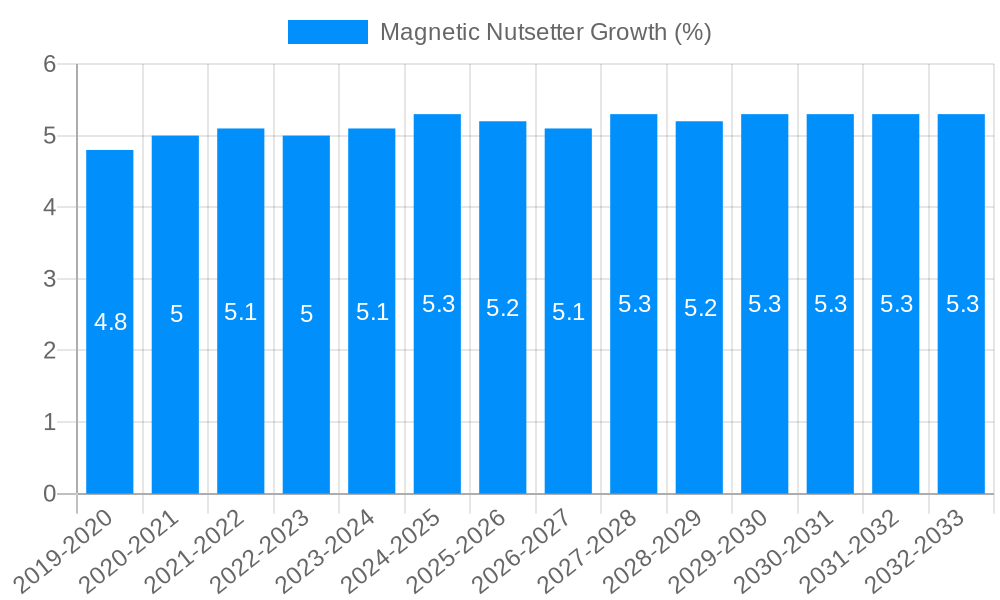

1. What is the projected Compound Annual Growth Rate (CAGR) of the Magnetic Nutsetter?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Magnetic Nutsetter

Magnetic NutsetterMagnetic Nutsetter by Type (Impact Nutsetter, Torsion Nutsetter), by Application (Residential, Commercial, Industrial), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

The global magnetic nutsetter market is poised for significant expansion, projected to reach an estimated USD 750 million by 2025. This growth is underpinned by a robust Compound Annual Growth Rate (CAGR) of approximately 6.5% over the forecast period of 2025-2033. The inherent advantages of magnetic nutsetters, such as enhanced screw-holding capabilities, improved user convenience, and increased efficiency in fastening tasks, are major driving forces behind this upward trajectory. Industries are increasingly recognizing the value of these tools in reducing dropped fasteners and streamlining assembly processes, particularly in demanding environments like automotive manufacturing, construction, and industrial maintenance. The widespread adoption of power tools and the continuous innovation in tool design, including the development of stronger magnetic fields and more durable materials, further fuel market demand.

