1. What is the projected Compound Annual Growth Rate (CAGR) of the Maintenance-free Chains?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Maintenance-free Chains

Maintenance-free ChainsMaintenance-free Chains by Application (Food, Bottling, Packaging, Textile, Sawmills, Car assembly, Others, World Maintenance-free Chains Production ), by Type (Single Pitch, Double Pitch, Double Pitch Carrier Roller, World Maintenance-free Chains Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

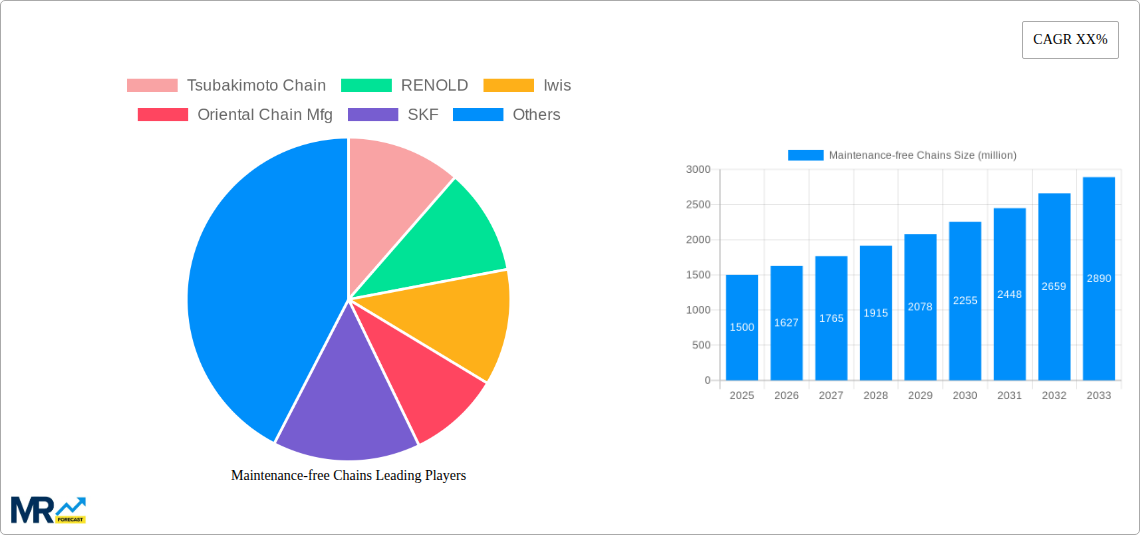

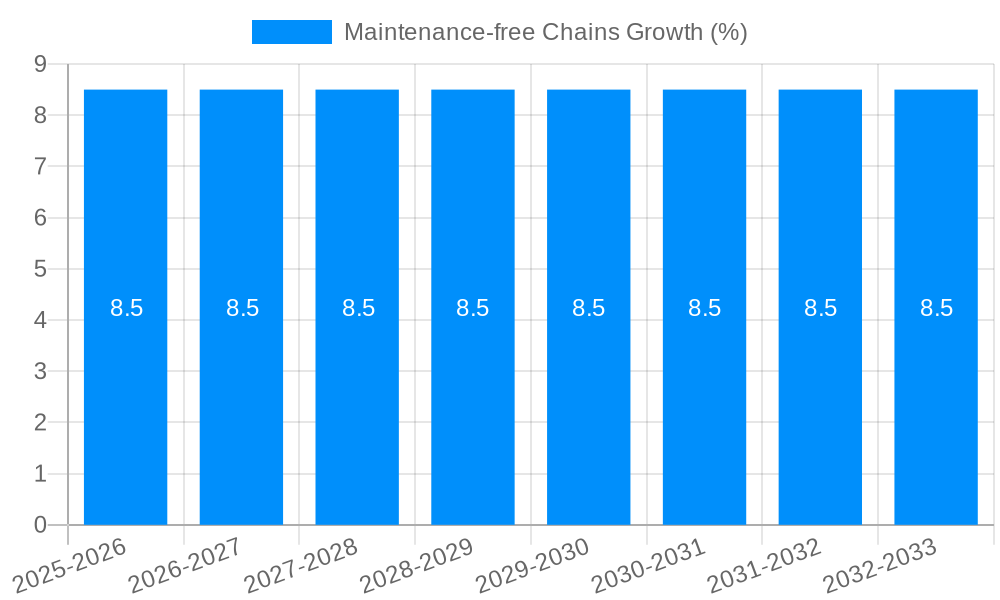

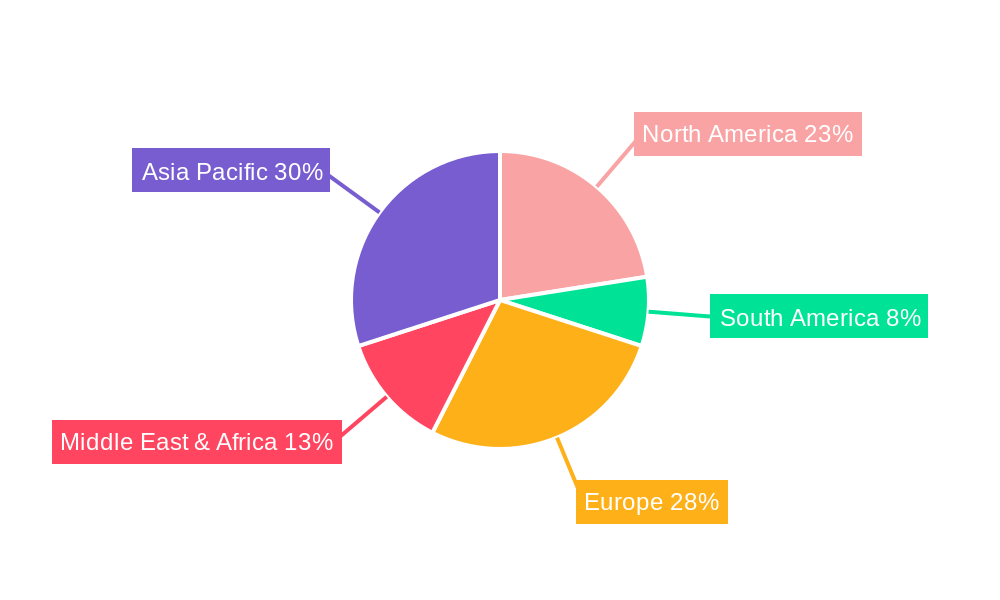

The global Maintenance-free Chains market is poised for substantial growth, projected to reach an estimated market size of USD 1,500 million by 2025, with a robust Compound Annual Growth Rate (CAGR) of 8.5% during the forecast period of 2025-2033. This expansion is primarily fueled by the increasing demand for automation and efficiency across various industrial sectors. Key drivers include the inherent benefits of maintenance-free chains, such as reduced downtime, lower operational costs, and enhanced product lifespan, making them indispensable in applications where traditional lubrication is impractical or undesirable. The packaging and food processing industries, in particular, are significant contributors, owing to stringent hygiene standards and the need for reliable, contamination-free operations. Furthermore, the automotive sector's push towards lighter, more durable components and the textile industry's adoption of advanced machinery are also propelling market adoption. Emerging economies in the Asia Pacific region, driven by rapid industrialization and a growing manufacturing base, are expected to represent a significant growth opportunity.

