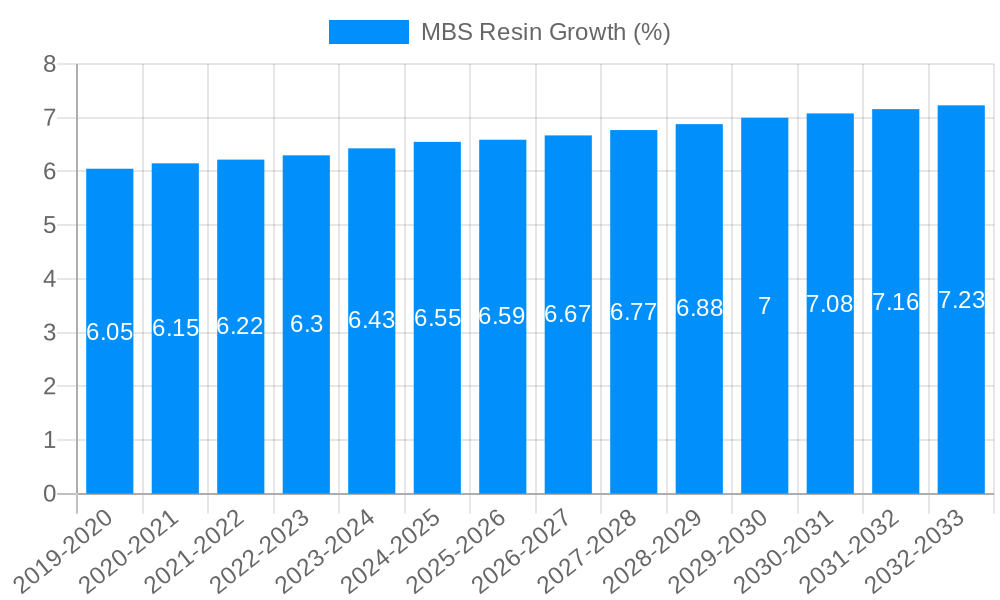

1. What is the projected Compound Annual Growth Rate (CAGR) of the MBS Resin?

The projected CAGR is approximately 5.9%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

MBS Resin

MBS ResinMBS Resin by Type (Transparent MBS, Non-transparent MBS), by Application (PVC Sheet, PVC Pipe, PVC Film, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

The global MBS (Melt Blown Stabilizer) Resin market is poised for significant expansion, projected to reach a substantial valuation by 2033. Driven by robust demand across diverse applications like PVC sheets, pipes, and films, the market is expected to witness a Compound Annual Growth Rate (CAGR) of 5.9% from its 2025 estimated size. This growth is fueled by the increasing adoption of PVC in construction, automotive, and packaging sectors, where MBS resins enhance impact resistance, processability, and clarity. The material’s versatility in both transparent and non-transparent formulations allows it to cater to a wide spectrum of product requirements, further solidifying its market position. Key players like Dow, Kaneka, LG, and Mitsubishi Chemical are actively investing in research and development, innovating to improve MBS resin properties and expand their product portfolios to meet evolving industry standards and sustainability demands.