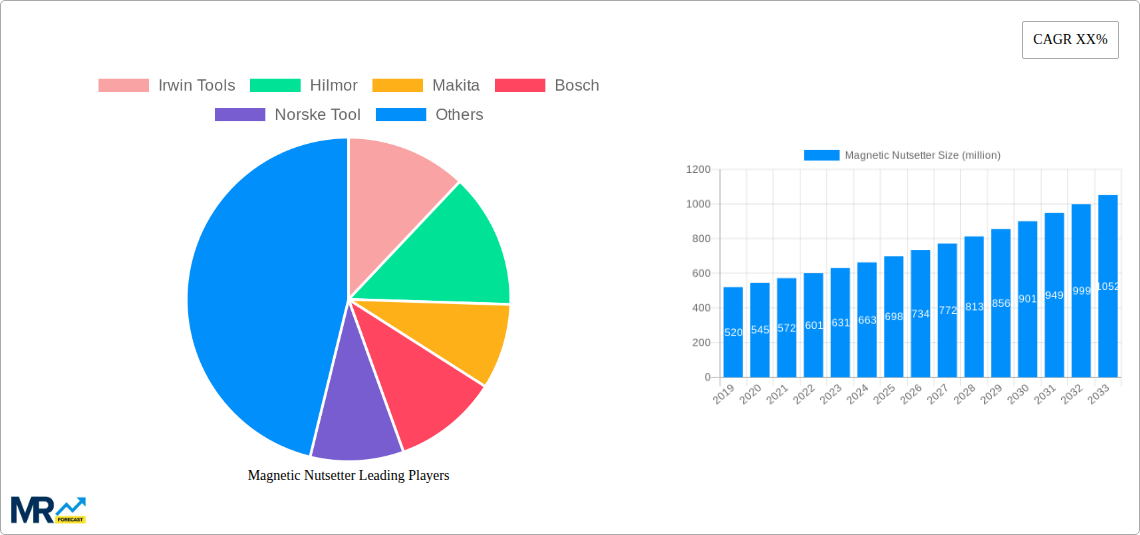

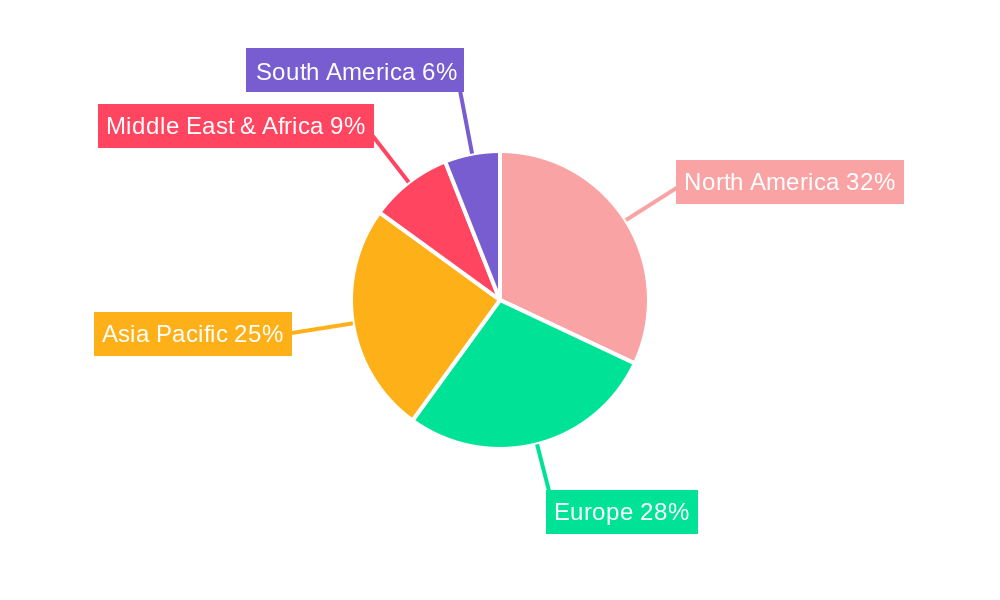

The market is segmented into distinct types, with Impact Nutsetters and Torsion Nutsetters representing key categories, each catering to specific torque requirements and applications. Residential, Commercial, and Industrial applications form the core of demand, with the industrial sector showcasing the highest consumption due to its reliance on high-volume, repetitive fastening operations. Geographically, North America and Europe currently lead the market, driven by established manufacturing bases and high disposable incomes. However, the Asia Pacific region is emerging as a dynamic growth engine, fueled by rapid industrialization, infrastructure development, and the increasing penetration of advanced tools in emerging economies like China and India. While the market benefits from strong growth drivers, challenges such as the initial cost of high-quality magnetic nutsetters and the availability of cheaper, non-magnetic alternatives in certain segments can pose minor restraints.

Here is a unique report description on Magnetic Nutsetters, incorporating your specified elements:

The global magnetic nutsetter market is poised for substantial expansion, driven by an increasing demand for efficiency and precision across a multitude of industries. This report delves into the market dynamics from a comprehensive Study Period of 2019-2033, with a Base Year of 2025 and an Estimated Year also in 2025, projecting the market's trajectory throughout the Forecast Period of 2025-2033, building upon the Historical Period of 2019-2024. XXX indicates a projected market valuation that will likely surpass five hundred million units in demand by the end of the forecast period. The proliferation of advanced fastening solutions, particularly in the automotive, construction, and manufacturing sectors, is a primary catalyst. Innovations in material science, leading to the development of more robust and durable nutsetters with superior magnetic retention capabilities, are also shaping market trends. The growing adoption of cordless power tools, which intrinsically benefit from the convenience and speed offered by magnetic nutsetters, further fuels this growth. Furthermore, the increasing focus on workplace safety and ergonomic design principles encourages the use of tools that minimize manual effort and reduce the risk of dropped fasteners, directly benefiting the magnetic nutsetter segment. The market is also witnessing a shift towards specialized nutsetters designed for specific applications, such as high-torque impact nutsetters and precision torsion nutsetters, catering to niche requirements and expanding the overall market footprint. The residential segment, though smaller than its industrial counterpart, is showing steady growth due to the DIY trend and the increasing complexity of home assembly projects. Commercial applications are also seeing robust uptake, driven by the need for efficient and reliable fastening in building maintenance and small-scale assembly. The industrial segment, a consistent powerhouse, will continue to dominate due to its insatiable need for high-performance tools in large-scale manufacturing and construction. The report will analyze these evolving trends, providing granular insights into regional preferences and technological advancements that are collectively orchestrating the future of this vital tool category.

