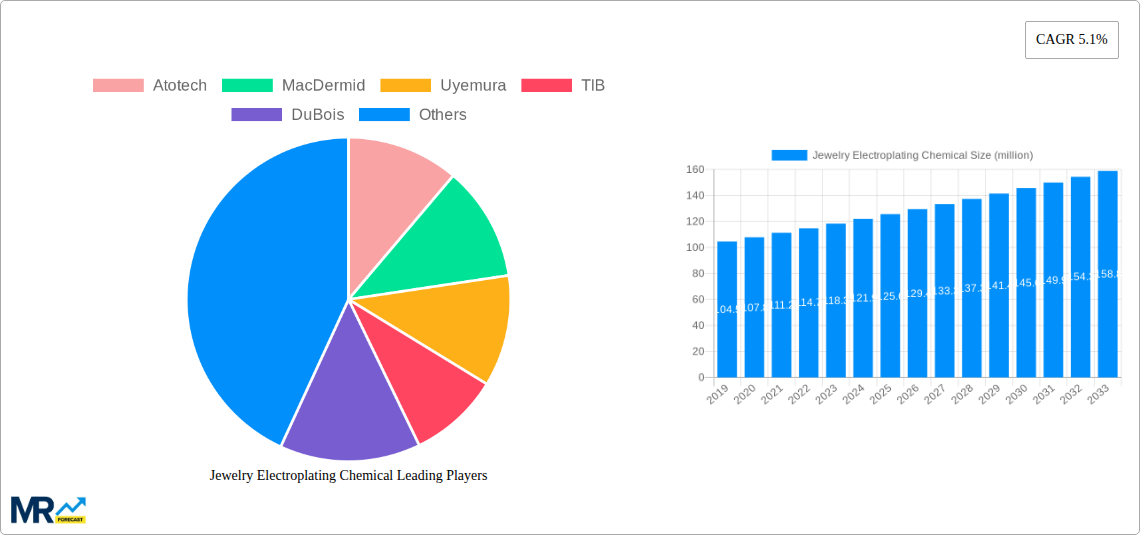

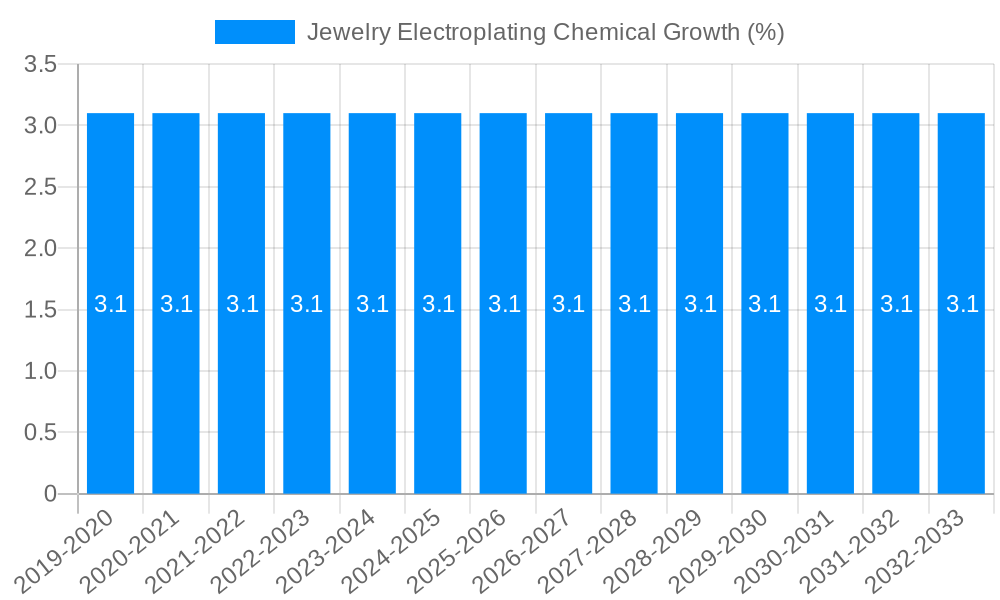

1. What is the projected Compound Annual Growth Rate (CAGR) of the Jewelry Electroplating Chemical?

The projected CAGR is approximately 5.1%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Jewelry Electroplating Chemical