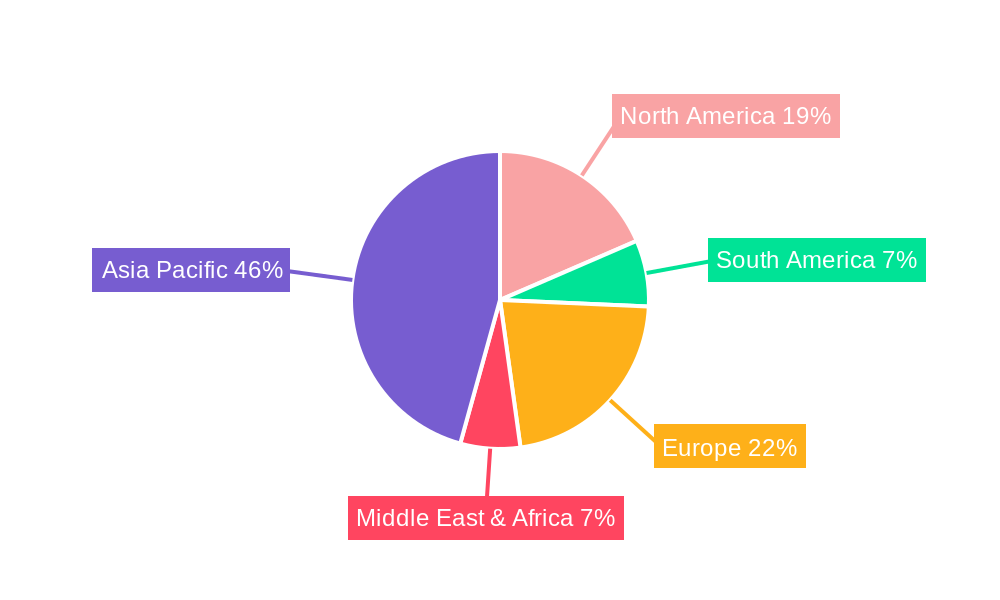

The market's trajectory is also shaped by evolving manufacturing processes and a growing emphasis on specialized applications. While Asia Pacific, led by China and India, is expected to remain a dominant region due to its extensive manufacturing base and burgeoning construction industry, North America and Europe are also experiencing steady growth, driven by technological advancements and stricter regulatory requirements for material performance. However, potential restraints such as fluctuating raw material prices and the emergence of alternative impact modifiers could present challenges. Nevertheless, the inherent advantages of MBS resins in improving PVC performance and the continuous innovation within the industry suggest a highly promising outlook for market participants. The strategic expansion and product development efforts by leading companies are crucial in navigating these dynamics and capitalizing on the burgeoning opportunities.

This comprehensive report provides an in-depth analysis of the global MBS Resin market, offering valuable insights for stakeholders navigating this dynamic sector. Spanning a study period from 2019 to 2033, with a base and estimated year of 2025 and a forecast period of 2025-2033, this report leverages historical data from 2019-2024 to paint a complete picture of market evolution and future potential.

The MBS resin market, characterized by its significant role as an impact modifier and processing aid for PVC, is exhibiting robust and consistent growth. During the historical period (2019-2024), the market witnessed steady demand driven by the expanding construction and packaging industries. The estimated year of 2025 projects a market valuation reaching XXX million units, underscoring its established significance. Looking ahead, the forecast period (2025-2033) is anticipated to see an accelerated growth trajectory, with projections indicating a market size of XXX million units by 2033. This upward trend is fueled by several key factors, including the increasing adoption of PVC in various applications due to its cost-effectiveness and versatility, coupled with the growing need for enhanced durability and performance in end-products. The distinction between transparent and non-transparent MBS resins will continue to be a crucial market differentiator. Transparent MBS, vital for applications like PVC sheets for windows and doors, and clear PVC films, is expected to maintain a strong demand base, driven by architectural advancements and sophisticated packaging solutions. Conversely, non-transparent MBS, crucial for PVC pipes and profiles where opacity and impact strength are paramount, will also see sustained growth, fueled by infrastructure development and the need for robust construction materials. The report meticulously analyzes the interplay of these segments, highlighting their respective growth rates and market shares. Furthermore, evolving regulatory landscapes concerning material sustainability and recycling are beginning to influence product development and material selection, hinting at future shifts towards bio-based or recyclable MBS alternatives. The increasing focus on high-performance materials in automotive interiors and durable consumer goods also presents emerging avenues for MBS resin utilization, contributing to the overall positive market sentiment. The report delves into these nuanced trends, providing quantitative data and qualitative analysis to guide strategic decision-making.

The relentless upward trajectory of the MBS resin market is underpinned by a confluence of powerful driving forces. Foremost among these is the ubiquitous and ever-growing demand for Polyvinyl Chloride (PVC) across a myriad of industries. As a critical additive, MBS resins are indispensable for enhancing the impact resistance and processability of PVC, making it suitable for a wider array of applications. The construction sector, a perennial powerhouse, continues to be a primary consumer of PVC, and consequently, of MBS resins. The global surge in urbanization, coupled with significant investments in infrastructure development and renovation projects, particularly in emerging economies, directly translates into heightened demand for PVC products like pipes, window profiles, and siding, thereby boosting the MBS resin market. Furthermore, the packaging industry, a dynamic and continuously evolving sector, relies heavily on PVC films and sheets for their protective qualities, clarity, and cost-efficiency. The increasing consumerism, the expansion of e-commerce, and the demand for more sophisticated and durable packaging solutions are all contributing significantly to the sustained growth of PVC, and by extension, the MBS resin market. Beyond these established sectors, the automotive industry's increasing adoption of lightweight and durable materials, including PVC components in interiors and exterior trim, also represents a growing avenue for MBS resin consumption. The inherent ability of MBS to improve the toughness and weatherability of PVC makes it an attractive additive for these demanding applications. Moreover, technological advancements in MBS resin production, leading to improved product performance and cost-effectiveness, further stimulate market adoption and expansion.