The market is characterized by a diverse range of applications, with the "Food" segment leading in adoption due to its critical need for cleanliness and reliability, followed closely by "Bottling" and "Packaging" sectors. The "Textile" and "Sawmills" segments also showcase strong growth potential as manufacturers seek to optimize production processes. Within product types, "Single Pitch" and "Double Pitch" chains are the dominant categories, catering to a broad spectrum of industrial requirements. Innovations in materials science and chain design are leading to enhanced performance characteristics, such as improved corrosion resistance and higher load-bearing capacities, further solidifying the market's upward trajectory. While the market exhibits strong growth, potential restraints could include the higher initial cost of some maintenance-free chain technologies compared to traditional lubricated chains, though this is often offset by long-term operational savings. Key players like Tsubakimoto Chain, RENOLD, and SKF are actively investing in research and development to introduce next-generation maintenance-free chain solutions, ensuring continued market dynamism and fulfilling the evolving needs of global industries.

This report offers an in-depth analysis of the global Maintenance-free Chains market, providing a comprehensive outlook for stakeholders. The study encompasses a detailed examination of market dynamics, historical trends, and future projections, with a specific focus on the period between 2019 and 2033. The base year for estimation is 2025, with the forecast period extending from 2025 to 2033, building upon the historical data from 2019-2024. The report delves into various product types, including Single Pitch, Double Pitch, and Double Pitch Carrier Roller chains, and meticulously analyzes their production volumes, projected to reach several million units. Furthermore, it investigates the market penetration and demand across key application segments such as Food, Bottling, Packaging, Textile, Sawmills, Car Assembly, and Others, providing a holistic view of the industry's landscape.