Jewelry Electroplating ChemicalJewelry Electroplating Chemical by Type (Pretreatment Agent, Electroplating Additive, Post-treatment Agent), by Application (Gold Plating, Silver Plating), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

The global Jewelry Electroplating Chemical market is projected for robust expansion, with an estimated market size of $125.6 million and a Compound Annual Growth Rate (CAGR) of 5.1% from 2019 to 2033. This steady growth is fueled by an increasing consumer demand for aesthetically pleasing and durable jewelry, driving the need for advanced electroplating solutions. Key market drivers include the rising disposable incomes in emerging economies, leading to greater consumer spending on luxury goods like jewelry, and the growing popularity of custom-designed and personalized jewelry, which heavily relies on intricate electroplating techniques. Furthermore, technological advancements in plating formulations are enabling the creation of more environmentally friendly and efficient processes, addressing regulatory concerns and appealing to a sustainability-conscious market. The demand for specialized plating chemicals that offer enhanced wear resistance, tarnish protection, and unique aesthetic finishes is also a significant growth catalyst.

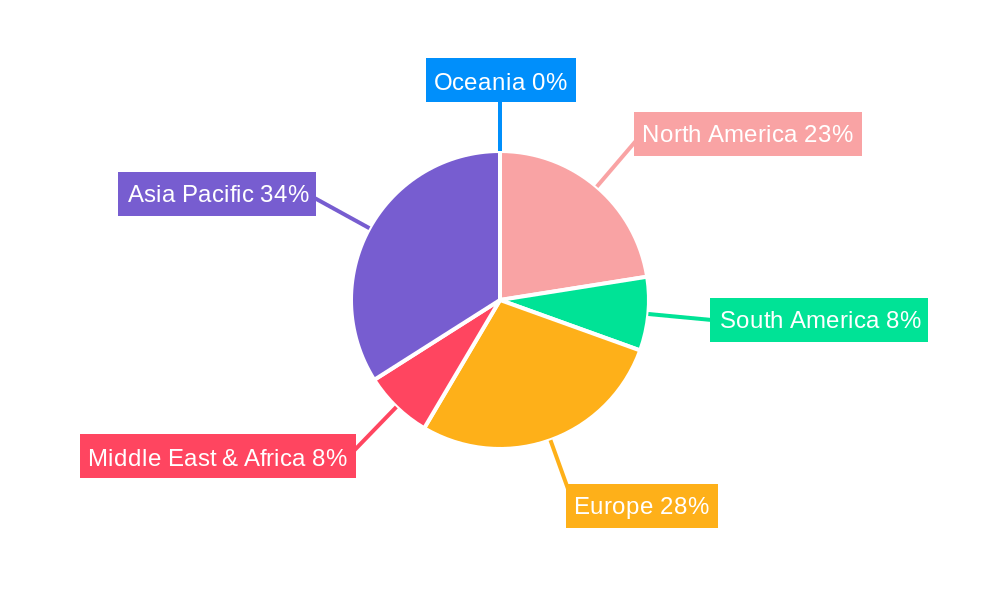

The market is segmented into pretreatment agents, electroplating additives, and post-treatment agents, with electroplating additives playing a crucial role in achieving desired finishes and properties. Application-wise, gold and silver plating dominate the market due to their perennial appeal and widespread use in fine jewelry. Geographically, the Asia Pacific region, particularly China and India, is expected to be a major growth engine, owing to its large manufacturing base and burgeoning middle class. North America and Europe also represent significant markets, driven by established jewelry industries and a strong consumer base for high-end products. While the market is experiencing positive momentum, potential restraints include the volatile pricing of precious metals, which can impact the overall cost of electroplating, and increasing environmental regulations surrounding the use of certain plating chemicals. However, ongoing innovation in the development of eco-friendly alternatives and efficient processes is poised to mitigate these challenges and sustain the market's upward trajectory.