Despite its robust growth, the MBS resin market is not without its inherent challenges and restraints that warrant careful consideration. One of the most significant headwinds stems from the increasing environmental scrutiny and regulatory pressures surrounding PVC and its additives. Growing concerns about the long-term environmental impact of PVC, including its disposal and the potential release of harmful chemicals during production and incineration, can lead to substitution efforts by alternative materials. This can indirectly impact the demand for MBS resins as a key component in PVC formulations. The price volatility of raw materials, particularly butadiene and styrene, which are crucial for MBS production, poses another significant challenge. Fluctuations in the global petrochemical market can lead to increased production costs, impacting the profitability of MBS manufacturers and potentially affecting the competitiveness of PVC products against alternatives. Furthermore, the presence of substitute impact modifiers and processing aids, such as acrylic polymers and other specialty additives, presents a competitive threat. While MBS resins offer a unique balance of properties, these substitutes may offer specific advantages in certain niche applications or at a lower cost, thereby limiting market penetration. The development of more advanced and specialized materials that can outperform traditional MBS in specific performance metrics also represents a potential restraint. The report provides a detailed analysis of these restraints, quantifying their potential impact on market growth and offering strategies for mitigation. The evolving landscape of recycling technologies and the drive towards a circular economy may also necessitate adaptations in MBS resin formulations to ensure compatibility with recycling processes, posing a development challenge.

Dominant Segments and Regions in the MBS Resin Market

The global MBS resin market exhibits a clear dominance in specific segments and regions, driven by localized demand, industrial infrastructure, and market maturity. Among the various segments, PVC Sheet emerges as a key dominator, projecting a significant market share and robust growth throughout the forecast period. This dominance is intrinsically linked to its widespread application in construction, automotive interiors, and consumer goods, where enhanced impact strength and aesthetic appeal are paramount. The demand for PVC sheets for window profiles, doors, decorative panels, and signage, particularly in rapidly developing economies and in regions undergoing significant infrastructure upgrades, fuels this segment's ascendancy. Consequently, the production and consumption of Transparent MBS, a critical component for high-quality PVC sheets requiring clarity and excellent impact modification, will also see substantial market penetration within this segment.

Another crucial segment contributing to market dominance is PVC Pipe. This segment is driven by the fundamental need for durable and reliable water supply, sewage systems, and agricultural irrigation. The extensive ongoing and planned infrastructure projects in both developed and developing nations, coupled with the increasing population and urbanization, are pivotal in sustaining the demand for PVC pipes. Non-transparent MBS, essential for providing the necessary impact resistance and durability to PVC pipes under various environmental conditions, plays a vital role in this segment's growth.

Geographically, Asia Pacific stands out as the dominant region in the MBS resin market. This dominance is attributed to several intertwined factors:

While Asia Pacific leads, North America and Europe also represent significant markets, driven by established industries, technological advancements, and stringent quality standards. North America's demand is fueled by the renovation and remodeling market and specialized industrial applications. Europe, with its focus on sustainability and high-performance materials, sees consistent demand for premium MBS applications. The report provides a detailed breakdown of the market share and growth projections for each key region and segment, offering a granular understanding of the global MBS resin landscape.

The MBS resin industry is poised for sustained growth, propelled by several key catalysts. The increasing global demand for durable and cost-effective construction materials, particularly PVC pipes and sheets, remains a primary growth driver. Furthermore, the expanding packaging sector, driven by consumerism and e-commerce, necessitates the use of high-performance PVC films and sheets, thereby boosting MBS consumption. Technological advancements in MBS production, leading to improved product quality and cost efficiencies, also contribute to market expansion. Emerging economies with rapid industrialization and infrastructure development initiatives present significant untapped potential for MBS resin application.

This report offers a comprehensive and in-depth analysis of the global MBS resin market, providing stakeholders with critical intelligence for strategic decision-making. It meticulously covers market size and segmentation, analyzing the dynamics of transparent and non-transparent MBS, and their applications in PVC sheets, pipes, films, and others. The report further delves into the intricate interplay of driving forces and challenges, offering a balanced perspective on the market's potential and risks. Regional analyses, including a focus on the dominant Asia Pacific market and its key contributing factors, are presented in detail. Future growth catalysts and significant industry developments, coupled with a thorough competitive landscape featuring leading global players, are also integral to this comprehensive coverage. The report’s extensive study period (2019-2033) ensures a robust understanding of historical trends and future projections, making it an indispensable resource for any entity involved in the MBS resin value chain.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 5.9% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 5.9%.

Key companies in the market include Dow, Kaneka, LG, Mitsubishi Chemical, Arkema, Denka, Formosa Plastic Group, Ineos Styrolution, Wanda Chemical, Ruifeng Chemical, Yuefeng Group, Weihai Jinhong Group, Shangdong Dingding Chemical, Shandow, Donglin, .

The market segments include Type, Application.

The market size is estimated to be USD 1885 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "MBS Resin," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the MBS Resin, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.