The global Maintenance-free Chains market is experiencing a robust upward trajectory, driven by an increasing demand for enhanced operational efficiency and reduced downtime across a multitude of industrial sectors. XXX, a significant market insight, reveals a projected growth in global production volume, estimated to surpass 50 million units by 2025. This surge is primarily attributed to the inherent advantages of maintenance-free chains, which eliminate the need for regular lubrication and frequent adjustments. This not only translates into substantial cost savings for end-users by minimizing labor and lubricant expenses but also contributes to a cleaner and safer working environment, particularly in sensitive industries like food processing and pharmaceuticals. The growing emphasis on sustainability and environmental regulations further bolsters the adoption of these advanced chain solutions, as they reduce waste associated with lubricants and their disposal. The report highlights a discernible trend towards higher performance and longer service life, with manufacturers continuously investing in research and development to engineer chains that can withstand extreme operating conditions, including high temperatures, corrosive environments, and heavy loads. This innovation is crucial for applications in sectors like automotive manufacturing, where precise and reliable power transmission is paramount. The increasing automation of industrial processes is another key driver, as maintenance-free chains seamlessly integrate into automated systems, offering consistent performance without manual intervention, thereby optimizing overall production throughput. The market is witnessing a diversification of product offerings, with specialized maintenance-free chains being developed for niche applications, catering to specific industry requirements and further expanding the market's reach. The strategic adoption of advanced materials and sophisticated manufacturing techniques are enabling the production of chains with superior wear resistance and tensile strength, further solidifying their competitive advantage over conventional lubricated chains. The global market, as analyzed in this report, is poised for sustained growth, fueled by these interwoven technological advancements and evolving industrial demands.

The remarkable growth of the Maintenance-free Chains market is being propelled by a confluence of compelling factors that are fundamentally reshaping industrial operations. Foremost among these is the relentless pursuit of operational efficiency and cost optimization by businesses worldwide. Maintenance-free chains, by their very design, significantly curtail expenditure on lubricants, labor for lubrication, and unscheduled downtime caused by chain failures or maintenance requirements. This direct cost reduction translates into a more favorable bottom line for end-users, making them an increasingly attractive proposition. Furthermore, stringent environmental regulations and a growing corporate responsibility towards sustainability are acting as powerful catalysts. The elimination of lubricant usage not only reduces waste but also contributes to a cleaner operational environment, minimizing the risk of contamination, especially critical in sectors like food and beverage processing, where product safety is of paramount importance. The increasing sophistication and automation of manufacturing processes across various industries necessitate highly reliable and consistent power transmission solutions. Maintenance-free chains excel in this regard, offering predictable performance without the variability associated with lubrication. This reliability is crucial for maintaining production schedules and meeting demanding output targets. The continuous innovation in material science and manufacturing technology by leading players is also a significant driver. The development of advanced alloys and specialized coatings allows for the creation of maintenance-free chains that offer superior wear resistance, corrosion resistance, and extended service life, even under harsh operating conditions. This technological advancement directly enhances the value proposition of these chains.

Despite the promising growth trajectory, the Maintenance-free Chains market is not without its challenges and restraints, which, if not effectively addressed, could impede its full potential. A primary concern remains the initial acquisition cost. Maintenance-free chains, due to their advanced materials and manufacturing processes, often come with a higher upfront price tag compared to traditional lubricated chains. This can be a significant barrier for small and medium-sized enterprises (SMEs) or industries with tight capital expenditure budgets, forcing them to weigh the long-term savings against the immediate investment. Furthermore, while the "maintenance-free" aspect is a major selling point, it's important to note that these chains still require occasional inspection for wear and tear, and their lifespan, though extended, is not infinite. Misunderstanding or over-reliance on the term "maintenance-free" could lead to neglect, potentially resulting in premature failure and unexpected costs. The availability of specialized maintenance-free chains for highly niche or extreme applications can also be a restraint. While the market is expanding, there might be specific industrial environments with unique requirements (e.g., extremely high speeds, ultra-low temperatures, or specific chemical resistance) where off-the-shelf maintenance-free solutions are not readily available or may require custom engineering, leading to higher costs and longer lead times. The technical expertise required for proper installation and application selection is another factor. While maintenance is reduced, incorrect selection or improper installation of a maintenance-free chain can still lead to suboptimal performance or premature wear. This necessitates adequate training and knowledge within the end-user's workforce or reliance on specialized support from manufacturers, which might not always be readily accessible. Lastly, the established infrastructure and familiarity with traditional lubricated chain systems create a inertia that can slow down the adoption of new technologies. Many industries have decades of experience and established maintenance protocols for lubricated chains, making the transition to a fundamentally different system a significant undertaking that requires careful planning and execution.