Here's a report description for Jewelry Electroplating Chemicals, incorporating your specified requirements:

The global jewelry electroplating chemical market is poised for significant expansion, driven by a confluence of evolving consumer preferences, technological advancements, and a burgeoning demand for aesthetically appealing and durable jewelry finishes. Our comprehensive analysis, spanning the historical period of 2019-2024, a base year of 2025, and a robust forecast period extending to 2033, reveals a dynamic landscape. The market value, estimated at a substantial $XXX million in the base year of 2025, is projected to witness consistent growth, reflecting the increasing sophistication of electroplating processes and their critical role in the luxury and fashion jewelry sectors. The study period of 2019-2033 allows for a deep dive into the trends that have shaped and will continue to influence this sector. Key insights highlight a growing demand for eco-friendly and sustainable electroplating solutions, pushing manufacturers to innovate and develop greener chemical formulations. Furthermore, the rise of personalized jewelry and intricate designs necessitates advanced chemical additives that offer precise control over plating thickness, uniformity, and surface finish. The market's trajectory is also influenced by the increasing adoption of advanced application techniques, such as pulsed electroplating and high-speed plating, which demand specialized chemical compositions for optimal performance. This includes a shift towards formulations that minimize waste and enhance the lifespan of plated jewelry, directly impacting both cost-effectiveness and environmental responsibility within the industry. The intricate interplay between these factors will define the growth narrative of the jewelry electroplating chemical market in the coming years. The market's segmentation by type, including Pretreatment Agents, Electroplating Additives, and Post-treatment Agents, along with application segments like Gold Plating and Silver Plating, provides a granular understanding of where innovation and investment are most impactful.

The jewelry electroplating chemical market is experiencing robust growth, fueled by several compelling driving forces. Foremost among these is the insatiable global demand for jewelry, particularly in emerging economies where rising disposable incomes are translating into increased purchasing power for luxury and fashion accessories. Electroplating plays an indispensable role in making high-quality finishes accessible and affordable, enabling a wider range of consumers to adorn themselves with aesthetically pleasing pieces. The continuous innovation within the jewelry design and manufacturing sectors also acts as a significant catalyst. As designers push the boundaries of creativity with intricate patterns, unique textures, and novel material combinations, the demand for specialized electroplating chemicals that can achieve these complex finishes escalates. This includes chemicals that offer superior adhesion, enhanced corrosion resistance, and vibrant, long-lasting colors. Furthermore, the growing emphasis on jewelry durability and longevity directly benefits the electroplating chemical market. Consumers are increasingly seeking pieces that retain their luster and integrity over time, prompting manufacturers to invest in high-performance plating solutions. The industry's commitment to sustainability is also a key driver, with a growing preference for electroplating chemicals that are environmentally friendly, reduce hazardous waste, and comply with stringent international regulations. This has spurred research and development into biodegradable and less toxic chemical formulations, opening new avenues for market growth and innovation.

Despite its promising growth trajectory, the jewelry electroplating chemical market is not without its challenges and restraints. A primary concern revolves around the stringent and evolving environmental regulations governing the use and disposal of certain chemicals. Many traditional electroplating processes involve hazardous materials, such as cyanide and heavy metals, the handling and disposal of which are subject to increasingly strict compliance requirements and associated costs. This necessitates significant investment in research and development for greener alternatives, which can be a barrier for smaller manufacturers. Fluctuations in the prices of raw materials, particularly precious metals like gold and silver, can also impact the overall cost of electroplating, leading to price volatility in the chemical market. The high initial investment required for advanced electroplating equipment and sophisticated chemical treatment facilities can pose a significant hurdle for new entrants and smaller players seeking to adopt cutting-edge technologies. Moreover, the skilled labor required to operate these complex processes and manage chemical formulations is not always readily available, leading to potential operational bottlenecks. The risk of counterfeit or substandard chemicals entering the market also poses a threat, potentially compromising the quality and integrity of the plated jewelry and eroding consumer trust. Finally, the cyclical nature of the fashion and luxury goods industries can lead to fluctuations in demand for jewelry, indirectly impacting the demand for electroplating chemicals.