The magnetic nutsetter market is experiencing a powerful surge propelled by a confluence of technological advancements and evolving industrial demands. The relentless pursuit of increased productivity and reduced labor costs across various sectors is a fundamental driver. Magnetic nutsetters significantly expedite fastening processes by securely holding nuts and bolts in place, eliminating the need for manual dexterity to prevent them from falling, especially in overhead or confined spaces. This inherent time-saving capability translates directly into enhanced operational efficiency, a critical factor for businesses aiming to optimize output and minimize downtime. Furthermore, the escalating complexity of modern manufacturing and construction projects necessitates tools that can handle a wider range of fastener sizes and types with greater precision and reliability. The development of specialized magnetic nutsetters, capable of withstanding higher torque applications and offering superior magnetic strength, directly addresses these evolving needs. The widespread adoption of battery-powered tools, which have become increasingly powerful and portable, complements the convenience offered by magnetic nutsetters, creating a synergistic effect that encourages their integration into standard toolkits. As these power tool segments continue to grow, so too will the demand for complementary accessories like magnetic nutsetters. The emphasis on worker safety also plays a crucial role. By securely holding fasteners, magnetic nutsetters minimize the risk of dropped objects, which can cause injury to workers or damage to equipment. This inherent safety feature is becoming increasingly important as industries prioritize accident prevention and create safer working environments.

Despite the robust growth trajectory, the magnetic nutsetter market is not without its challenges and restraints that could temper its expansion. One significant factor is the inherent limitation of magnetic strength, particularly in applications involving extremely heavy-duty fasteners or in environments with significant electromagnetic interference, which can weaken the magnetic grip. This necessitates the development of specialized, higher-strength magnetic materials or alternative retention mechanisms, potentially increasing manufacturing costs. The market also faces competition from alternative fastening methods and tool designs that may offer comparable or even superior performance in specific niches. For instance, advanced power tool chucks with integrated gripping mechanisms or specialized nut holders might present viable alternatives in certain high-demand scenarios. The price sensitivity of some segments, particularly for smaller businesses or DIY enthusiasts, can also act as a restraint. While the efficiency gains are undeniable, the upfront cost of high-quality magnetic nutsetters, especially those featuring specialized alloys or advanced magnetic technologies, might deter some potential buyers. Furthermore, the relatively short lifespan of some magnetic components due to wear and tear or exposure to harsh industrial conditions can lead to recurring replacement costs, which might influence purchasing decisions. The need for consistent quality control in manufacturing to ensure reliable magnetic retention across all products is paramount. Any perceived inconsistency or failure in magnetic grip could lead to a loss of confidence among users, impacting brand reputation and market penetration. Finally, the rapid pace of technological evolution means that companies must continually invest in research and development to stay ahead, which can be a significant hurdle for smaller players in the market.

The global magnetic nutsetter market is characterized by distinct regional strengths and segment dominance, with Industrial applications poised to be the primary driver of market expansion throughout the forecast period.

Industrial Segment Dominance: The Industrial segment, encompassing sectors like automotive manufacturing, heavy machinery production, aerospace, and large-scale construction, will continue to represent the largest share of the magnetic nutsetter market. The sheer volume of fasteners used in these industries, coupled with the critical need for speed, precision, and safety, makes magnetic nutsetters indispensable.

North America and Europe as Leading Regions: North America and Europe are expected to remain the dominant regions in the magnetic nutsetter market.

Impact Nutsetter as a Dominant Type: Within the types of magnetic nutsetters, Impact Nutsetters are anticipated to witness the most significant growth and market share.

The magnetic nutsetter industry is experiencing robust growth fueled by several key catalysts. The escalating demand for enhanced productivity and reduced labor costs across manufacturing, construction, and automotive sectors is a primary driver. Technological advancements in materials science are leading to stronger magnets and more durable nutsetter designs, improving performance and longevity. The widespread adoption of cordless power tools, which benefit immensely from the convenience and speed of magnetic nutsetters, further propels market expansion. Additionally, a growing emphasis on workplace safety, minimizing dropped fasteners and improving ergonomic handling, positions magnetic nutsetters as a preferred choice for a safer and more efficient work environment.

This comprehensive report on the magnetic nutsetter market offers in-depth analysis and actionable insights for stakeholders. It covers the historical performance from 2019-2024, establishes a strong foundation with the base year of 2025, and projects future market trends and opportunities through to 2033. The report meticulously examines key market drivers such as technological innovation, increasing demand for productivity, and the growing emphasis on workplace safety. It also identifies potential challenges and restraints, providing a balanced perspective on the market landscape. Furthermore, the report offers detailed regional and segment-specific analysis, highlighting dominant regions like North America and Europe and the key segments like Industrial applications and Impact Nutsetters. Leading industry players are profiled, along with significant recent developments, providing a holistic view of the competitive environment and future trajectory of the magnetic nutsetter industry.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Irwin Tools, Hilmor, Makita, Bosch, Norske Tool, Sutton Tools, AndyMark, Mountz Torque, Montana Brand Tools, Vega Industries, Bramec, Sygma Industries, Black+Decker, Milwaukee Tool, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Magnetic Nutsetter," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Magnetic Nutsetter, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.