The global Maintenance-free Chains market is characterized by regional dominance driven by industrialization levels, technological adoption rates, and the presence of key end-use sectors. Among the key regions, Asia Pacific is projected to emerge as a dominant force. This dominance is underpinned by the region's rapidly expanding manufacturing sector, particularly in countries like China and India, which are global hubs for production across various industries. The increasing adoption of advanced manufacturing technologies and automation in these nations directly fuels the demand for high-performance, low-maintenance components. Furthermore, significant investments in infrastructure development and the burgeoning automotive industry, a major consumer of chain systems, are contributing to the region's stronghold. The presence of a substantial number of manufacturers and suppliers within Asia Pacific also ensures a competitive landscape, driving innovation and potentially more accessible pricing, although initial costs remain a factor.

Within the application segments, the Packaging and Bottling sectors are anticipated to lead the market in terms of volume and revenue. These industries are inherently reliant on continuous and efficient conveyor systems for product movement, filling, and sealing. The high-speed, high-throughput nature of modern packaging and bottling operations makes the reliability and reduced downtime offered by maintenance-free chains particularly valuable. The stringent hygiene requirements in food and beverage packaging further amplify the appeal of these chains, as they eliminate the risk of lubricant contamination. The Food industry, as a broader category encompassing processing and handling, also presents significant growth opportunities due to similar demands for cleanliness and uninterrupted operations.

The Car Assembly segment is another critical driver of the Maintenance-free Chains market. The automotive industry's reliance on automated assembly lines and the need for precise, synchronized movement of components make maintenance-free chains an essential element. As vehicle production continues to grow globally, particularly with the increasing complexity of modern vehicles and the rise of electric mobility, the demand for robust and reliable chain systems that minimize production bottlenecks is set to escalate. The drive for lean manufacturing principles within the automotive sector further emphasizes the importance of components that reduce variability and require minimal intervention.

In terms of Type, Single Pitch and Double Pitch chains are expected to command the largest market share, reflecting their widespread use in general-purpose conveying and power transmission applications across various industries. However, the Double Pitch Carrier Roller type is likely to witness significant growth, particularly in applications where increased load-bearing capacity and reduced friction are essential, such as in heavier-duty conveying systems and specialized industrial machinery. The ability of carrier roller chains to support higher loads and operate with less wear makes them an attractive option for demanding environments within sectors like material handling, mining, and heavy manufacturing.

The Maintenance-free Chains industry is experiencing a significant uplift driven by several key growth catalysts. The escalating emphasis on operational efficiency and cost reduction across industries is paramount. Businesses are actively seeking ways to minimize downtime, reduce labor costs associated with lubrication, and extend the lifespan of their equipment, making maintenance-free chains an increasingly attractive investment. Furthermore, stringent environmental regulations are pushing manufacturers towards cleaner technologies, and the elimination of lubricants in chain systems aligns perfectly with these sustainability goals. The advancement in material science and manufacturing technologies is continuously improving the performance, durability, and application range of maintenance-free chains, making them suitable for even more demanding environments. Finally, the increasing adoption of automation and smart manufacturing practices necessitates reliable, low-maintenance components that can seamlessly integrate into complex production lines.

The global Maintenance-free Chains market is characterized by the presence of several established and innovative companies. These leading players are instrumental in driving technological advancements and market expansion. Key contributors include:

The Maintenance-free Chains sector has witnessed several key developments that have shaped its growth and technological evolution:

This comprehensive report provides a deep dive into the Maintenance-free Chains market, offering invaluable insights for businesses looking to understand and capitalize on emerging trends. The report meticulously analyzes global production volumes, projected to reach millions of units by 2025, across various product types including Single Pitch, Double Pitch, and Double Pitch Carrier Roller chains. It scrutinizes the market's performance across key application segments such as Food, Bottling, Packaging, Textile, Sawmills, and Car Assembly, identifying areas of significant demand and future growth potential. The study leverages data from the Historical Period (2019-2024) and projects future trends through the Forecast Period (2025-2033), with a specific focus on the Base Year (2025) and Estimated Year (2025). This forward-looking perspective, coupled with an in-depth understanding of market drivers, challenges, and key players, empowers stakeholders with the knowledge needed to make informed strategic decisions in this dynamic and evolving industry.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Tsubakimoto Chain, RENOLD, Iwis, Oriental Chain Mfg, SKF, Ammega, Wippermann, HKK Chain, ZEXUS CHAIN, Donghua, DONG BO CHAIN, Sugiyama Chain, PEER Chain, PTI, Tien Yuan Chains, Bison Chain, .

The market segments include Application, Type.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Maintenance-free Chains," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Maintenance-free Chains, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.