Within the jewelry electroplating chemical market, several key regions and specific segments are poised for significant dominance. Focusing on the Application segment of Gold Plating, and considering regions with a strong jewelry manufacturing base and a high consumer demand for gold embellishments, Asia-Pacific is projected to be a dominant force.

Asia-Pacific Dominance: This region, particularly countries like China, India, and Southeast Asian nations, has a deeply ingrained culture of gold jewelry consumption. These countries are not only major producers of gold jewelry but also significant global exporters. The sheer volume of jewelry manufacturing, coupled with a rapidly growing middle class that views gold as both an investment and a status symbol, translates into an immense demand for gold electroplating chemicals. The presence of a vast number of small and medium-sized enterprises (SMEs) involved in jewelry production, alongside large-scale manufacturers, ensures a consistent and widespread need for reliable and cost-effective electroplating solutions. Furthermore, ongoing technological adoptions and investments in modernizing manufacturing facilities within the Asia-Pacific region are expected to further solidify its leadership. The region's robust supply chain for raw materials and its competitive manufacturing costs also contribute to its dominant position in this segment.

Gold Plating Segment Dominance: The Gold Plating segment, within the broader jewelry electroplating chemical market, will continue to command the largest share and exhibit strong growth. Gold's intrinsic value, its timeless appeal, and its hypoallergenic properties make it the most sought-after metal for jewelry finishing.

The interplay between the Asia-Pacific region and the Gold Plating application segment creates a powerful nexus of demand, innovation, and market leadership. The continuous pursuit of aesthetic perfection and durability in gold jewelry, coupled with the region's manufacturing prowess, will ensure their sustained dominance in the foreseeable future, contributing significantly to the global market value projected to reach $XXX million by 2033.

The jewelry electroplating chemical industry is propelled by several key growth catalysts. The increasing demand for affordable luxury, driven by a rising global middle class, makes electroplating a vital tool for delivering aesthetically pleasing finishes on base metals. Furthermore, ongoing advancements in electroplating technology, such as the development of eco-friendly and high-performance chemical formulations, are expanding application possibilities and improving efficiency. The growing trend towards personalization and customization in jewelry design necessitates specialized chemicals that allow for intricate detailing and unique finishes, further stimulating market growth.

This report provides an in-depth and comprehensive analysis of the jewelry electroplating chemical market, encompassing the study period of 2019-2033, with a base year of 2025 and a forecast period extending to 2033. It delves into the intricate market dynamics, including market size estimations in the $XXX million range, key growth drivers, prevailing challenges, and emerging opportunities. The report offers a granular breakdown of the market by type (Pretreatment Agent, Electroplating Additive, Post-treatment Agent) and application (Gold Plating, Silver Plating), providing insights into segment-specific trends and performance. It further analyzes the market landscape across key geographical regions, identifying dominant markets and evaluating the competitive strategies of leading players. This comprehensive coverage ensures stakeholders have the necessary information to navigate this evolving industry and capitalize on future growth prospects.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 5.1% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 5.1%.

Key companies in the market include Atotech, MacDermid, Uyemura, TIB, DuBois, Yantai Zhaojin Kanfort Precious Metal, .

The market segments include Type, Application.

The market size is estimated to be USD 125.6 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Jewelry Electroplating Chemical," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Jewelry Electroplating Chemical, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.